Method for extracting L-hydroxyproline from L-hydroxyproline fermentation liquor

A technology of hydroxyproline and fermentation broth, applied in the directions of additional food elements, animal feed, organic chemistry, etc., can solve problems such as large water consumption, environmental pollution, unstable yield, etc., to reduce the generation of waste water and avoid environmental problems. Pollution, saving effect of deionized water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

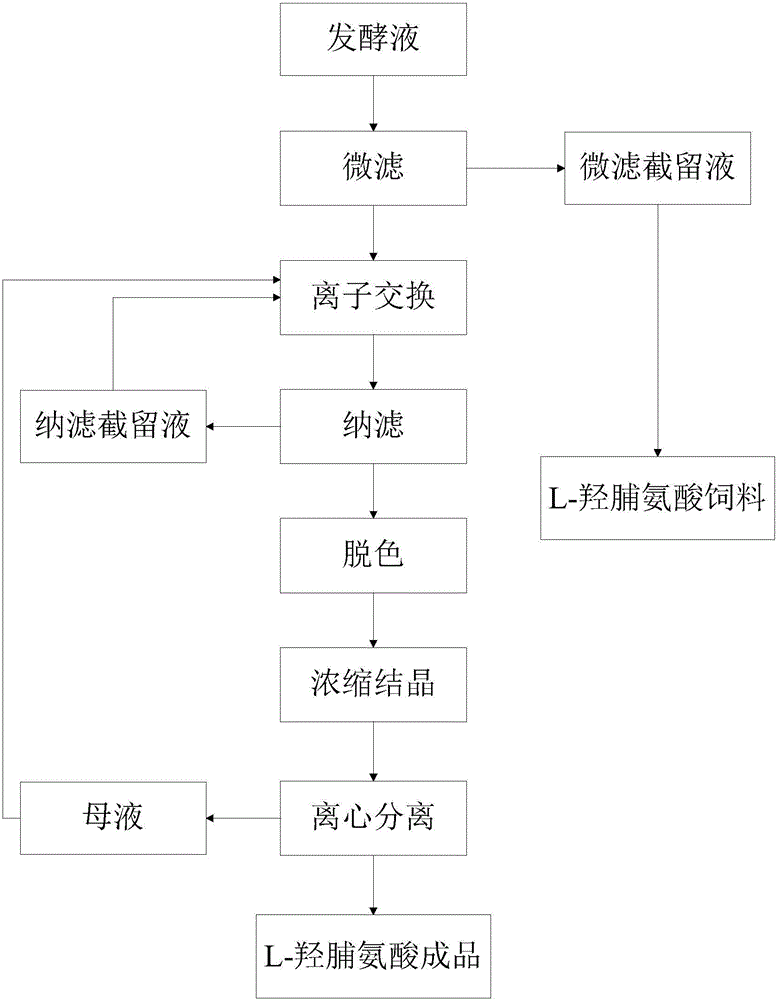

Image

Examples

Embodiment 1

[0028] Get 10L of microfiltration supernatant and microfiltration retentate (reserved for later use) through the fermentation liquid after L-hydroxyproline fermentation through 0.05 micron ~ 0.1 micron ceramic membrane, adjust pH to be 6 ~ 7, then with 12.5ml At a flow rate of / min, first pass through 1LC100 strongly acidic cation exchange resin, and then pass through 1.5LA830 weakly basic anion exchange resin. The ion exchange liquid is passed through a nanofiltration membrane with a molecular weight of 800-1000 Da to obtain a nanofiltration clear liquid and a nanofiltration retentate. The nanofiltration retentate is adjusted to a pH of 6-7 and sent back to the ion exchange resin circulation process. The nanofiltration liquid is added with 0.5% by volume of activated carbon for injection at 25° C. for 1.5 hours, and filtered to obtain a clear liquid with a light transmittance of 96%.

[0029] Concentrate the above decolorized solution in vacuum at 55°C to 1 / 8 of its volume, l...

Embodiment 2

[0034] Get the fermented liquid after L-hydroxyproline fermentation to obtain 99.6L microfiltration liquid and microfiltration retentate (reserved for later use) through 0.05 micron~0.1 micron ceramic membrane treatment, adjust pH to be 6~7, then use 135ml The flow rate of / min passes through 9L732 type strong acid cation exchange resin first, and then passes through 15LA830 weakly basic anion exchange resin. The ion exchange liquid is passed through a nanofiltration membrane with a molecular weight of 800-1000 Da to obtain a nanofiltration clear liquid and a nanofiltration retentate. The nanofiltration retentate is adjusted to a pH of 6-7 and sent back to the ion exchange resin circulation process. The nanofiltration liquid is decolorized at 25° C. for 1.5 hours by adding 0.5% of its volume of activated carbon for injection, and filtered to obtain a clear liquid with a light transmittance of 95.7%.

[0035] Concentrate the above decolorized solution in vacuum at 55°C to 1 / 8 o...

Embodiment 3

[0038] Feed Preparation of L-Hydroxyproline

[0039] A batch of reserve microfiltration retentate and 1 / 3 batch of mother liquor are mixed, spray-dried to obtain L-hydroxyproline feed product, and L-hydroxyproline is about 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com