Construction method for heating power water feeding system with PPR polyurethane foaming heat preservation pipe

A technology for a water supply system and a construction method, which is applied in the directions of heat preservation and protection of pipes and pipes through heat insulation, can solve the problems of high construction cost of stainless steel pipes + heat preservation cotton, complicated construction procedures of stainless steel pipes, unfavorable energy saving and environmental protection, etc., and achieves heat preservation performance. Good, low installation cost, simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

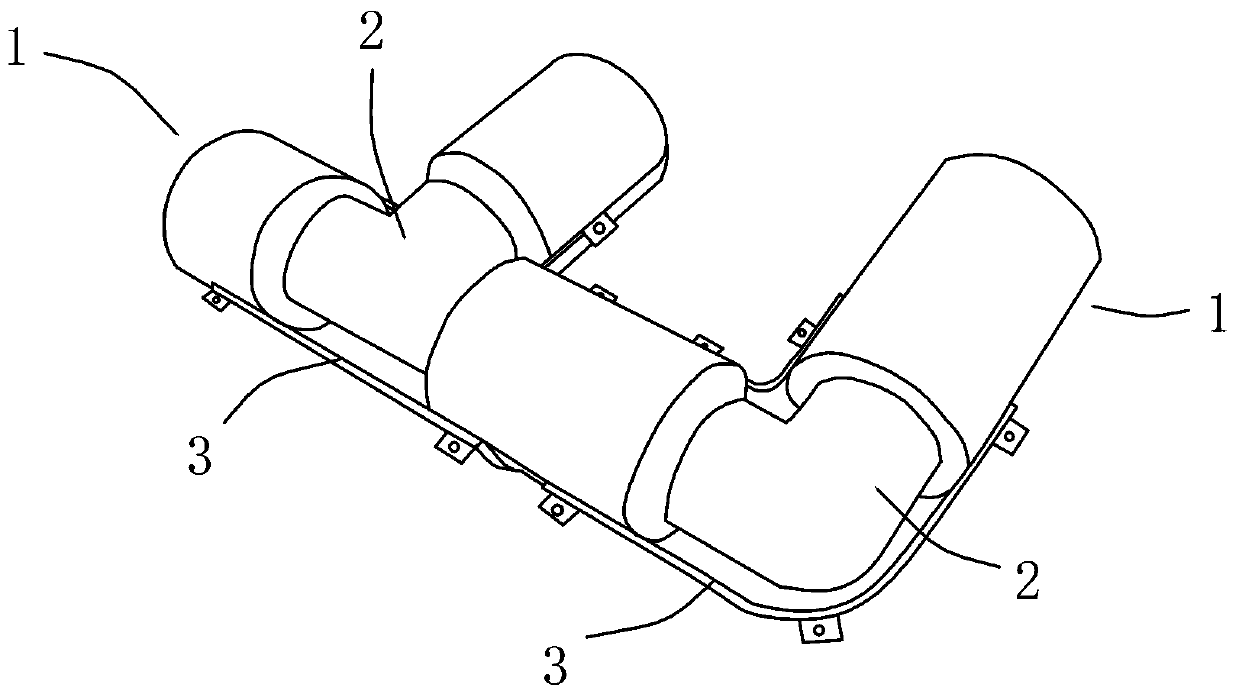

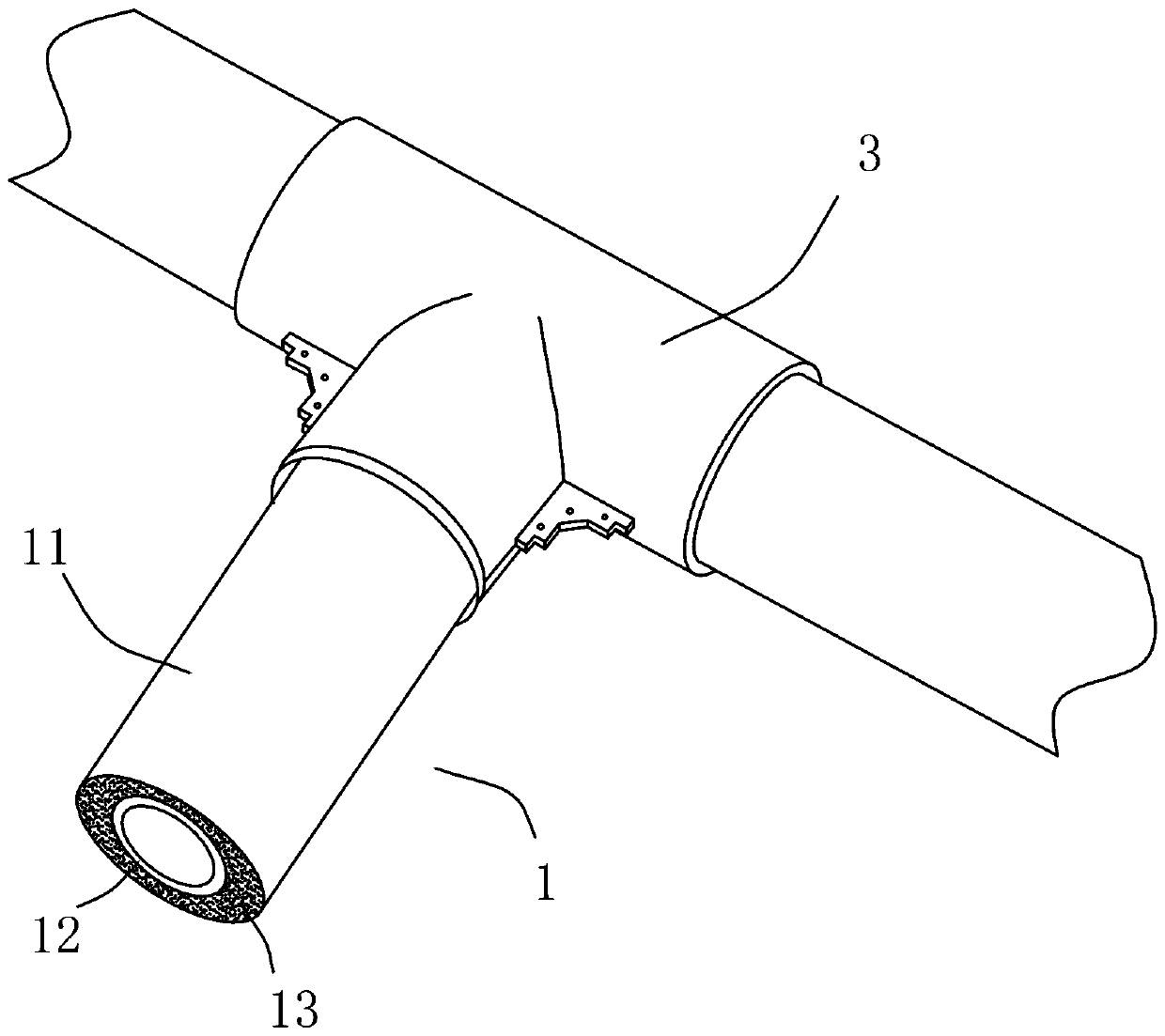

[0024] see Figure 1-3 As shown, the present invention relates to a construction method of a PPR polyurethane foam insulation pipe thermal water supply system, comprising the following steps,

[0025] (a) According to the construction site conditions, use BIM pipeline modeling, design construction drawings, construction operations and technical personnel carefully familiarize themselves with the drawings, understand the design intent, and prepare materials after clearing the layout of the drawings and the actual pipeline;

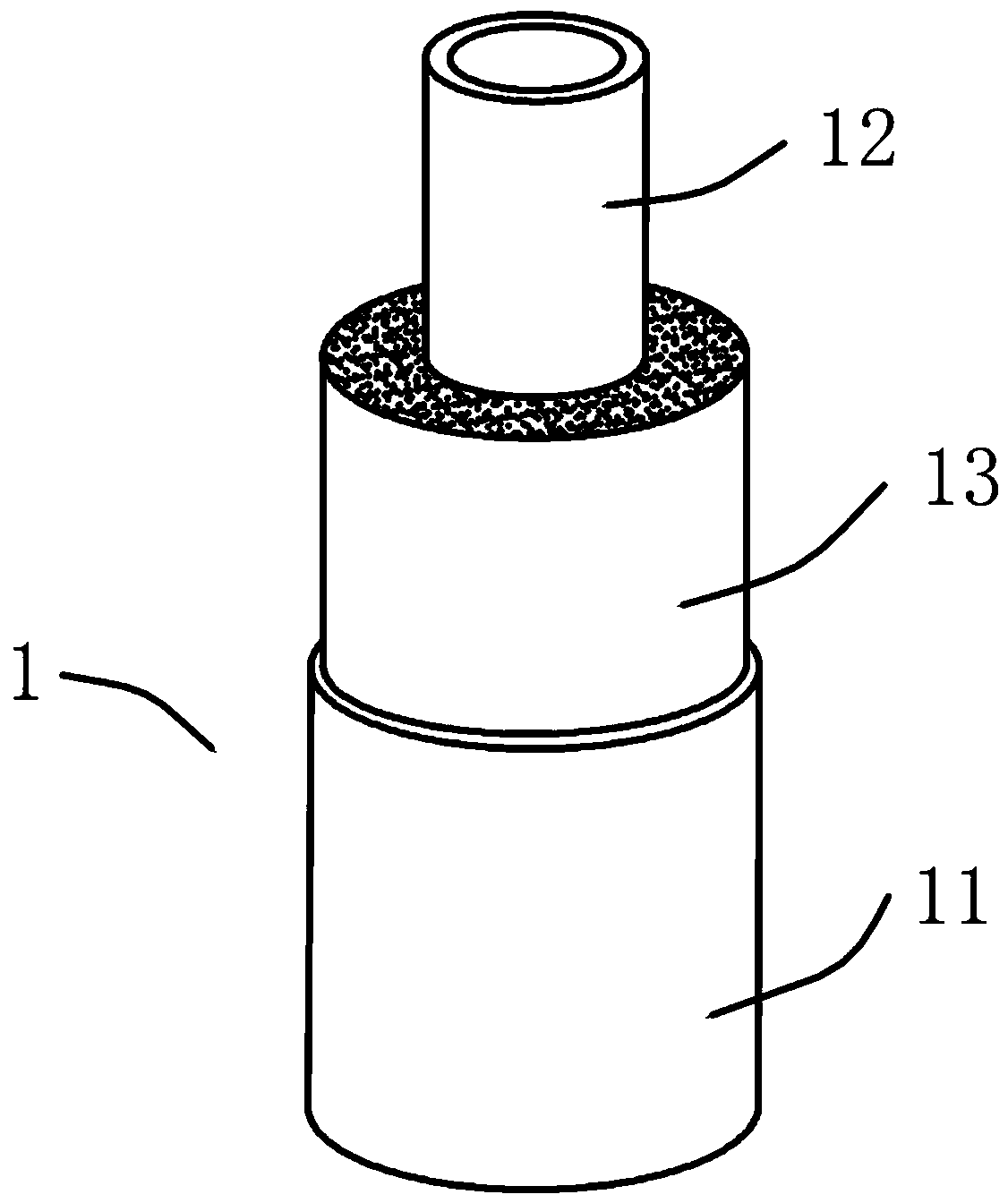

[0026] (b) Pipe prefabrication processing: the insulation pipe 1 includes a PVC outer pipe 11, a PPR inner pipe 12 placed in the PVC outer pipe 11 and a polyurethane insulation layer 13 filled between the two pipes, and the PPR inner pipe 12 is placed on the PVC outer pipe. Inside the pipe 11, keep the double pipe concentricity, seal the lower part of the double pipe, inject polyurethane foam slurry from the upper side to the double pipe, fill the gap betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com