Novel modifier with basalt fibers for asphalt mixtures and method for preparing novel modifier

A technology of basalt fiber and asphalt mixture is applied in the field of pavement paving materials, new basalt fiber asphalt mixture modifier and preparation field, which can solve the problems of unsuitability for asphalt mixture, and achieve obvious practical effect and enhanced tensile strength. Ability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

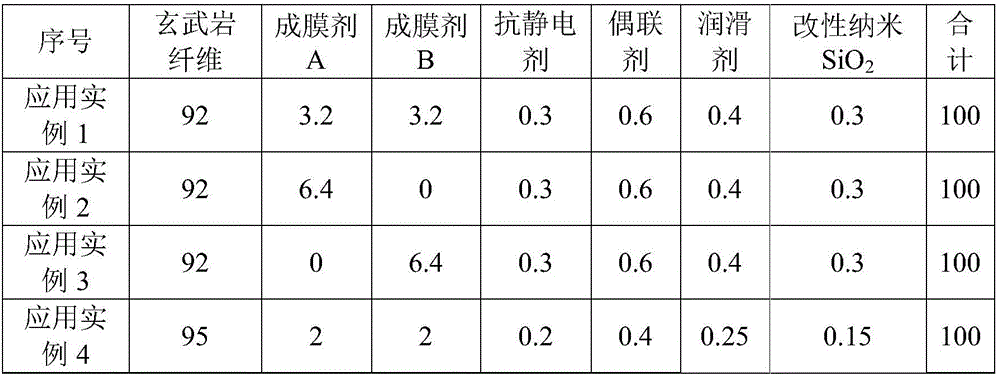

Embodiment 1

[0033] Film-forming agent A, film-forming agent B, antistatic agent, coupling agent, lubricant, modified nano-SiO 2 Mix and stir according to the mass ratio of 32:32:3:6:4:3 and heat to 70-80°C in the infiltration tank. Specifically, 3.2 parts of film-forming agent A, 3.2 parts of film-forming agent B, 0.3 parts of antistatic agent, 0.6 parts of coupling agent, 0.4 parts of lubricant, and 0.3 parts of modified nano-SiO 2 , in the infiltration pool, 0.3 parts of modified nano-SiO 2 The suspension was dripped into the mixed emulsion of 3.2 parts of film-forming agent A and 3.2 parts of film-forming agent B under stirring conditions, and continued high-speed stirring for 1.5 to 2 hours, and then added 0.4 parts of lubricant, 0.3 parts of antistatic agent, 0.6 part of coupling agent, and then continue to stir for 2 to 2.5 hours to obtain a uniform white liquid; in the infiltration pool, heat the prepared white uniform liquid and keep the temperature at 70 to 80 ° C; wherein, the ...

Embodiment 2

[0038] Film-forming agent A, film-forming agent B, antistatic agent, coupling agent, lubricant, modified nano-SiO 2 Mix and stir according to the mass ratio of 64:0:3:6:4:3 and heat to 70-80°C in the infiltration tank. Specifically, 6.4 parts of film-forming agent A, 0 parts of film-forming agent B, 0.3 parts of antistatic agent, 0.6 parts of coupling agent, 0.4 parts of lubricant, and 0.3 parts of modified nano-SiO 2 , in the infiltration pool, 0.3 parts of modified nano-SiO 2 Drop the suspension into 6.4 parts of film-forming agent A emulsion under stirring conditions, continue to stir at high speed for 1.5 to 2 hours, then add 0.4 parts of lubricant, 0.3 parts of antistatic agent, and 0.6 parts of coupling agent in sequence, and continue stirring for 2 After ~2.5 hours, a uniform white liquid is obtained; in the infiltration tank, the prepared white uniform liquid is heated, and the temperature is kept at 70-80 ° C; wherein, the infiltration tank is 2 meters long, 0.5 mete...

Embodiment 3

[0043] Film-forming agent A, film-forming agent B, antistatic agent, coupling agent, lubricant, modified nano-SiO 2 Mix and stir according to the mass ratio of 0:64:3:6:4:3 and heat to 70-80°C in the infiltration pool. Specifically, 0 parts of film-forming agent A, 6.4 parts of film-forming agent B, 0.3 parts of antistatic agent, 0.6 parts of coupling agent, 0.4 parts of lubricant, and 0.3 parts of modified nano-SiO 2 , in the infiltration pool, 0.3 parts of modified nano-SiO 2 Drop the suspension into 6.4 parts of film-forming agent B emulsion under stirring condition, continue to stir at high speed for 1.5-2 hours, then add 0.4 parts of lubricant, 0.3 parts of antistatic agent, 0.6 parts of coupling agent in sequence, and continue stirring for 2 After ~2.5 hours, a uniform white liquid is obtained; in the infiltration tank, the prepared white uniform liquid is heated, and the temperature is kept at 70-80 ° C; wherein, the infiltration tank is 2 meters long, 0.5 meters wide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com