Rib type brackets and method for constructing top way steel pipe support and top plate through brackets

A steel pipe support and bracket technology, which is applied in water conservancy projects, excavation, artificial islands, etc., can solve the problems of fixed connection, reduced construction efficiency, and large volume of steel corbels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

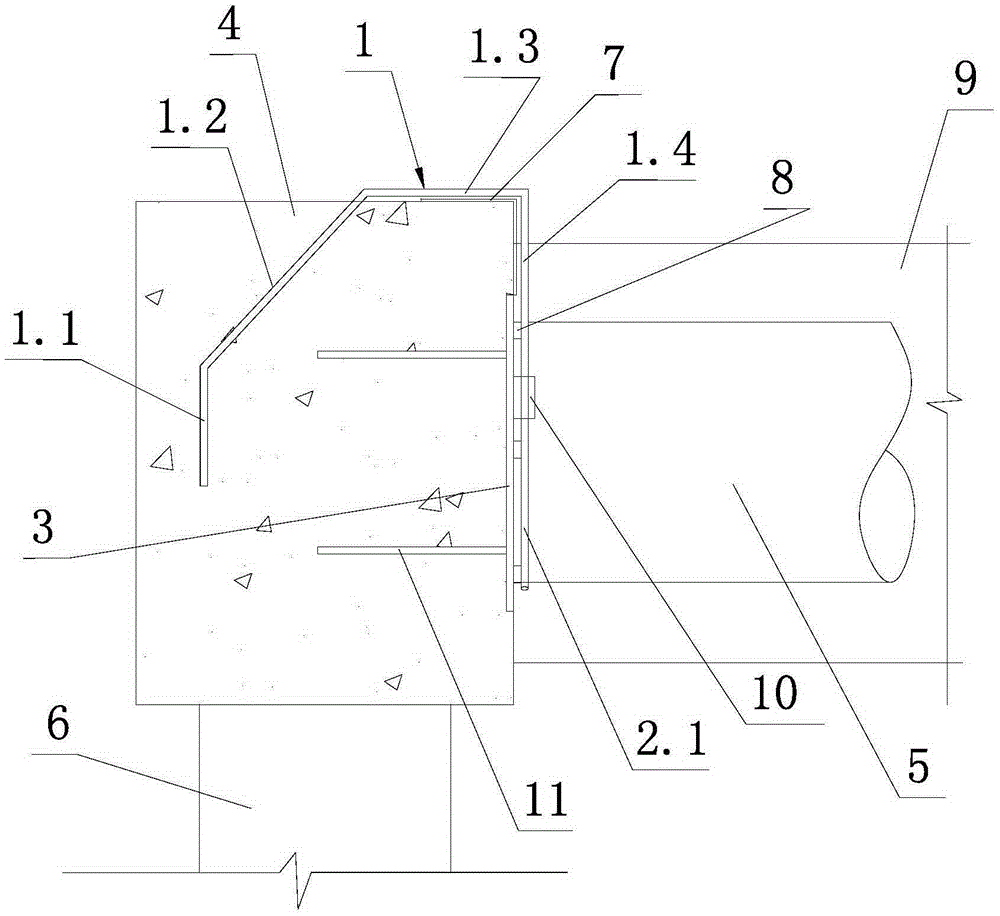

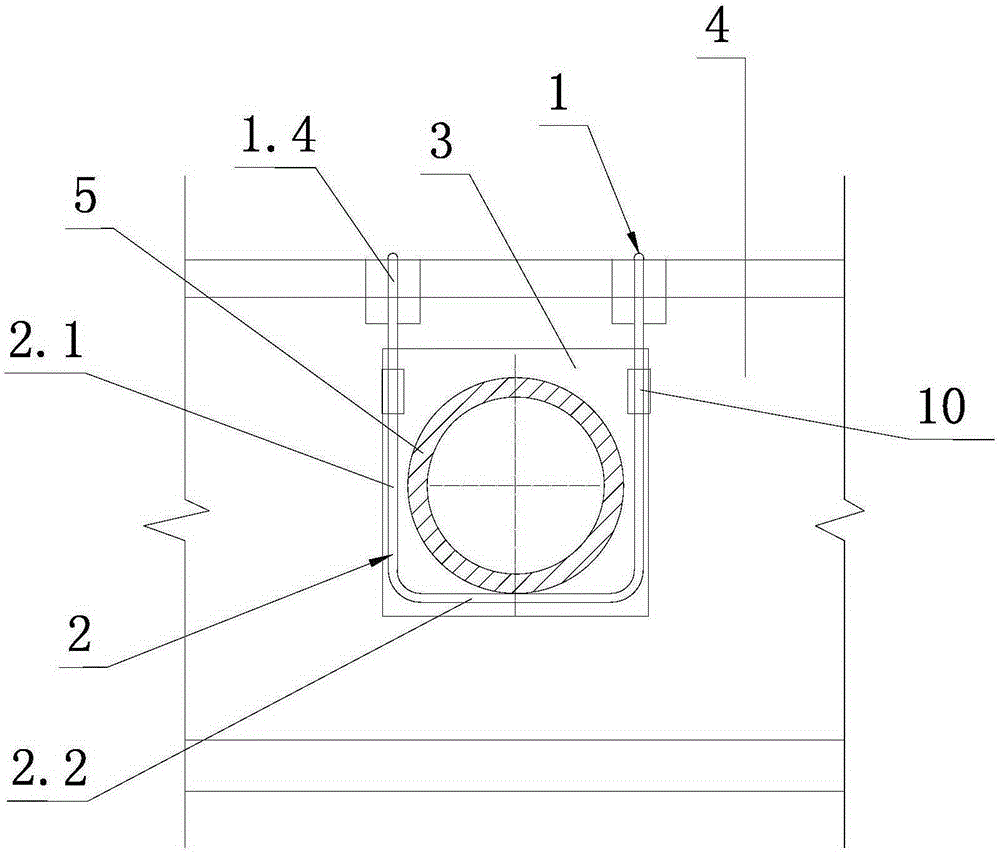

[0022] Such as figure 1 , figure 2 As shown, the bar bracket of the present invention includes two anchor bars 1, a U-shaped support bar 2 and a pre-embedded steel plate 3. Each anchoring steel bar 1 is composed of anchoring vertical bar 1.1, anchoring inclined bar 1.2, exposed transverse bar 1.3 and exposed vertical bar 1.4. Specifically, the upper end of anchoring vertical bar 1.1 is fixed to the lower end of anchoring inclined bar 1.2, and the upper end of anchoring The rear end of the horizontal bar 1.3 is fixed, the front end of the exposed horizontal bar 1.3 and the upper end of the exposed vertical bar 1.4 are fixed, and the above four sections of steel bars are formed by bending the same straight steel bar. The anchoring vertical bars 1.1 and the anchoring inclined bars 1.2 are located inside the concrete of the capping beam 4; and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com