Single-side joint structure and single-side joint method for expressway extension

A technology of expressway and splicing position, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, which can solve the problems of difficulty in coordinating the deformation between the two pavements of the old road, difficulty in draining the double pavement of the old road, and difficulty in leveling the top surface of the base layer. Achieve the effect of improving anti-reflection crack ability, good splicing effect and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

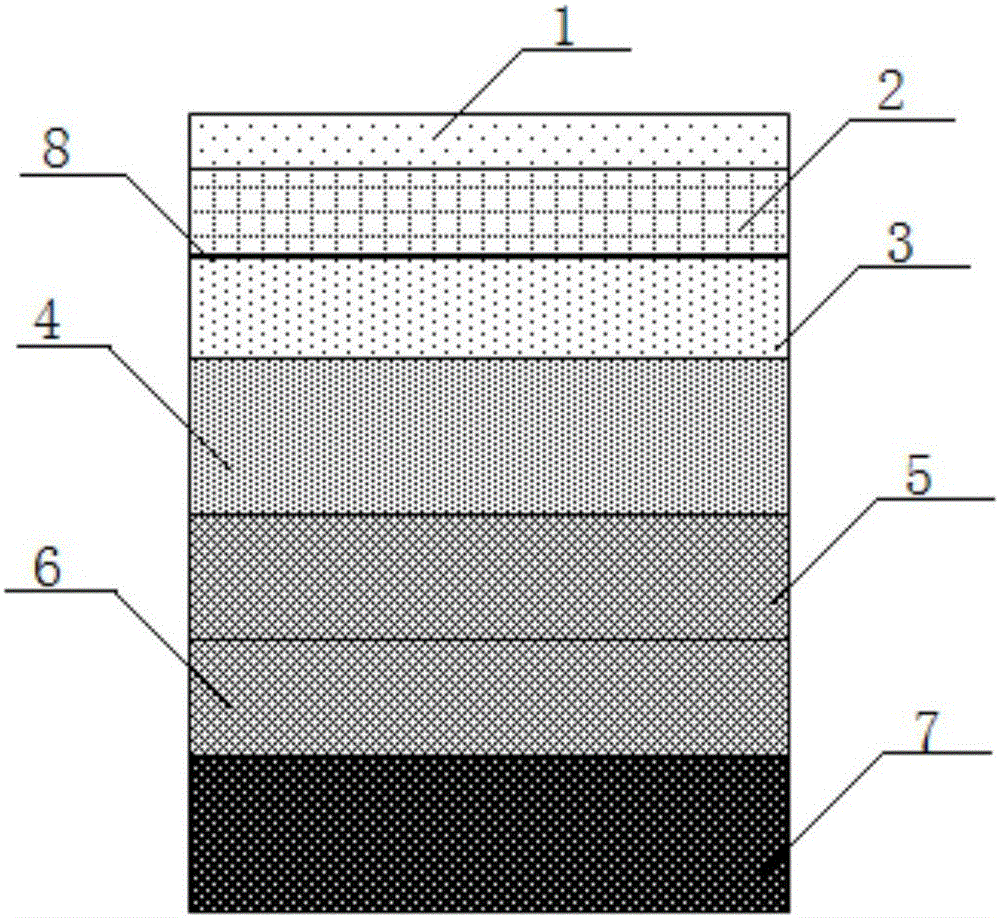

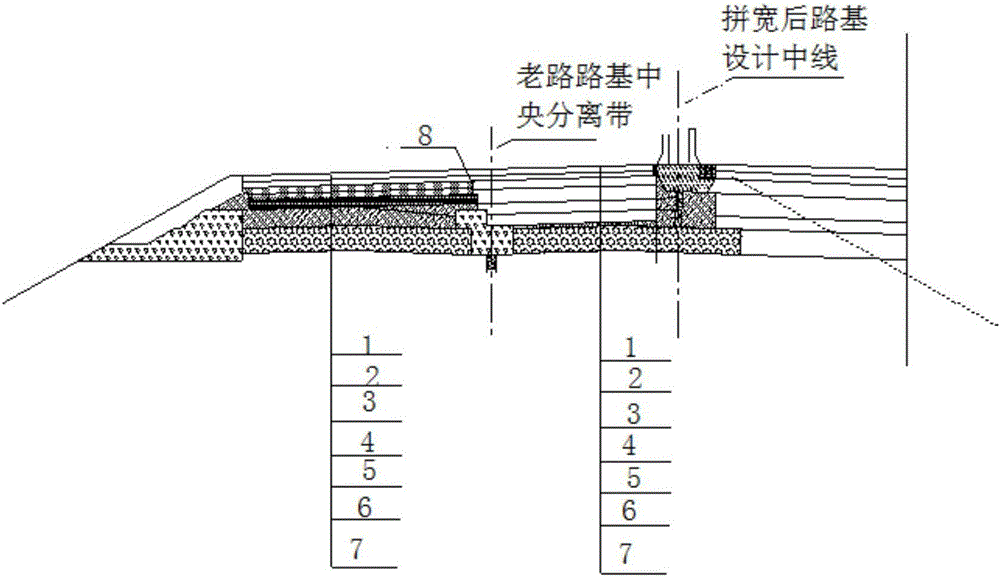

[0029] Such as figure 1 The schematic diagram of the structure of the one-side splicing structure used for the extension of the expressway shown in the present invention is a layered composite structure, and the upper layer 1, the middle layer 2, and the lower layer are sequentially arranged from top to bottom. 3. Cold recycled base 4, water stabilized base and cushion 7, wherein the water stabilized base is a double-layer composite structure, including upper water stabilized base 5 and lower water stabilized base 6.

[0030] Among them, the upper layer 1 is 4 cm SMA-13 asphalt mixture, using SBS modified asphalt, and the gradation composition is shown in Table 1; the middle surface layer 2 is 6 cm composite modified AC-20 asphalt mixture, using SBS modified asphalt, the outer The 0.3% compound synergistic modifier of the mass of the mineral material can be thermoplastic polyolefin elastomer (TPO) composed of low melting point polyethylene wax, rubber with a soft segment gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com