High-efficiency safe environment-friendly all-synthetic cutting fluid and preparation method thereof

A safe, environmentally friendly and fully synthetic technology, which is used in the preparation of high-efficiency, safe and environmentally friendly fully synthetic cutting fluids, and in the field of high-efficiency, safe and environmentally friendly fully synthetic cutting fluids, and can solve the problems of unfavorable surface observation of workpieces, affecting the visibility of working fluids, and human skin irritation. It can achieve the effects of excellent biological stability, excellent lubrication or rust and corrosion inhibition performance, and stable system performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

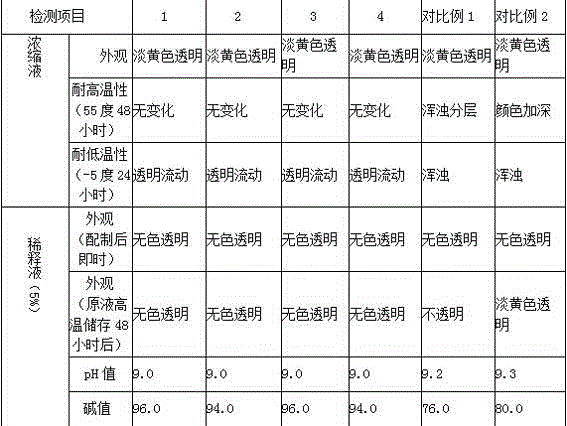

Examples

Embodiment 1

[0033] A safe, environmentally friendly and high-efficiency fully synthetic cutting fluid, which consists of the following components by weight percentage:

[0034] Synthetic ester 21%

[0035] Surfactant 6%

[0036] Rust inhibitor 7%

[0037] pH regulator 10%

[0038] Corrosion inhibitor 1%

[0039] Deionized water 55%

[0040] Wherein, the synthetic ester is a mixture of vegetable oil-modified high-molecular polymer ester and vegetable oil-modified low-molecular synthetic ester, and the mass ratio of the two is 2:1;

[0041] Surfactant is fatty acid amide 5% or C 16-18 Polyoxyethylene ether 1%;

[0042] Rust inhibitor is 2% undecane dibasic acid or 5% tribasic carboxylic acid;

[0043] The pH regulator is 3% of monoisopropanolamine or 7% of triethanolamine;

[0044] The corrosion inhibitor is sodium metasilicate 1%.

[0045] The preparation method of the above-mentioned safe, environment-friendly and high-efficiency...

Embodiment 2

[0051] A safe, environmentally friendly and high-efficiency fully synthetic cutting fluid, which consists of the following components by weight percentage:

[0052] Synthetic ester 25%

[0053] Surfactant 8%

[0054] Rust inhibitor 6%

[0055] pH regulator 10%

[0056] Corrosion inhibitor 1.5%

[0057] Deionized water balance

[0058] Among them, the synthetic ester is 15% of vegetable oil modified polymer ester or 10% of trimethylolpropane oleate;

[0059] The surfactant is fatty acid amide 6% or isomerized alcohol polyoxyethylene ether 2%;

[0060]Antirust agent is borate 2% or modified carboxylate 4%;

[0061] The pH regulator is 3% of monoisopropanolamine or 7% of triethanolamine;

[0062] The corrosion inhibitor is 1.3% siloxane or 0.2% benzotriazole.

[0063] The preparation method of the above-mentioned safe, environment-friendly and high-efficiency fully synthetic cutting fluid comprises the following steps:

[0...

Embodiment 3

[0069] A safe, environmentally friendly and high-efficiency fully synthetic cutting fluid, which consists of the following components by weight percentage:

[0070] Synthetic ester 20%

[0071] Surfactant 5%

[0072] Rust inhibitor 12%

[0073] pH regulator 8%

[0074] Corrosion inhibitor 2.2%

[0075] Deionized water balance

[0076] Among them, the synthetic ester is vegetable oil modified low molecular synthetic ester 10% or trimethylol propane oleate 10%;

[0077] The surfactant is fatty acid amide 4% or isomerized alcohol polyoxyethylene ether 1%;

[0078] Antirust agent is borate 5% or undecane dibasic acid 2% or tribasic carboxylate 5%;

[0079] The pH regulator is diglycolamine 4% or triethanolamine 4%;

[0080] The corrosion inhibitor is benzotriazole 0.2% or siloxane 2%.

[0081] The preparation method of the above-mentioned safe, environment-friendly and high-efficiency fully synthetic cutting fluid comprises th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com