Imino-containing acrylic resin, its preparation method and application

A technology of imino acrylic and resin, applied in the direction of coating, etc., can solve the problems of losing practical value, achieve excellent performance and solve contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Example 1 - Product Example

[0096] 1, a kind of preparation method containing imino acrylic resin, it is characterized in that having the following steps:

[0097] A. Under the protection of nitrogen, add 1,4-butanediol, 1,2-pentanediol and tert-butylamine to the reaction vessel at one time, and the added 1,4-butanediol and 1,2-pentanediol The molar ratio of the total amount of alcohol to tert-butylamine is 8:1; add dibutyltin dilaurate and zinc naphthenate as catalysts, the amount added is 0.2% of the total mass of the reactants, then seal the reaction vessel, heat up to 140°C, and stir After reacting for 3 hours, N,N'-tert-butyl hydroxybutylimine was synthesized;

[0098] B. Add ethyl methacrylate, tert-propyl methacrylate, butyl methacrylate and the synthesized N,N'-tert-butyl hydroxybutyl imine in a molar ratio of 5:1 to the condenser In the reaction vessel of the device, add 7-diaminophenothiazine of 0.3% polymerization inhibitor and 0.3% alkaline earth metal d...

Embodiment 2

[0100] Example 2 - Use of the product (application example)

[0101] Get the imino-containing acrylic resin prepared in Example 1, the proportioning of paint is:

[0102] Imino Acrylic Resin Solution 4

[0103] HDI trimer solution (NVM 45 %) 1

[0104] Thinner 1~1.5

[0105] The resin solution and the curing agent are mixed evenly and then diluted to 13-14:1 with diluent xylene. After the preparation is complete, it should be left for at least 15 minutes.

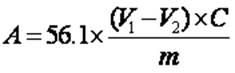

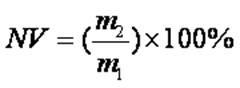

[0106] The test methods commonly used in the coating field in the above example 2 are used to obtain similar results as shown in Table 2 for the related properties of the automotive repair coating.

[0107] project Test Results testing method VOC / wt% ≤20 GB / T23985-2009 Solid content / wt% 40 GB / T1725-2007 Storage period / month ≥6 Centrifuge at 3000rpm for 30min without precipitation Gloss (60°) ≥95 GB / T1743-89 pencil hardness ≥2H GB / T1730-93 Adhesion (cross-cut met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com