High-strength temperature resistant viscoelastic fracturing fluid copolymer

A copolymer and viscoelastic technology, which is applied in the field of high-strength temperature-resistant viscoelastic fracturing fluid copolymer, can solve the problems of good shear resistance and achieve easy operation, good temperature resistance and shear resistance, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

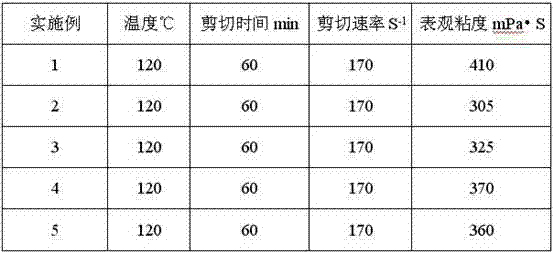

Examples

Embodiment 1

[0032] Example 1: Take 21.5% of acrylamide, 9.5% of 2-acrylamido-2-methyl-1-propanesulfonate, and 4.8% of 3-acrylimido-3-methylbutyric acid Add it into deionized water, fully dissolve, then add 8.5% acrylic acid and stir evenly, neutralize with sodium hydroxide to PH=5~6, finally add 0.75% dodecanethiol, control the temperature at room temperature, pour it into a sealed insulation Nitrogen is passed through the reactor with a thermometer for 30 minutes, and then 0.02% initiator ammonium persulfate and 0.02% initiator sodium bisulfite are added. After 10 to 20 minutes, the nitrogen gas is stopped, and the reaction is 2 to 3 hours to obtain a viscous Gel-like polymer is further dried and granulated to finally obtain a high-strength temperature-resistant viscoelastic fracturing fluid copolymer.

Embodiment 2

[0033] Example 2: Take 30% of acrylamide, 2% of 2-acrylamido-2-methyl-1-propanesulfonate, 2% of 3-acrylimido-3-methylbutyric acid Add it into deionized water, fully dissolve, then add 5% acrylic acid and stir evenly, neutralize with sodium hydroxide to PH=5~6, finally add 2% dodecanethiol, control the temperature at room temperature, pour it into a sealed insulation Nitrogen is passed through the reactor with a thermometer for 30 minutes, and then 0.02% initiator ammonium persulfate and 0.02% initiator sodium bisulfite are added. After 10 to 20 minutes, the nitrogen gas is stopped, and the reaction is 2 to 3 hours to obtain a viscous Gel-like polymer is further dried and granulated to finally obtain a high-strength temperature-resistant viscoelastic fracturing fluid copolymer.

Embodiment 3

[0034] Example 3: Take 25% of acrylamide, 5% of 2-acrylamido-2-methyl-1-propanesulfonate, and 1% of 3-acrylimido-3-methylbutyric acid Add it into deionized water, fully dissolve, then add 7% acrylic acid and stir evenly, neutralize with sodium hydroxide to PH = 5~6, finally add 1.5% dodecanethiol, control the temperature at room temperature, pour into the sealed insulation Nitrogen is passed through the reactor with a thermometer for 30 minutes, and then 0.02% initiator ammonium persulfate and 0.02% initiator sodium bisulfite are added. After 10 to 20 minutes, the nitrogen gas is stopped, and the reaction is 2 to 3 hours to obtain a viscous Gel-like polymer is further dried and granulated to finally obtain a high-strength temperature-resistant viscoelastic fracturing fluid copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com