Thermal management integration module and electric vehicle

An integrated module and thermal management technology, applied in the field of vehicles, can solve the problems of intricate cabins, occupying a large layout space, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, the multi-channel integrated board 110 adopts such as Figure 4 A multi-channel integrated board 110 of the structure shown.

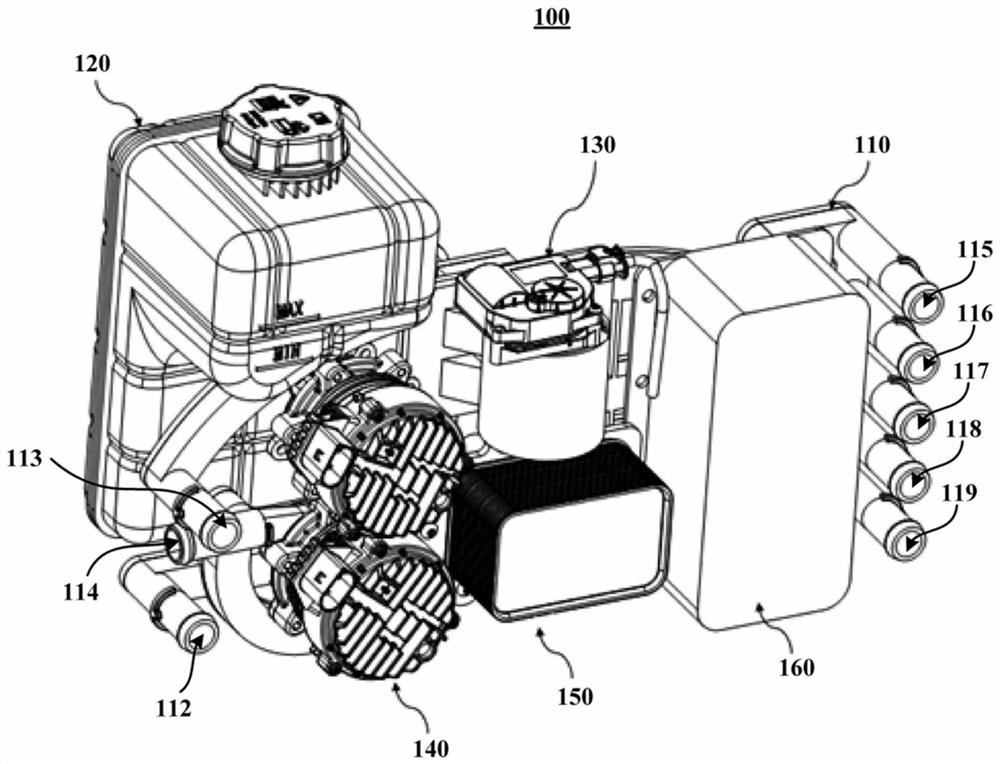

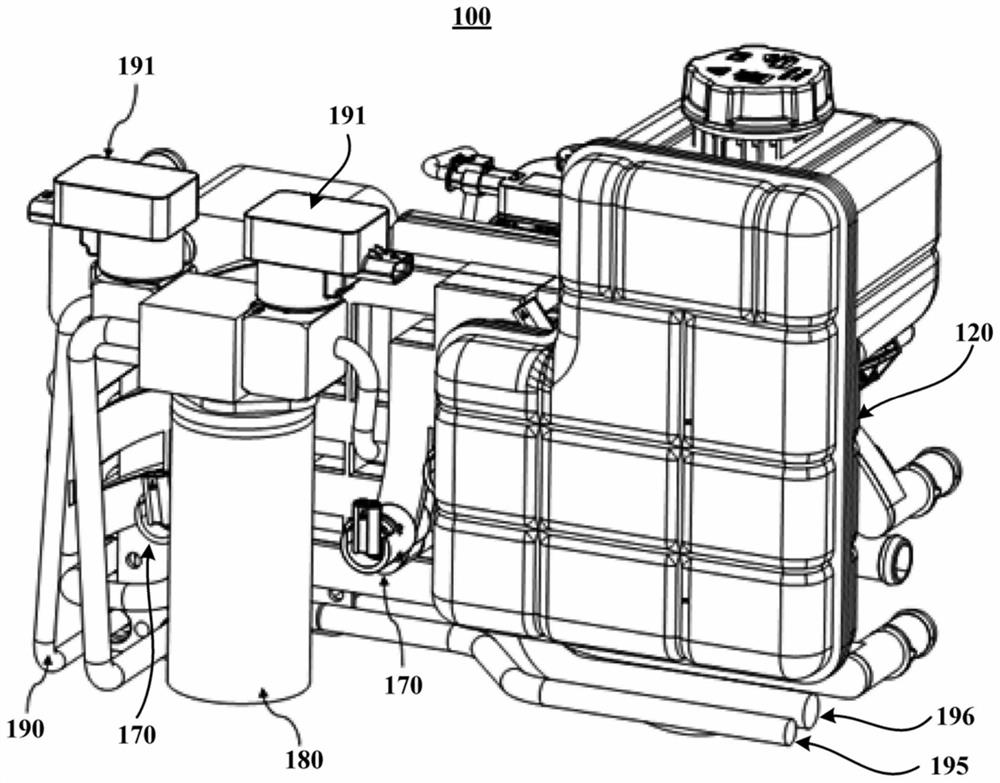

[0055] Such as figure 1 and figure 2 As shown, in this embodiment, the thermal management components integrated on the multi-channel integrated board 110 may include an expansion kettle 120, a multi-way valve 130, a water pump 140, a heat exchanger 150, a water-cooled condenser 160, a temperature sensor 170, and a drying bottle 180 , at least two of the electronic expansion valve 191 , the two-way proportional valve 192 , and the air conditioning pipeline 190 .

[0056] In the case where the thermal management components include the water pump 140, according to the schematic diagram of the vehicle thermal management, the number of the water pumps 140 is usually at least two, and one of the water pumps 140 (maybe called a motor water pump) is configured to drive the motor cooling circuit of the vehicle The coolant in the b...

Embodiment 2

[0072] The difference between embodiment 2 and embodiment 1 mainly lies in:

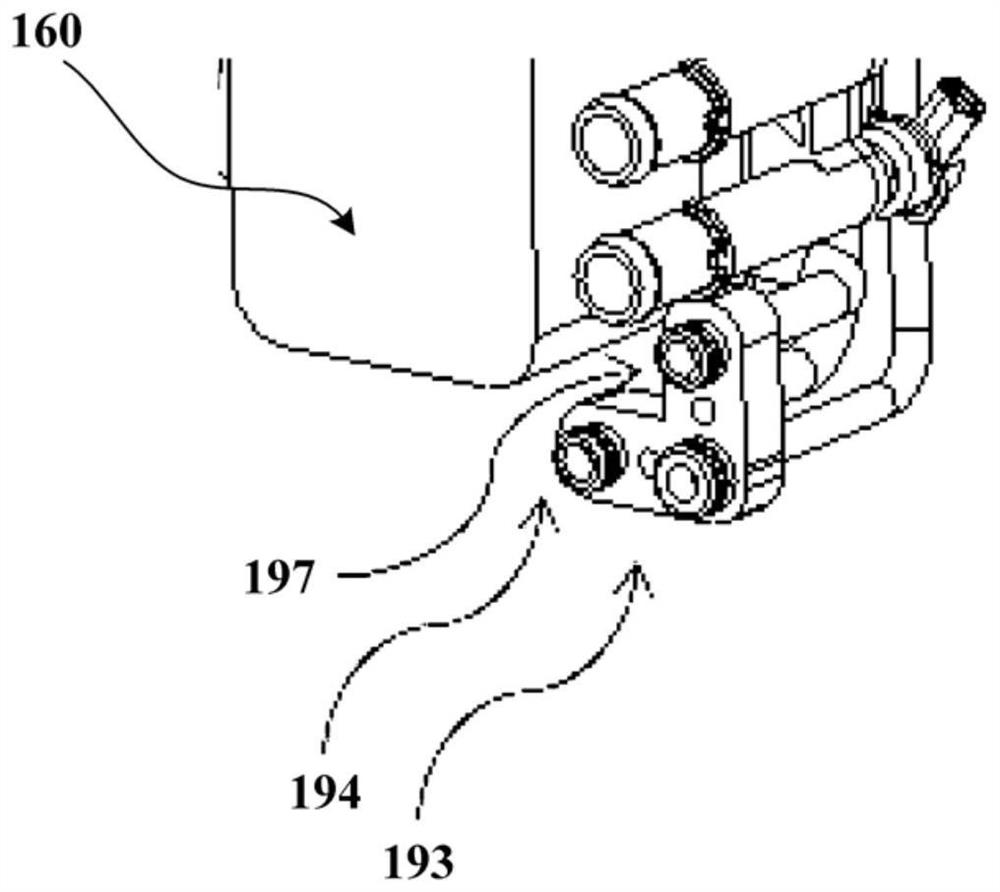

[0073] The thermal management components related to the refrigerant circulation circuit of the vehicle air conditioner integrated on the multi-channel integrated board 110 do not include the drying bottle 180, and the number of the electronic expansion valve 191 is only one. At this time, if Figure 6 and Figure 7 As shown, the electronic expansion valve 191 is correspondingly installed on the same side of the multi-channel integrated plate 110 as the heat exchanger 150 and adjacent to the heat exchanger 150. A condenser 160 is connected. The main part of the air-conditioning pipeline 190 extends on one side of the multi-channel integrated board 110 where the expansion kettle 120 is located, and forms a compressor outlet interface 196 on the same side as the expansion kettle 120 and below the expansion kettle 120, and a built-in condenser outlet interface 194 Formed on the valve seat of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com