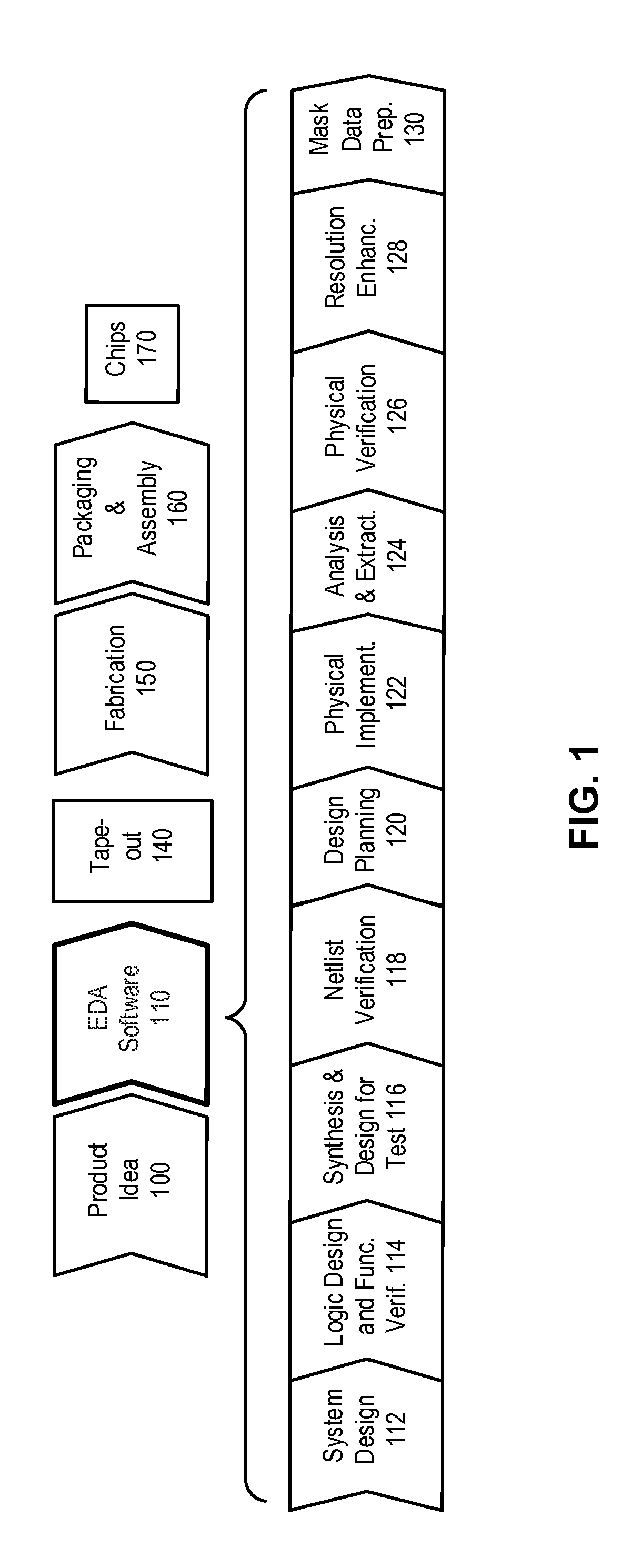

Patents

Literature

115 results about "Design intent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon tolerance specification using shapes as design intent markers

ActiveUS7458045B2High yieldCAD circuit designSoftware simulation/interpretation/emulationEngineeringSilicon

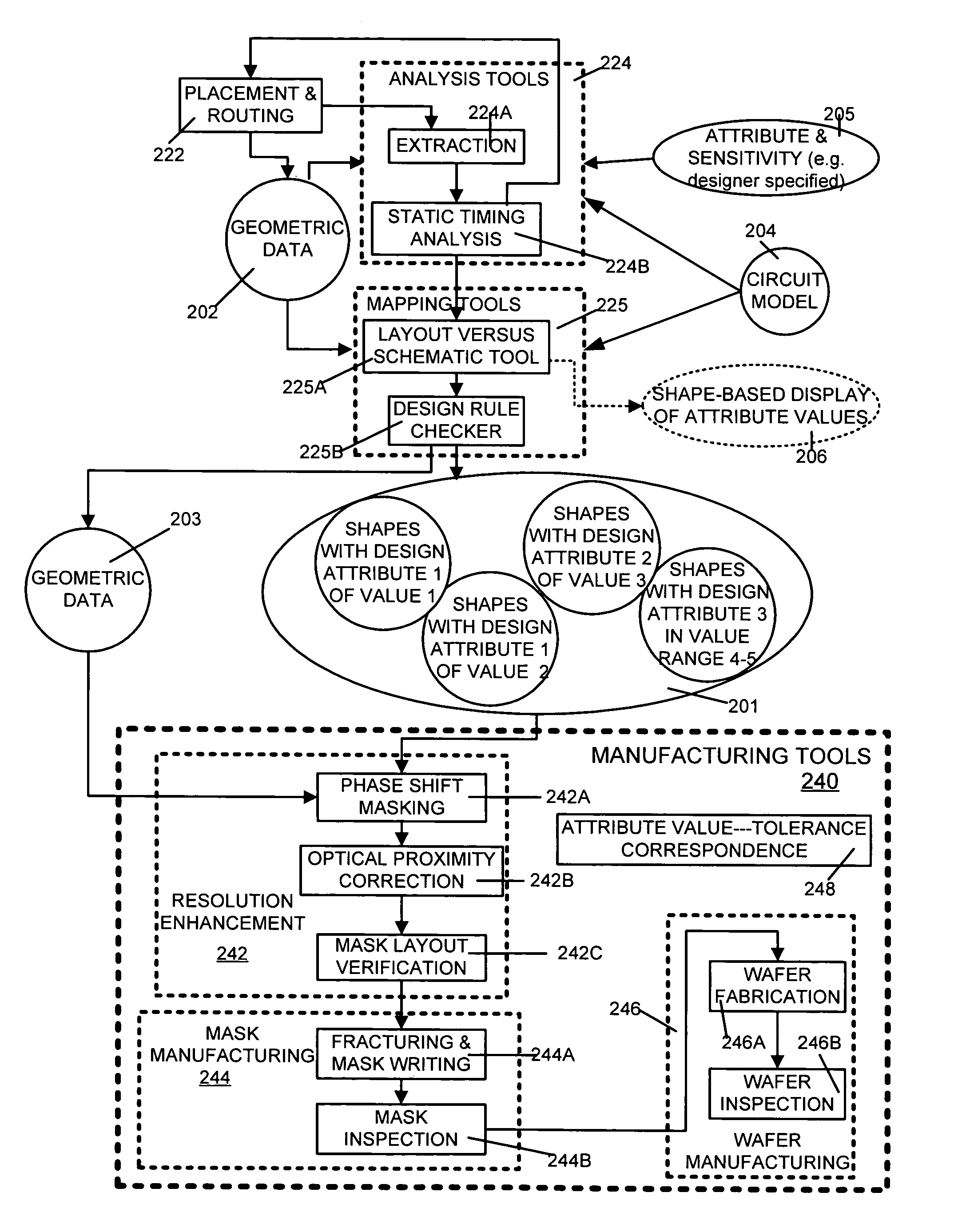

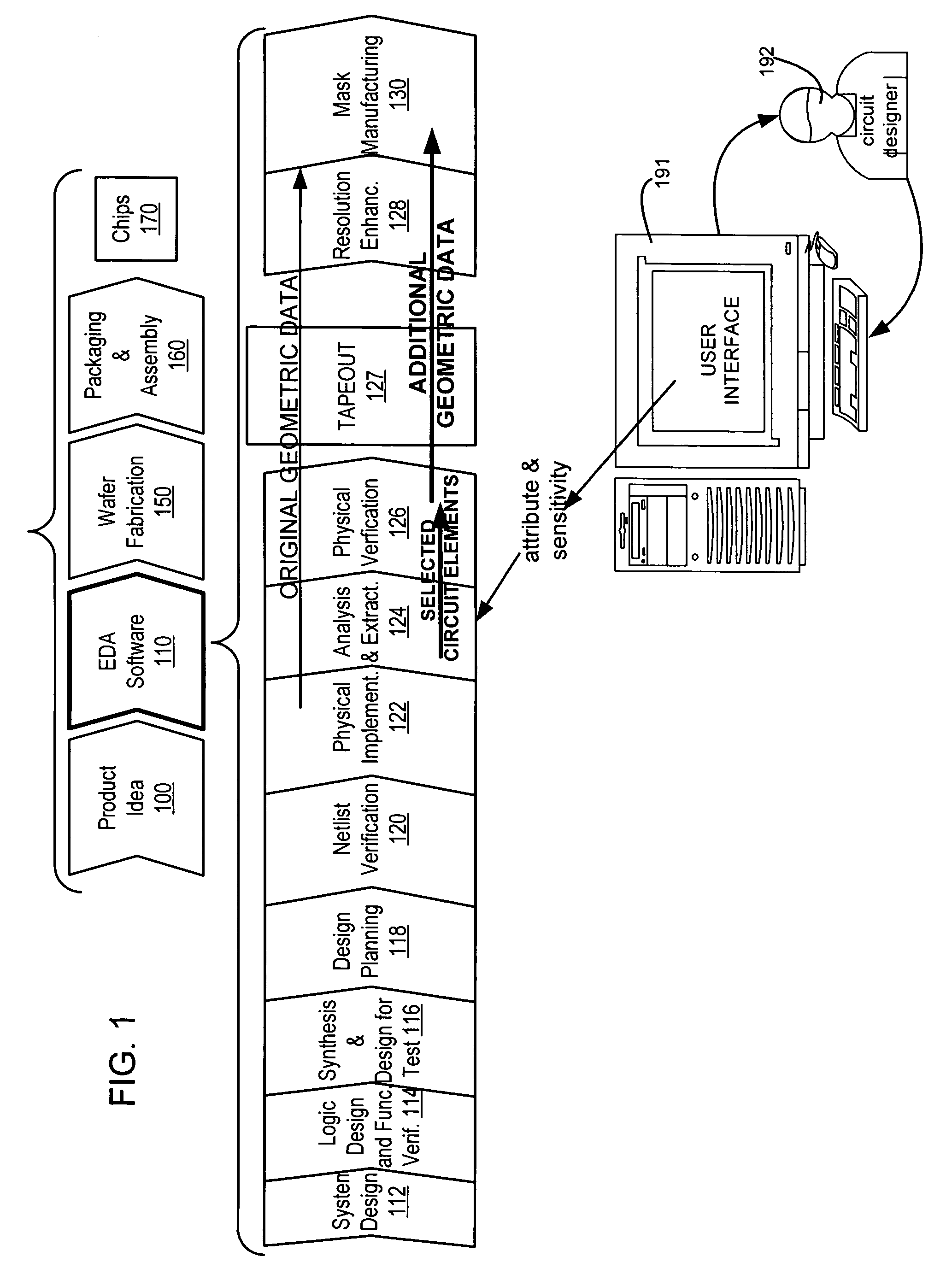

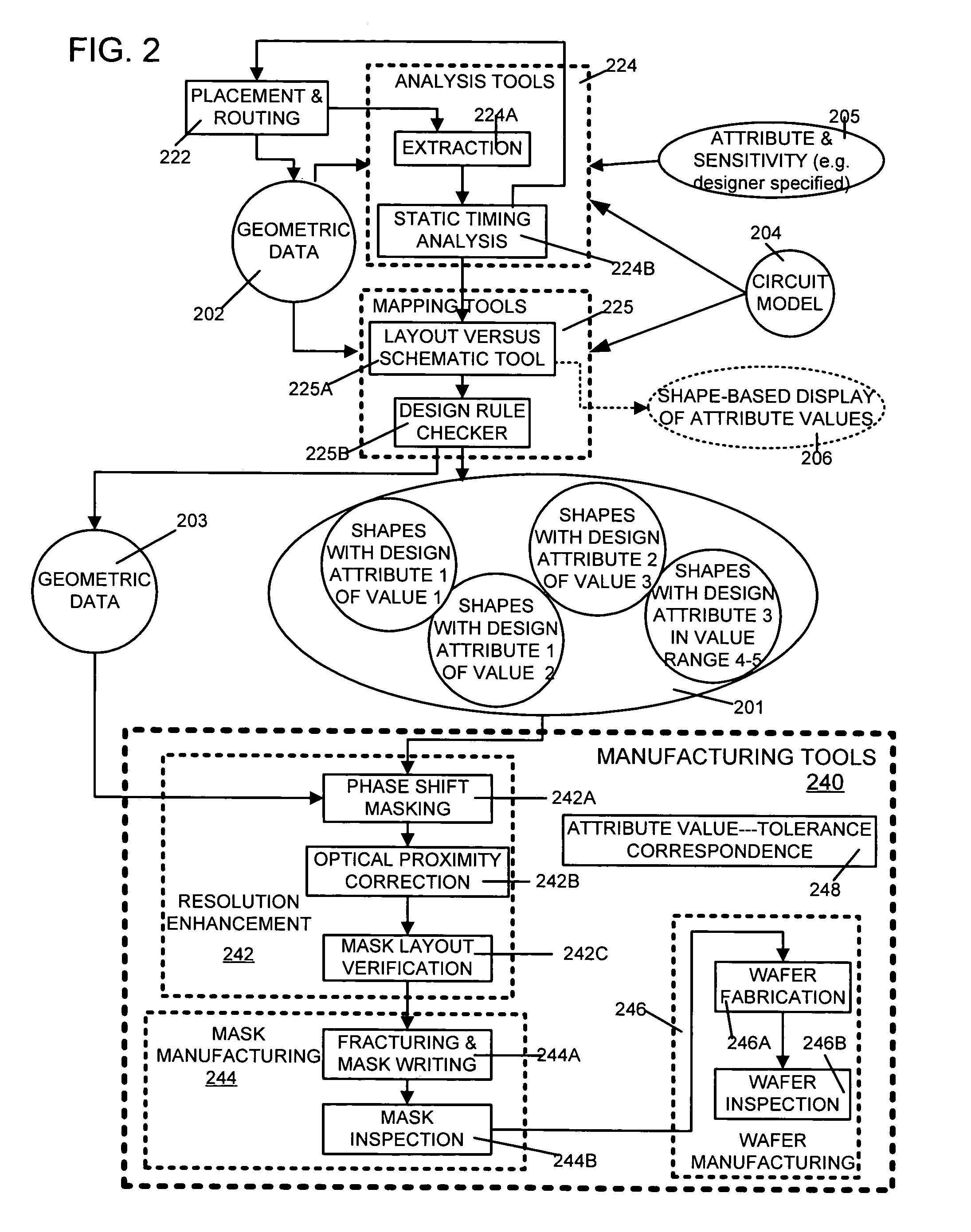

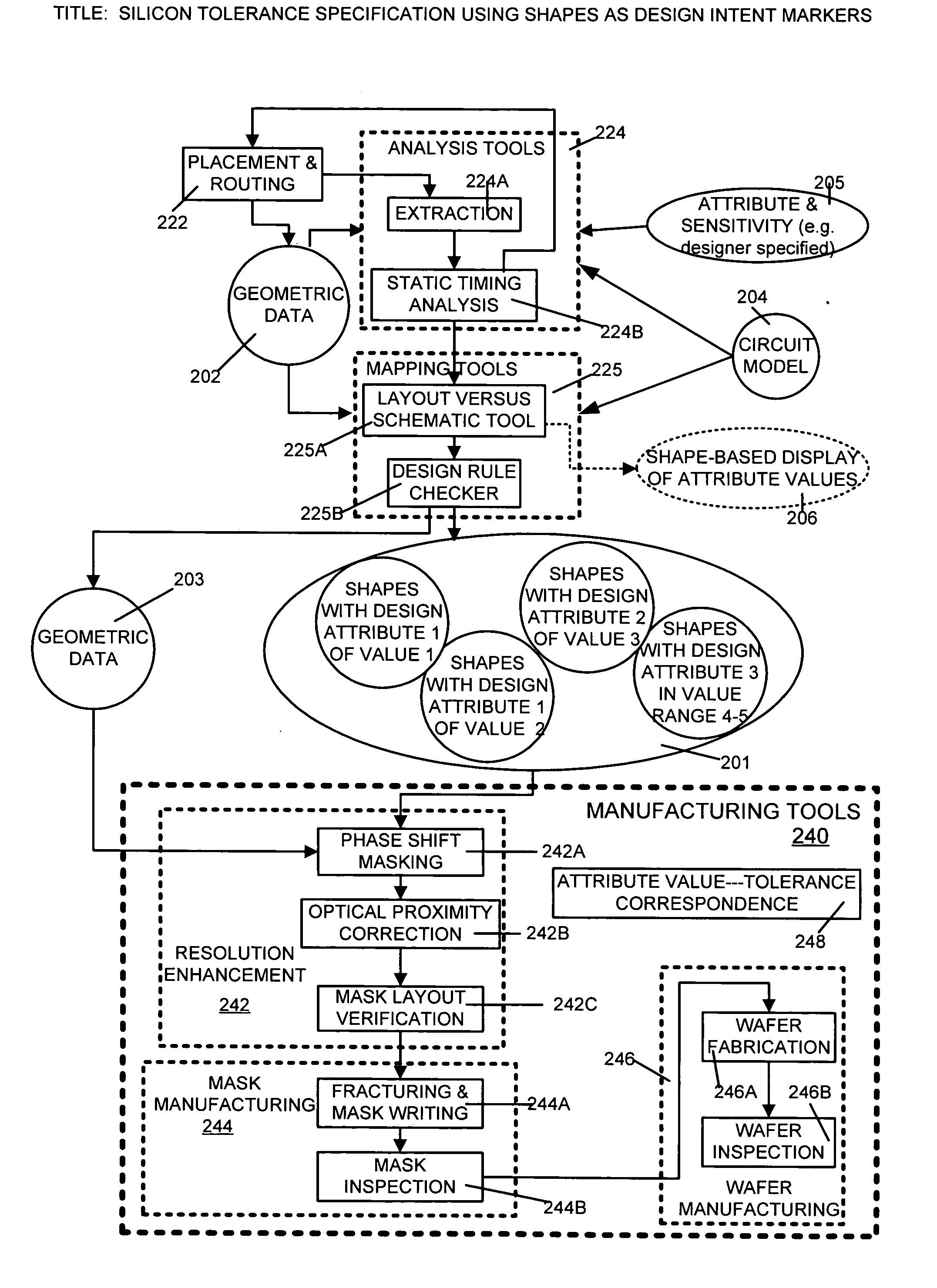

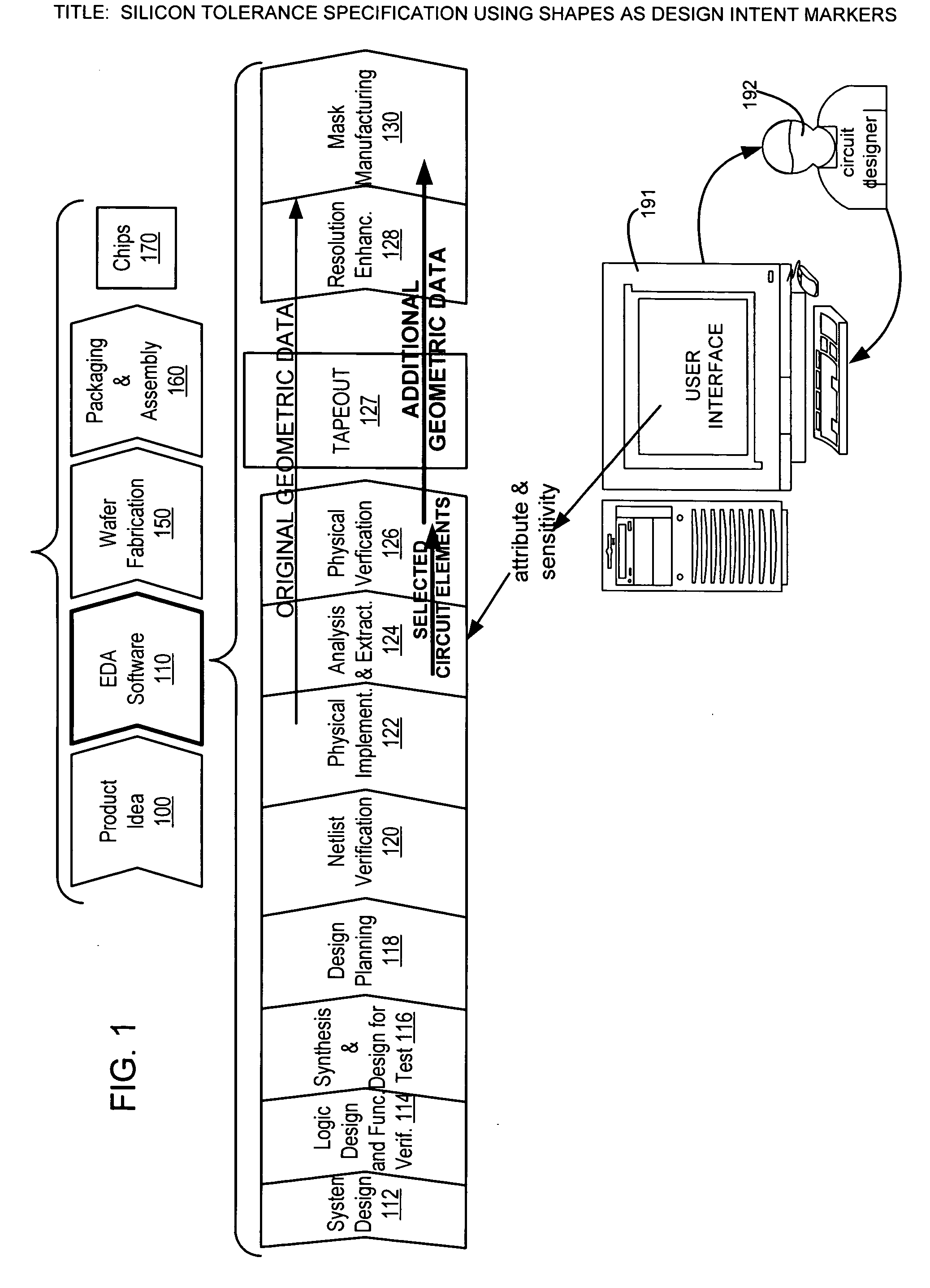

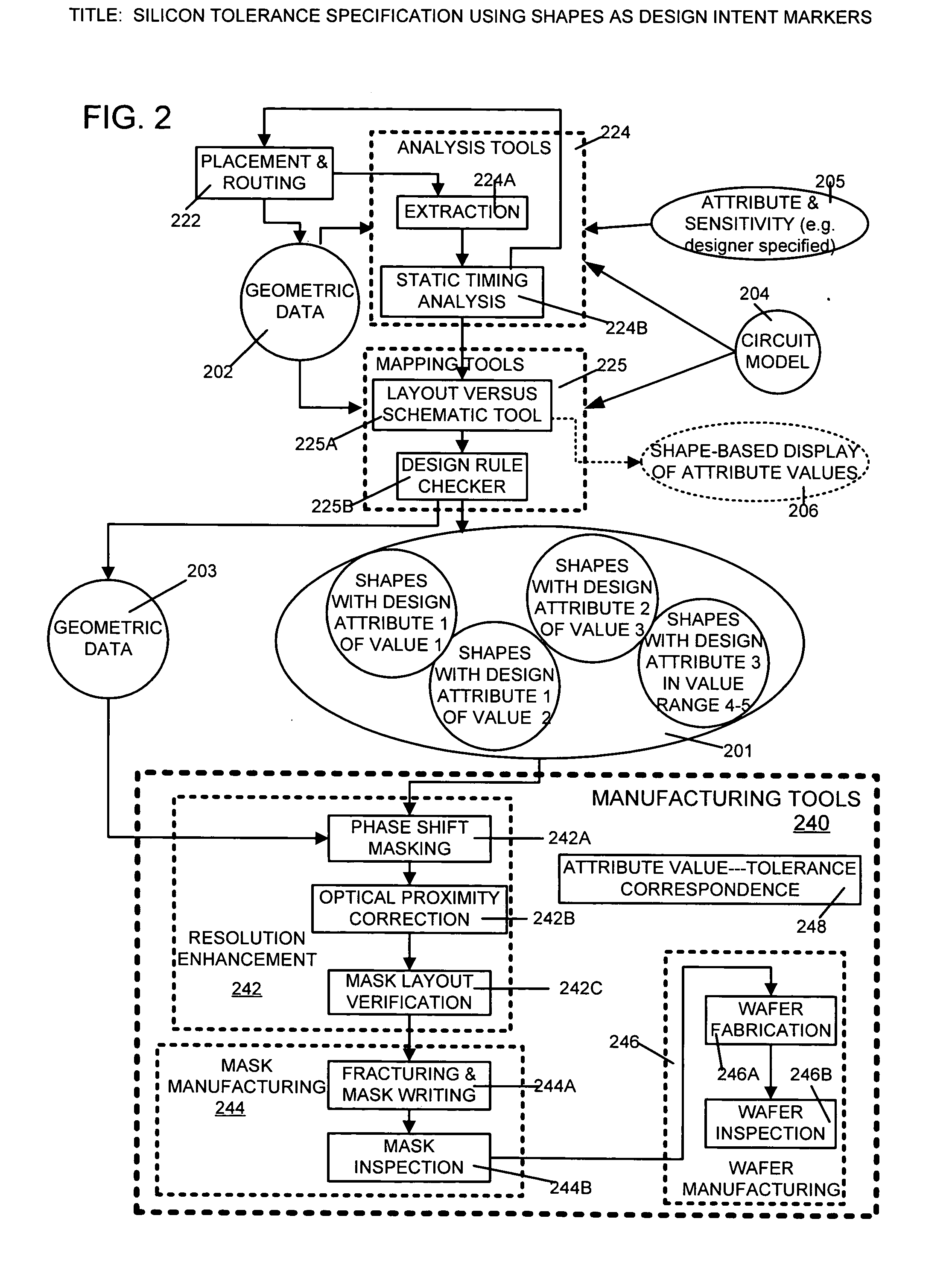

Design-specific attributes of a circuit (such as timing, power, electro-migration, and signal integrity) are used to automatically identify one or more regions of one or more layers in a layout of the circuit. The automatically identified regions may be provided to a manufacturing tool in GDSII by use of overlapping shapes in, or alternatively by moving existing shapes to, a different layer / datatype pair. For example, information about the automatically identified regions may be stored using a conventional datatype (e.g. value 0) with a new layer, or alternatively using a conventional layer (e.g. metal 3) with a new datatype (e.g. value 1), depending on the embodiment. The automatically identified regions contain cells and / or features (e.g. groups of shapes and / or individual shapes) whose tolerance in silicon (to be fabricated) is automatically changed from default, based on the design-specific attribute(s) and sensitivity thereto, expressed as design intent by a circuit designer.

Owner:SYNOPSYS INC

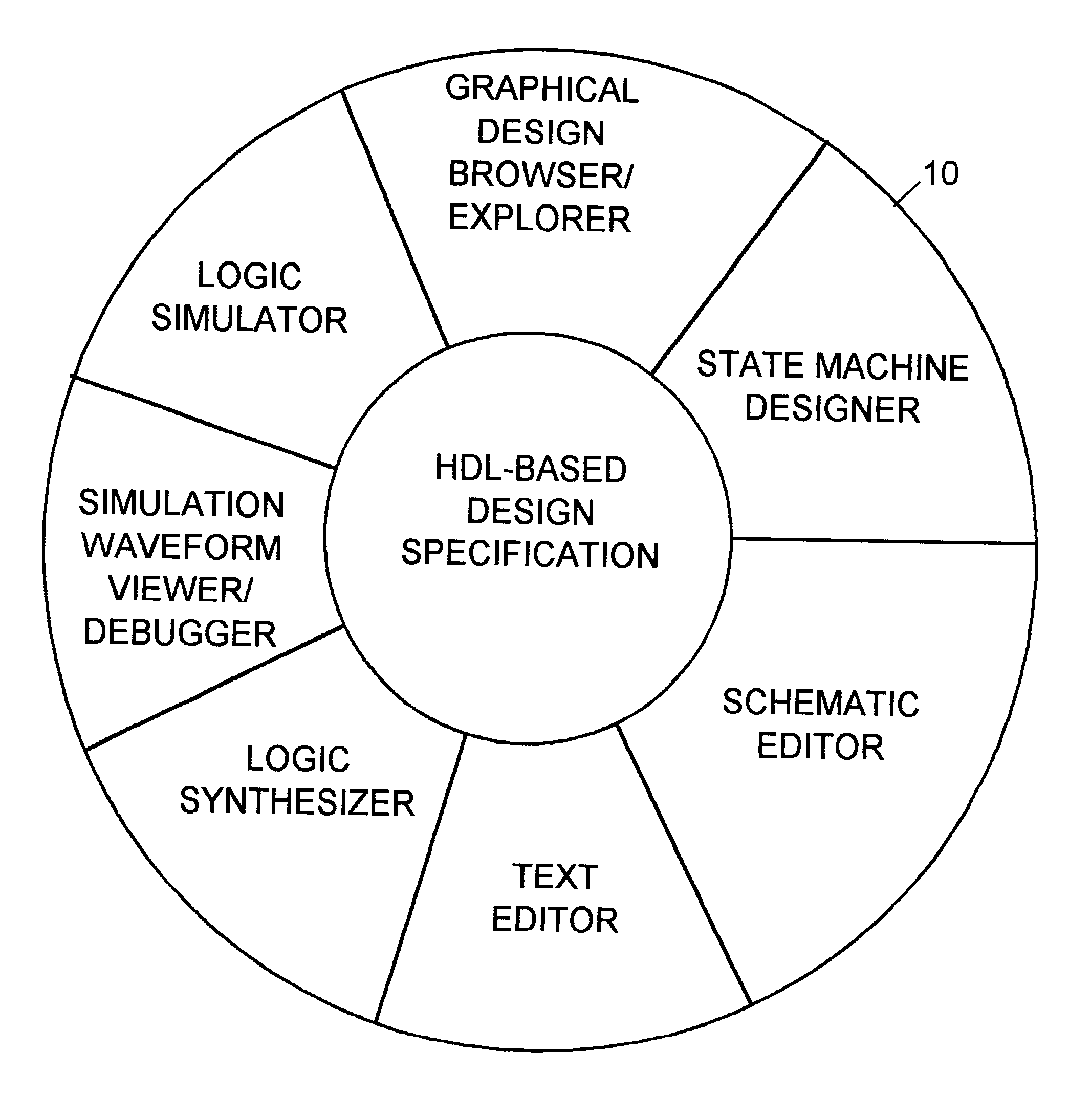

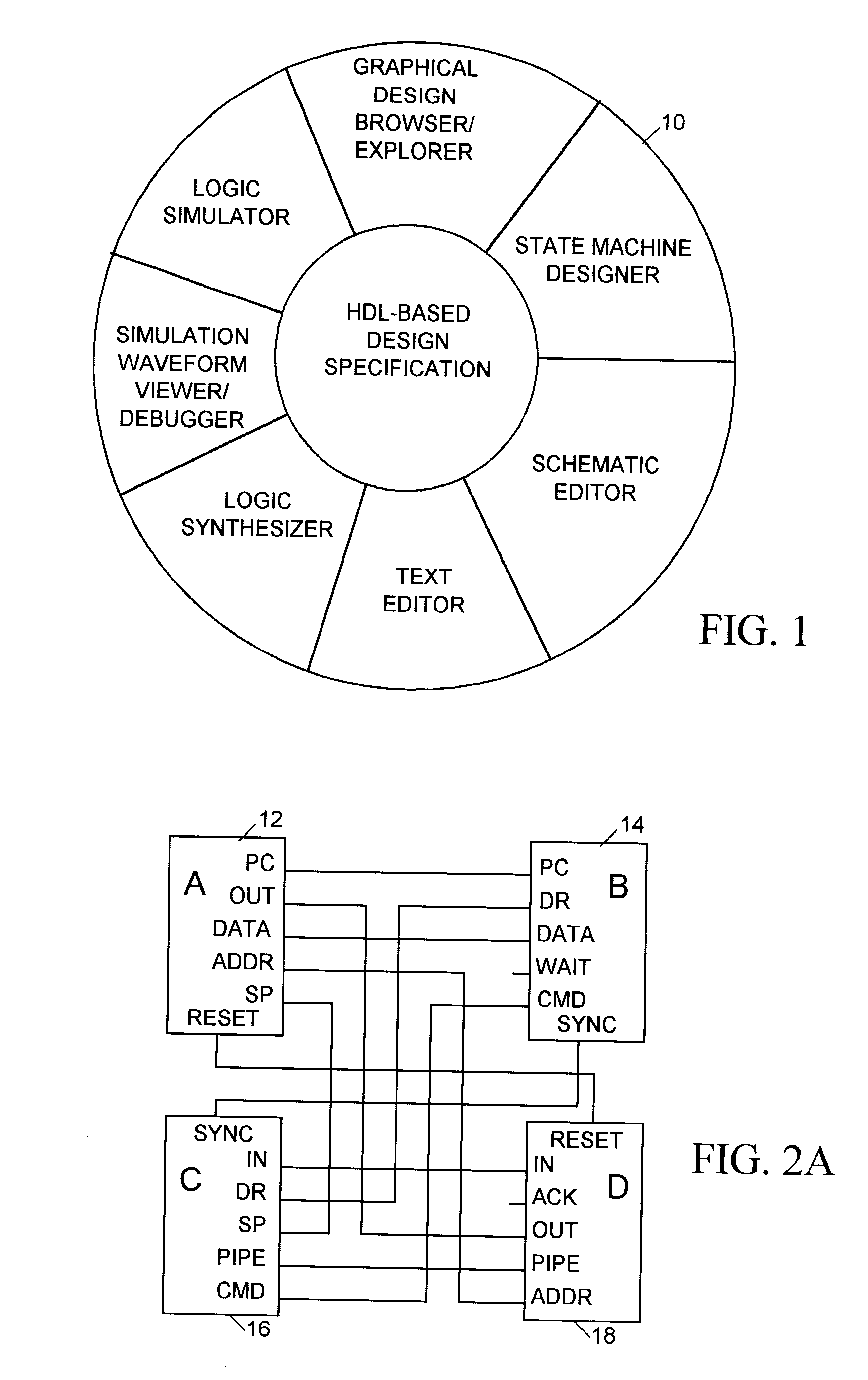

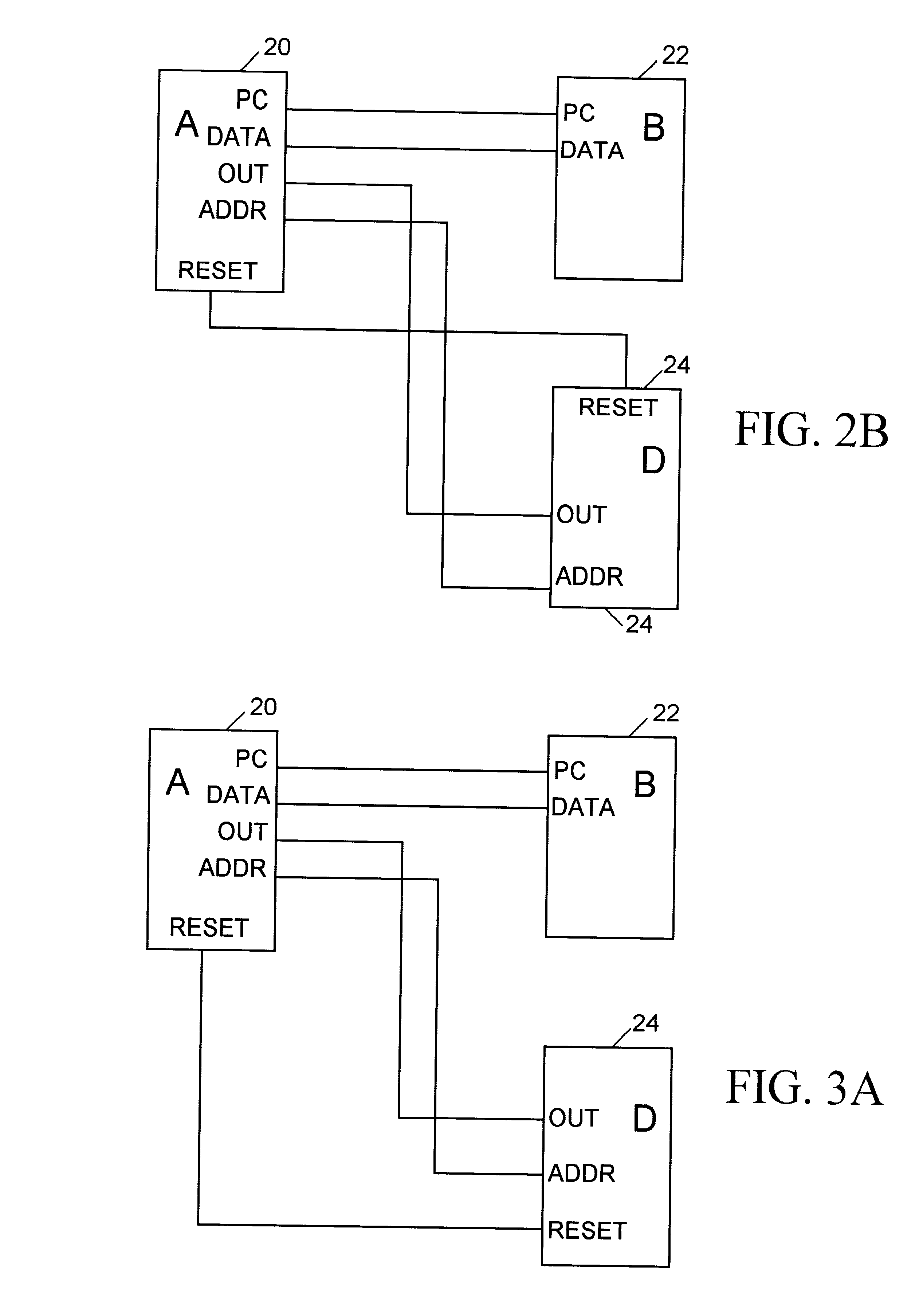

System and method for browsing graphically an electronic design based on a hardware description language specification

InactiveUS6366874B1CAD circuit designSoftware simulation/interpretation/emulationGraphicsProgramming language

Hardware description language (HDL)-centered design system and methodology uses HDL specification effectively as master depository for design intent or knowledge. Through network browser, designers conveniently navigate or explore design graphically. Designers selectively review or save design in entirety or portions. Design capture, analysis, and manipulation are based on HDL specification, either directly through text file editing, or indirectly through use of graphical tools.

Owner:SYNOPSYS INC

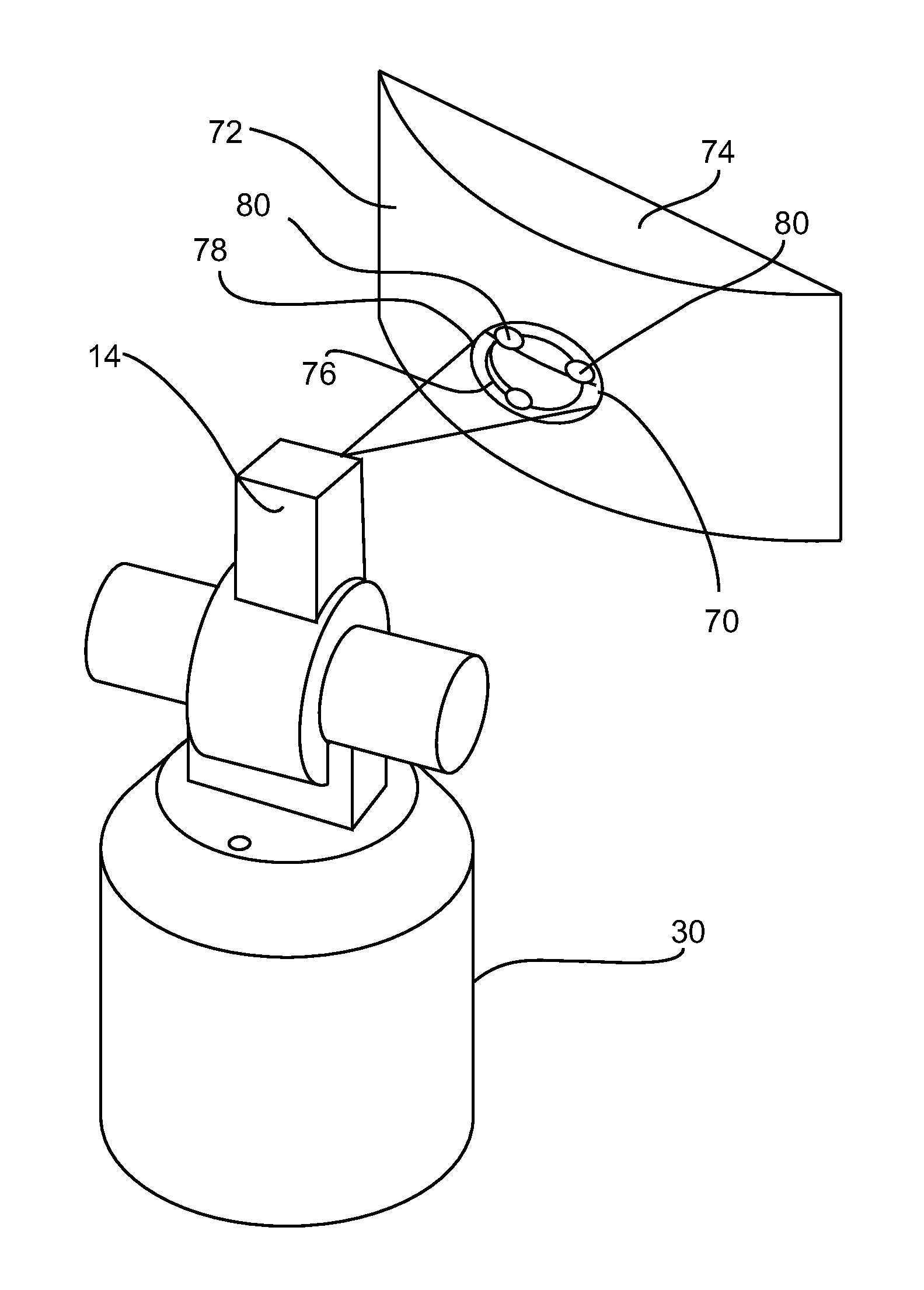

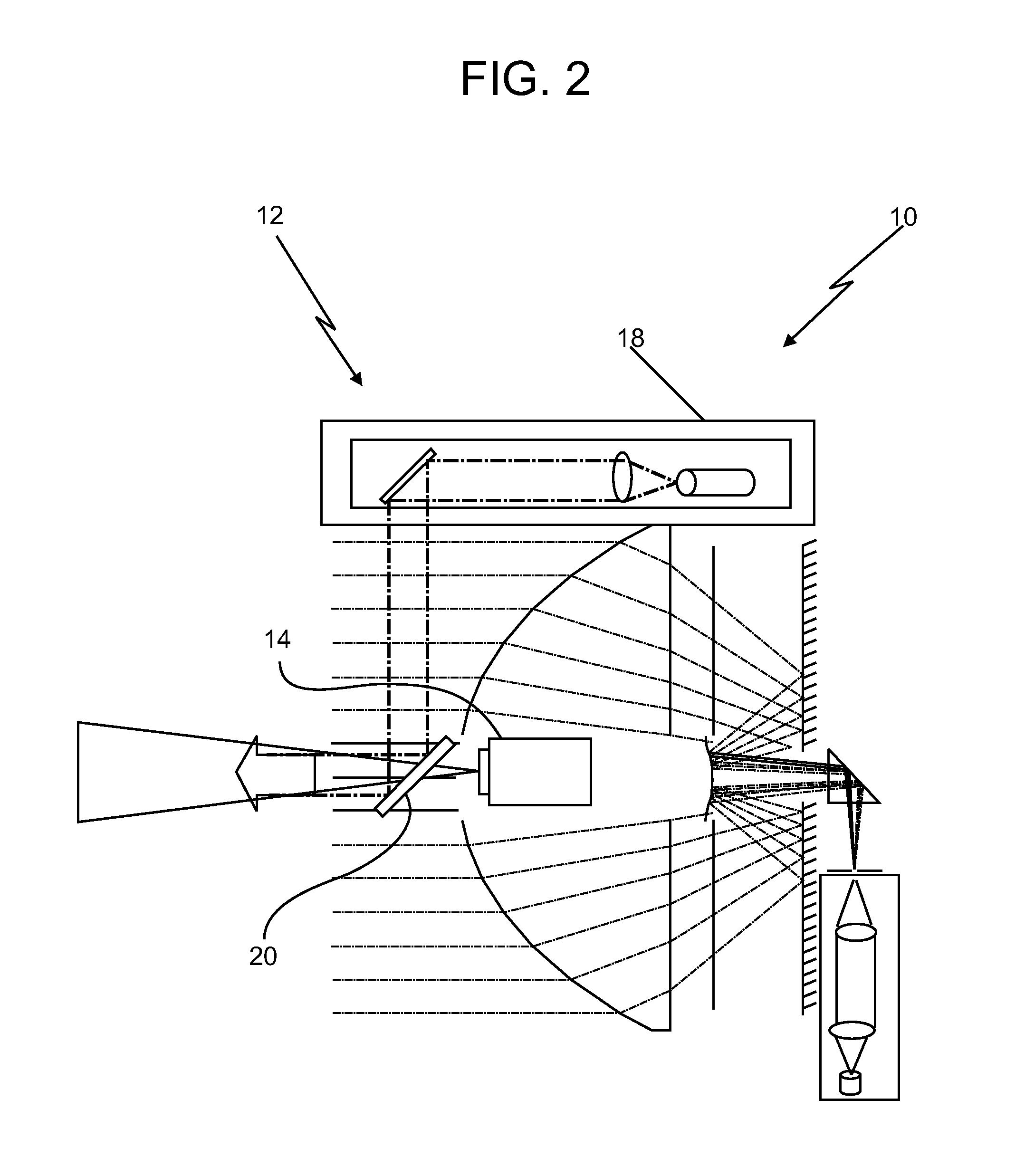

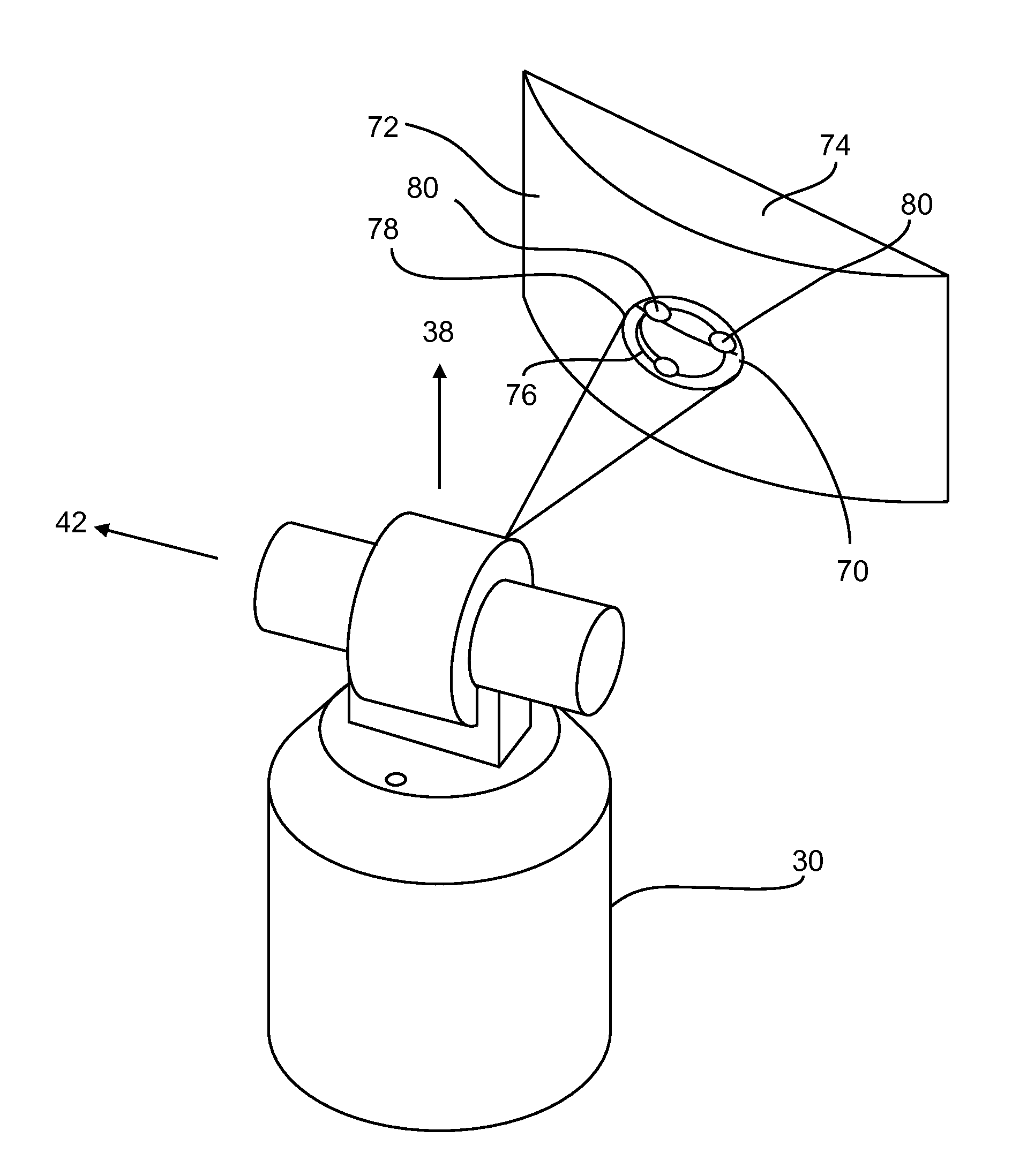

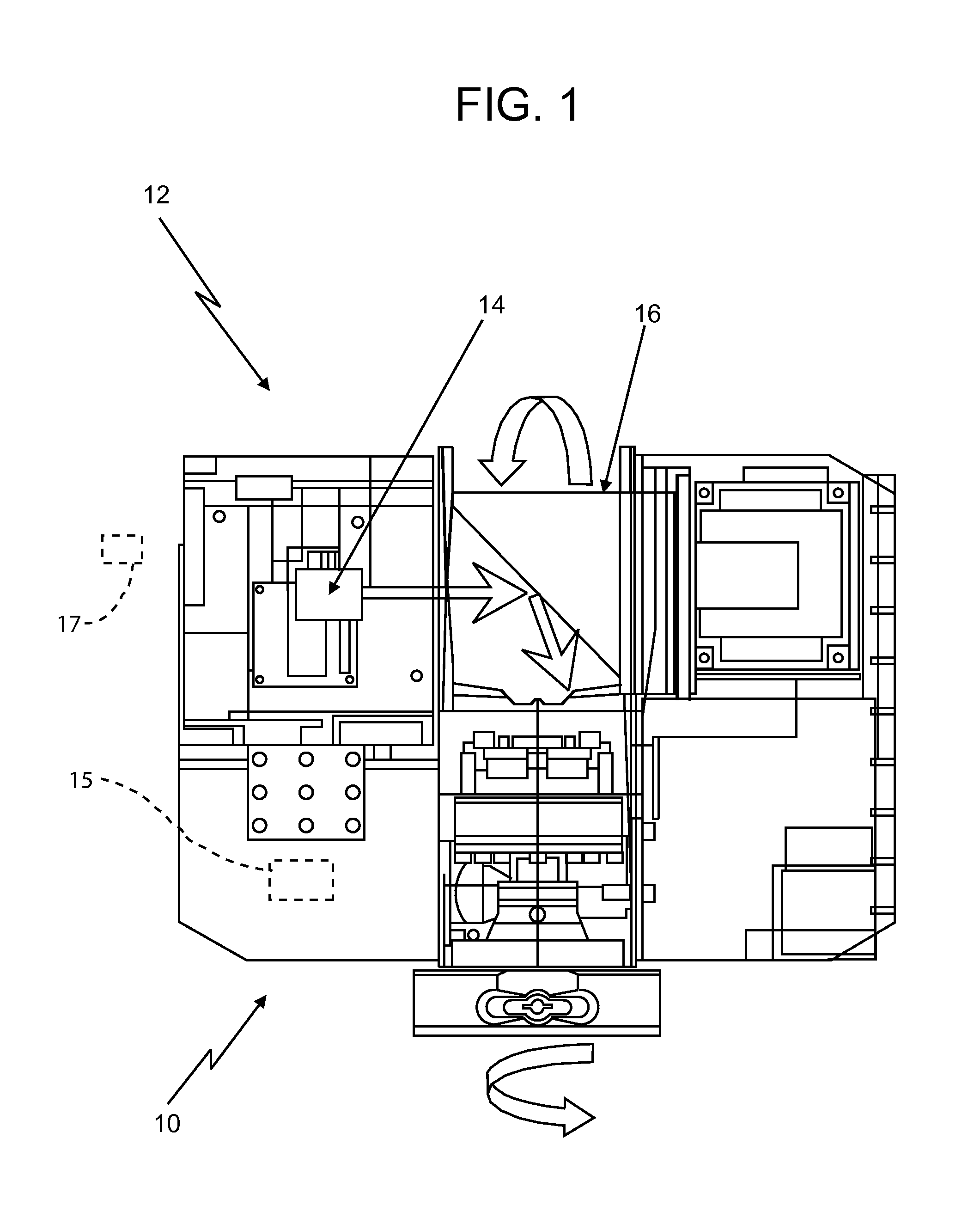

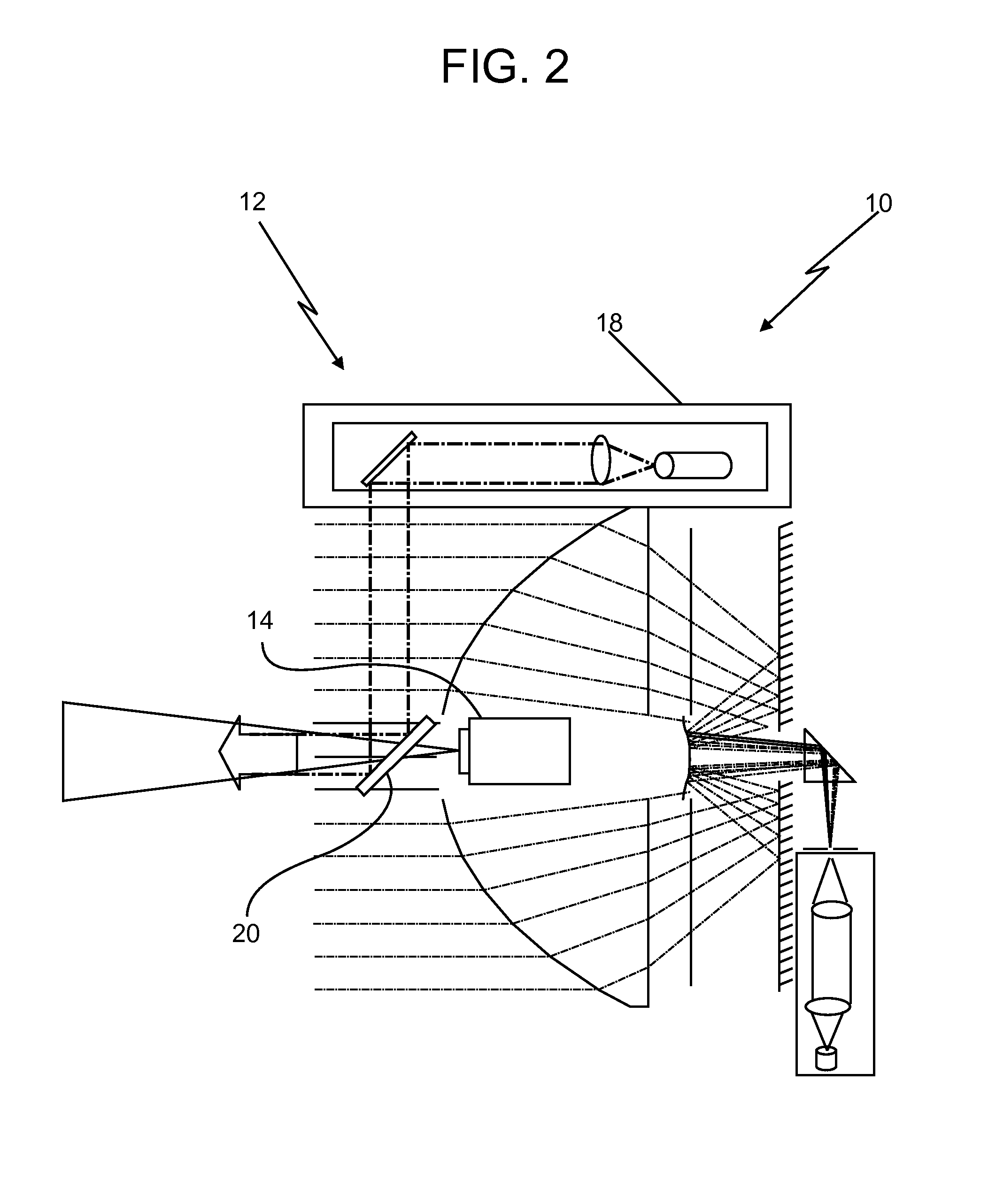

Laser scanner or laser tracker having a projector

A laser scanner or a laser tracker includes a light source that emits a light beam within an environment, and a data capture component that captures the light beam reflected back to the laser scanner or tracker from the environment. The laser scanner or tracker also includes a projector integrated within a body of the laser scanner or tracker or mounted to the body of the laser scanner or tracker at a predetermined location, the projector being operable to project visible information onto an object located within the environment, the projected visible information being indicative of images, data or information, the projected visible information being at least one of design intent information, information acquired by the laser scanner or tracker, or guidance to an operator.

Owner:FARO TECH INC

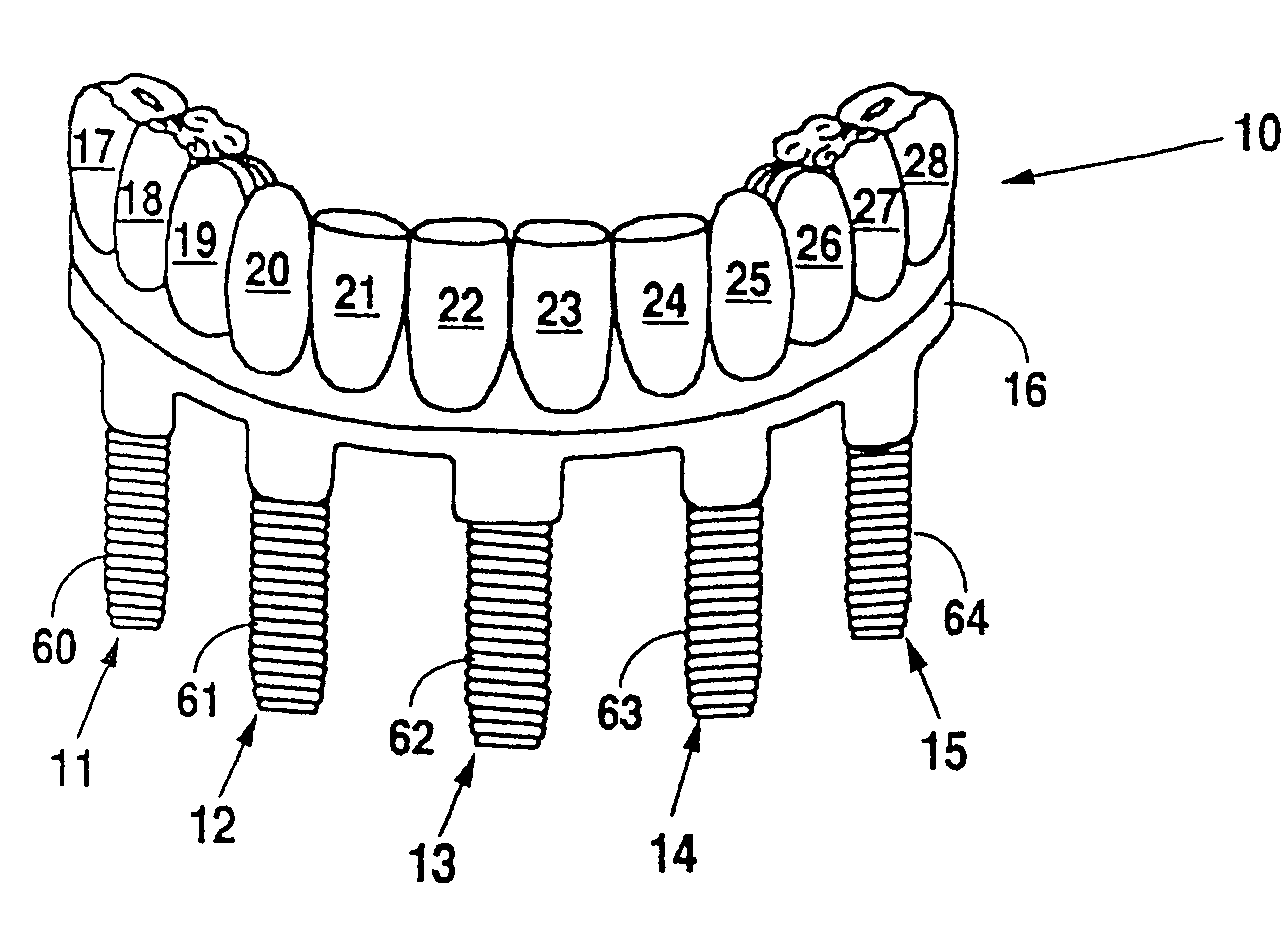

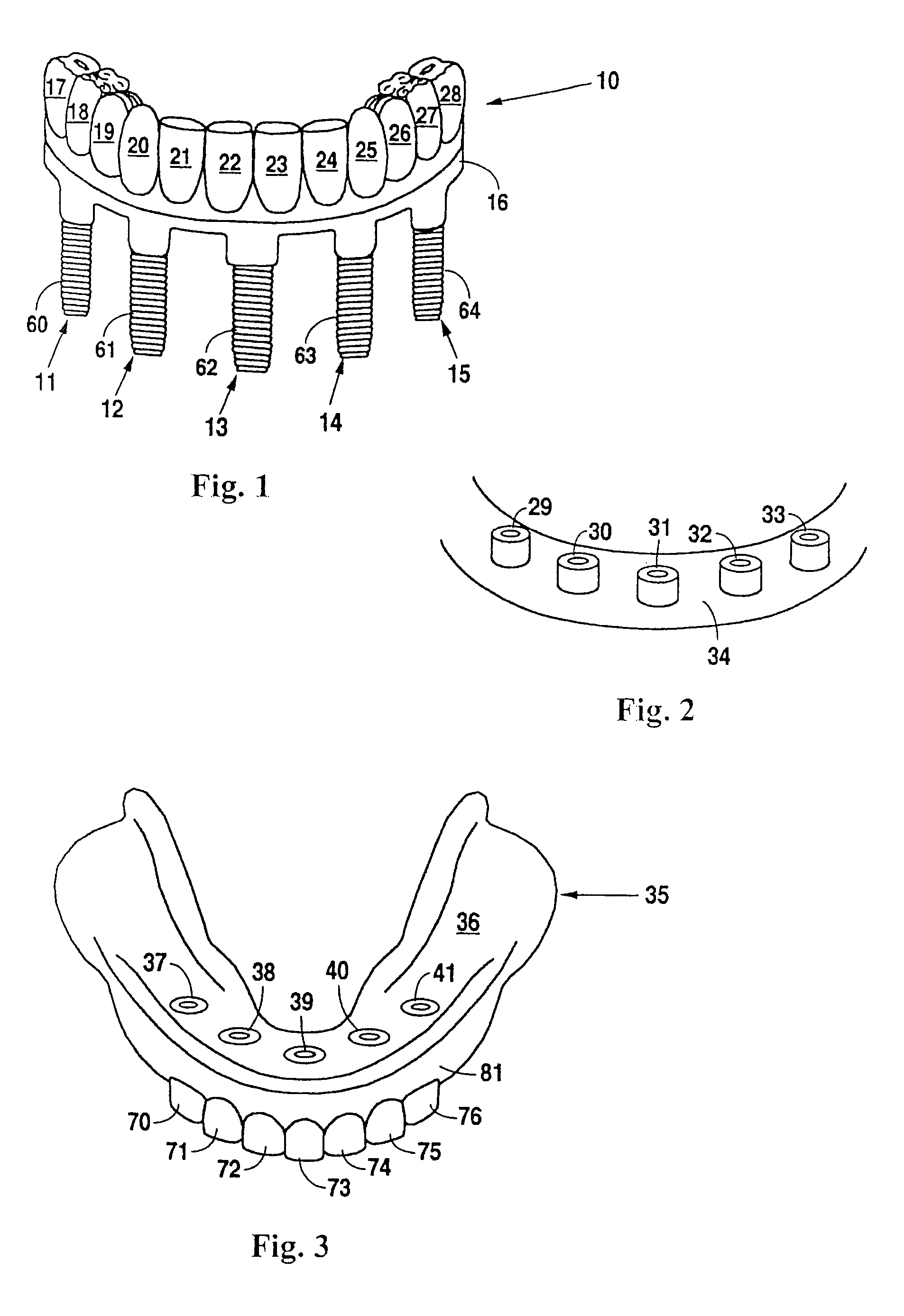

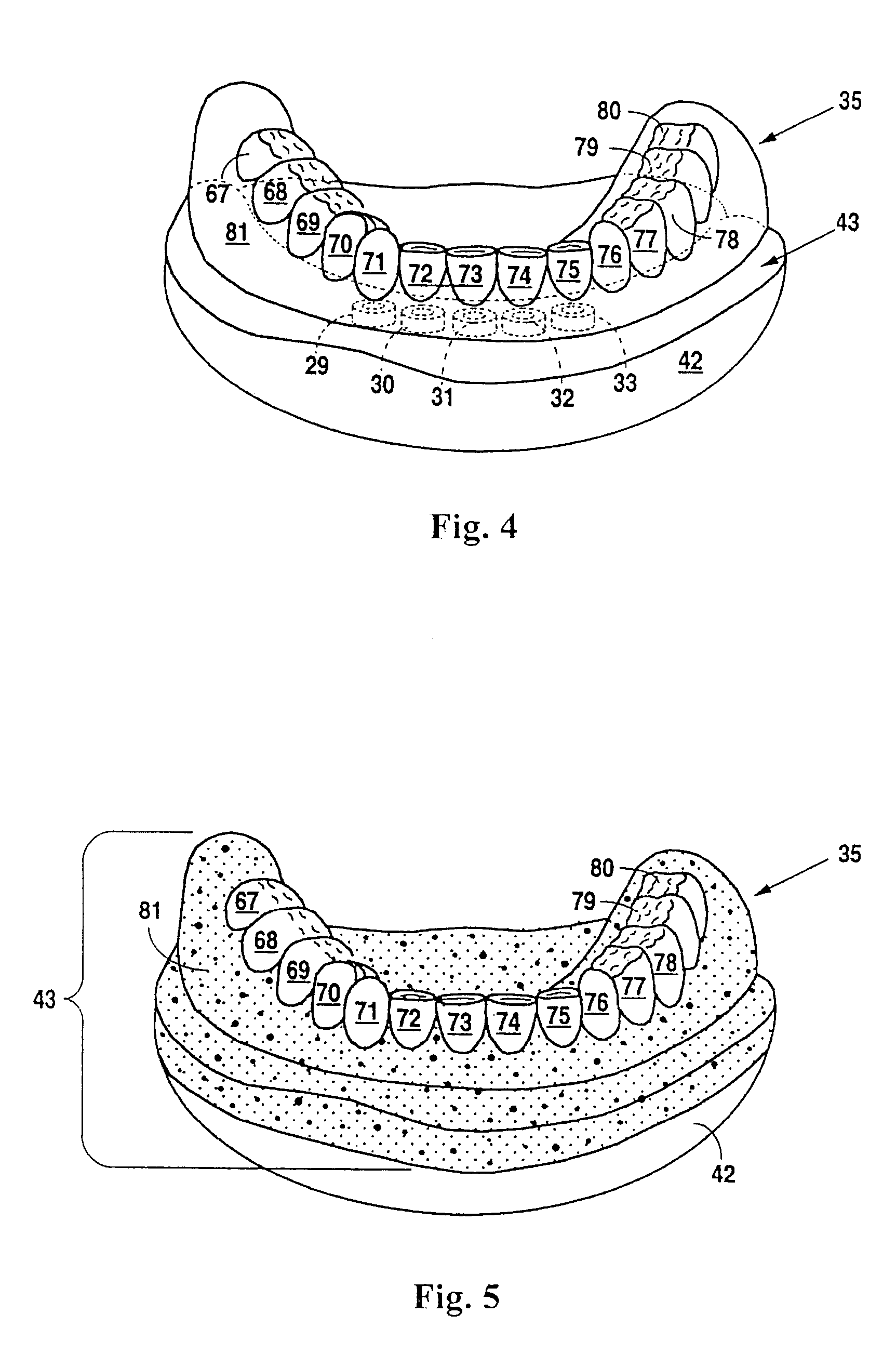

Design and manufacture of dental implant restorations

The present invention provides a method of making and aligning digital images from oral tissues, dental implants, healing components, and dental restorations to design and manufacture dental implant retained restorations. Image data about the space available for the planned restoration, orientation of dental implants or abutments and aesthetic contour and occlusion of the prosthesis are all integrated into a virtual three-dimensional model of the prosthesis that can be sent to the clinician or laboratory to validate design intent and to manufacture the prosthesis. The virtual model is used by either a conventional rapid prototyping machine to produce a castable pattern or a number controlled mill to machine the restoration.

Owner:VOXELOGIX CORP

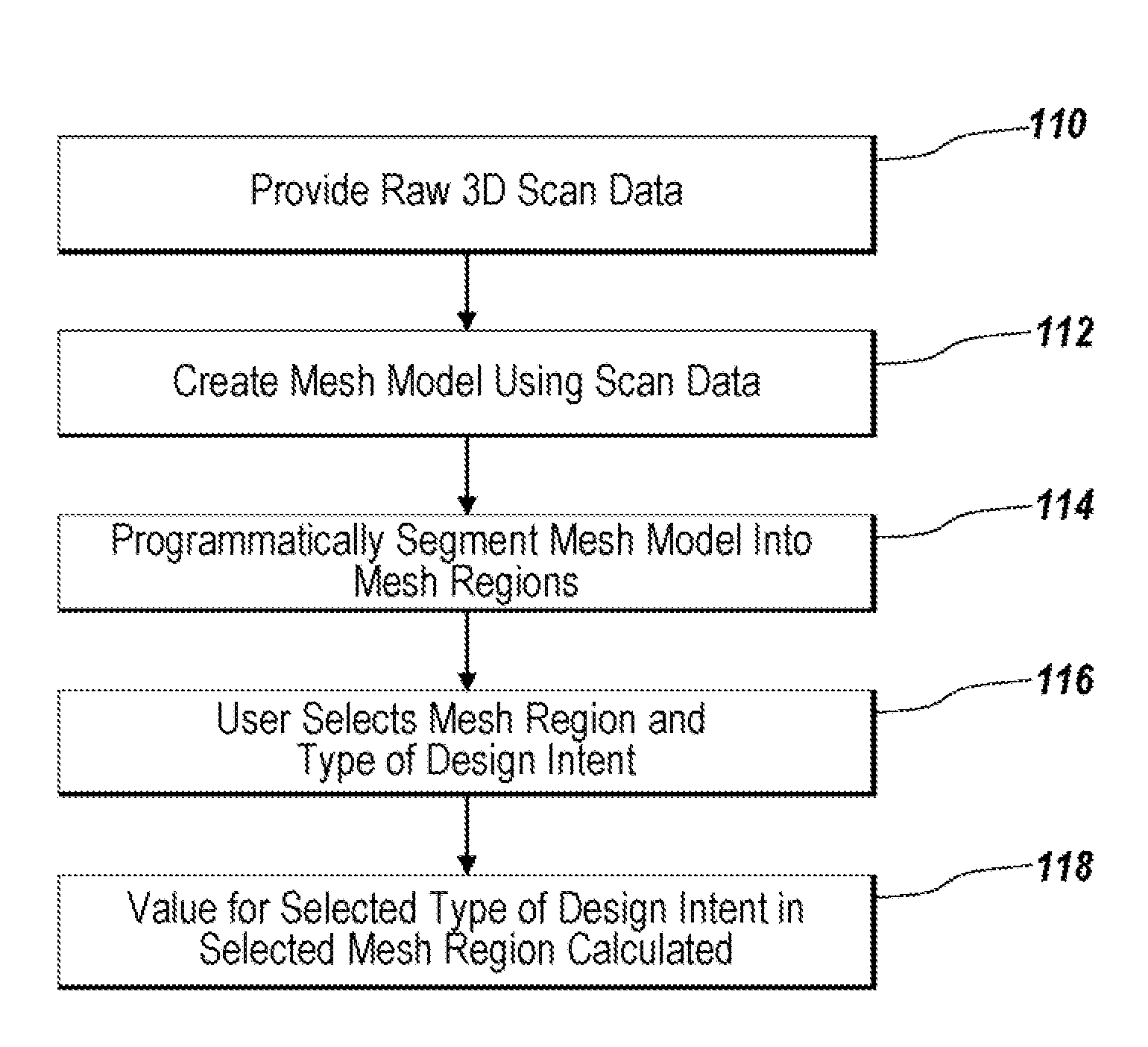

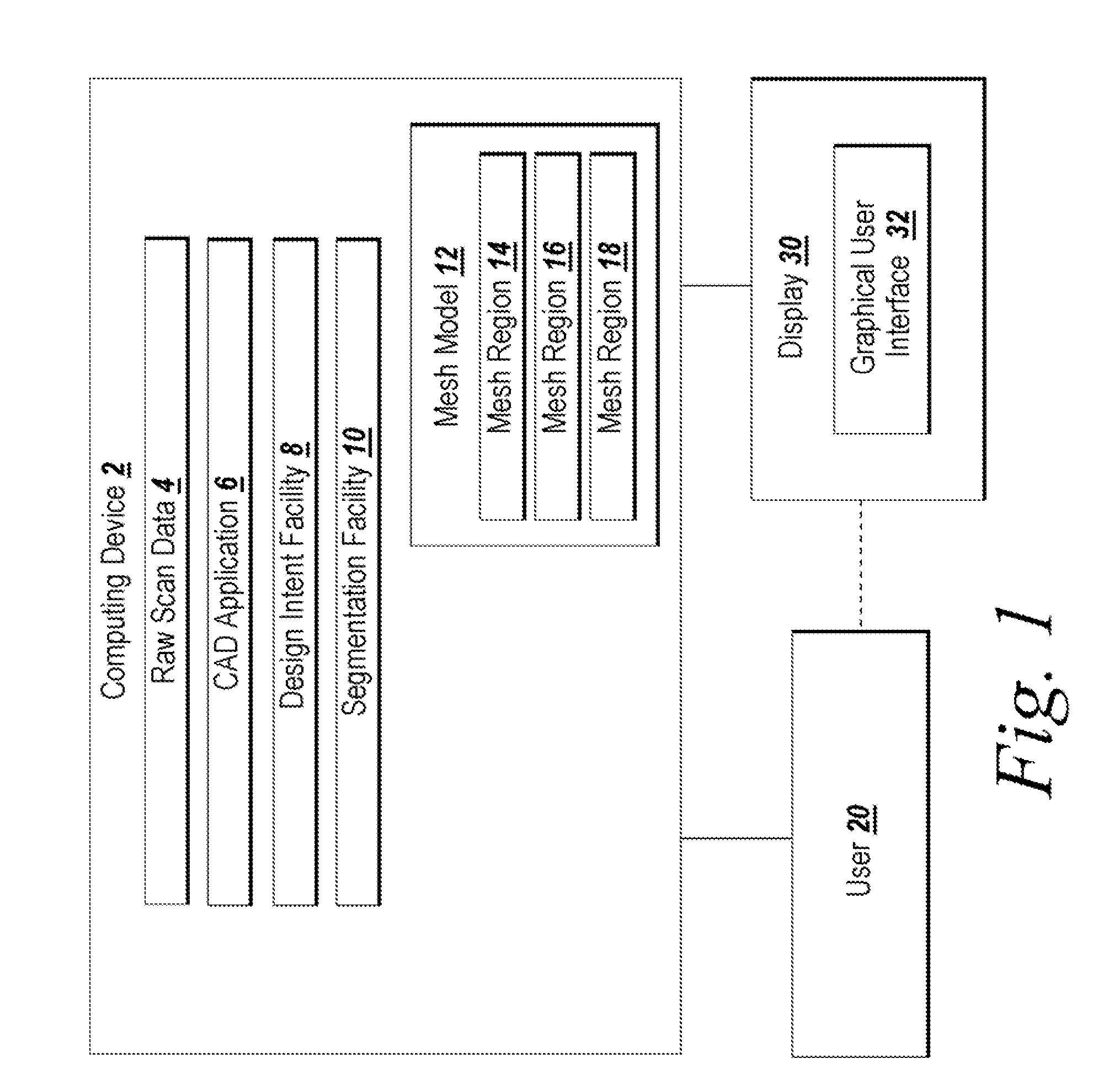

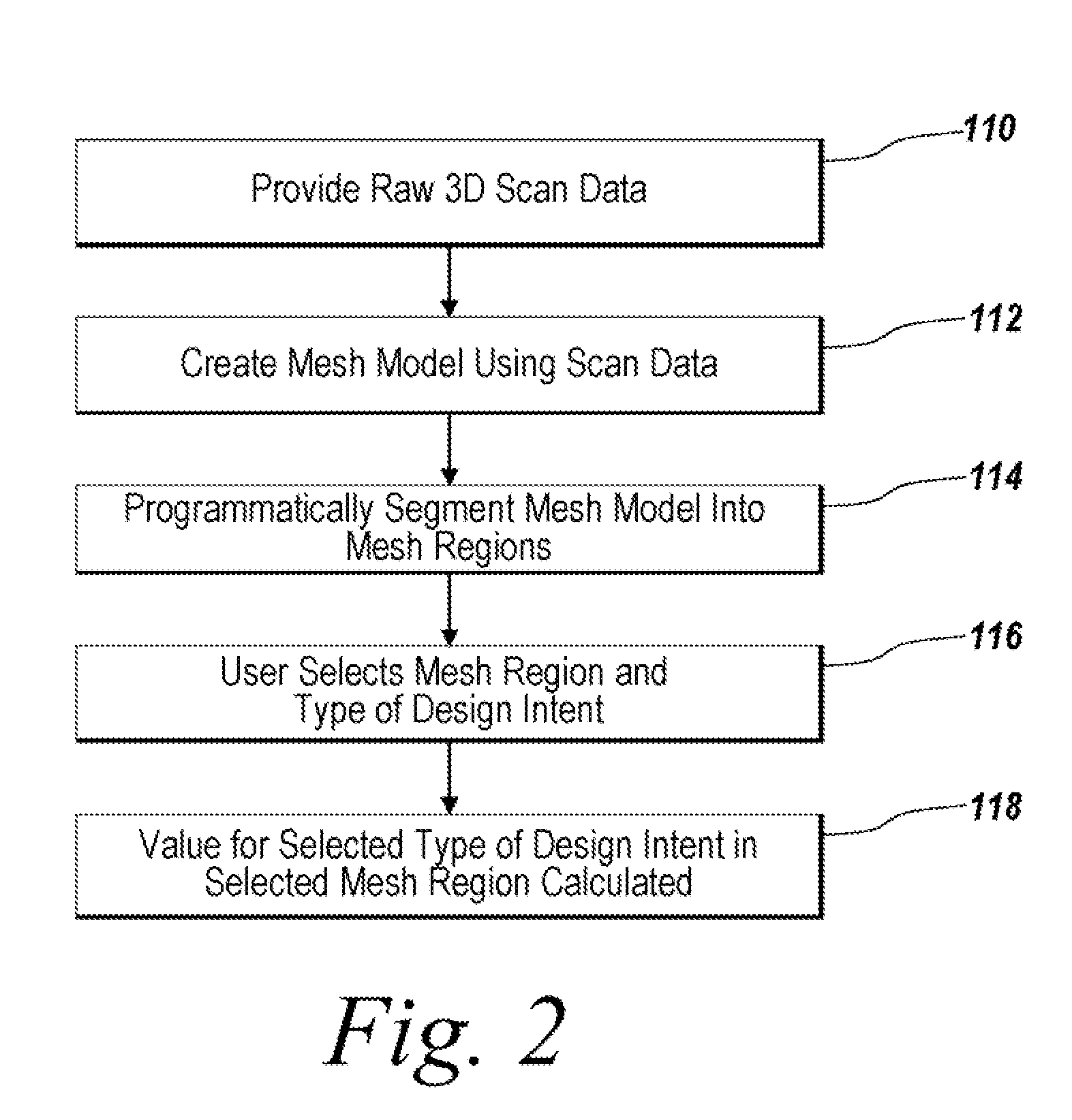

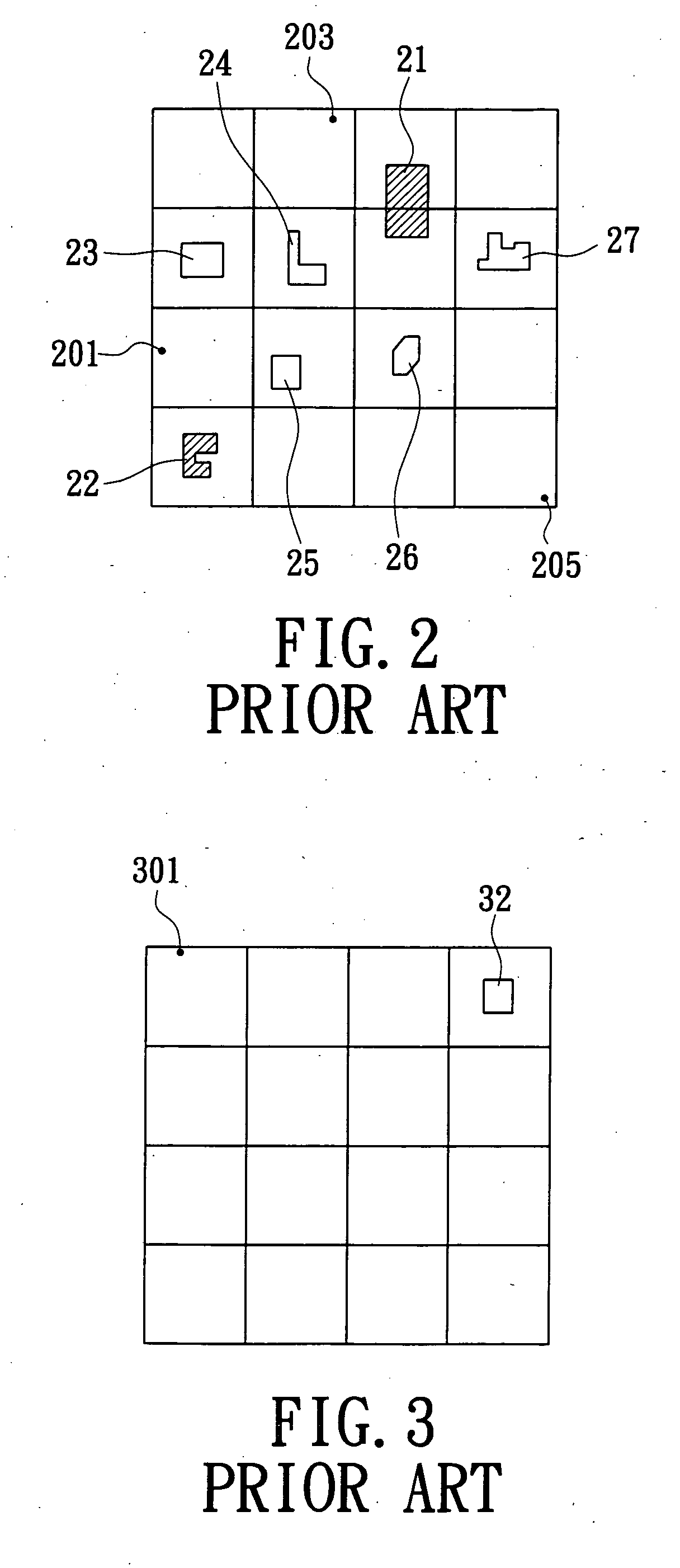

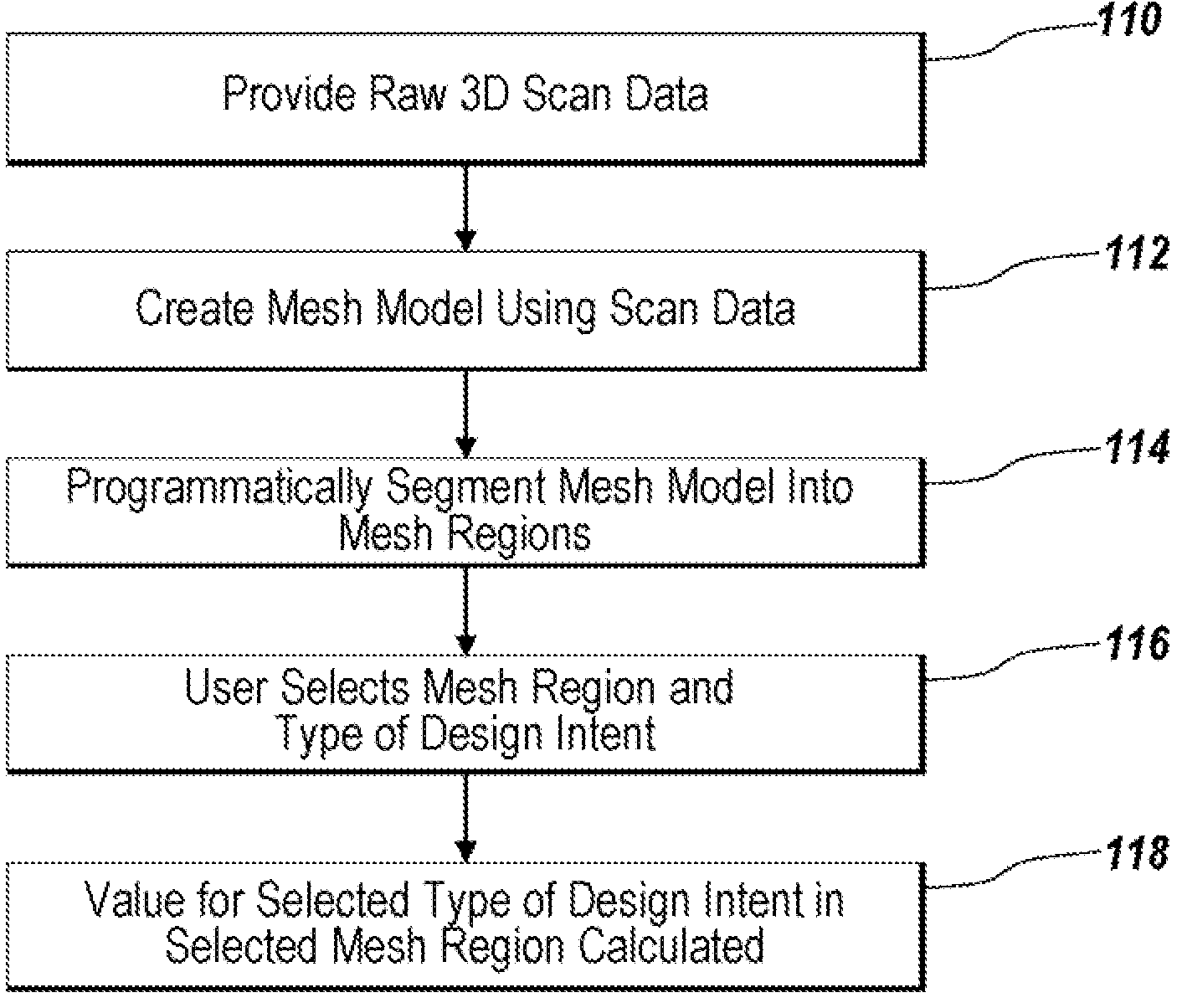

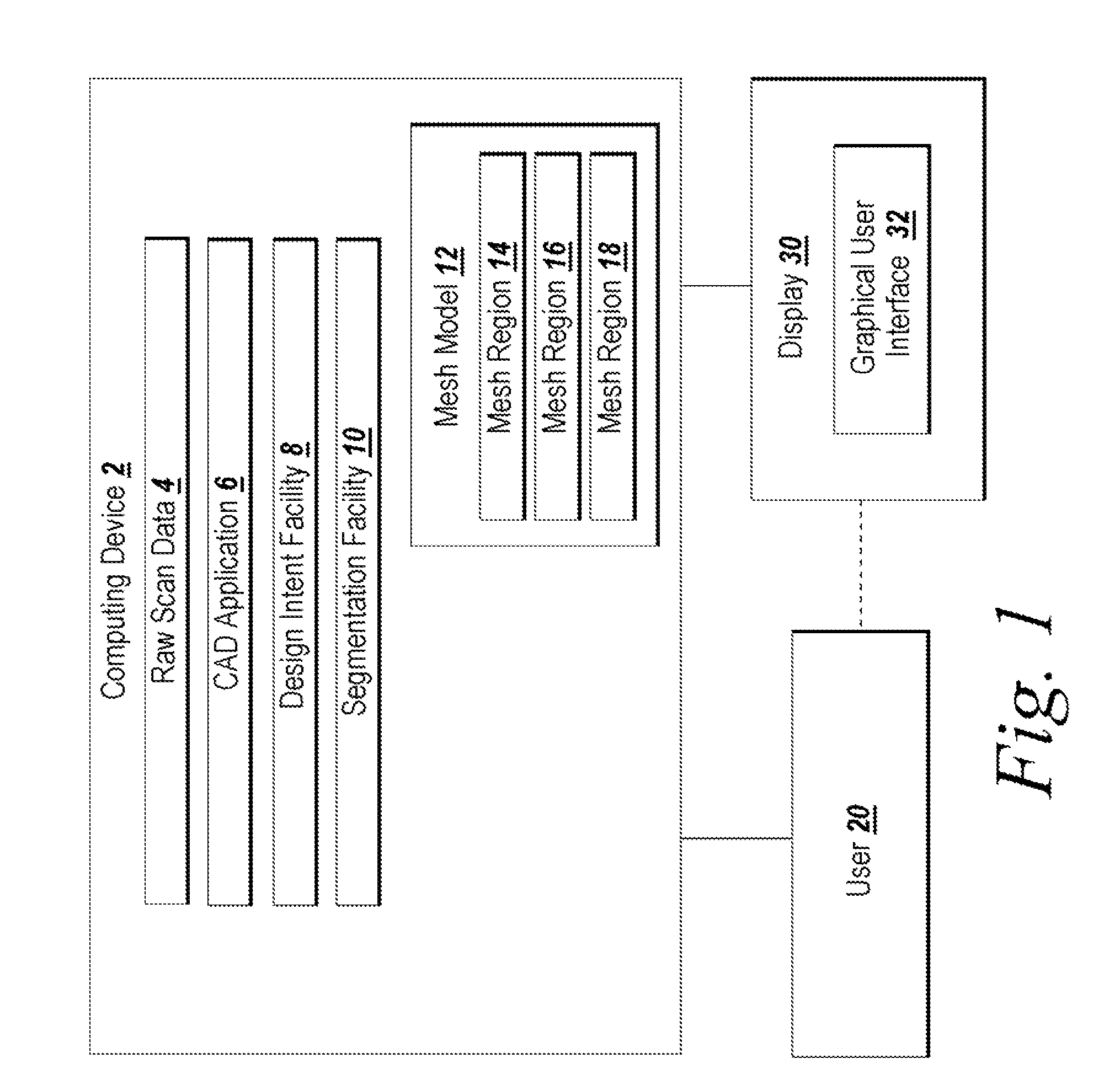

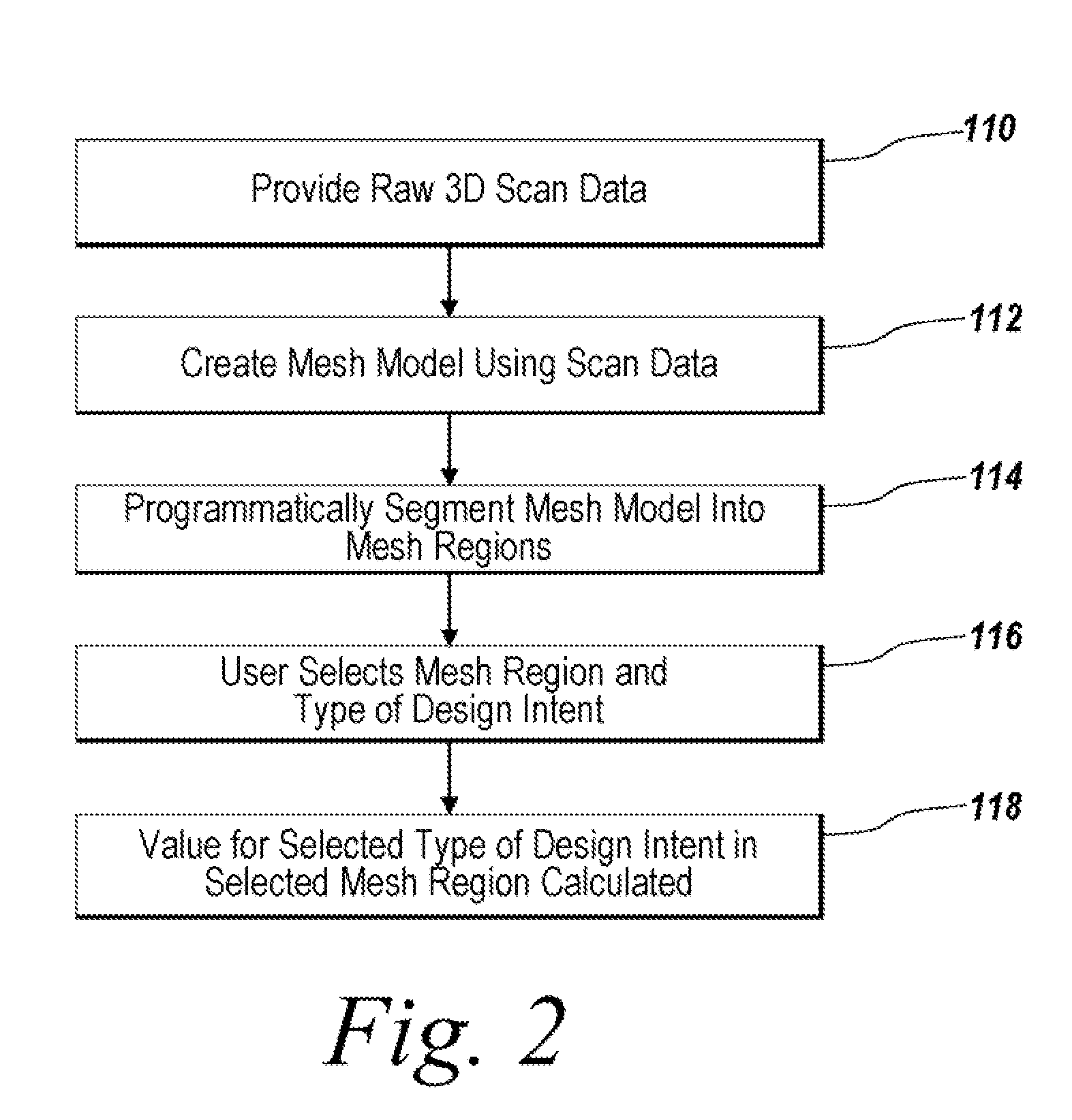

System and Method for Identifying Original Design Intents Using 3D Scan Data

ActiveUS20080040080A1Computer aided designSpecial data processing applicationsGraphicsGraphical user interface

Programmatic extraction and management of solid and surface modeling parameters from raw 3D scan data is discussed. An automated process reads raw 3D scan data and works in communication with a CAD system able to perform CAD part modeling. The user is provided with an automatic function to segment a mesh model (formed from the raw 3D scan data) into dozens of mesh regions. A graphical user interface is provided which enables a user to choose a type of the design intent along with the mesh regions from which the design intent is calculated. Each design intent is represented in a vector, a plane or a poly-line depending upon the type of design intent. In response to a user demand for the parameters of a modeling feature, a best approximation of the requested parameter value is calculated by processing the raw 3D scan data using a set of functions.

Owner:INUS TECH

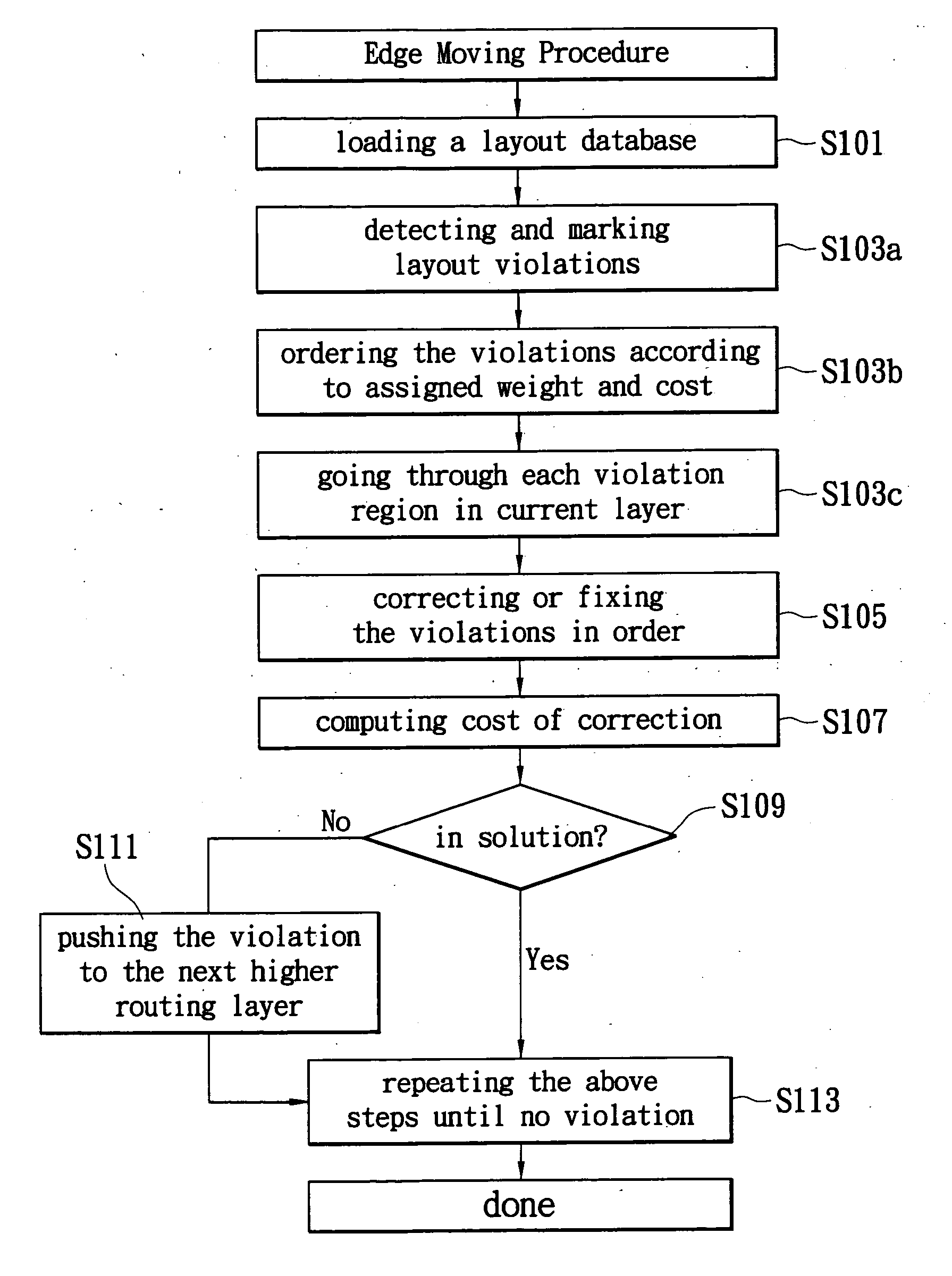

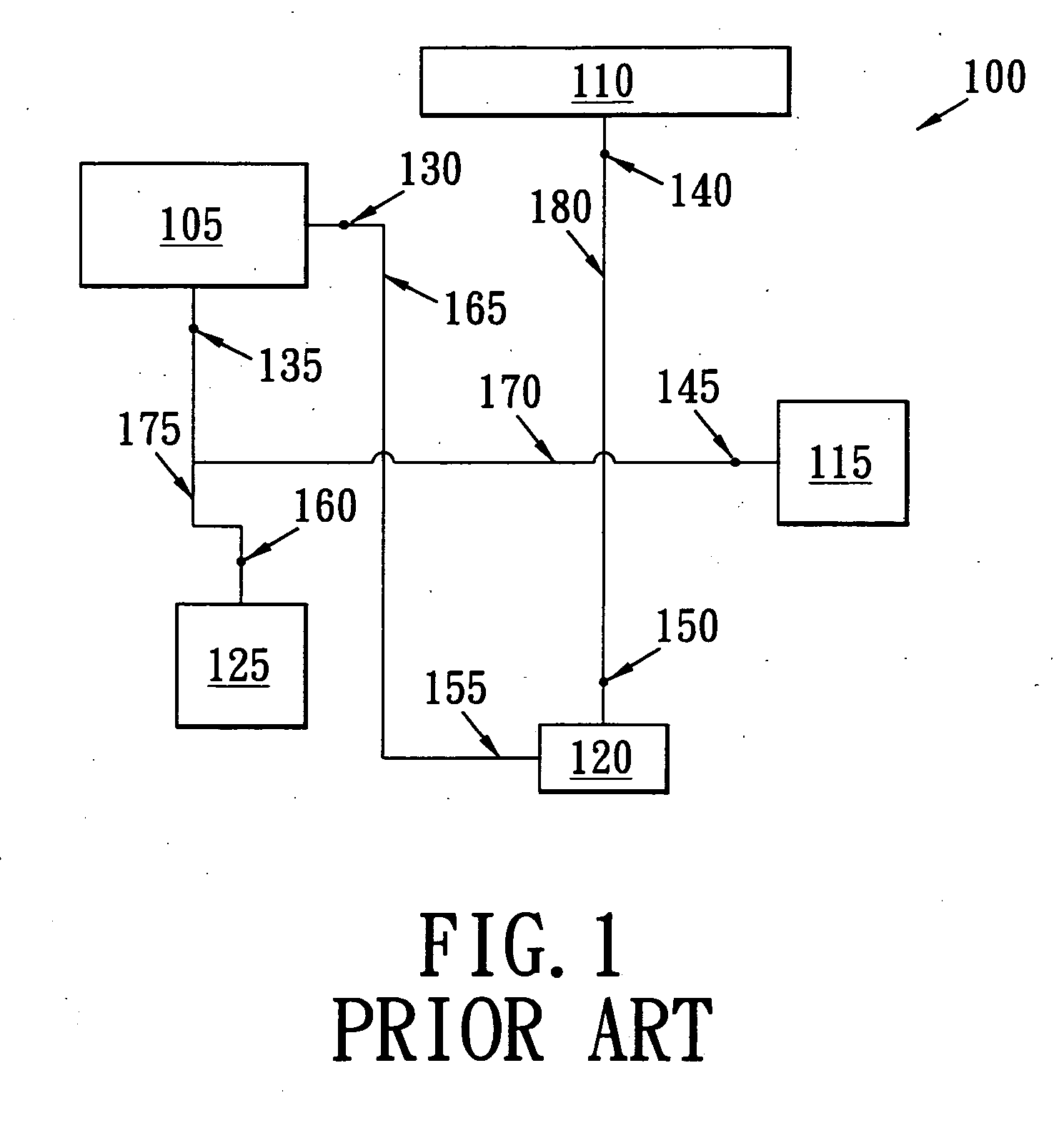

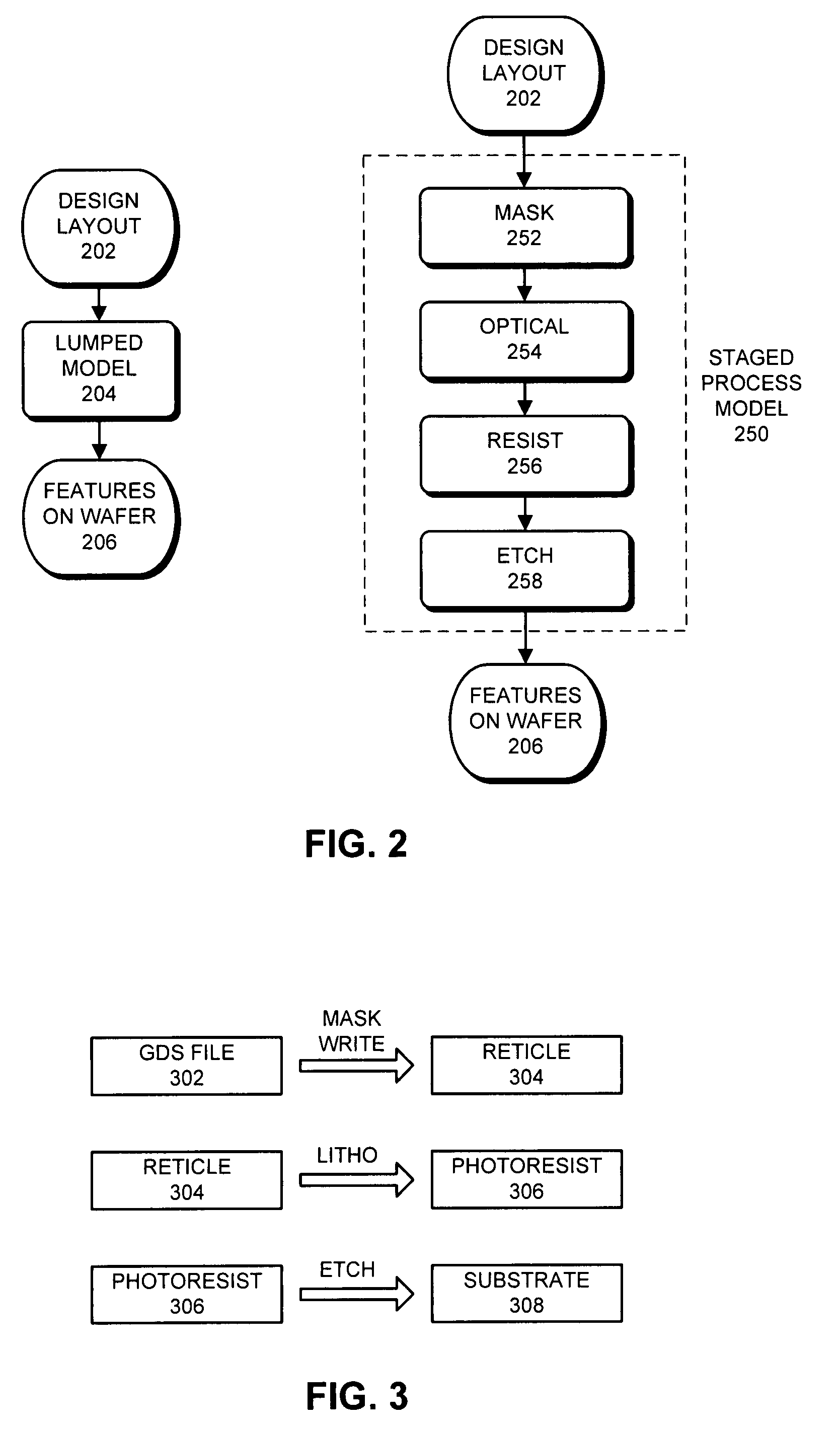

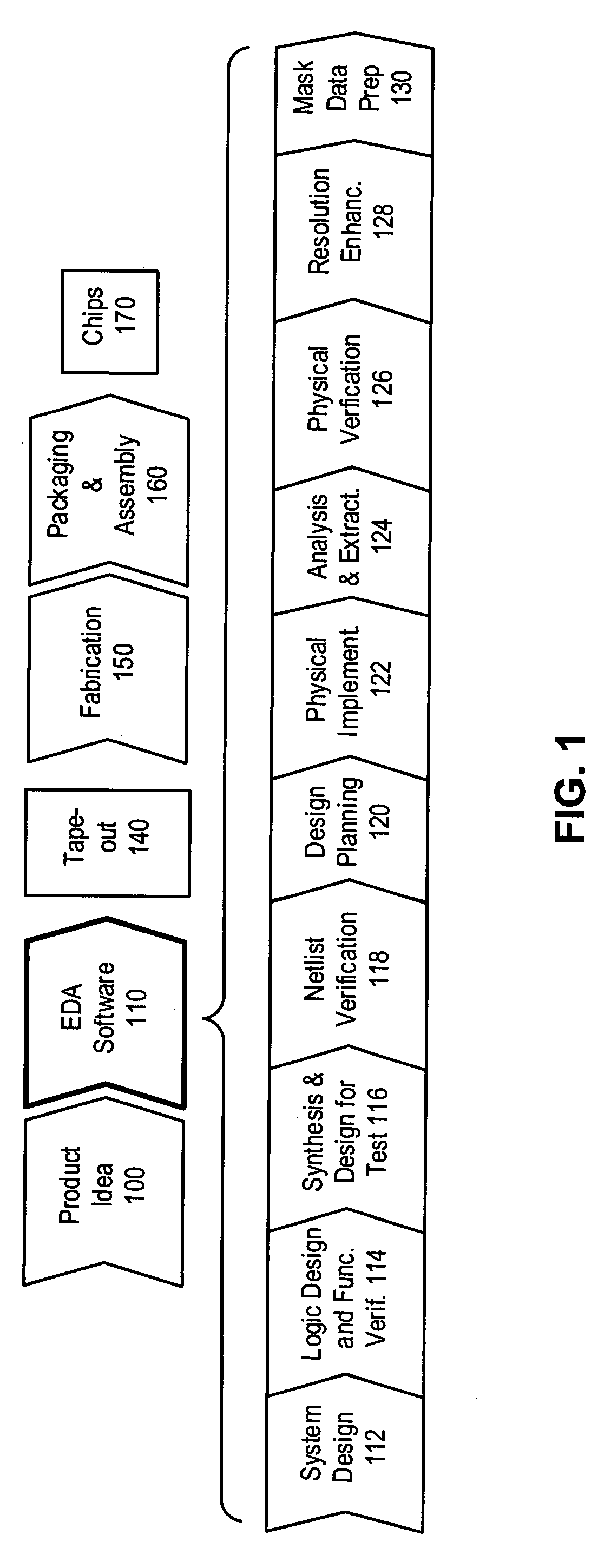

Method and apparatus for integrated circuit layout optimization

InactiveUS20070101303A1Originals for photomechanical treatmentComputer aided designResolution enhancement technologiesLithographic artist

A method and apparatus for integrated circuit layout optimization are provided. In the conventional art, the major challenges in building integrated circuits (IC) at sub-wavelength geometries include i) to ensure the design intent is faithfully transferred onto silicon; ii) to ensure the design is manufacturable, or with acceptable yield subject to process variations. The present invention provides the method to process a layout database to optimize or correct or fix layout violations or enhancements. The layout violations are identified through various means such as design rules, recommended rules, timing / signal integrity / power constraints, lithography rules, Resolution Enhancement Technologies (RET) requirements and preferences, and process and manufacturing constraints. Particularly, the method, techniques and procedures of creating software tools of the present invention used to perform the layout violations or enhancements are disclosed.

Owner:LIZOTECH

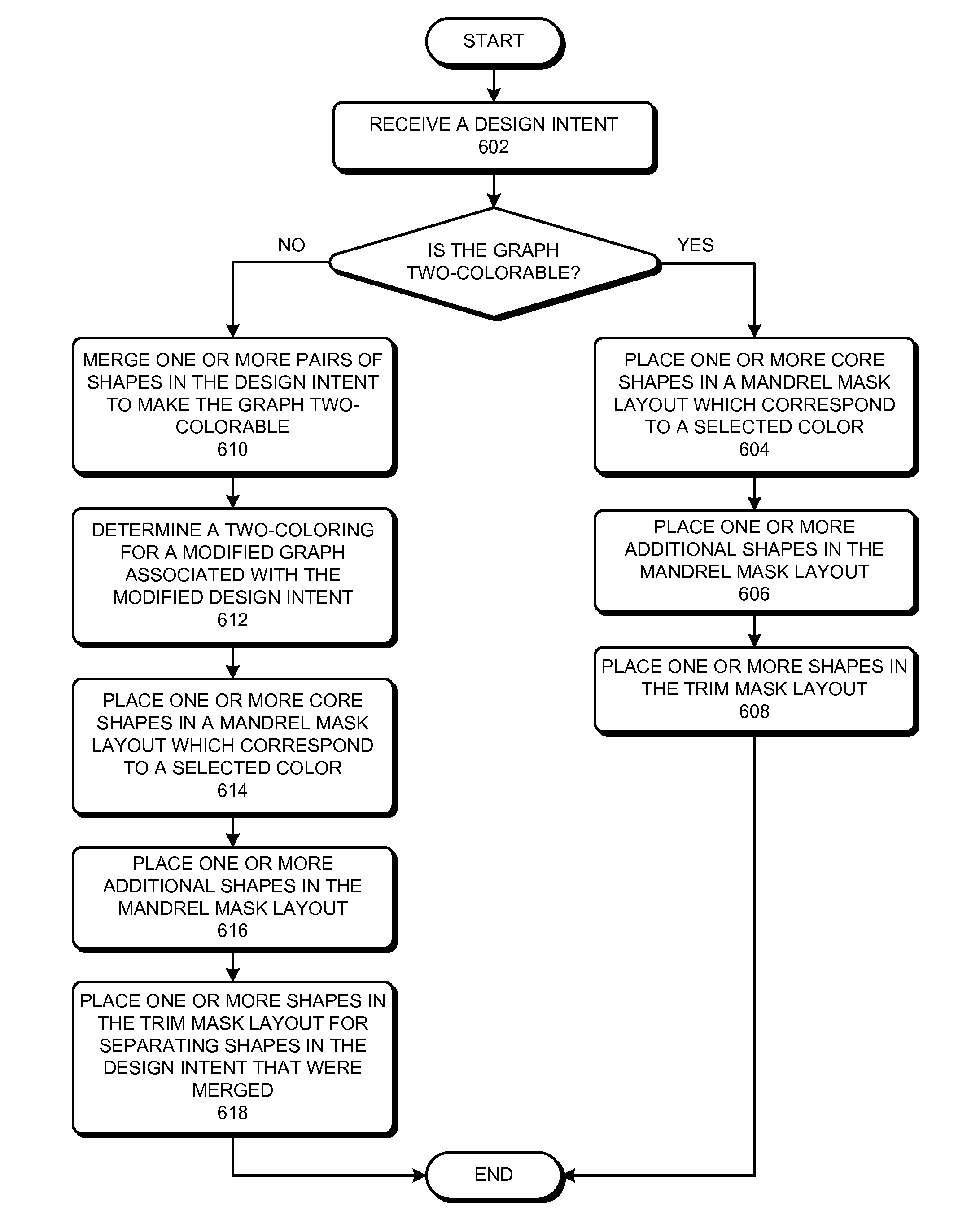

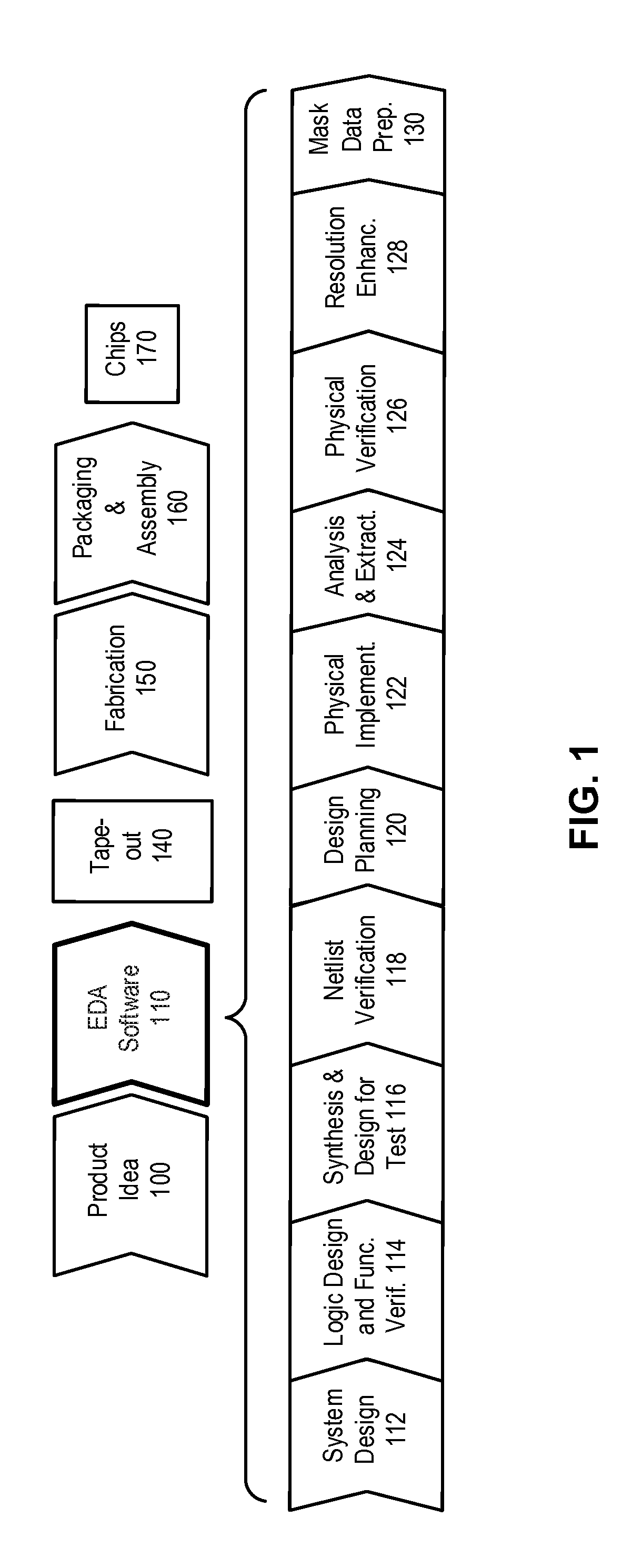

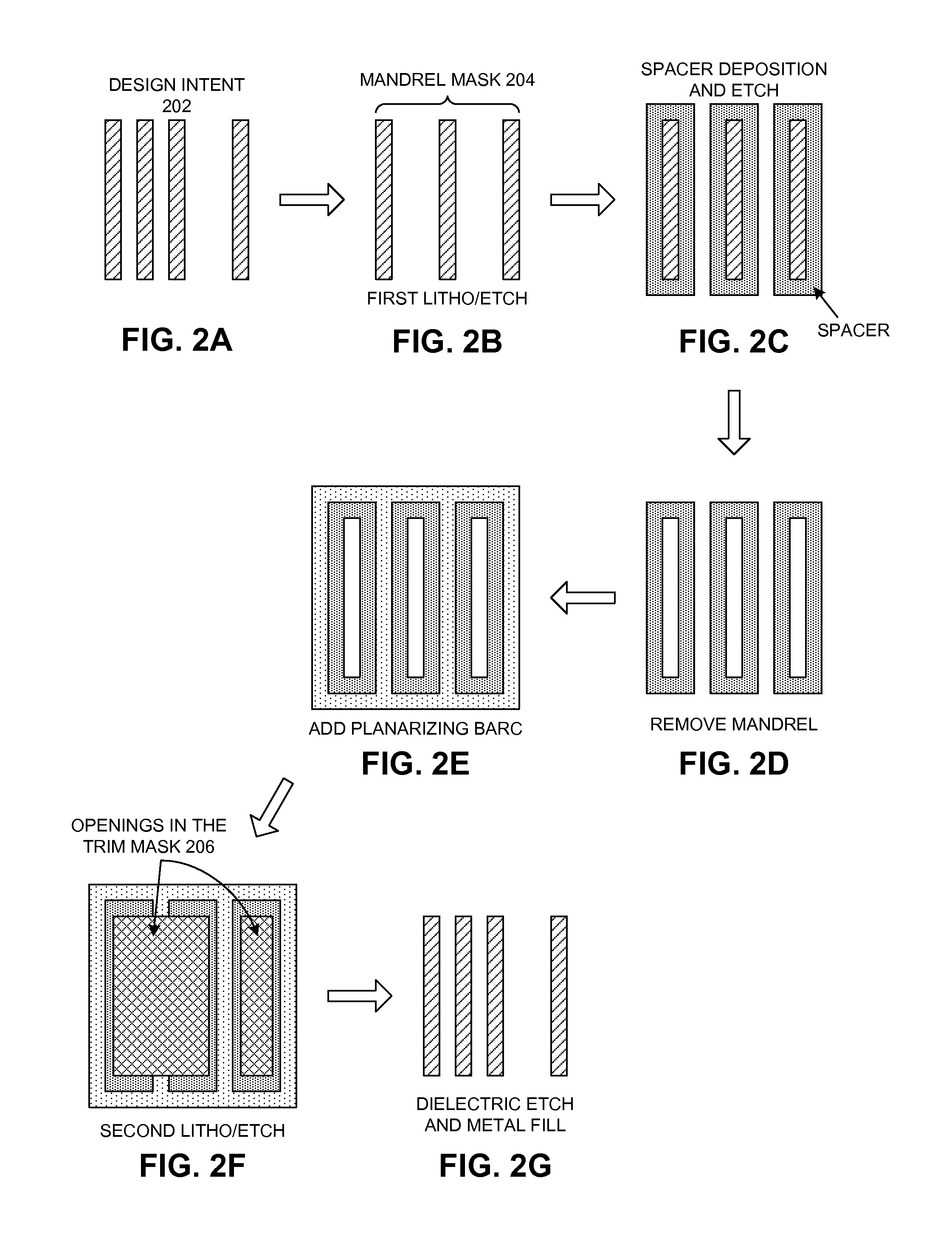

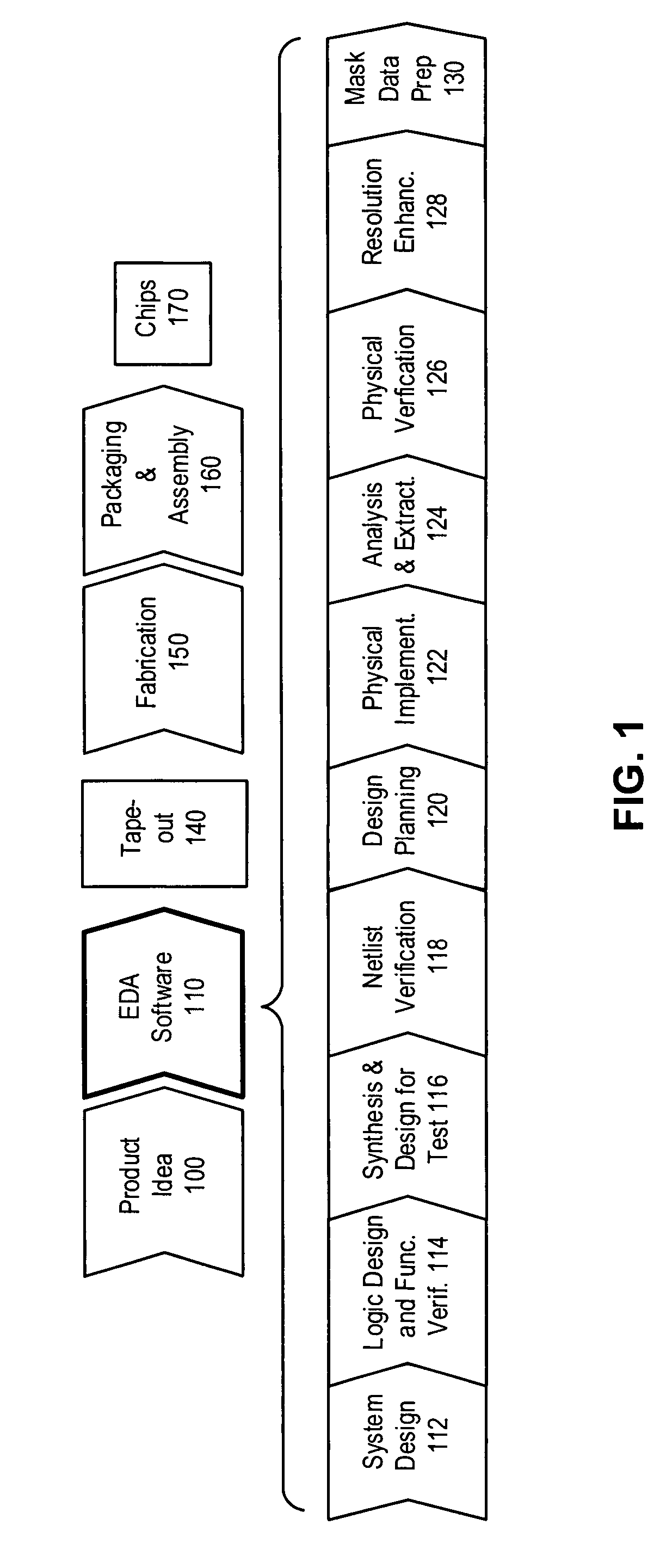

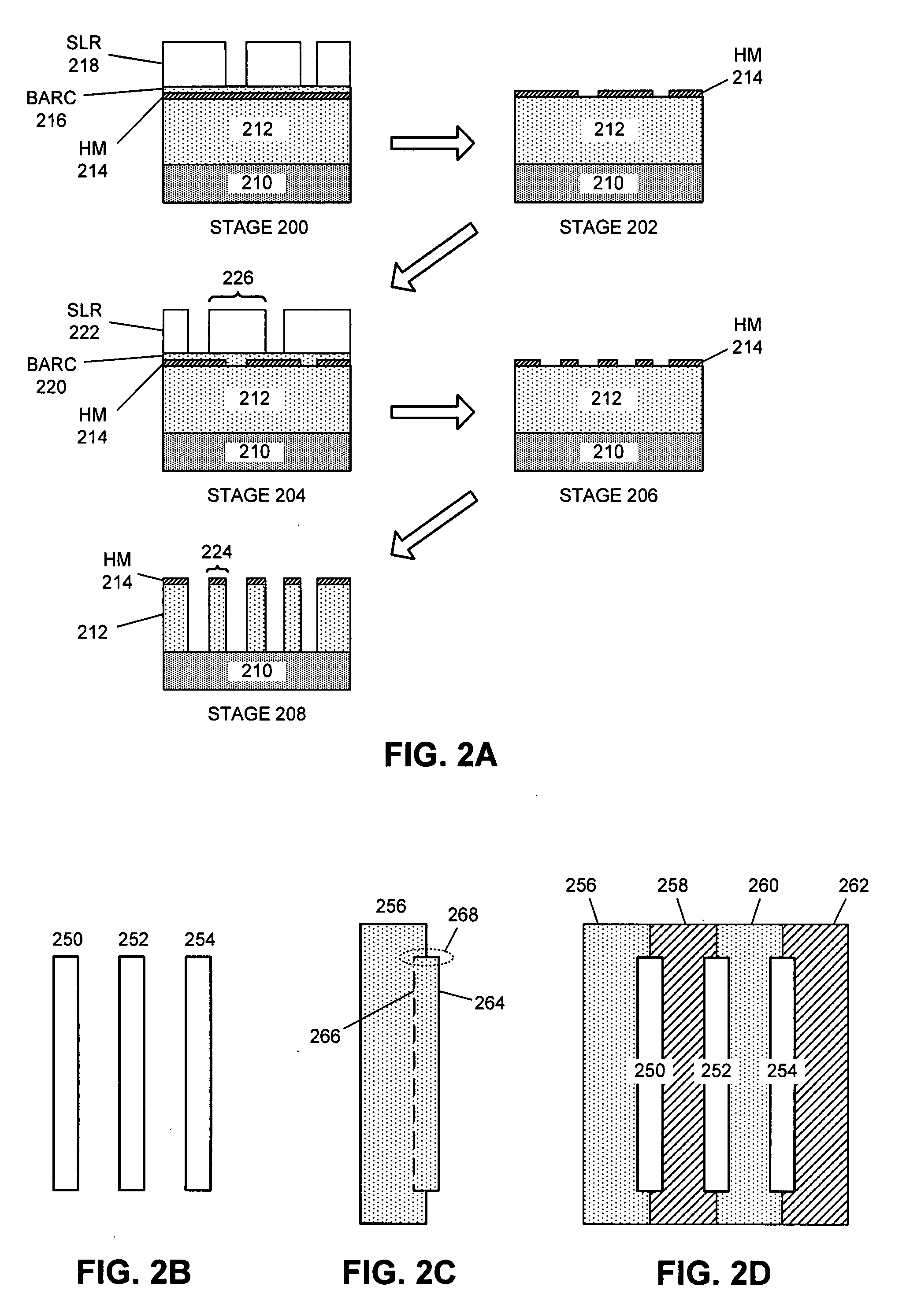

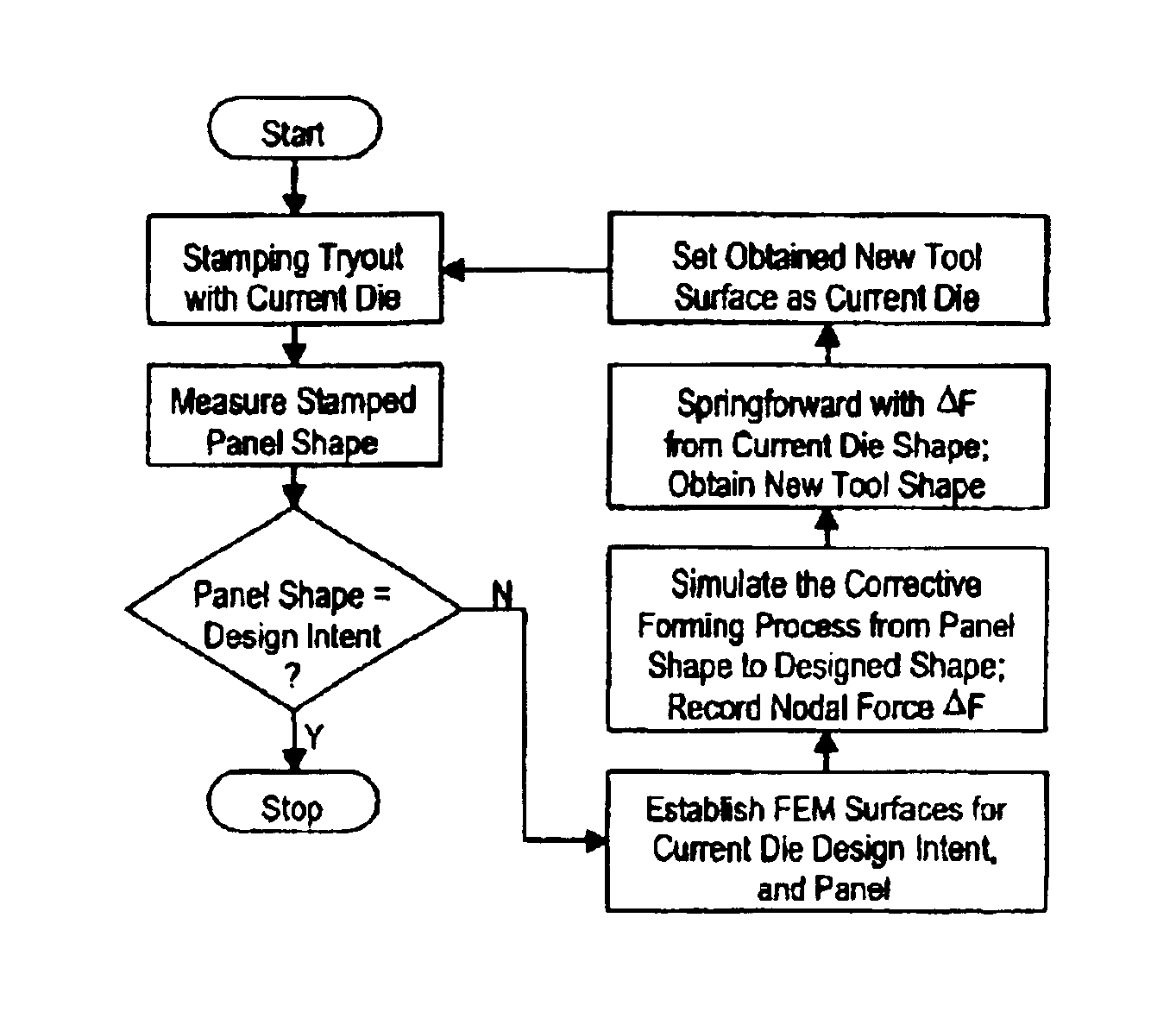

Method and apparatus for determining mask layouts for a spacer-is-dielectric self-aligned double-patterning process

ActiveUS8312394B2Improve manufacturabilityMinimum run lengthCAD circuit designSpecial data processing applicationsGraphicsEngineering

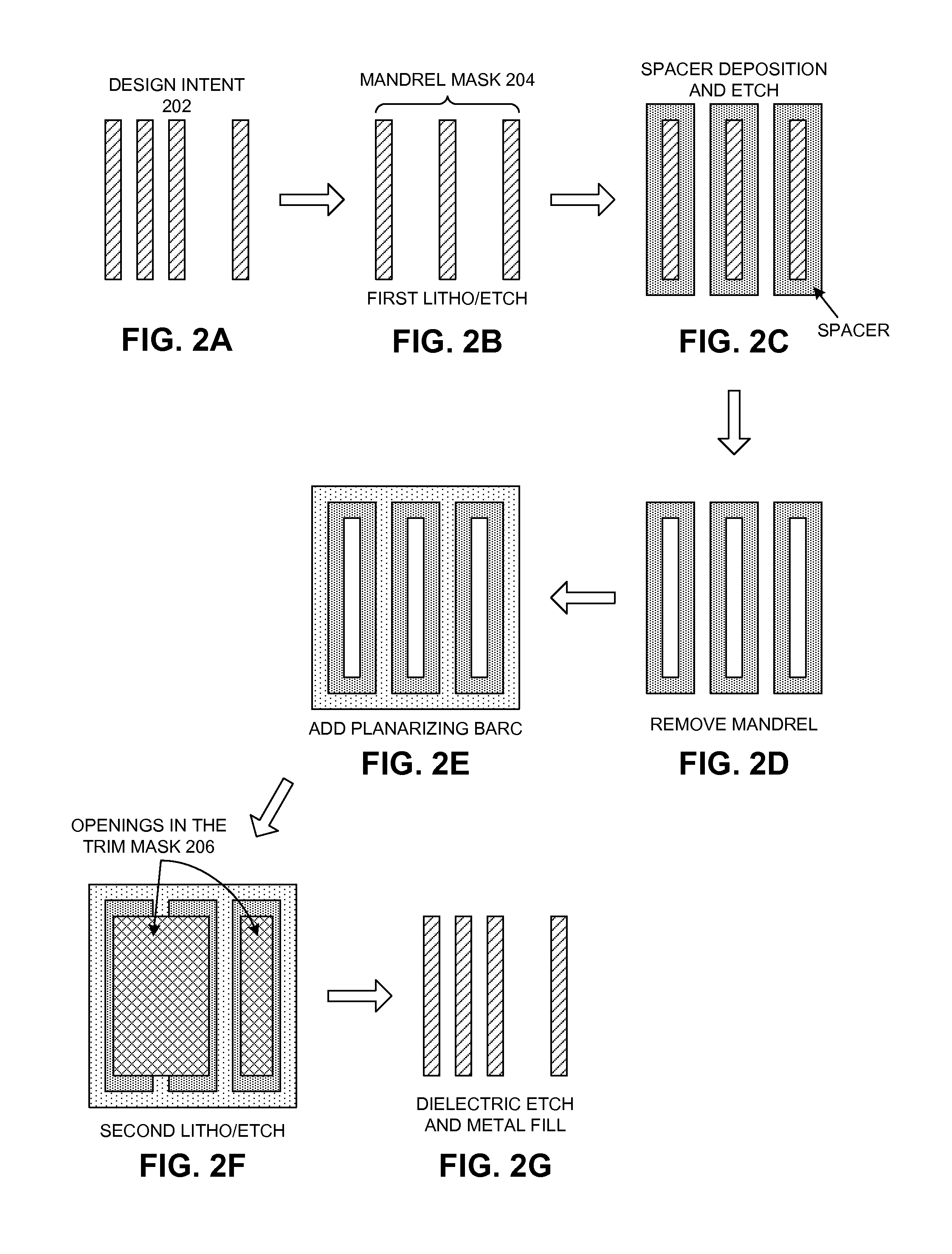

Methods and apparatuses are described for determining mask layouts for printing a design intent on a wafer using a spacer-is-dielectric self-aligned double-patterning process. A system can determine whether a graph corresponding to a design intent is two-colorable. If the graph is not two-colorable, the system can merge one or more pairs of shapes in the design intent to obtain a modified design intent, so that a modified graph corresponding to the modified design intent is two-colorable. The system can then determine a two-coloring for the modified graph. Next, the system can place one or more core shapes in a mandrel mask layout which correspond to vertices in the modified graph that are associated with a selected color in the two-coloring. The system can then place one or more shapes in a trim mask layout for separating the shapes in the design intent that were merged.

Owner:SYNOPSYS INC

Silicon tolerance specification using shapes as design intent markers

ActiveUS20060095889A1High yieldIncrease costCAD circuit designSoftware simulation/interpretation/emulationEngineeringSilicon

Design-specific attributes of a circuit (such as timing, power, electro-migration, and signal integrity) are used to automatically identify one or more regions of one or more layers in a layout of the circuit. The automatically identified regions may be provided to a manufacturing tool in GDSII by use of overlapping shapes in, or alternatively by moving existing shapes to, a different layer / datatype pair. For example, information about the automatically identified regions may be stored using a conventional datatype (e.g. value 0) with a new layer, or alternatively using a conventional layer (e.g. metal 3) with a new datatype (e.g. value 1), depending on the embodiment. The automatically identified regions contain cells and / or features (e.g. groups of shapes and / or individual shapes) whose tolerance in silicon (to be fabricated) is automatically changed from default, based on the design-specific attribute(s) and sensitivity thereto, expressed as design intent by a circuit designer.

Owner:SYNOPSYS INC

Generalized constraint collection management method

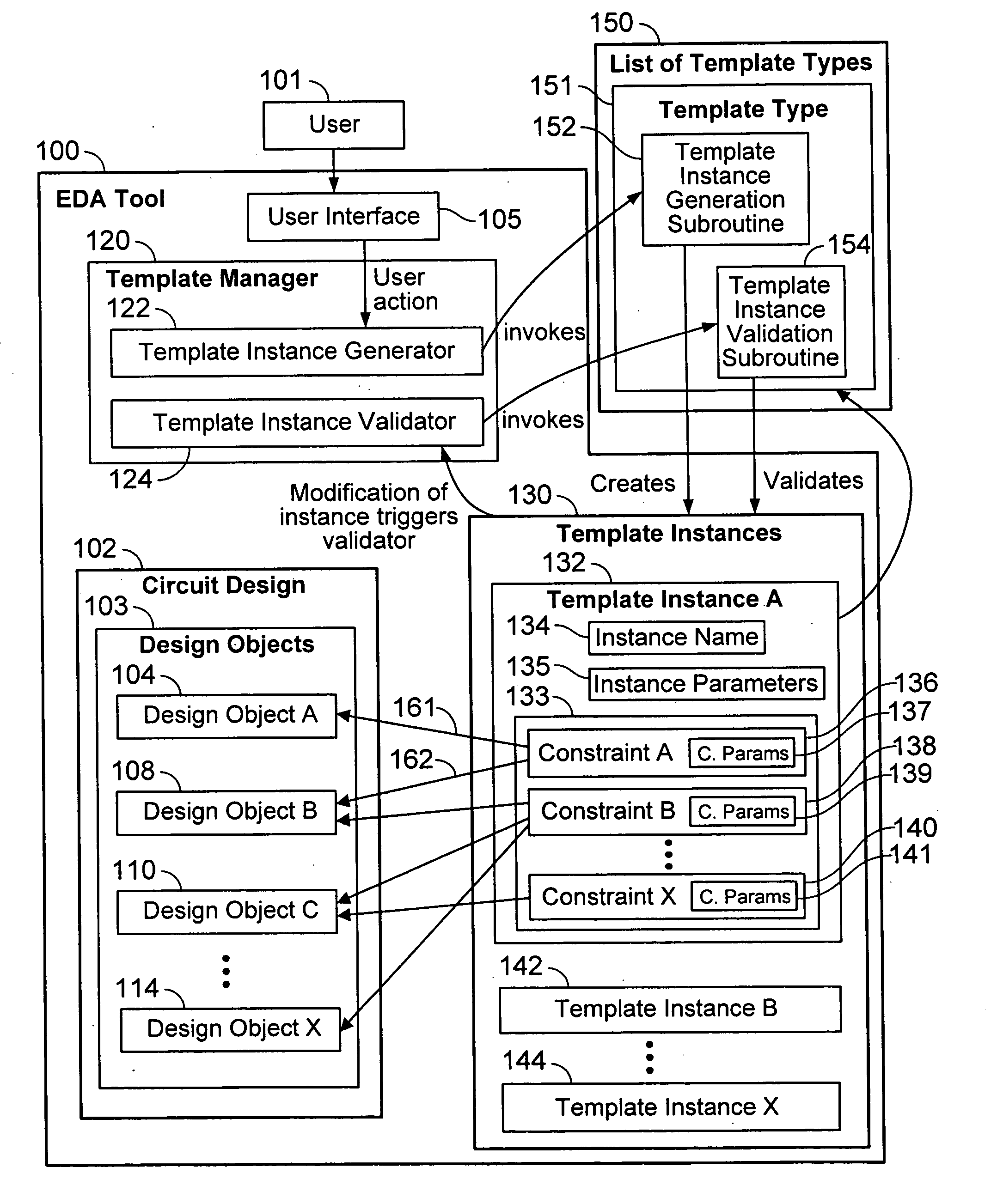

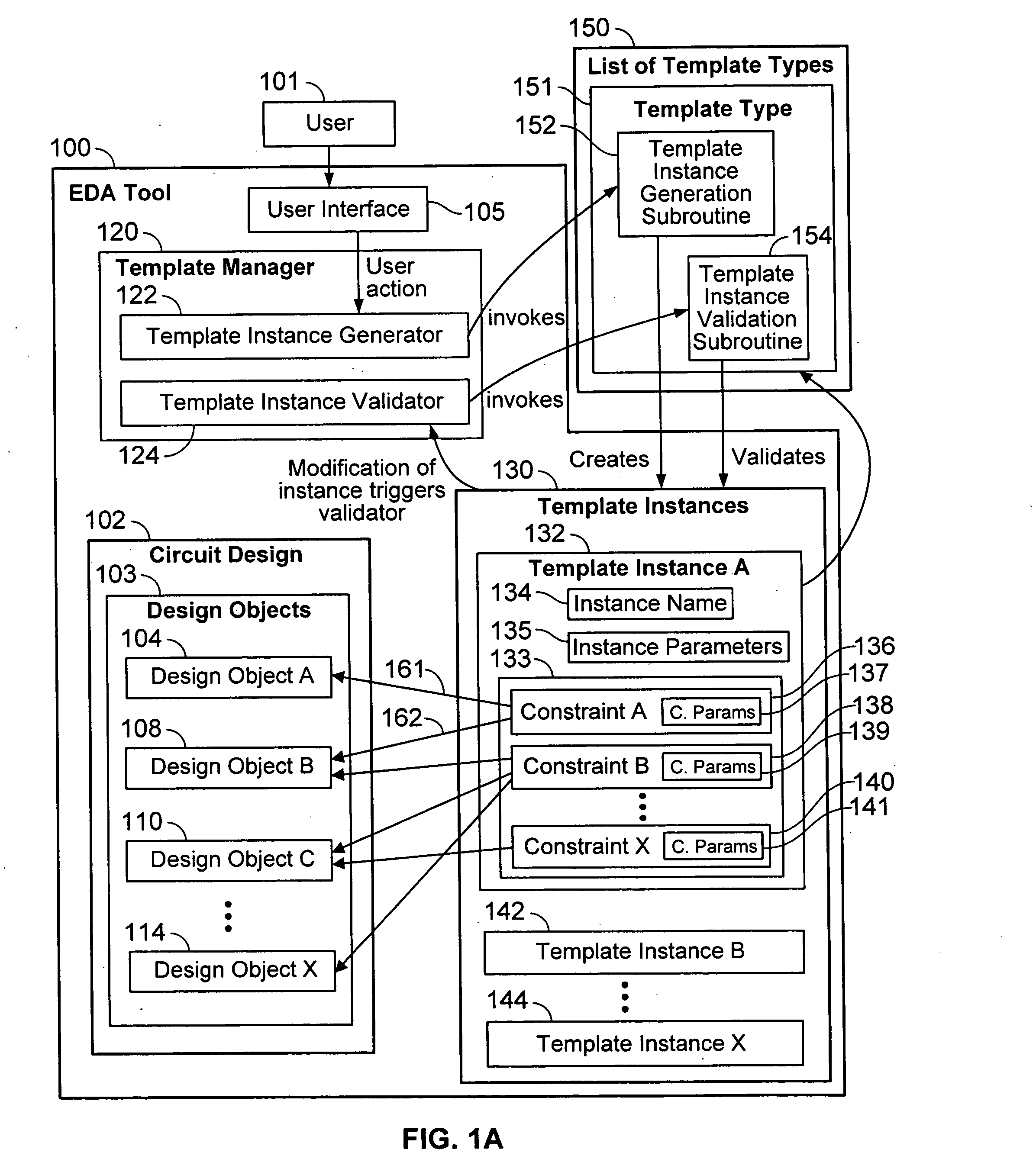

ActiveUS20080077901A1Computer programmed simultaneously with data introductionCAD circuit designCollection managementElectronic design automation

Techniques are provided to allow users of Electronic Design Automation (EDA) tools to define constraint template types for efficiently associating constraints with design objects to specify design intent. Processes for creating and validating the constraints are provided by user-defined plug-ins, thereby allowing users to annotate circuit designs with constraints for proprietary layout and fabrication processes without exposing the constraints to tool vendors or competitors. The constraints are re-created from the template types whenever the circuit design is loaded into the EDA tool, so that the constraints are based upon the latest version of the template type. The constraints are also re-created when validation fails. Constraint groups are reusable in different designs, technology nodes, and processes because they automatically expand to provide the specific constraints to achieve a goal. The specific constraints in a template type can be modified as technology changes, and the modification will automatically be applied to the design objects.

Owner:CADENCE DESIGN SYST INC

Method and apparatus for determining mask layouts for a spacer-is-dielectric self-aligned double-patterning process

ActiveUS20120137261A1Improve manufacturabilityMinimum run lengthCAD circuit designSpecial data processing applicationsGraphicsEngineering

Methods and apparatuses are described for determining mask layouts for printing a design intent on a wafer using a spacer-is-dielectric self-aligned double-patterning process. A system can determine whether a graph corresponding to a design intent is two-colorable. If the graph is not two-colorable, the system can merge one or more pairs of shapes in the design intent to obtain a modified design intent, so that a modified graph corresponding to the modified design intent is two-colorable. The system can then determine a two-coloring for the modified graph. Next, the system can place one or more core shapes in a mandrel mask layout which correspond to vertices in the modified graph that are associated with a selected color in the two-coloring. The system can then place one or more shapes in a trim mask layout for separating the shapes in the design intent that were merged.

Owner:SYNOPSYS INC

Method and apparatus to determine if a pattern is robustly manufacturable

ActiveUS7739651B2Originals for photomechanical treatmentSpecial data processing applicationsGenerative DesignEngineering

One embodiment provides a method to determine if a pattern is robustly manufacturable. During operation, the system may receive a first pattern and a design intent, wherein the first pattern is intended to generate the design intent. Next, the system may determine a second pattern using the design intent, wherein subjecting the second pattern to a second manufacturing process is expected to generate a third pattern that is substantially similar to the design intent. The system may then determine if a first semiconductor manufacturing process is capable of robustly manufacturing the second pattern. If the second pattern is not robustly manufacturable, the system may generate an indicator that indicates that the first pattern is not robustly manufacturable.

Owner:SYNOPSYS INC

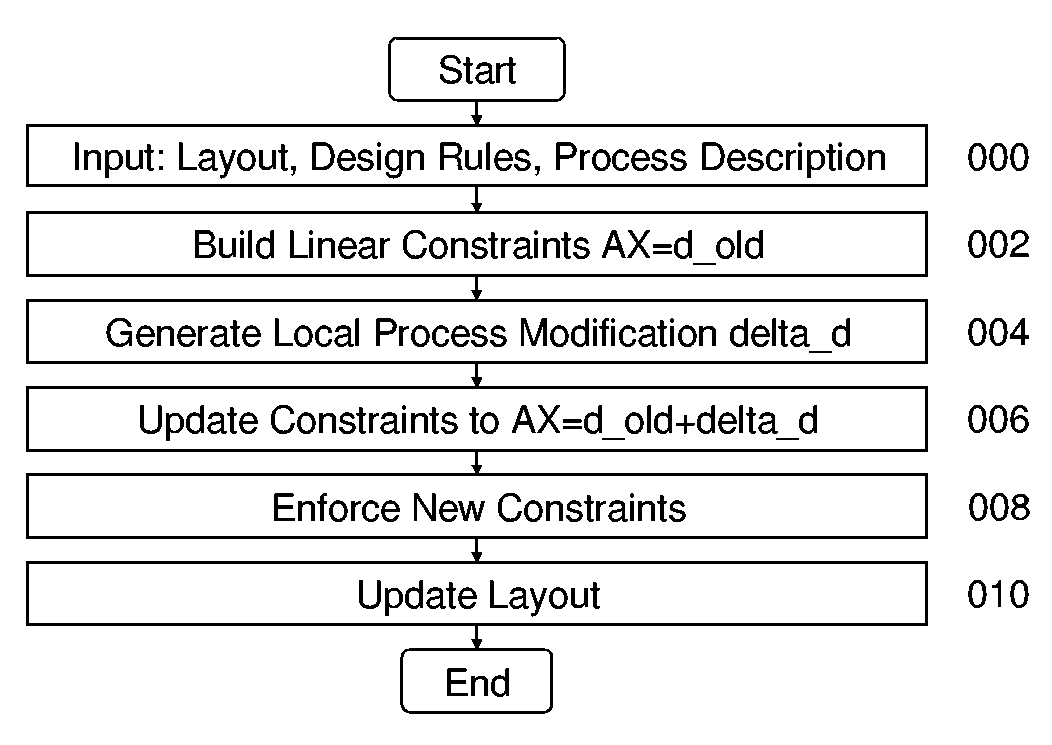

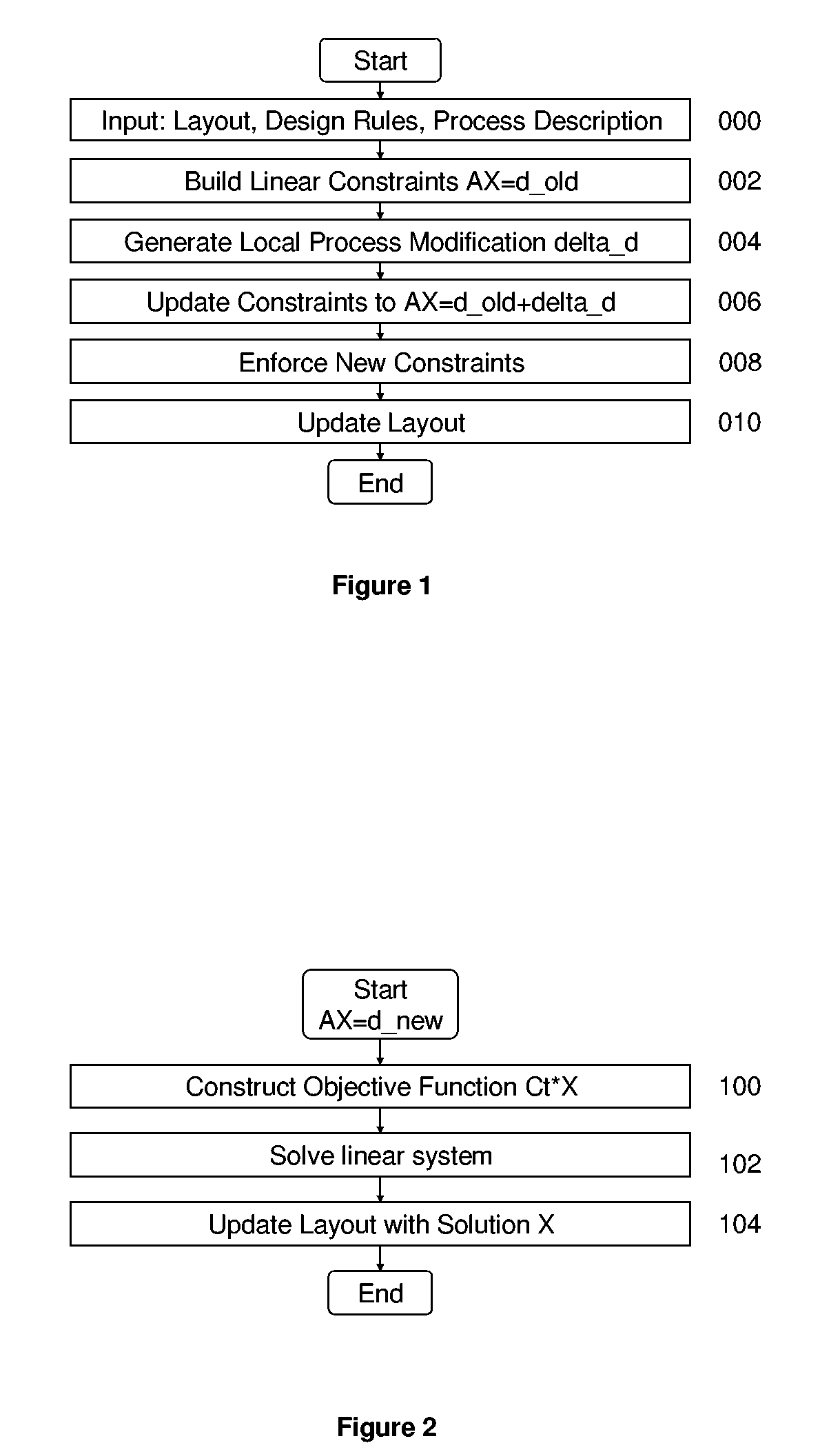

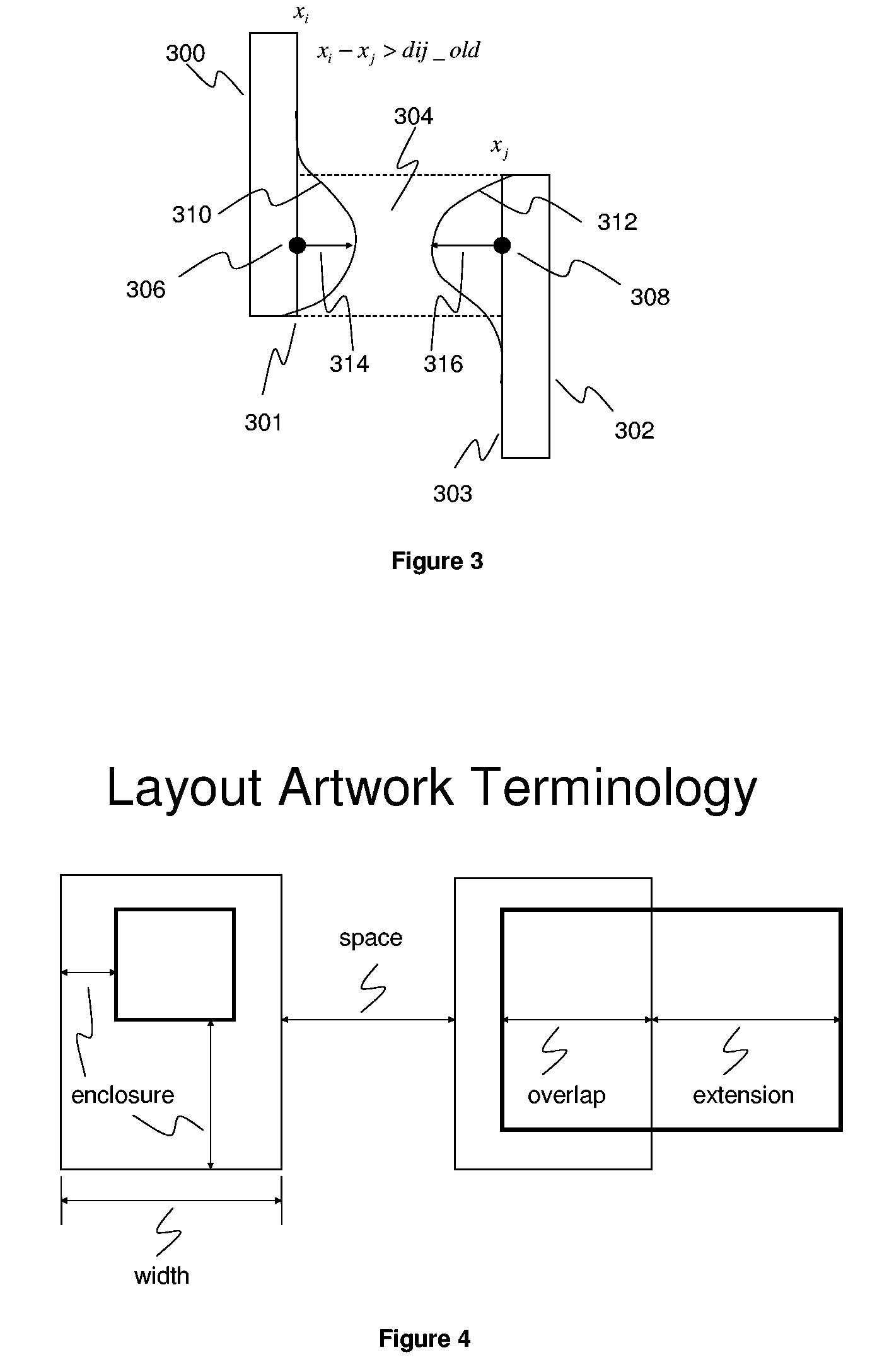

Methods and system for improving integrated circuit layout

ActiveUS7448012B1Reduce guard bandImprove chip yieldSolid-state devicesCAD circuit designPresent methodIntegrated circuit layout

In accordance with the present method and system for improving integrated circuit layout, a local process modification is calculated from simulated process response variables at a set of control points. Said modification values are incorporated into the layout constraints imposed by design rules and design intent to account for manufacturing friendliness. Solving the updated constraint equation with user specified objective function produces a new layout with increased manufacturability. The new layout may further contain data tags that enable optimal process correction to be performed on selected locations, leading to reduction in data size and mask complexity. Also in accordance with this invention, physical design tools are enhanced to read and process anisotropic design rules.

Owner:IYM TECH

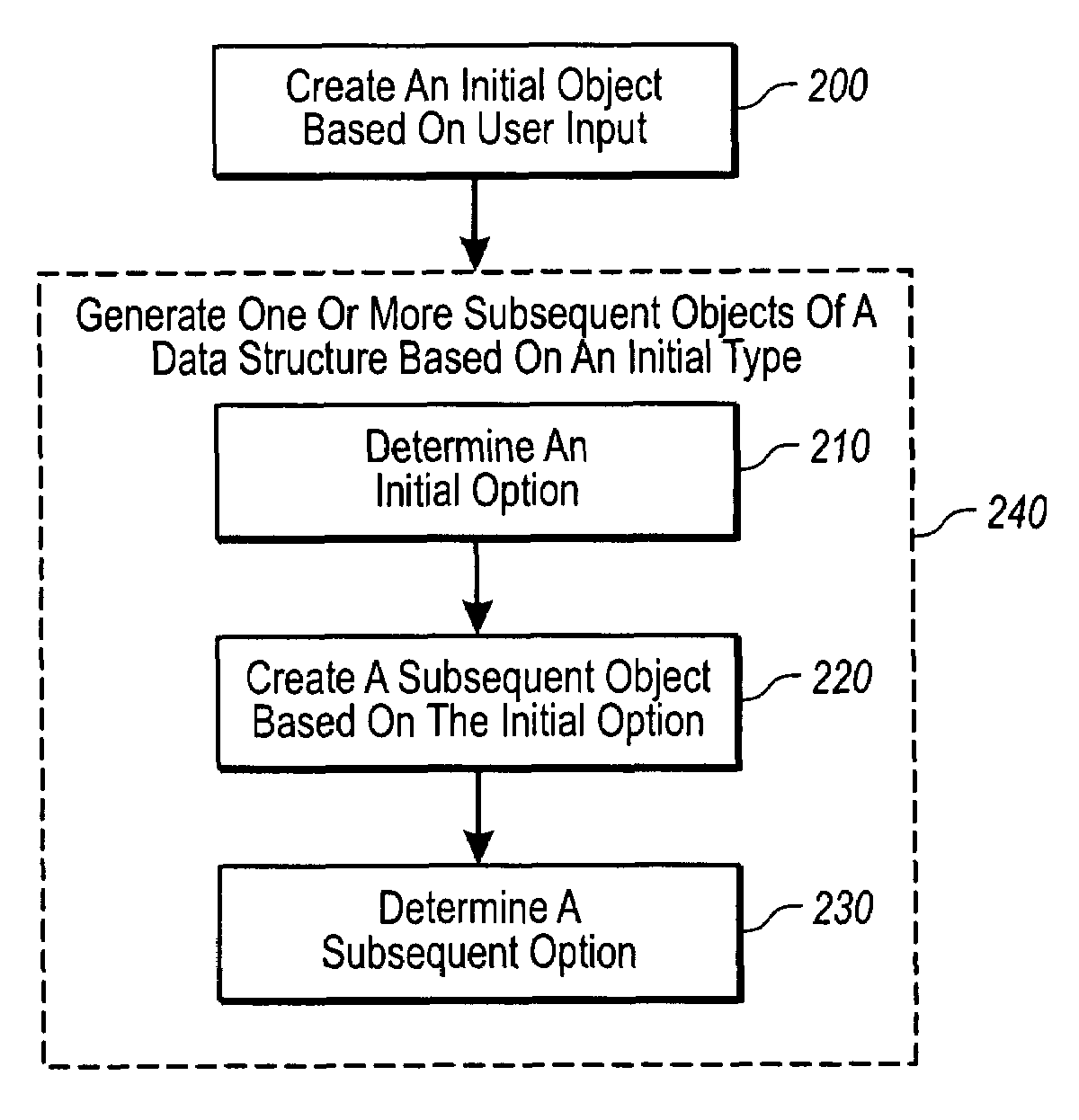

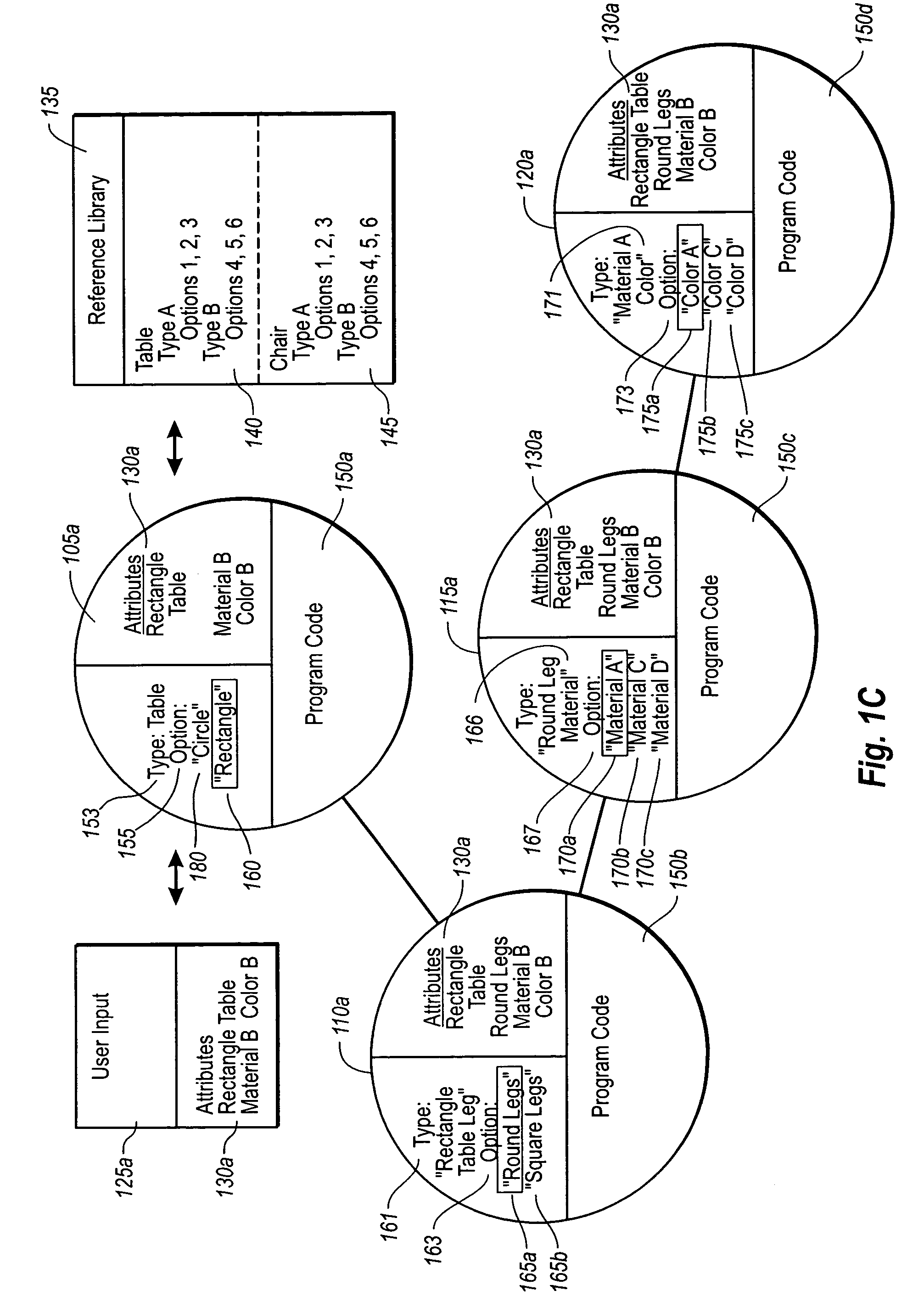

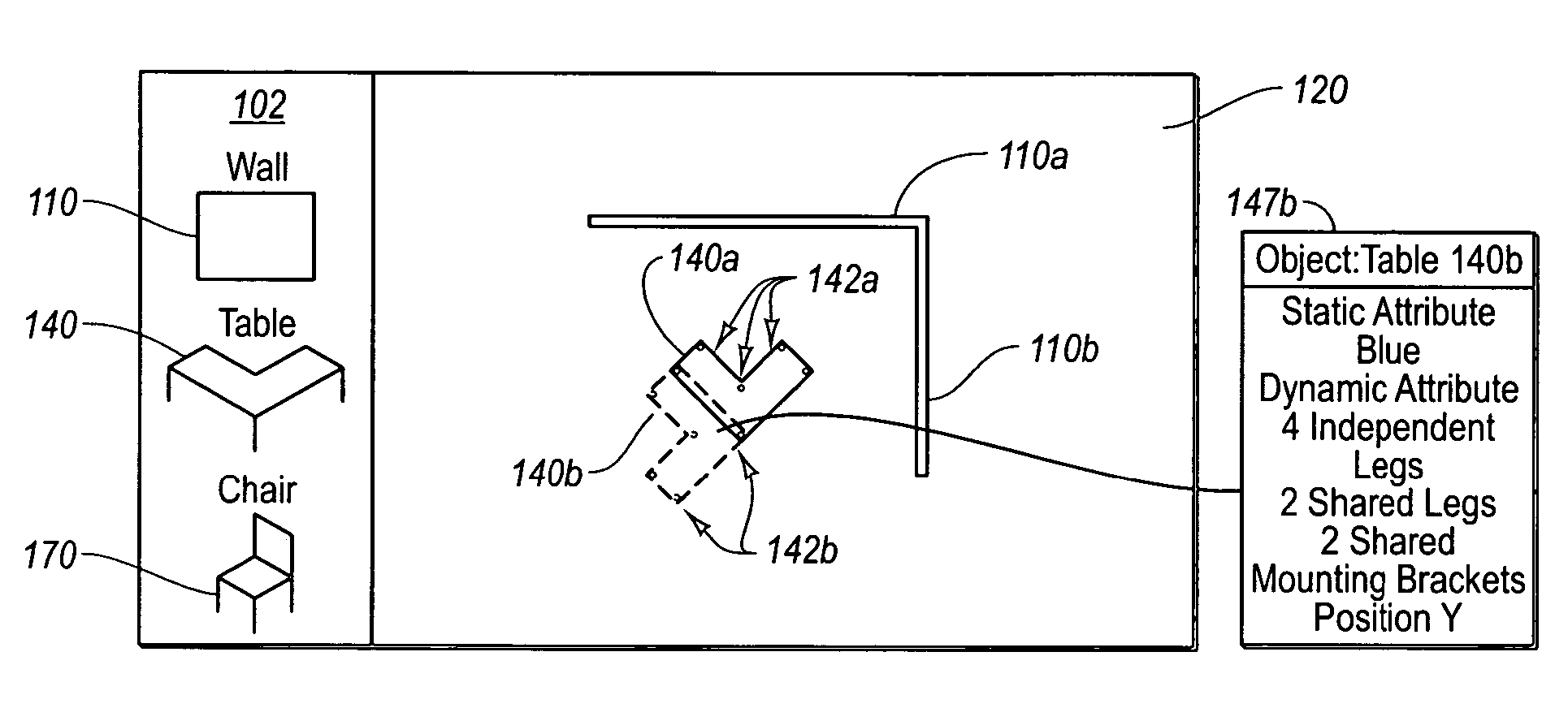

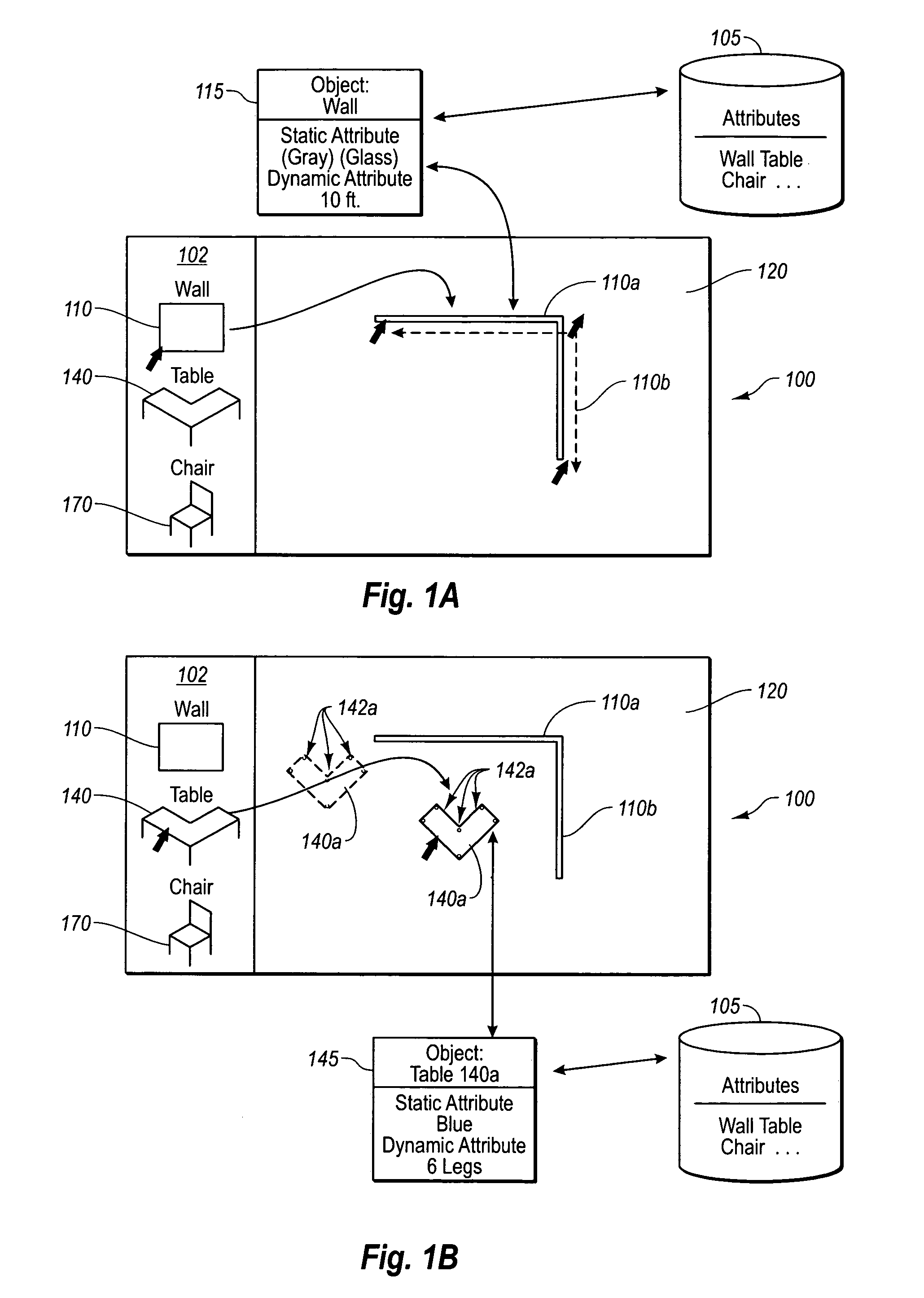

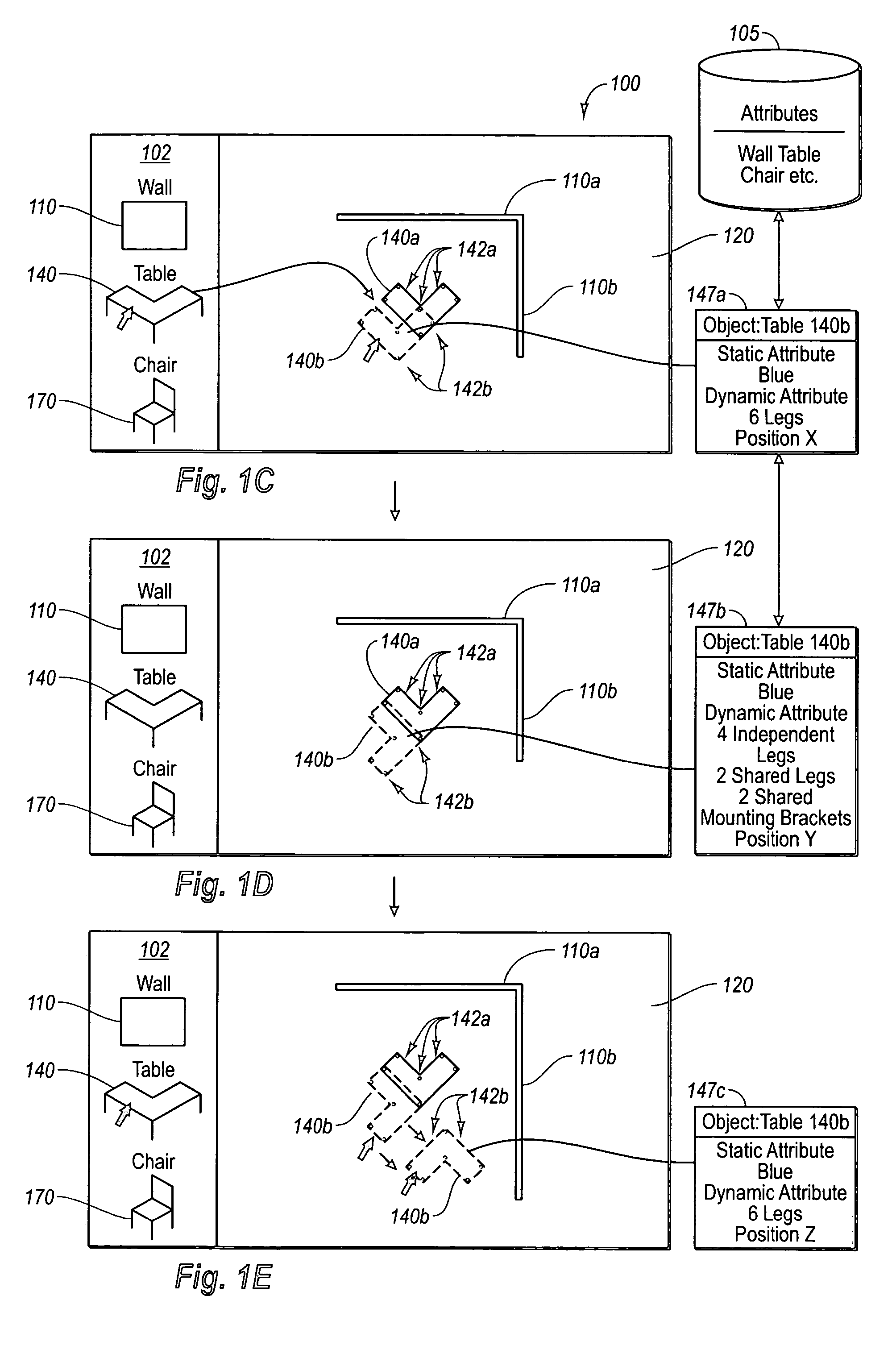

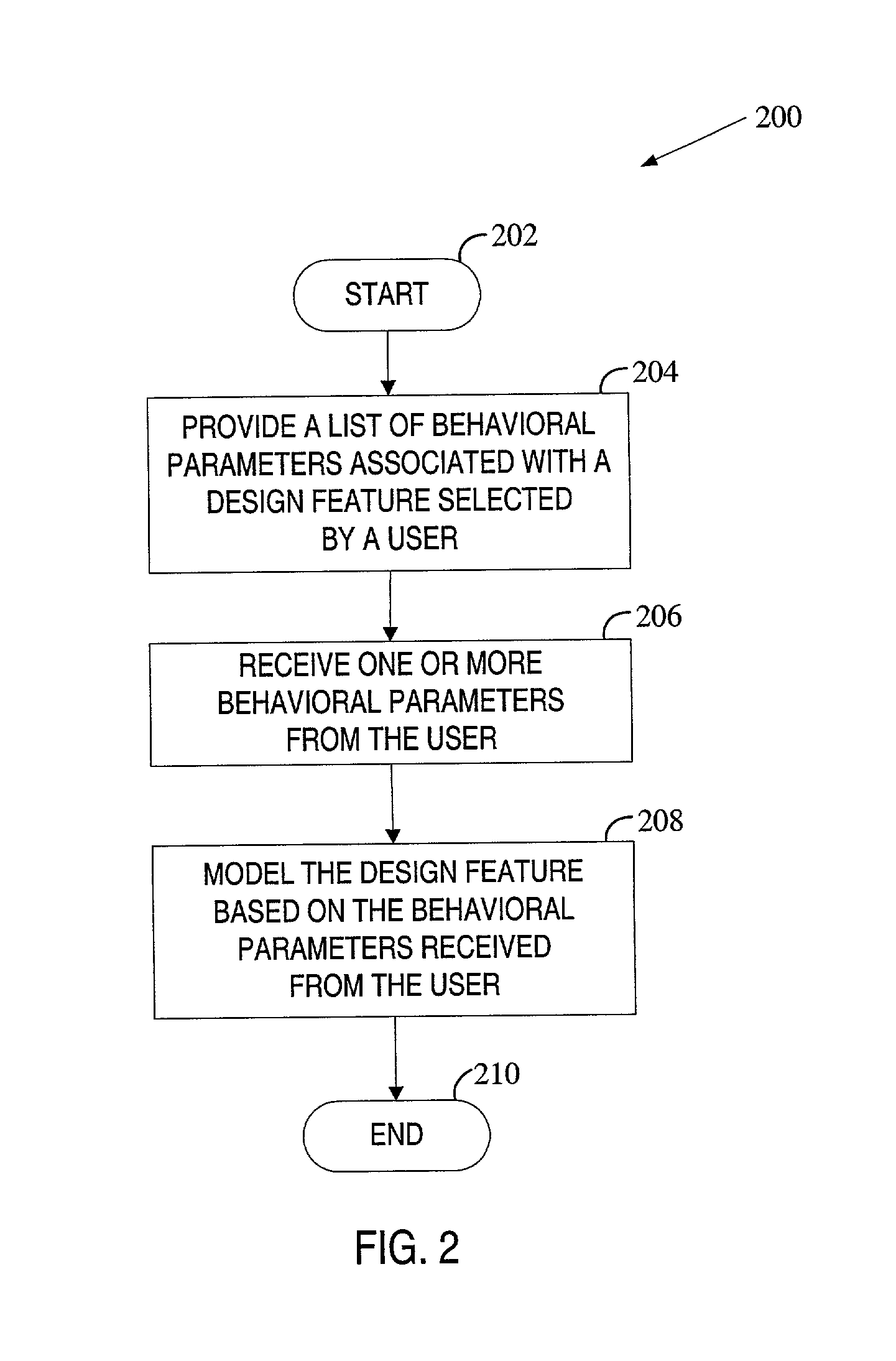

Capturing a user's intent in design software

ActiveUS20060041842A1Efficient constructionAccurate representationGeometric CADCAD network environmentInterior spaceUser input

A software program for use in designing interior and exterior spaces receives user input that is associated with one or more attributes. Subsequent user input, having other attributes, is resolved in light of the first input attributes to create a real-world depiction of design choices in real-time. For example, design choices that conflict with prior design choices are resolved (or modified as necessary) to ensure that each of the prior and present user input choices are represented in an appropriate way. The resolution by the design software is also used to create an accurate parts (and / or price) list so that when the user has completed the design of an exterior or interior space, the design can be submitted directly as an order to be fulfilled. Generally, continual resolution ensures that the user's design intent is captured in an accurate and efficient way in a user interface.

Owner:ARMSTRONG WORLD INDUSTRIES

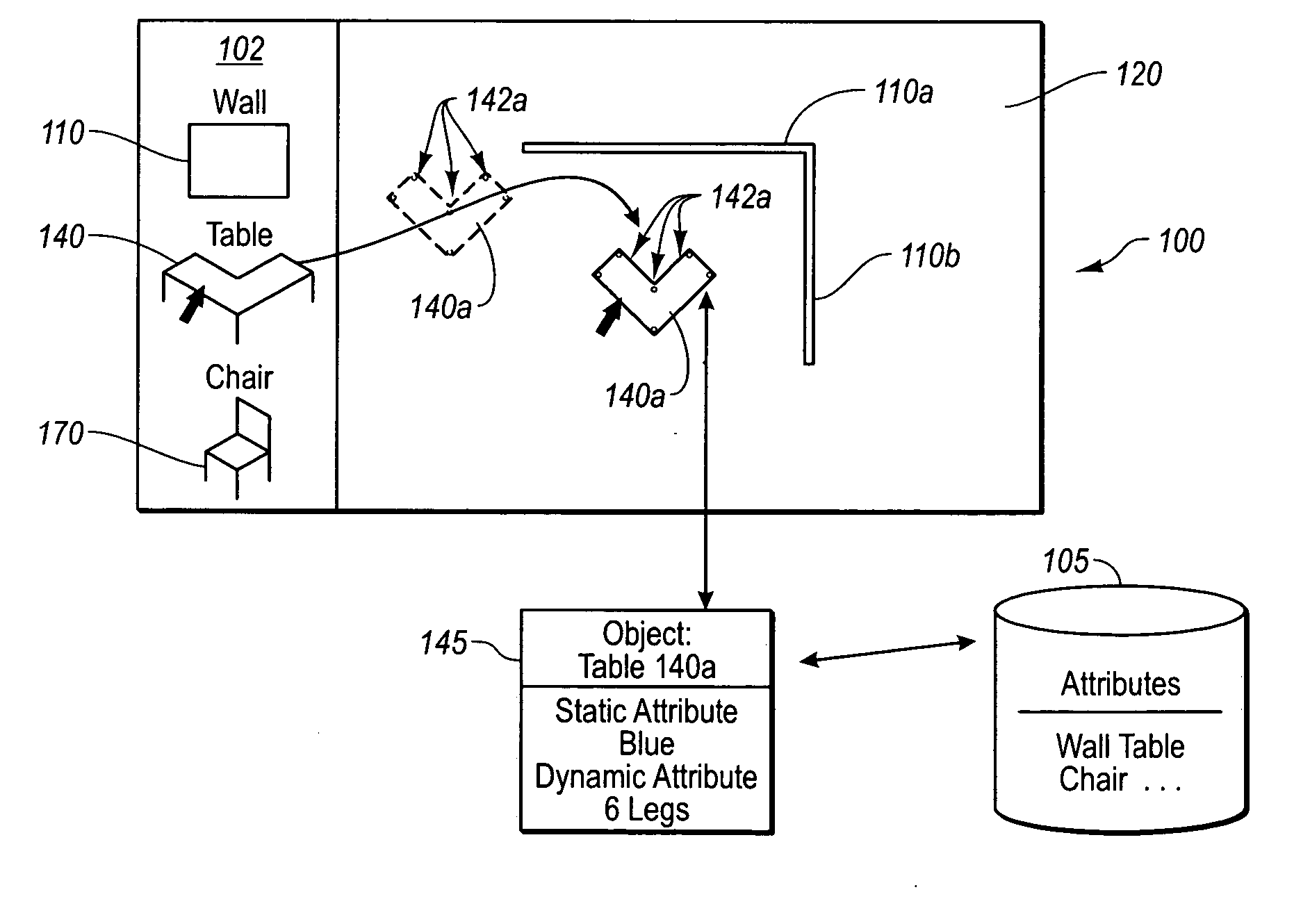

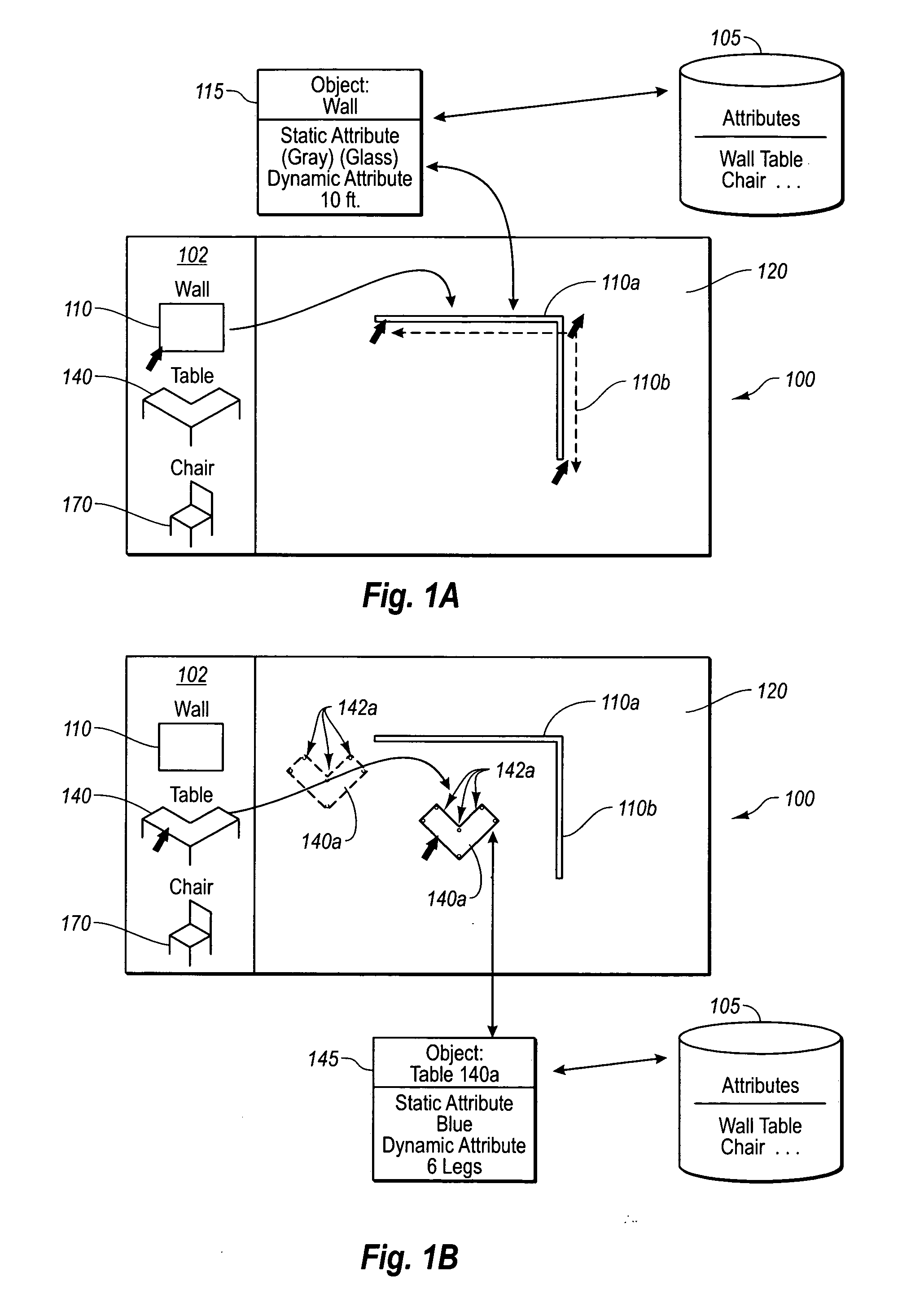

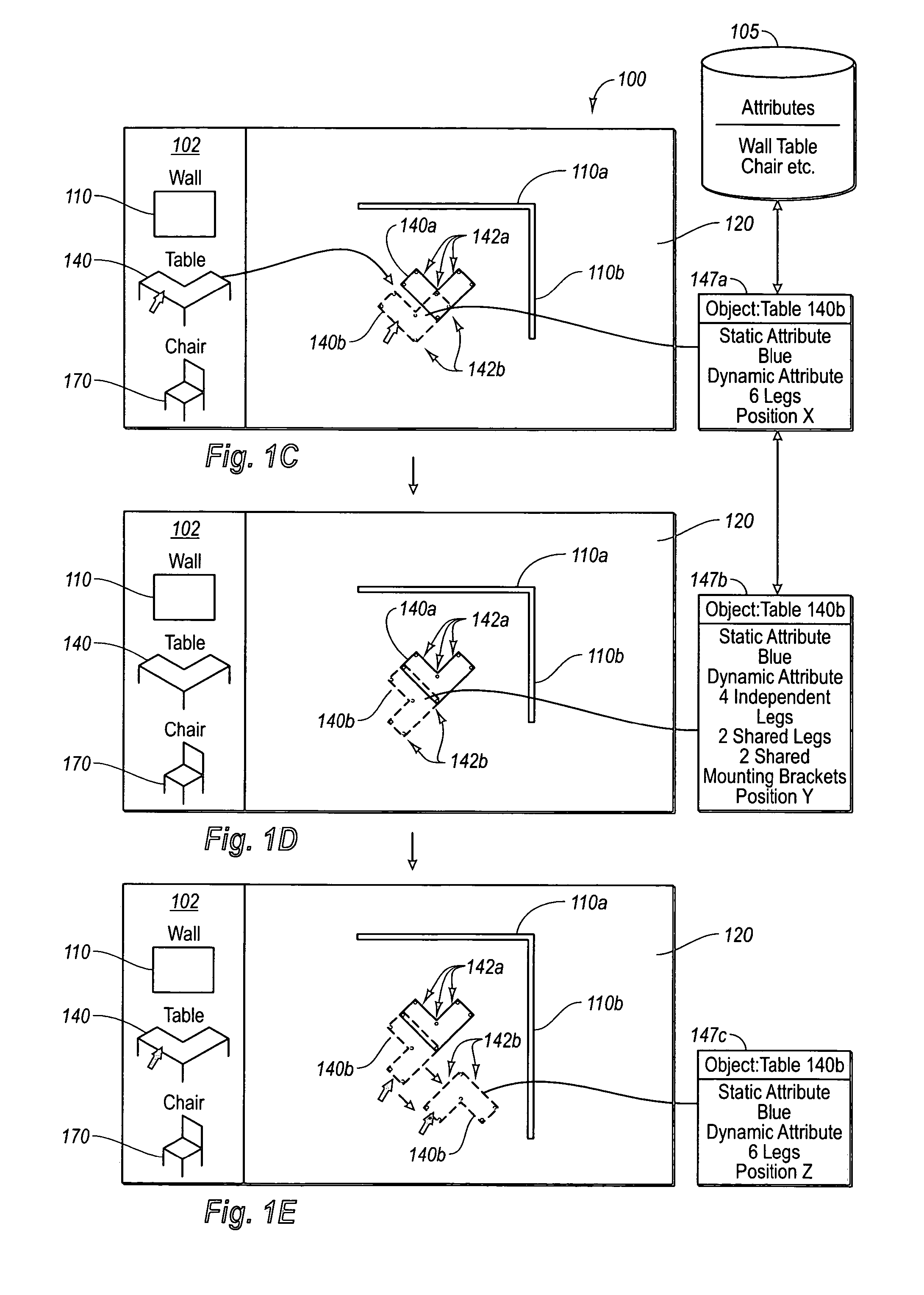

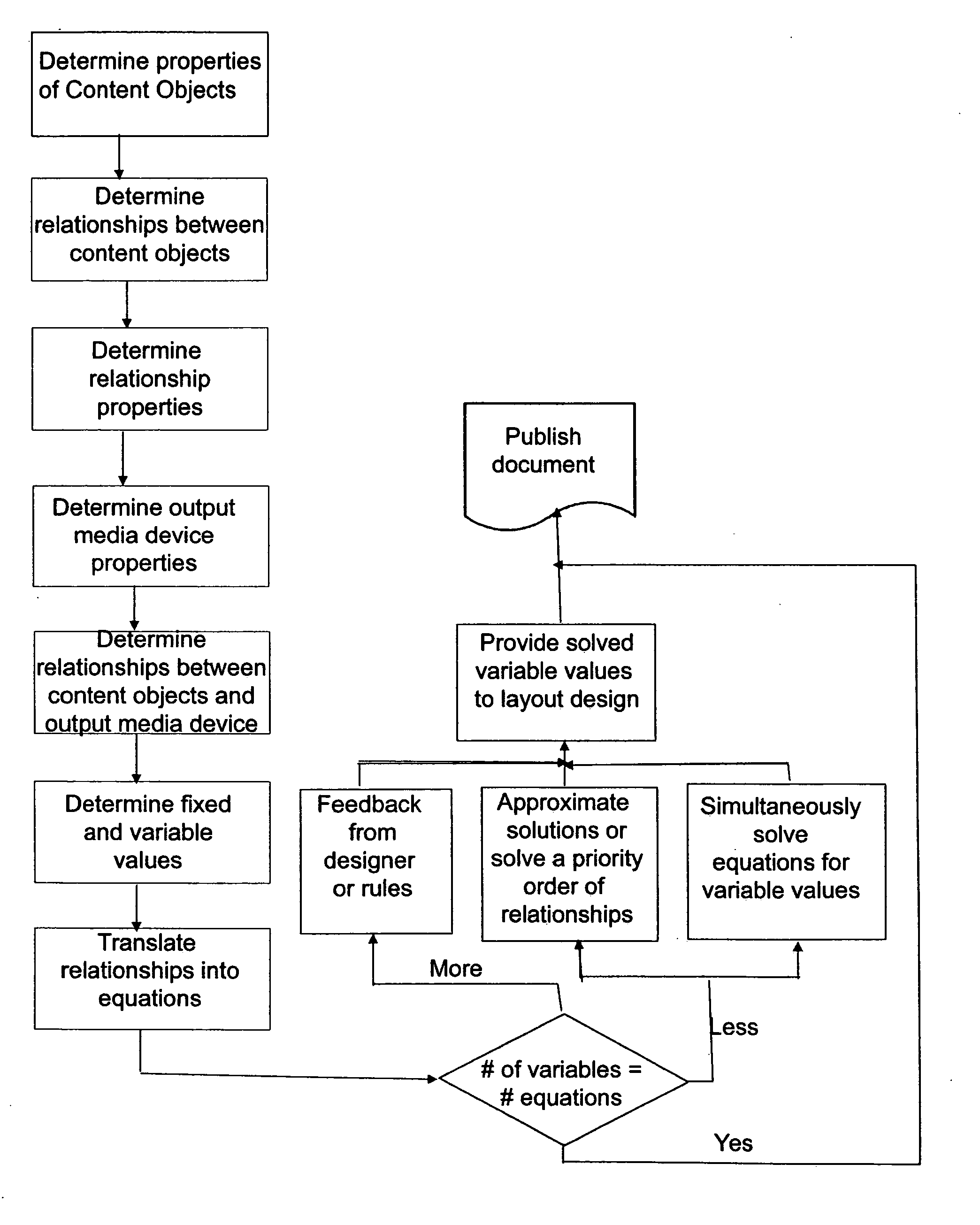

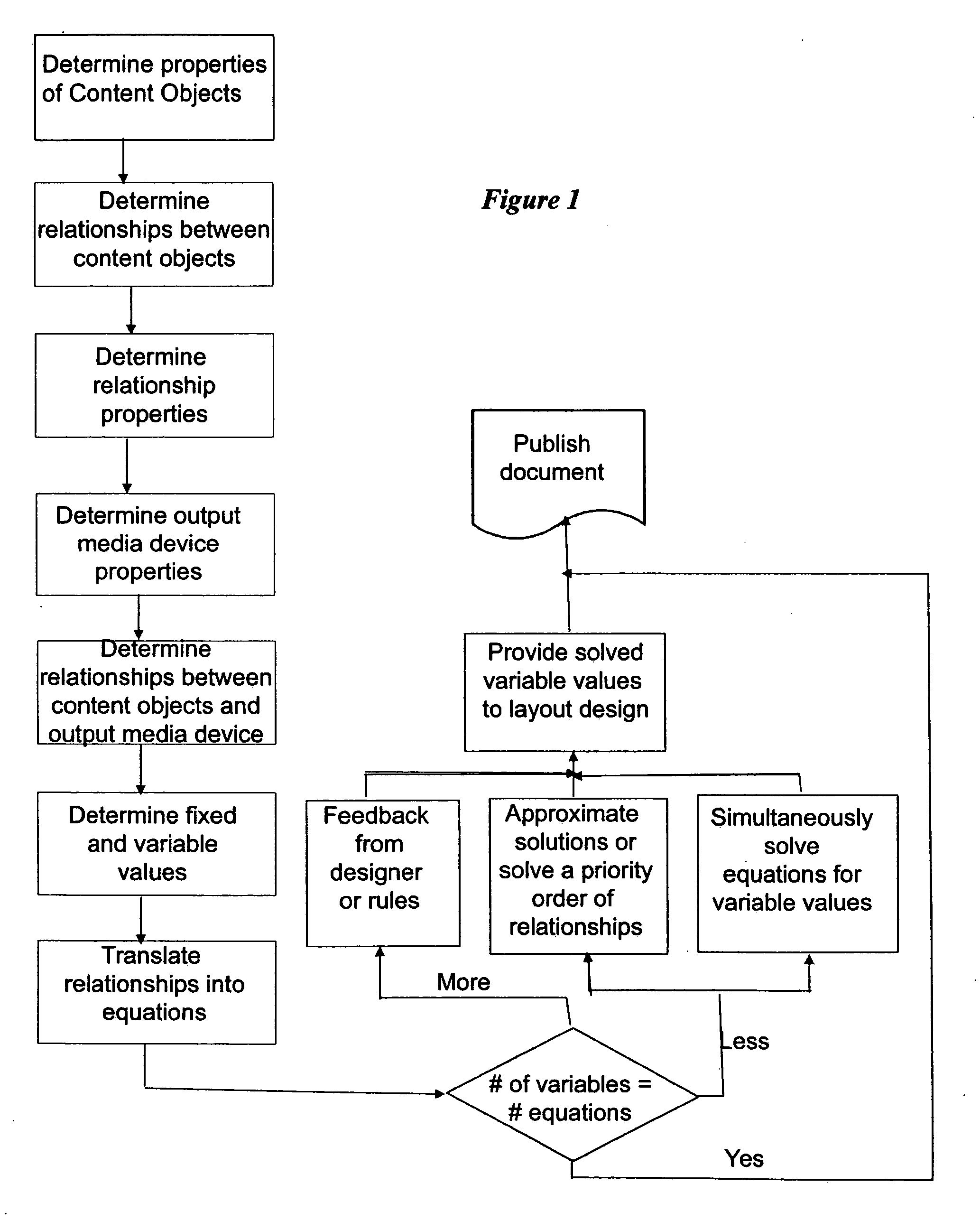

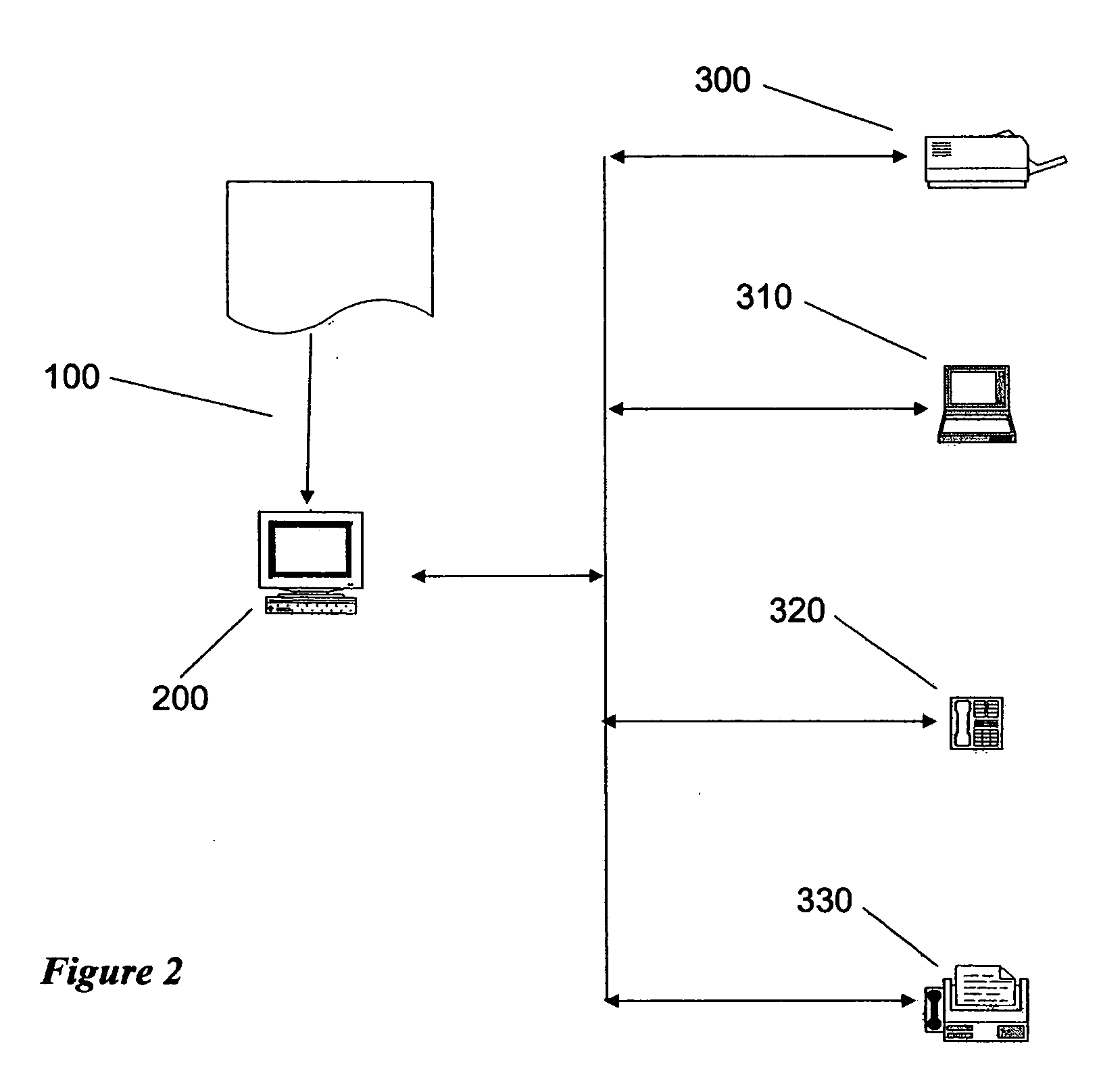

Dynamic layout system and processes

InactiveUS20070028165A1Natural language data processingSpecial data processing applicationsComputer graphics (images)Free form

A completely free form layout of the physical content of a publication. The publication is represented as an unstructured set of content objects whose design relationships are specified as separate relationship objects, all of which interact with objects representing the properties of the display media. Through this representation, the present invention is better able to capture, represent and display the design intent of a designer throughout the entire design process.

Owner:QUARK INC

Capturing a user's design intent with resolvable objects

Owner:ARMSTRONG WORLD IND INC

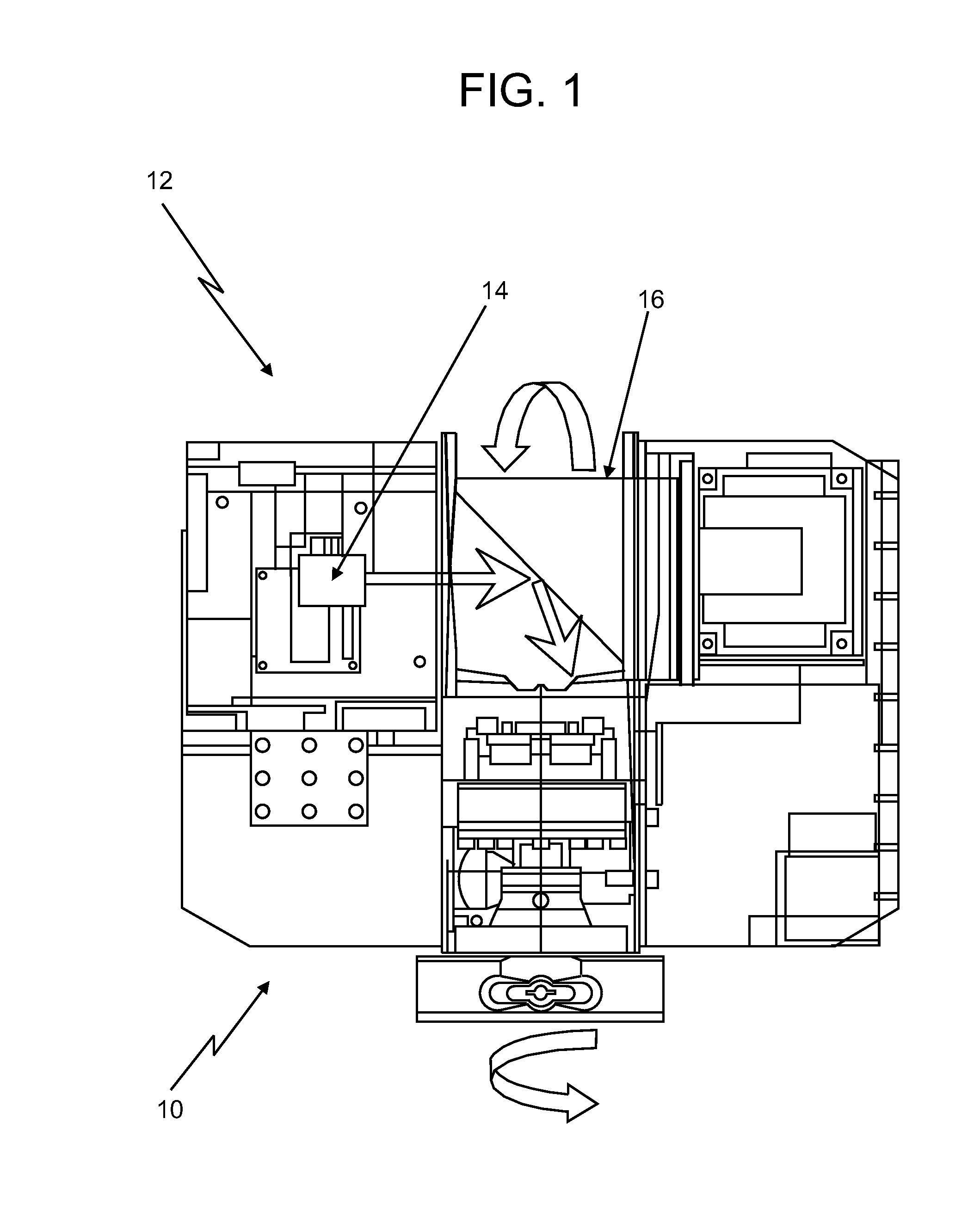

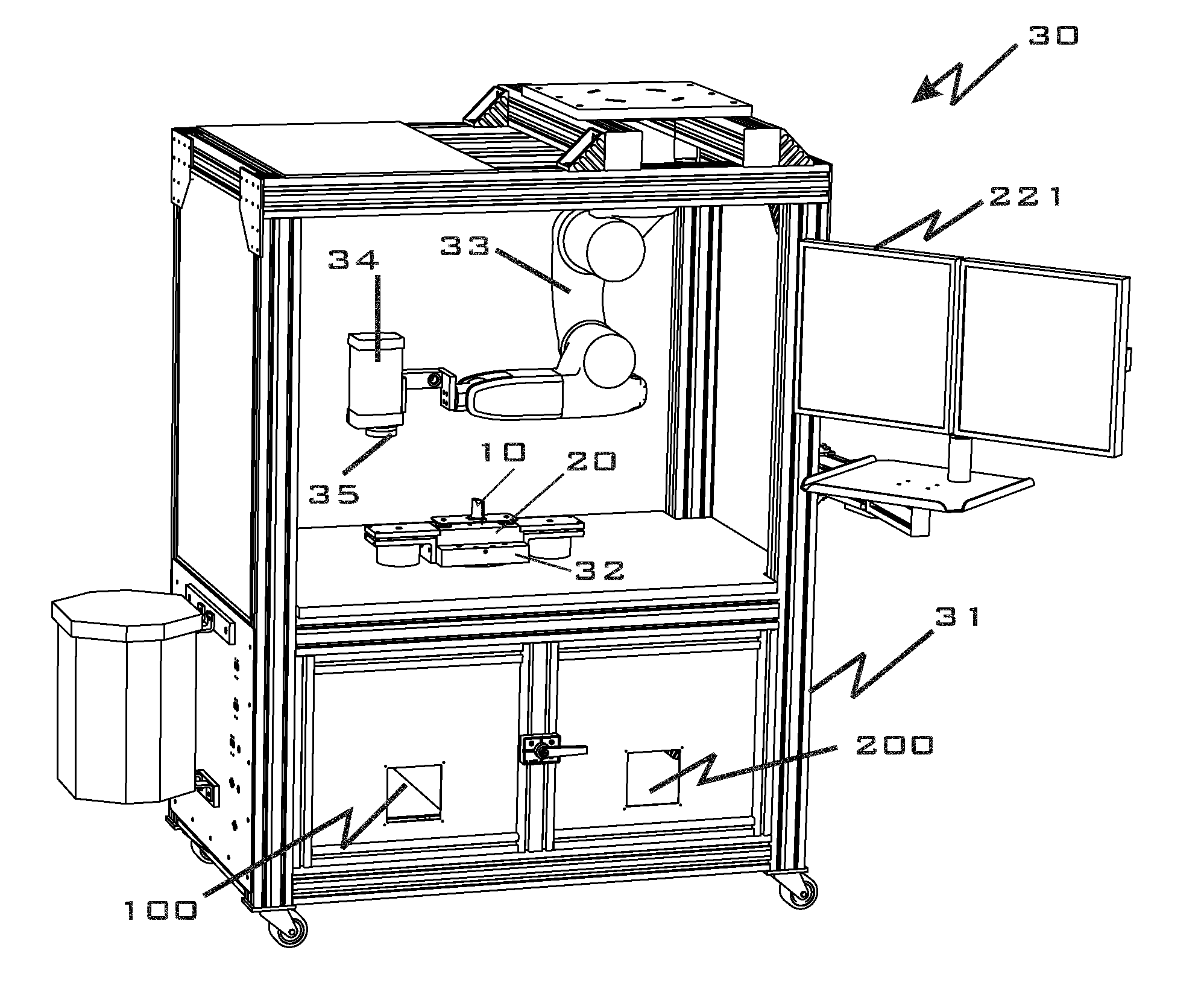

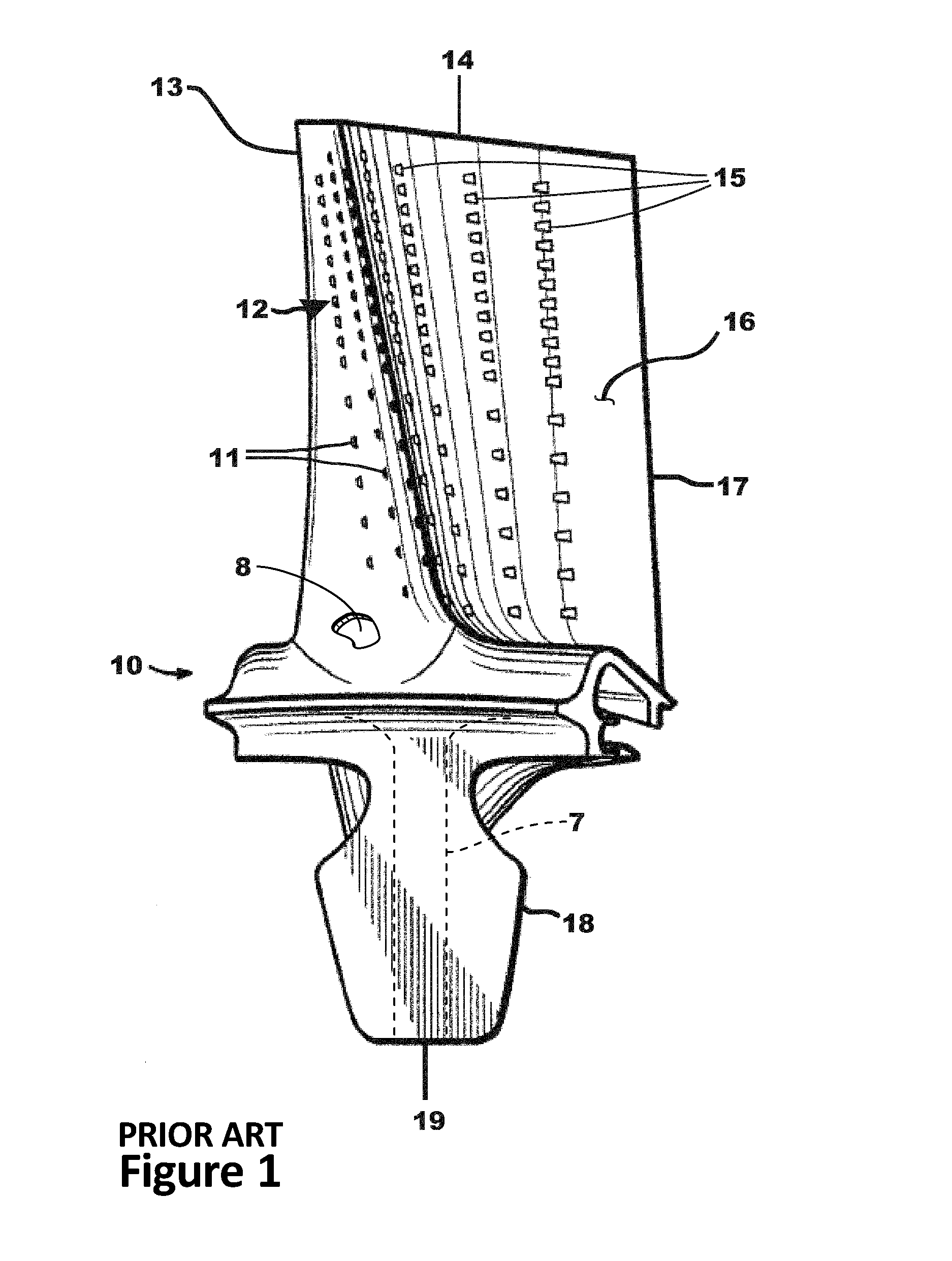

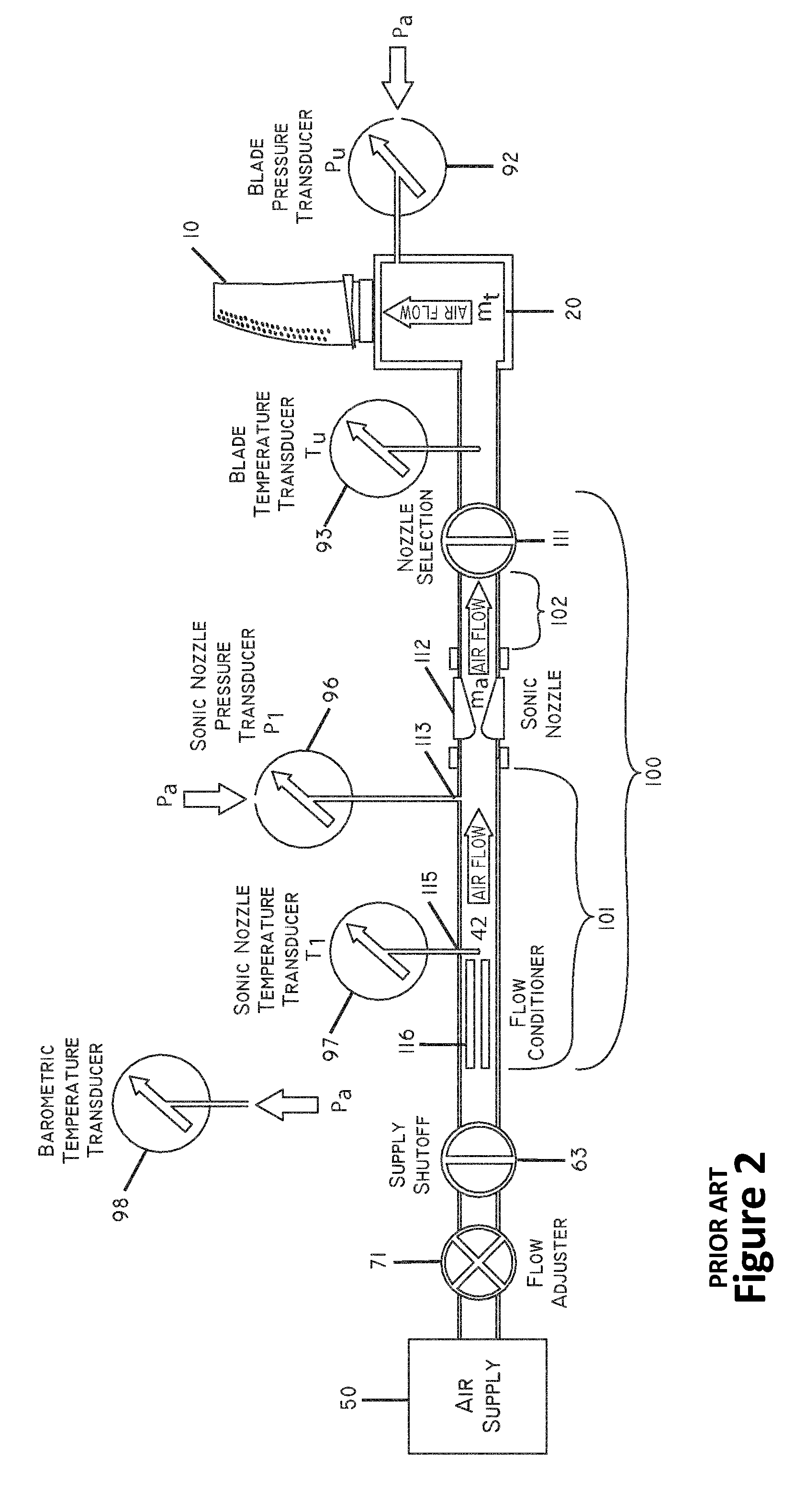

Apparatus and Method For Measurement of the Film Cooling Effect Produced By Air Cooled Gas Turbine Components

InactiveUS20110119020A1Reduce the impactQuality improvementRadiation pyrometryMaterial heat developmentInfrared signatureCooling effect

A method for measurement of a film cooling effect is disclosed. Film cooling is a technique developed to protect gas turbine engine components from the extremely high temperatures created during its operation. A controlled air pressure is ducted into the hollow interior of the component and the mass rate of air flowing through the plurality of film cooling features or openings is measured. A coolant is then injected into the hollow interior of the component and allowed to flow out of a film cooling feature onto the heated outer surface of the component. The resulting infrared signature is a measure of the relative cooling effect generated by the individual film cool feature. The film cooling effect for an individual feature is quantified as the proportion of mass rate of airflow contributed by its relative individual cooling effect. The area, location and shape of the cooling effect are further classified to determine the degree of conformance to its design intent.

Owner:MEYER TOOL

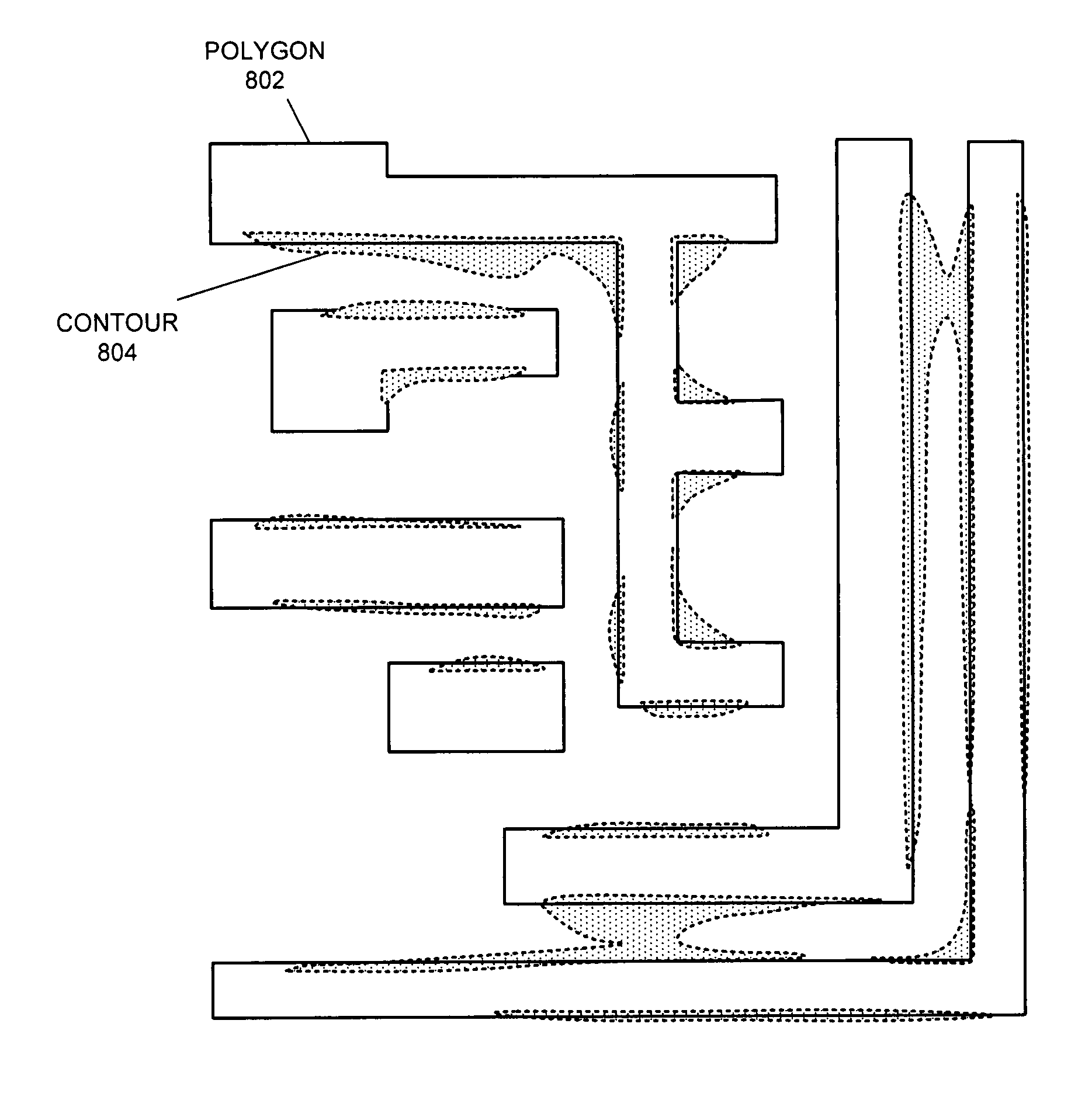

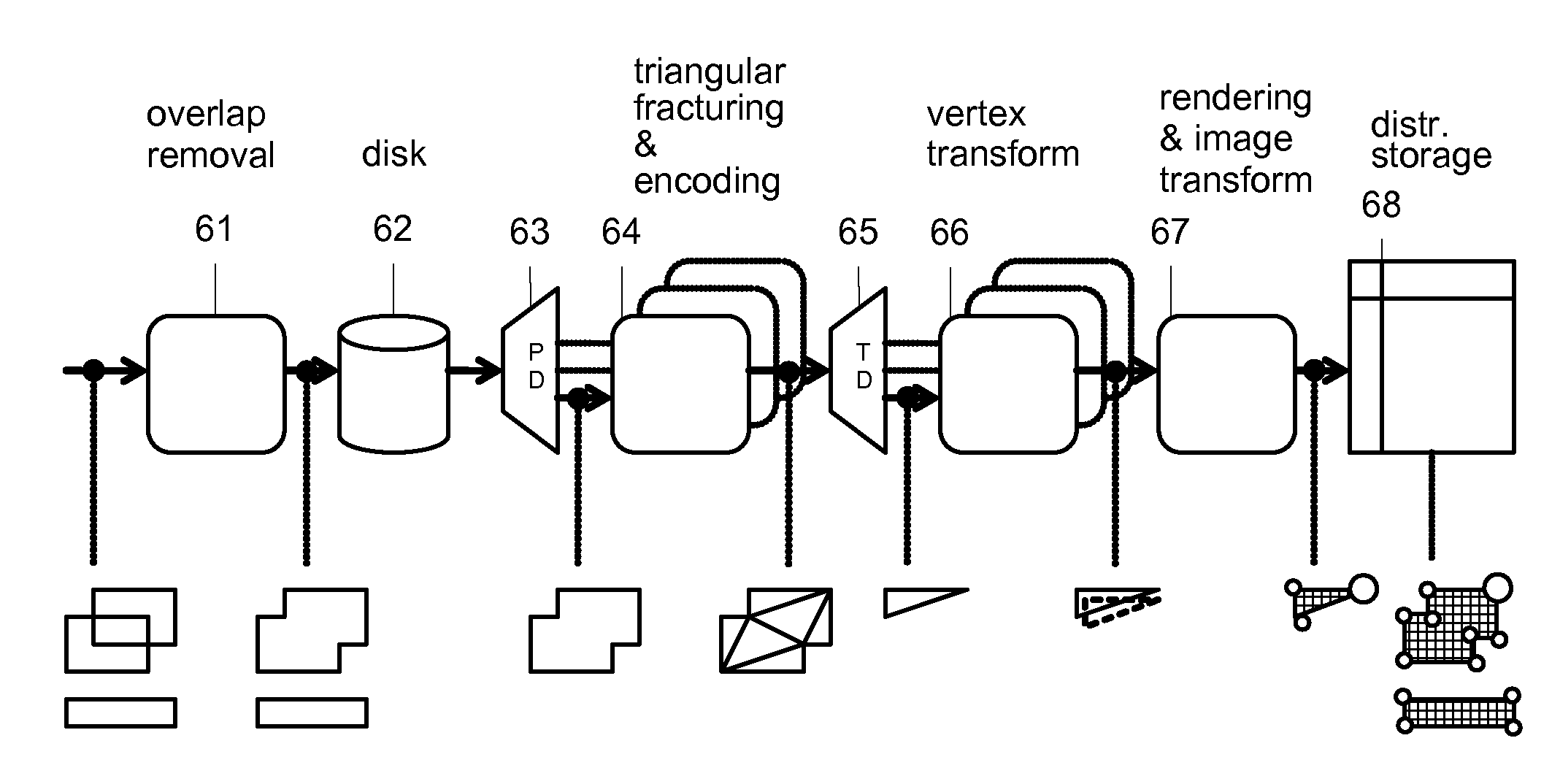

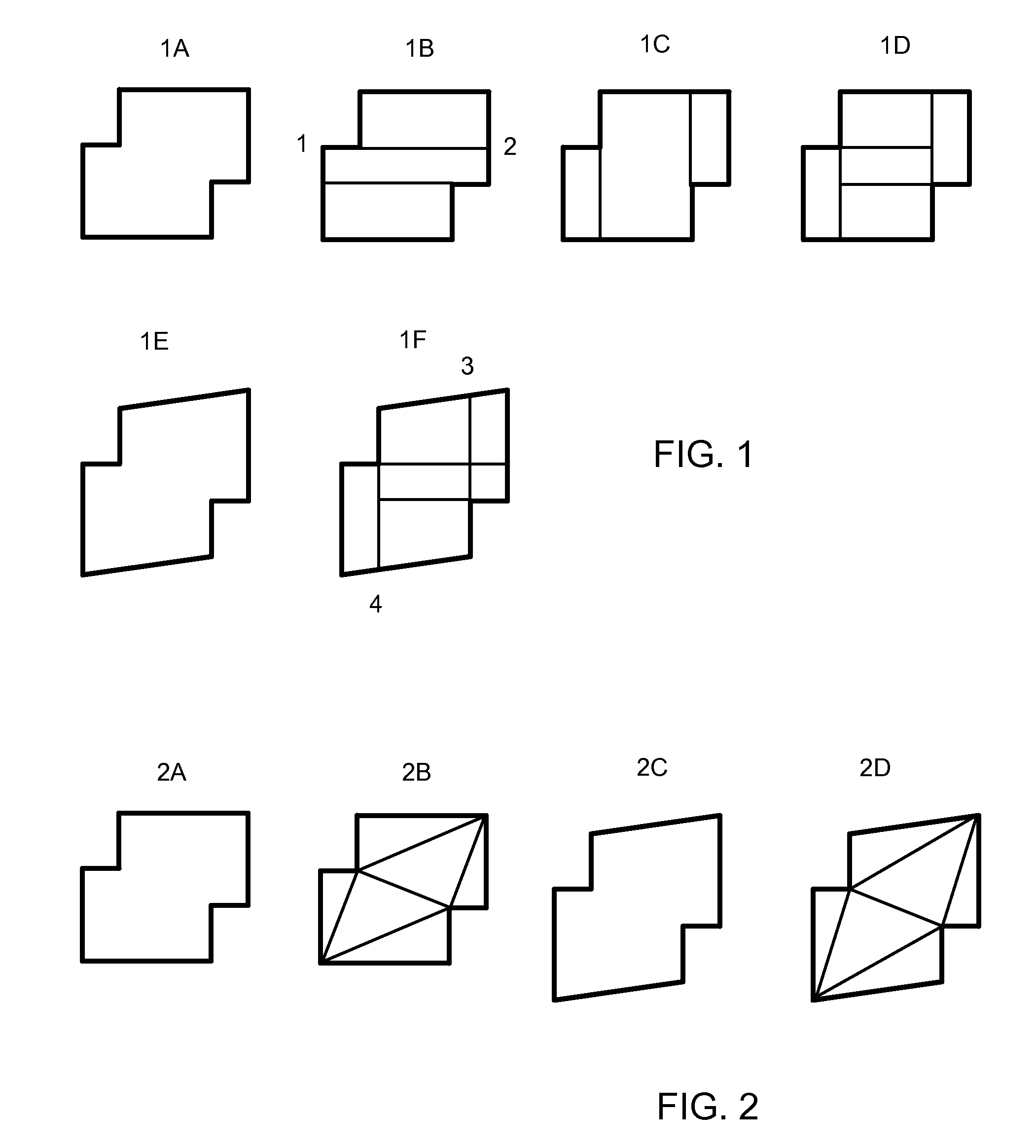

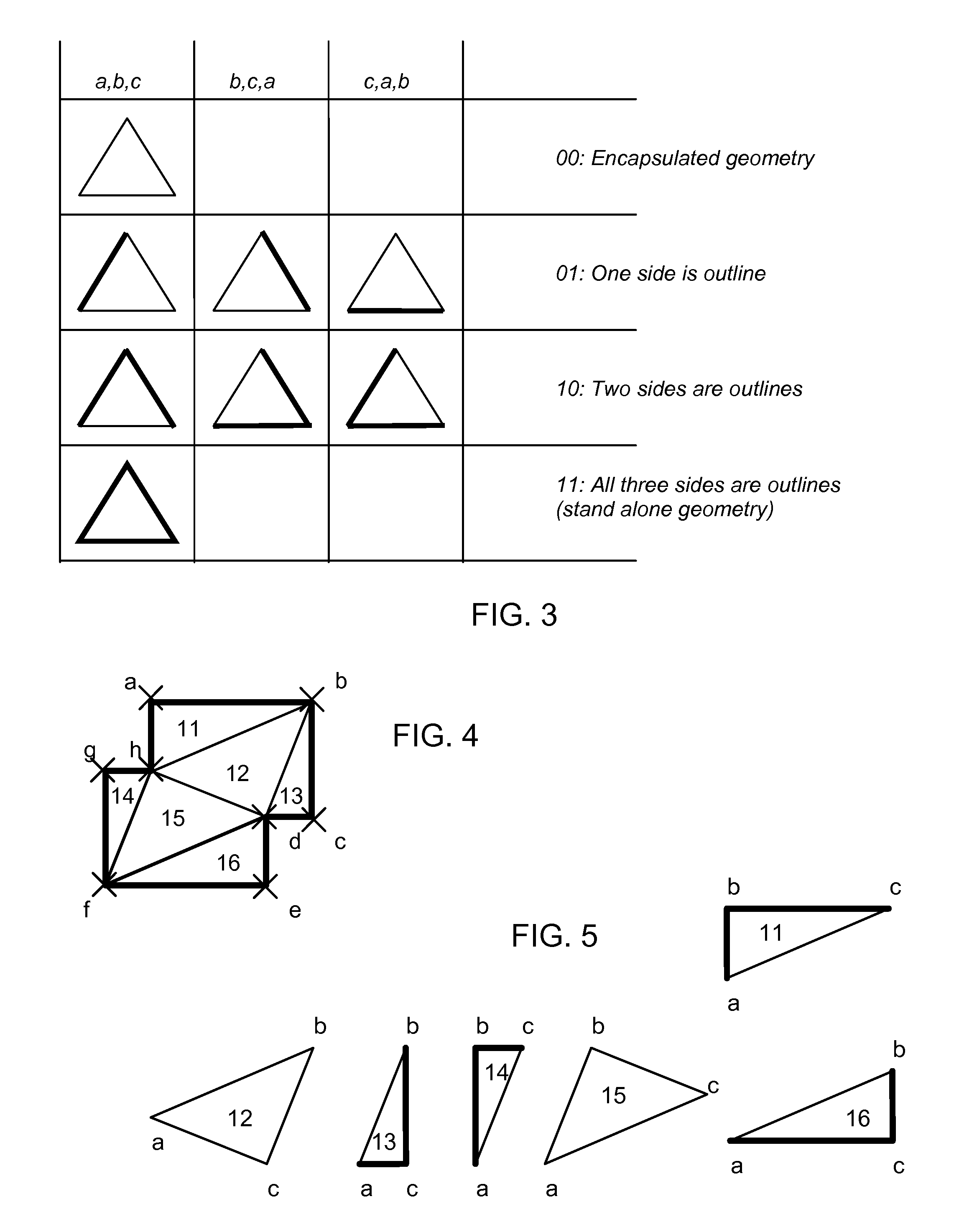

Triangulating Design Data and Encoding Design Intent for Microlithographic Printing

ActiveUS20080260283A1Electric discharge tubesGeometric image transformationTriangulationComputer science

The present disclosure relates to fracturing of polygon data, with one application being microlithography. In particular, it relates to preserving data regarding edges and / or vertices of the original polygons as the polygons are triangulated and even if the results of triangulation are further fractured.

Owner:MICRONIC LASER SYST AB

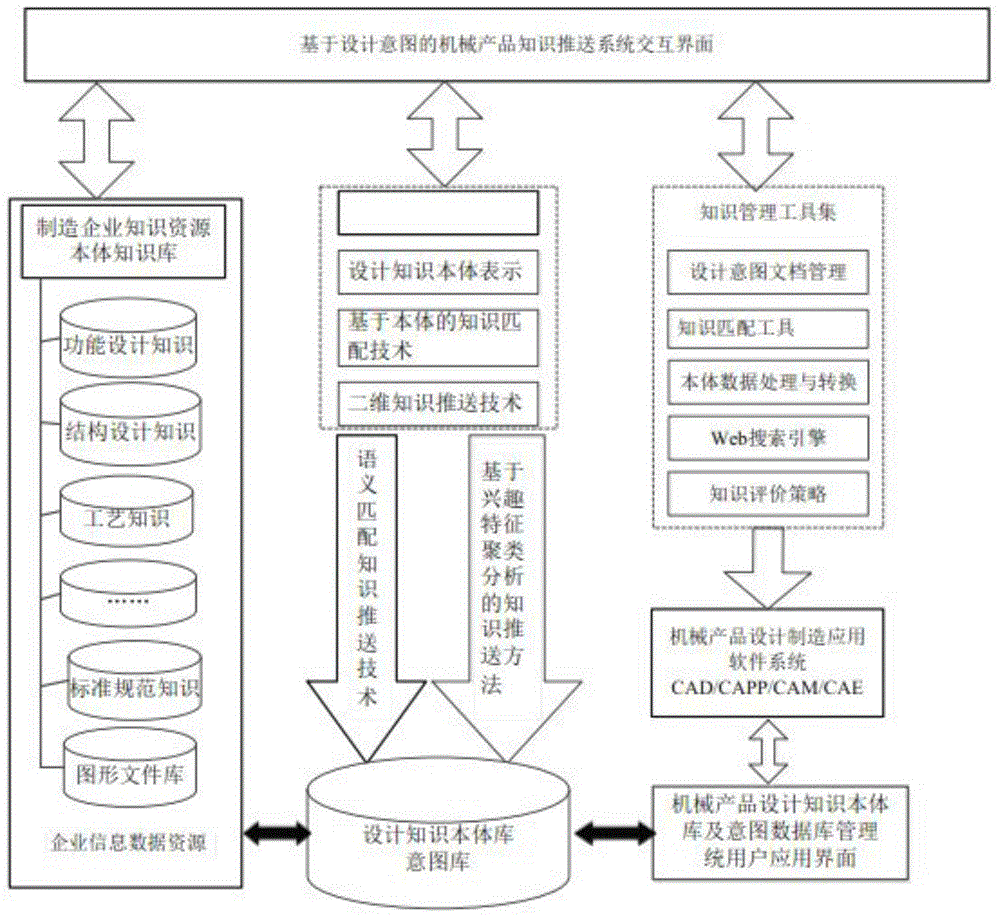

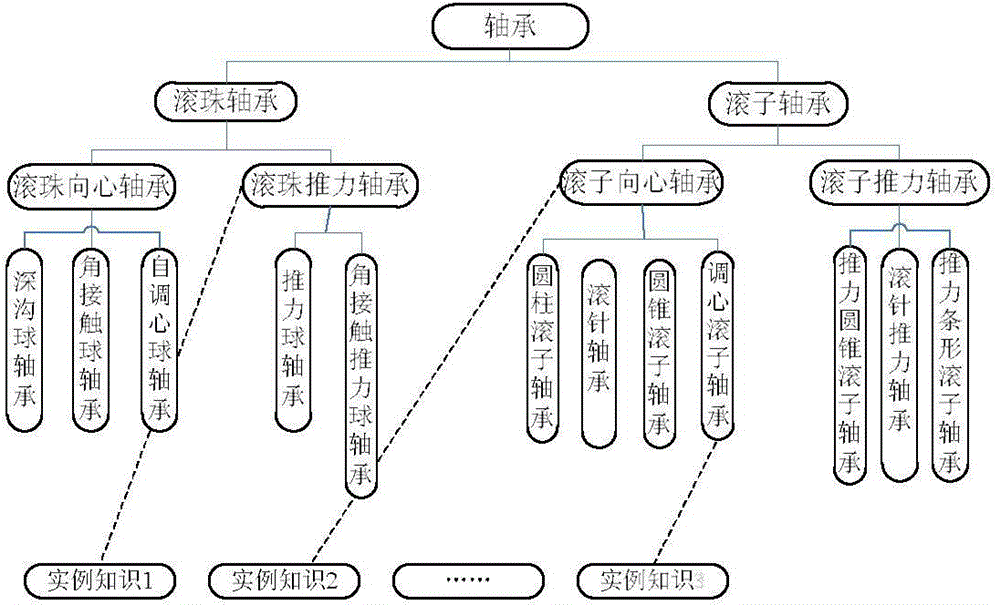

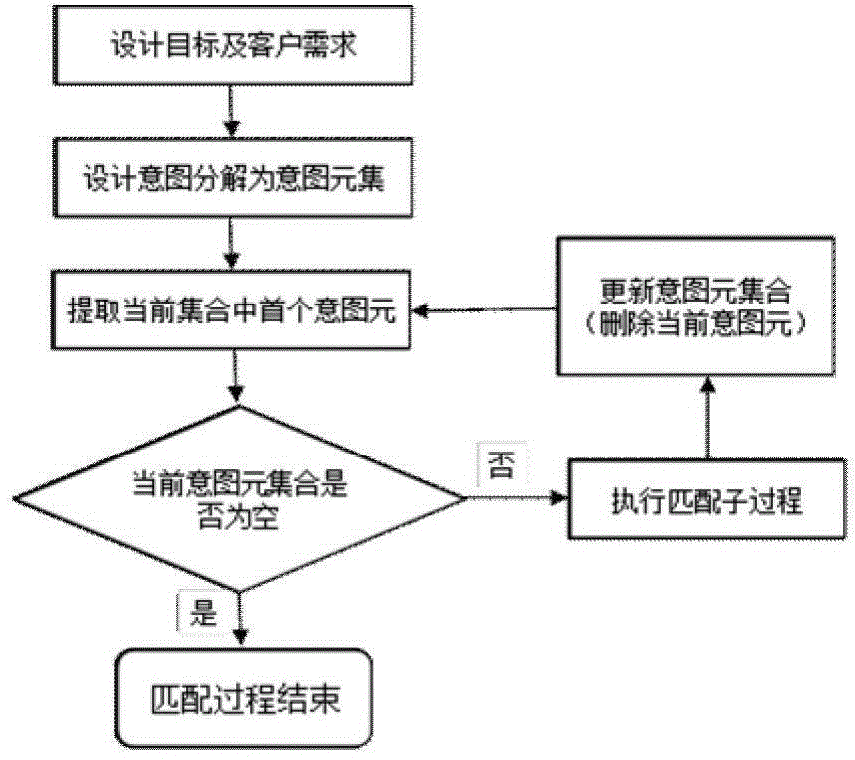

Mechanical product design two-dimensional knowledge pushing method based on design intent

ActiveCN104899242ARich knowledge push resultsAdapt to the needs of deepening developmentSpecial data processing applicationsInformatizationConcept Attribute

The present invention discloses a mechanical product design two-dimensional knowledge pushing method based on design intents. The mechanical product design two-dimensional knowledge pushing method mainly comprises: establishing a mechanical product design intent database, establishing a design intent acquisition and decomposition method, constructing a design intent attribute table by a rough set theory and performing reduction to obtain the simplest design intent set; establishing a mechanical product design knowledge ontology database; and calculating similarity degrees between intent elements and a compared knowledge ontology in a sequential traversing manner by using an improved similarity degree matching algorithm based on a knowledge ontology concept semantic distance and a concept attribute, sequentially carrying out matching on each intent element, of which the similarity degree is greater than a threshold value, in an intent element set from large to small according to the similarity degrees until completing all the matching, and completing matching of the knowledge ontologies by utilizing a text semantic similarity degree calculating method. The mechanical product design two-dimensional knowledge pushing method can solve the problem of low knowledge intelligent degree of knowledge pushing in the mechanical product design, can improve efficiency of mechanical product design and is suitable for the requirement of the manufacturing information engineering technology for deepening development.

Owner:SICHUAN UNIV

Method and apparatus for determining mask layouts for a multiple patterning process

ActiveUS20080244504A1Improve toleranceIncreasing trenchOriginals for photomechanical treatmentSpecial data processing applicationsEngineeringDesign intent

One embodiment provides a method for determining mask layouts. During operation, the system can receive a design intent. Next, the system can determine a set of critical edges in the design layout, and select a first edge and a second edge. The system can then determine a first trench and a second trench using the first edge and the second edge, respectively. Note that an edge of the first trench may substantially overlap with the first edge, and an edge of the second trench may substantially overlap with the second edge. Next, the system may assign the first trench and the second trench to the first mask layout and the second mask layout, respectively. The system can then increase the first trench and the second trench, thereby improving pattern fidelity. The resulting mask layouts may be used in a double patterning process.

Owner:SYNOPSYS INC

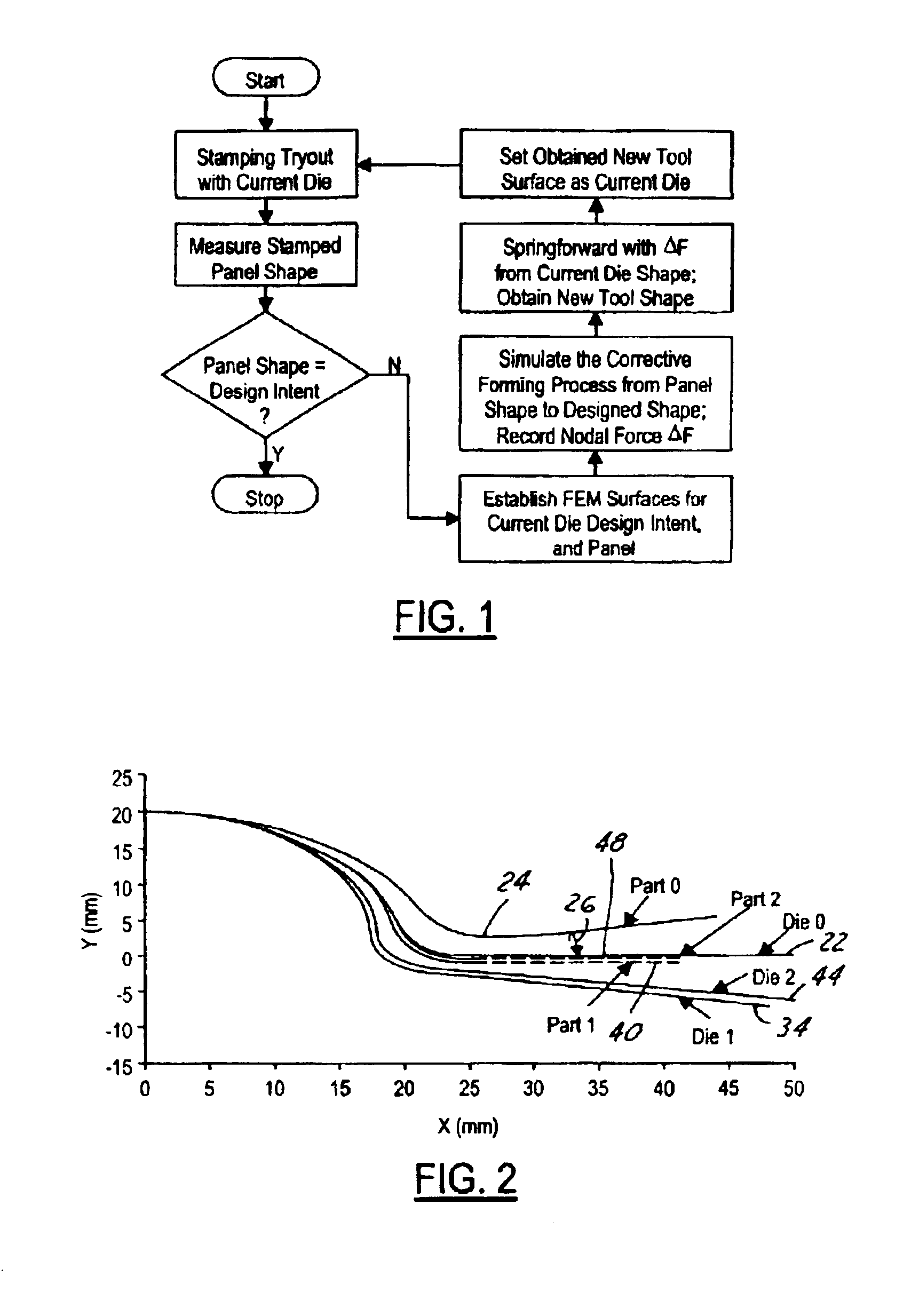

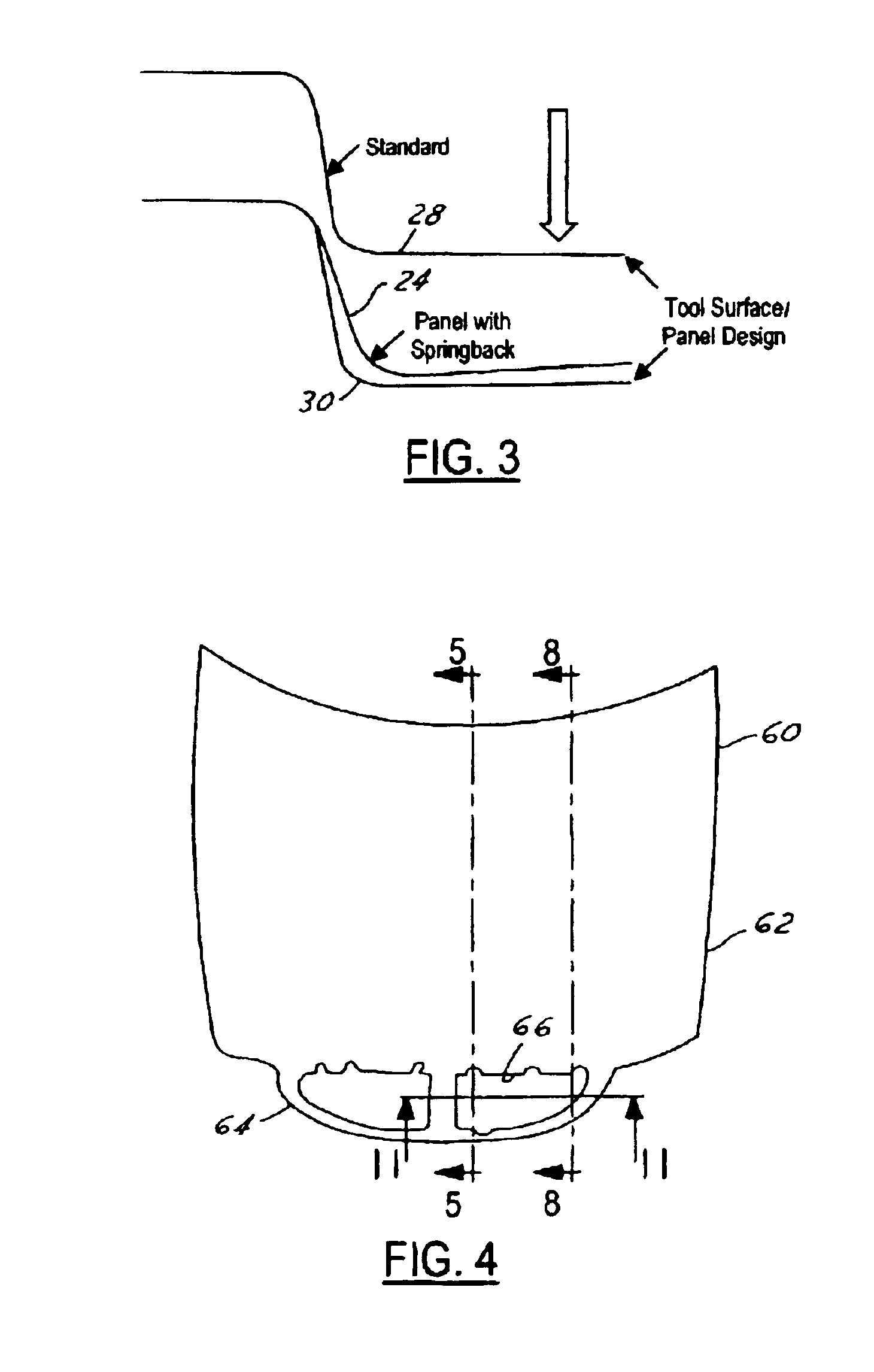

Method of modifying stamping tools for spring back compensation based on tryout measurements

InactiveUS6947809B2Apparent advantageShaping toolsSpecial data processing applicationsIndustrial engineeringDesign intent

A method of developing a stamping die for a workpiece is provided, which includes the steps of stamping a workpiece in a current die. A measurement is made of the stamped workpiece to determine its profile. The profile is compared with the design intent workpiece to determine dimensional variance. If the variance is within predetermined limits, the development is complete. If the variance is beyond limits, a conceptual determination is made of the residual forces in the current die stamped workpiece when the current die stamped workpiece is restamped by a design intent die. This conceptual determination is carried out on a computer. From the determination of residual forces, a new current die is developed. The new current die then stamps the workpiece. The steps are repeated until the stamped workpiece profile is within predetermined limits.

Owner:FORD GLOBAL TECH LLC

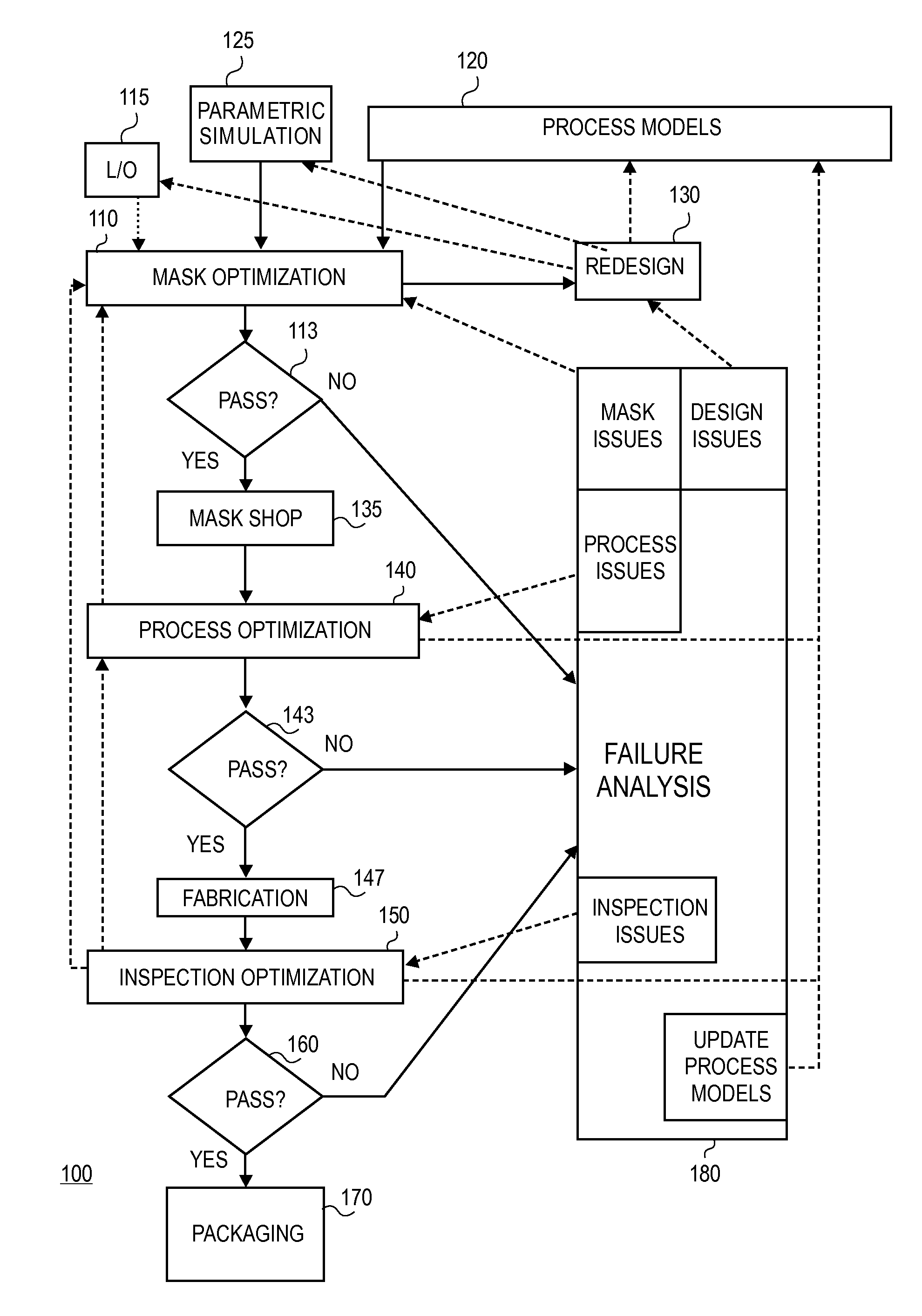

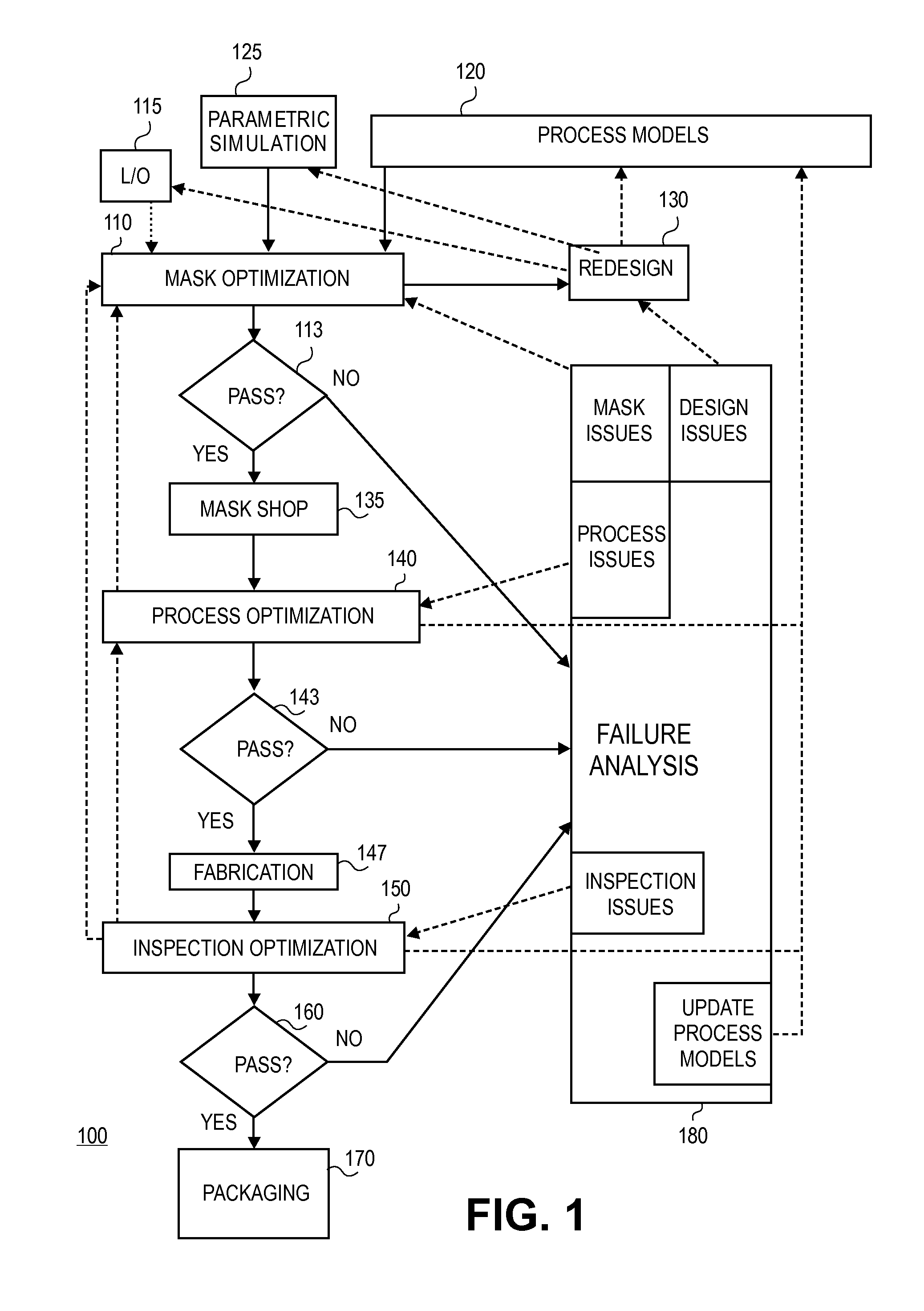

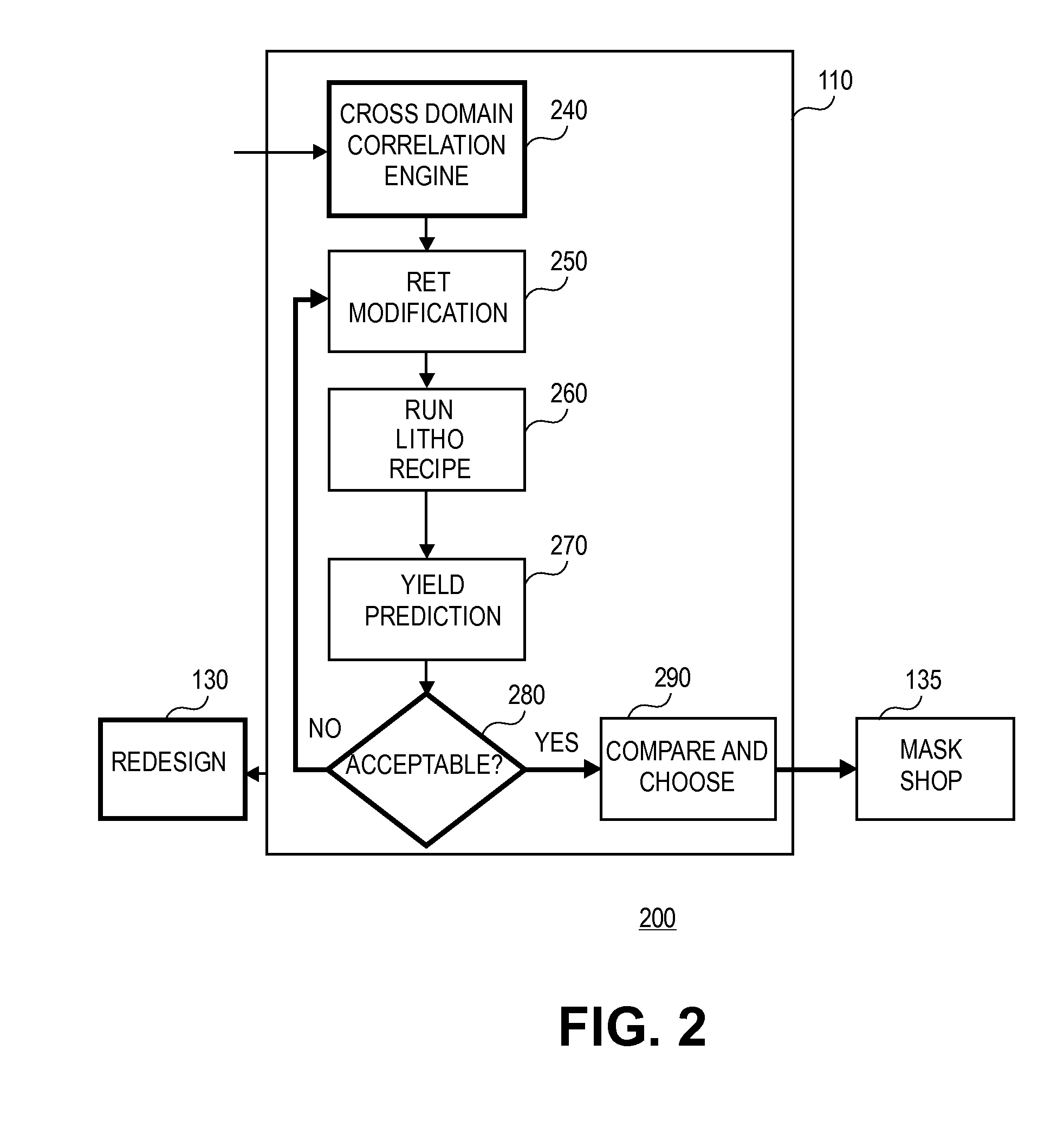

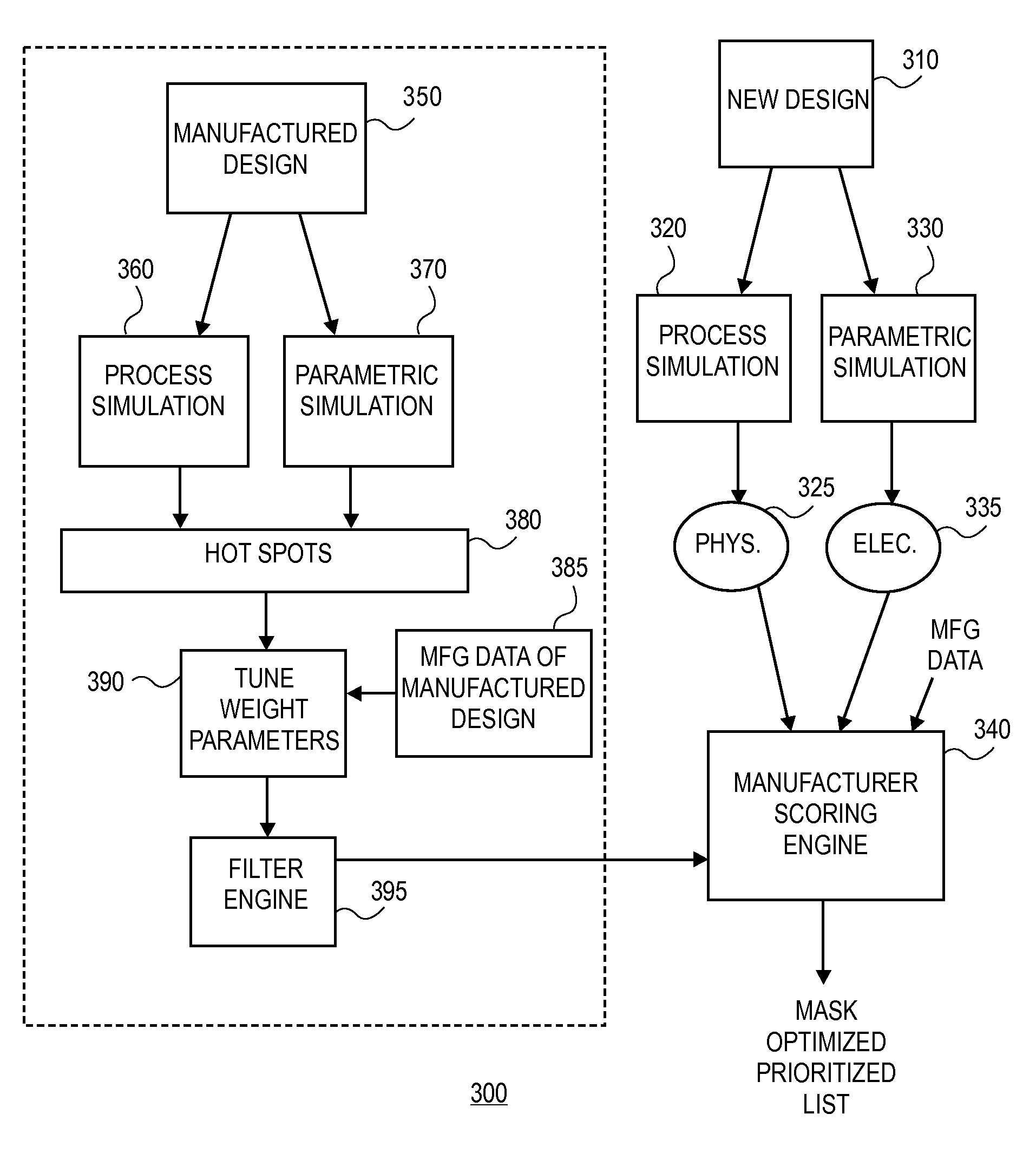

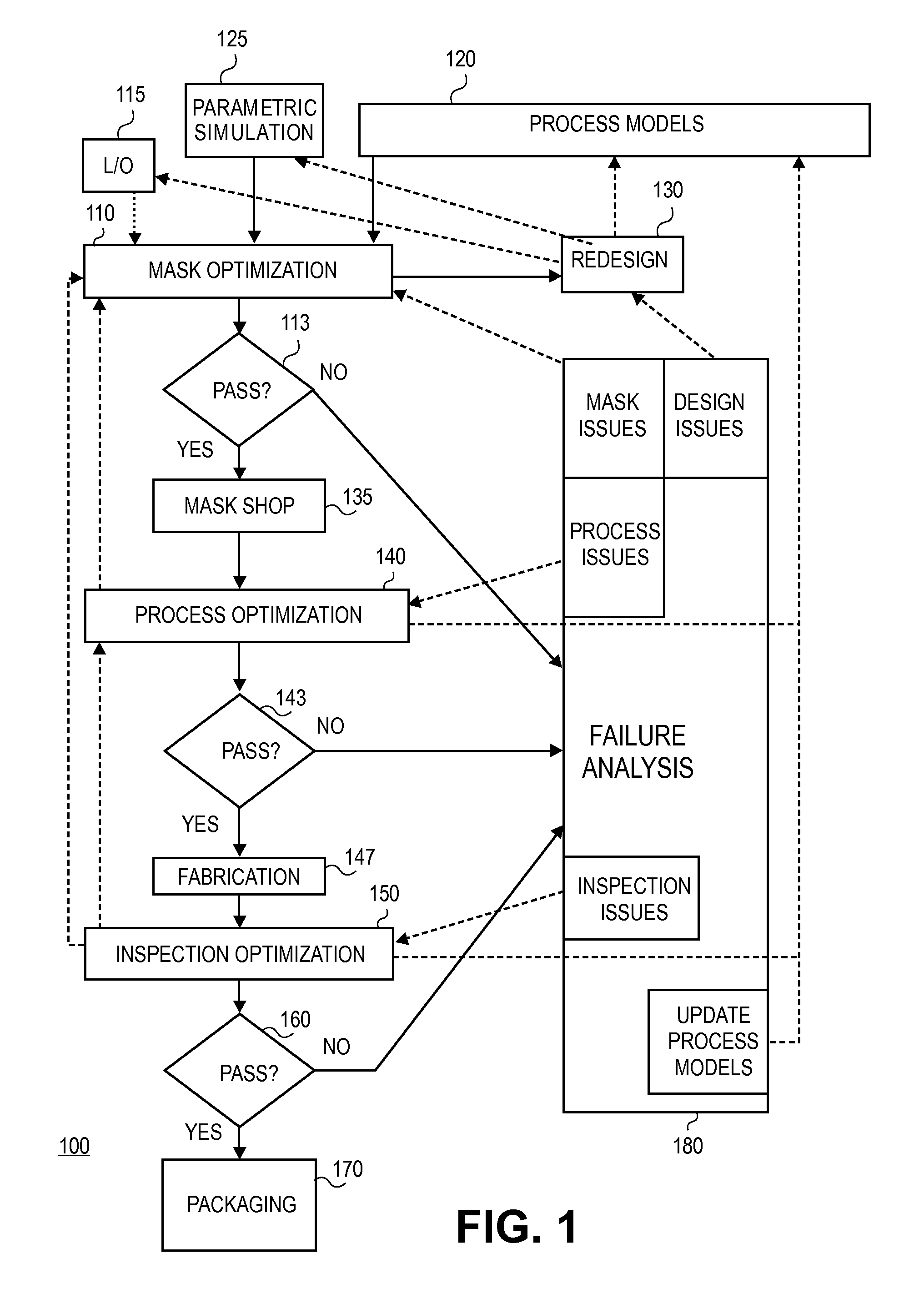

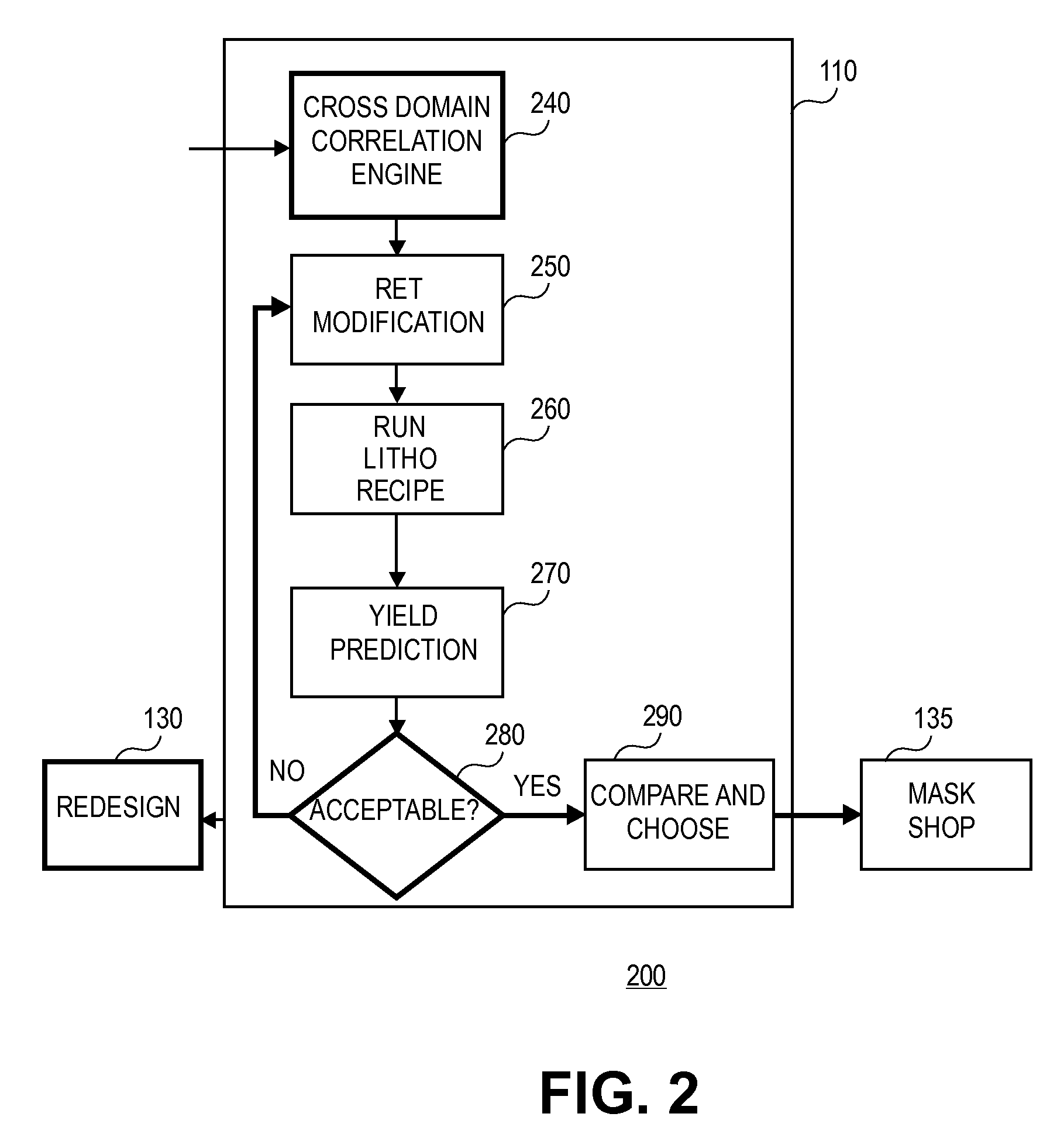

Modeling and cross correlation of design predicted criticalities for optimization of semiconductor manufacturing

InactiveUS20080147374A1CAD circuit designSpecial data processing applicationsMetrologyInformation sharing

A method and apparatus for modeling and cross correlation of design predicted criticalities include a feedback loop where information from the manufacturing process is provided to cross correlation engine for optimization of semiconductor manufacturing. The information may include parametric information, functional information, and hot spots determination. The sharing of information allows for design intent to be reflected in manufacturing metrology space; thus, allowing for more intelligent metrology and reduces cycle time.

Owner:CADENCE DESIGN SYST INC

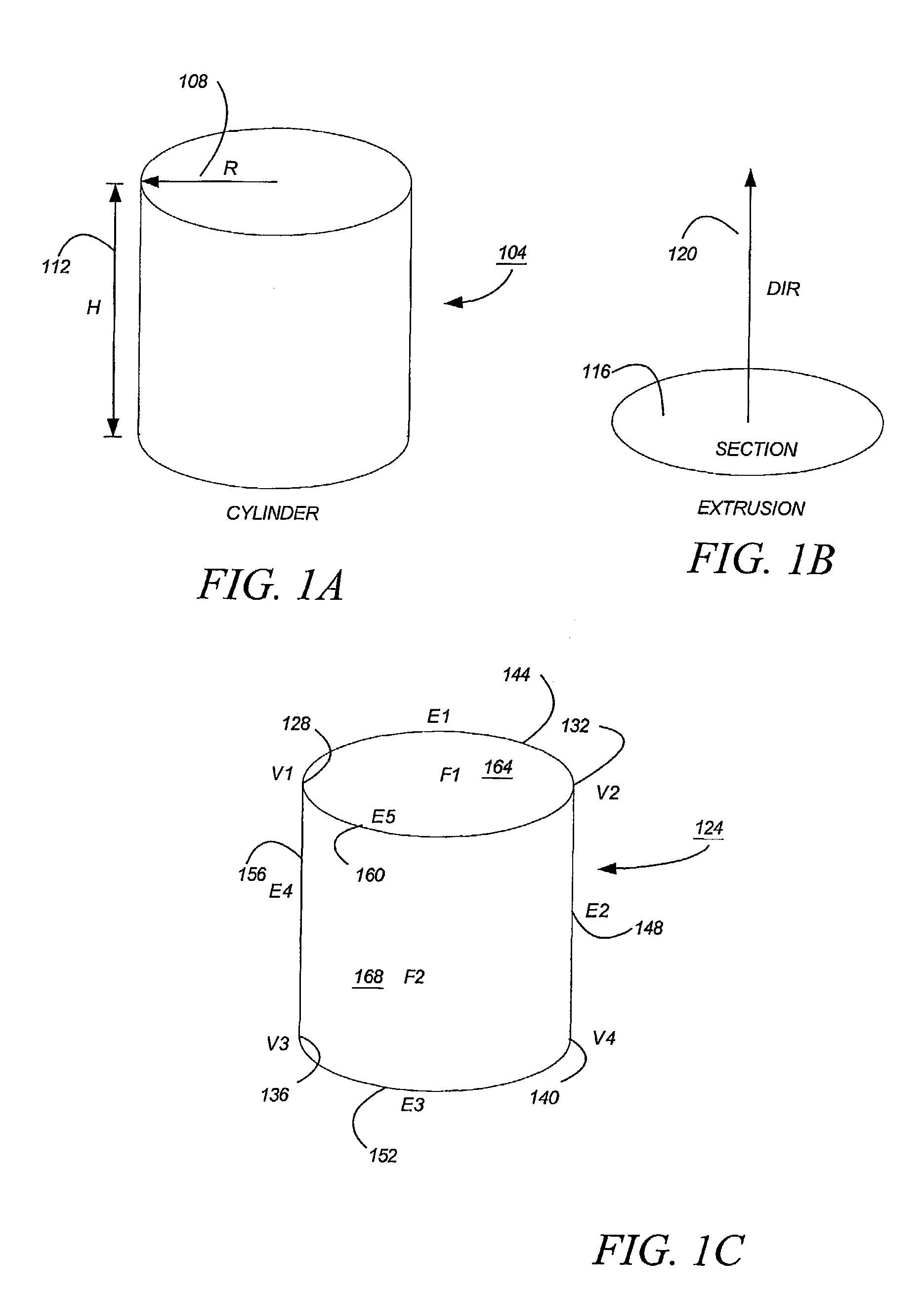

System and method for identifying original design intents using 3D scan data

ActiveUS7814441B2Computer aided designSpecial data processing applicationsGraphicsGraphical user interface

Programmatic extraction and management of solid and surface modeling parameters from raw 3D scan data is discussed. An automated process reads raw 3D scan data and works in communication with a CAD system able to perform CAD part modeling. The user is provided with an automatic function to segment a mesh model (formed from the raw 3D scan data) into dozens of mesh regions. A graphical user interface is provided which enables a user to choose a type of the design intent along with the mesh regions from which the design intent is calculated. Each design intent is represented in a vector, a plane or a poly-line depending upon the type of design intent. In response to a user demand for the parameters of a modeling feature, a best approximation of the requested parameter value is calculated by processing the raw 3D scan data using a set of functions.

Owner:INUS TECH

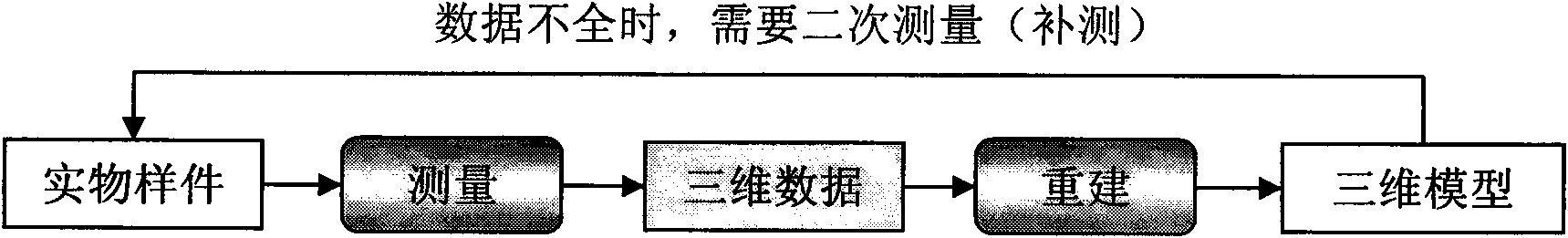

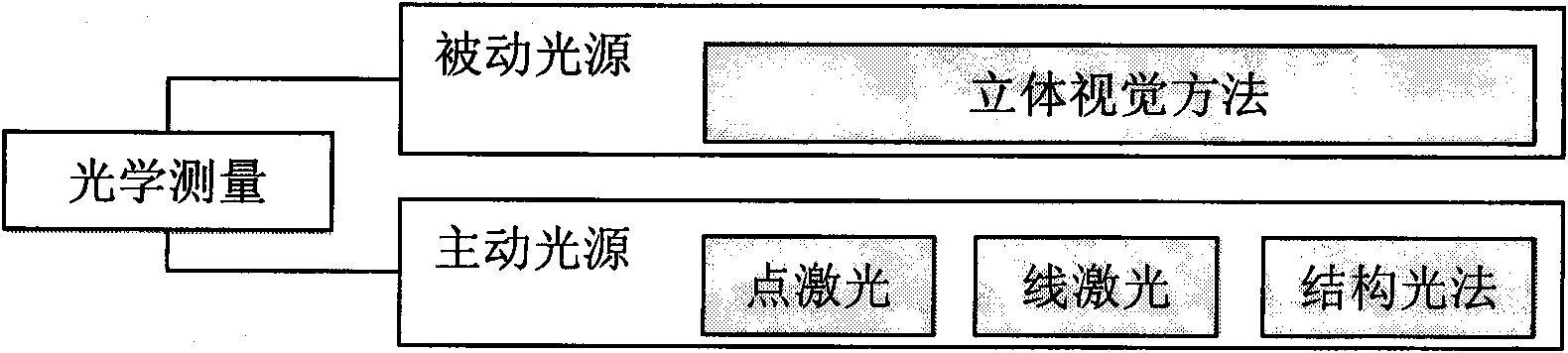

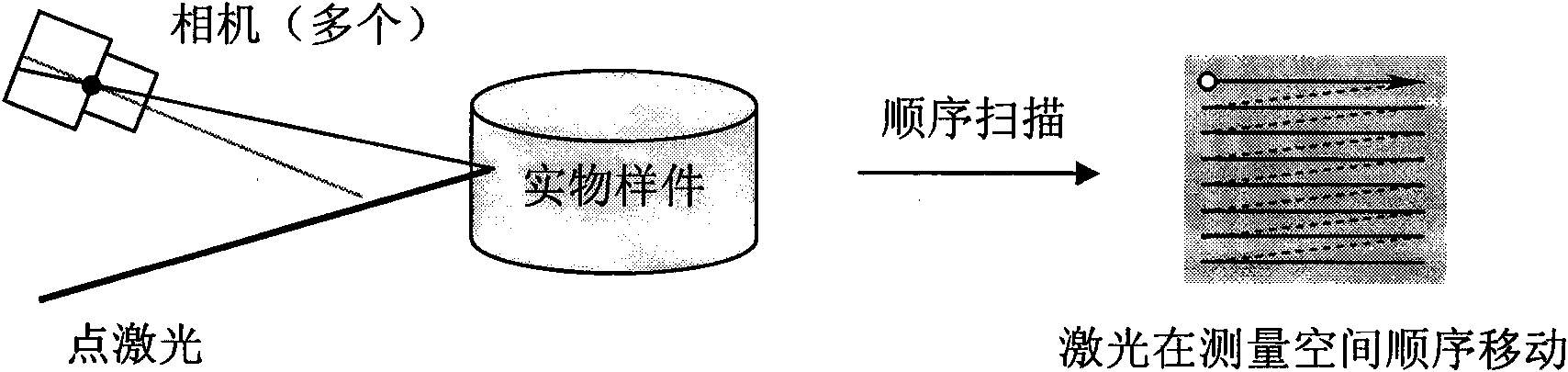

Integrated method for measurement and reconstruction of three-dimensional model and system thereof

InactiveCN101630418ASimplify the reverse engineering processFully consider the design intentUsing optical meansStereoscopic photographySurface markerComputer vision

The invention relates to an integrated method for the measurement and reconstruction of a three-dimensional model and a system thereof. The method comprises the following steps: 1) obtaining the three-dimensional coordinates of surface markers of an object sample; 2) interactively constructing the three-dimensional model based on the three-dimensional coordinates. The method integrates measurement and reconstruction as a whole and simplifies an inverse reconstruction process of the three-dimensional model to benefit for the rapid inverse reconstruction of the object sample and to avoid complex secondary measurement (supplement measurement) and guarantee the integrity of the reconstructed model. Color and texture information of surfaces of the samples can be reconstructed, data volume of the reconstructed model is small and is suitable for being used under network environment. Repeated measure can be effectively avoided to improve the efficiency of measurement and reconstruction. A measuring apparatus has the advantages of small volume, light weight and convenient motion. The design intent of the model can be fully considered in the measurement and reconstruction process in favor of measurement planning.

Owner:白晓亮 +2

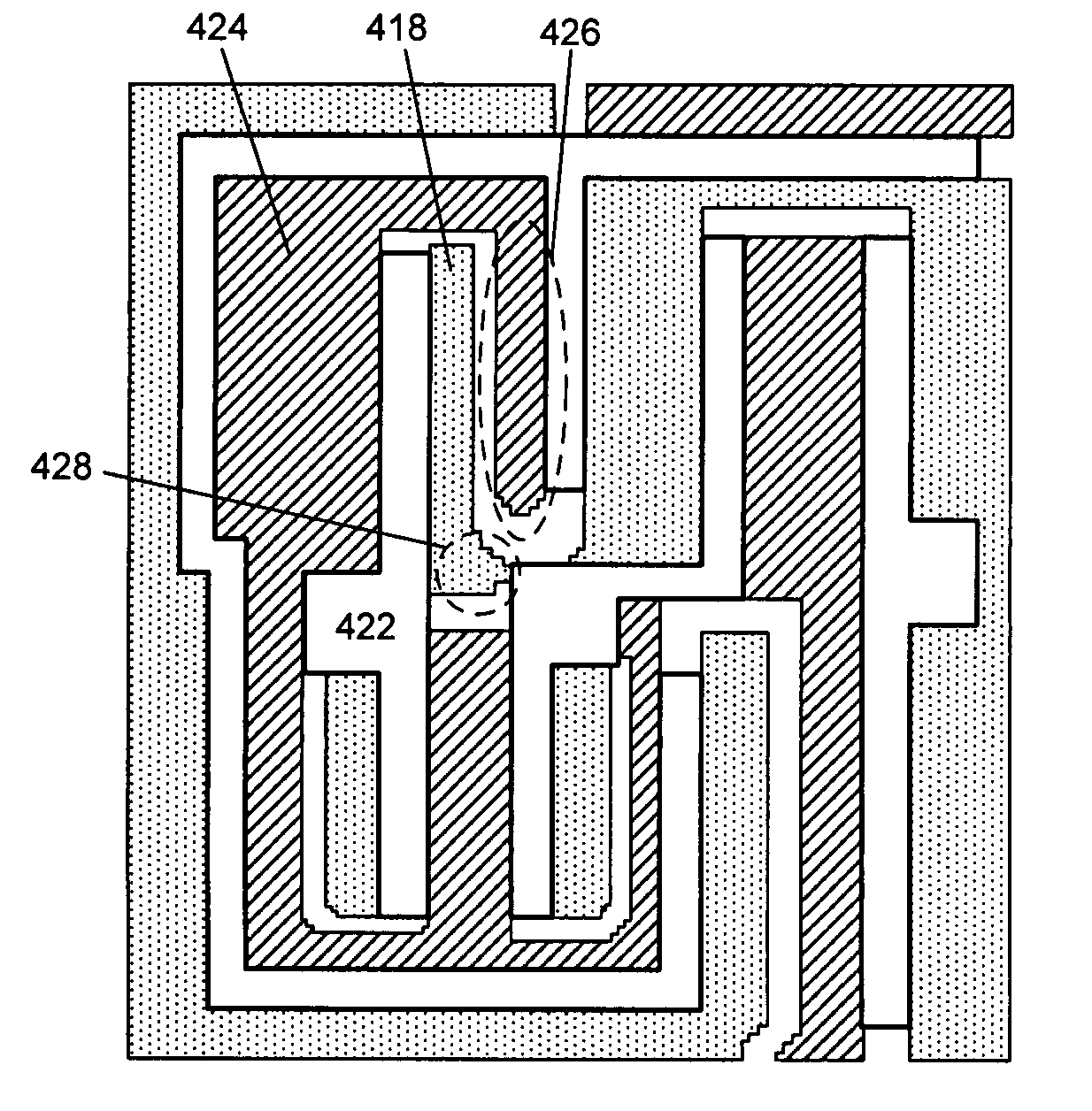

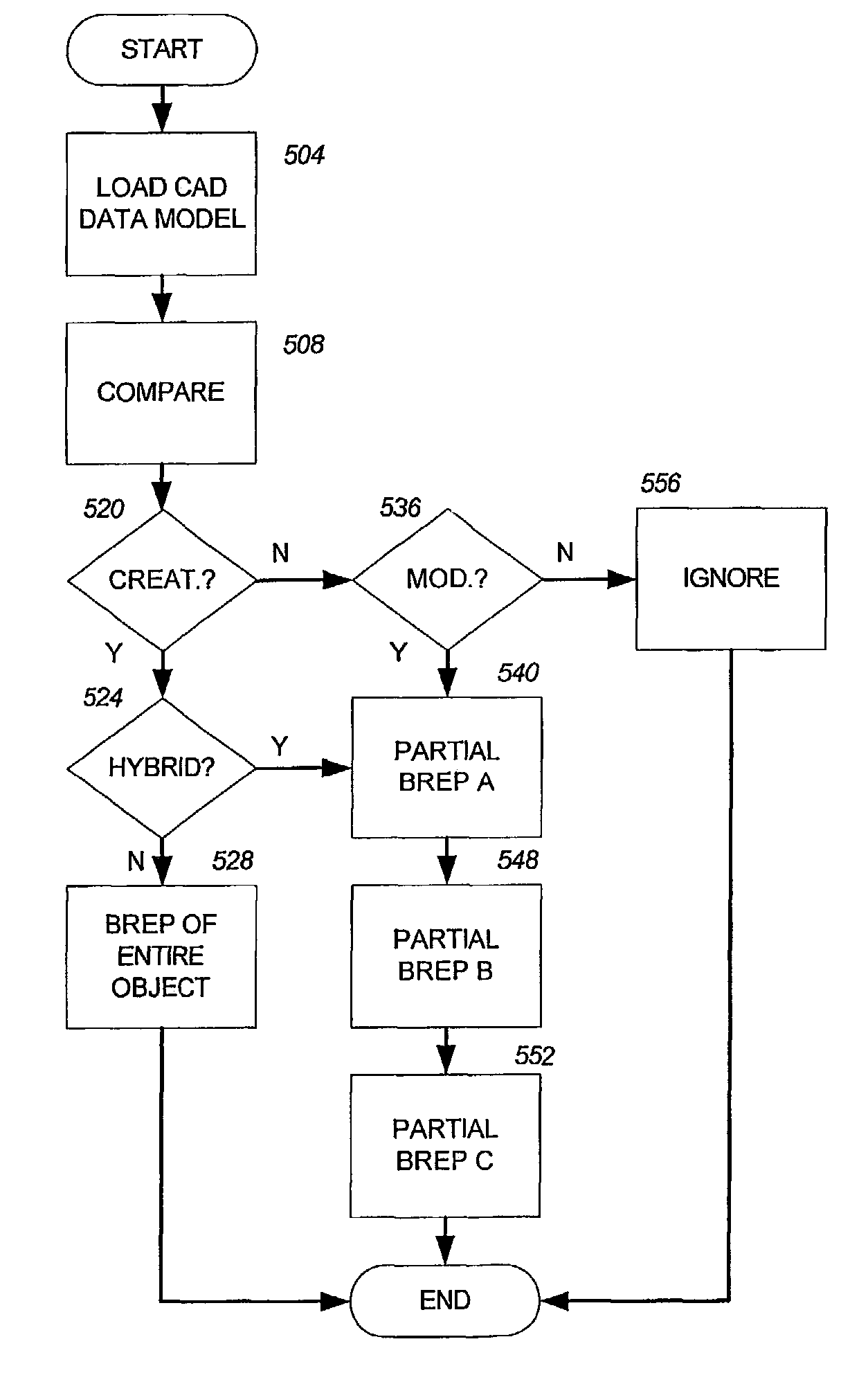

Boundary representation per feature methods and systems

InactiveUS7277835B2Cathode-ray tube indicatorsComputation using non-denominational number representationPattern matchingData exchange

Computer implemented methods and systems for CAD data exchange, and in particular for creating boundary representations (“breps”) on a feature-by-feature basis are disclosed. According to an embodiment of the techniques described herein, a parameterized feature from a parametric based design system is exported from a source CAD system (404). Iterative steps and complimentary extraction techniques are employed by one or more processors (452, 456) to create an importable design model of the parameterized feature (433), which is imported into a target CAD system (408). While the techniques can include API (436), pattern matching (440), and user emulation (444) techniques, they include a brep per feature (450) technique. By exporting the brep on a per feature (453) basis from the source CAD system (404), the design intent of a CAD designer can be preserved on importation into the target CAD system (408). In particular, where a parametric representation (433) of the feature fails to import into the target system (408), an unparameterized representation (453) of the feature can be substituted.

Owner:PROFICIENCY

Capturing a user's intent in design software

ActiveUS8751950B2Efficient constructionAccurate representationGeometric CADCAD network environmentInterior spaceUser input

A software program for use in designing interior and exterior spaces receives user input that is associated with one or more attributes. Subsequent user input, having other attributes, is resolved in light of the first input attributes to create a real-world depiction of design choices in real-time. For example, design choices that conflict with prior design choices are resolved (or modified as necessary) to ensure that each of the prior and present user input choices are represented in an appropriate way. The resolution by the design software is also used to create an accurate parts (and / or price) list so that when the user has completed the design of an exterior or interior space, the design can be submitted directly as an order to be fulfilled. Generally, continual resolution ensures that the user's design intent is captured in an accurate and efficient way in a user interface.

Owner:ARMSTRONG WORLD IND INC

Modeling and cross correlation of design predicted criticalities for optimization of semiconductor manufacturing

InactiveUS7694244B2CAD circuit designSoftware simulation/interpretation/emulationMetrologyInformation sharing

A method and apparatus for modeling and cross correlation of design predicted criticalities include a feedback loop where information from the manufacturing process is provided to cross correlation engine for optimization of semiconductor manufacturing. The information may include parametric information, functional information, and hot spots determination. The sharing of information allows for design intent to be reflected in manufacturing metrology space; thus, allowing for more intelligent metrology and reduces cycle time.

Owner:CADENCE DESIGN SYST INC

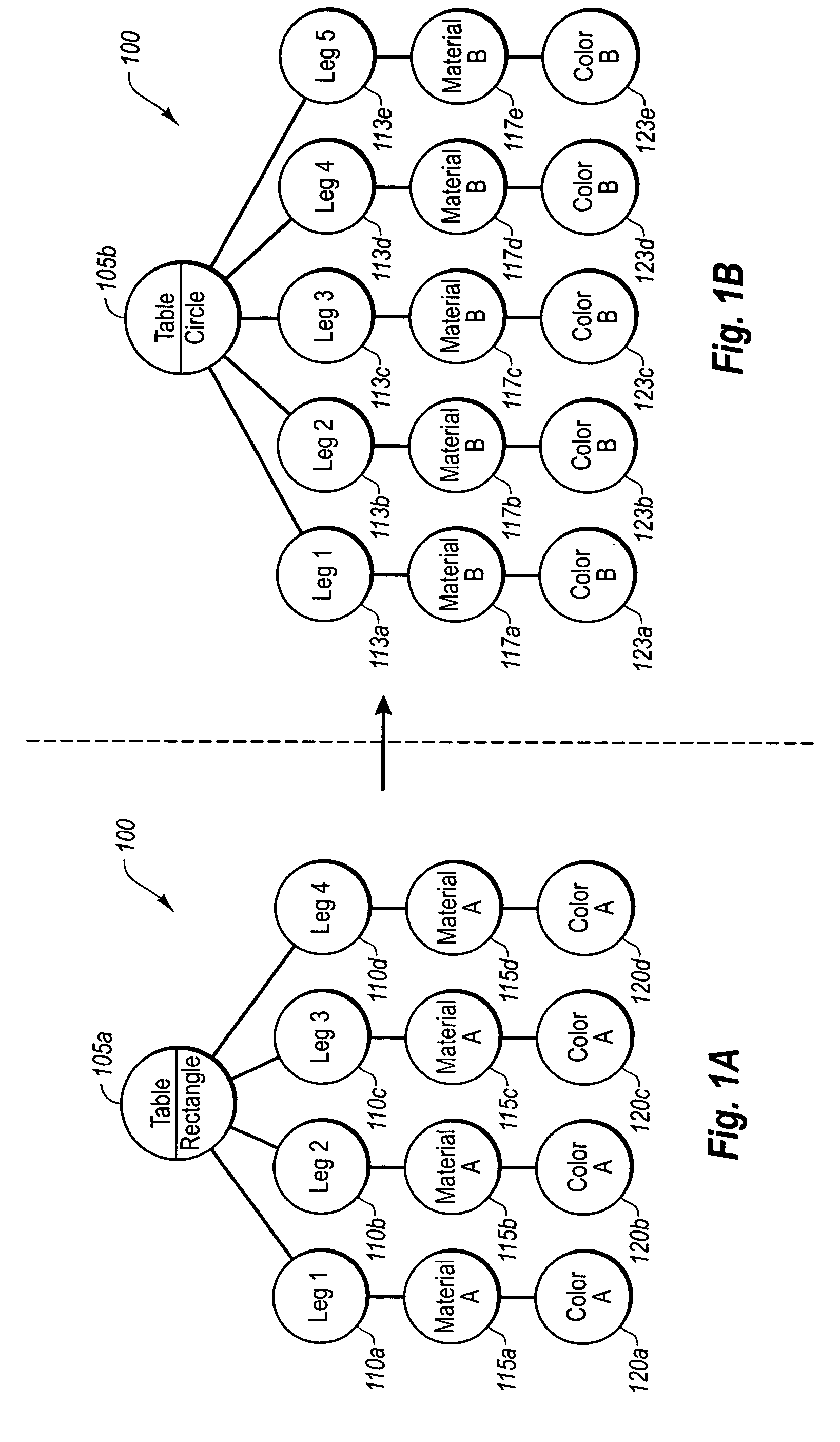

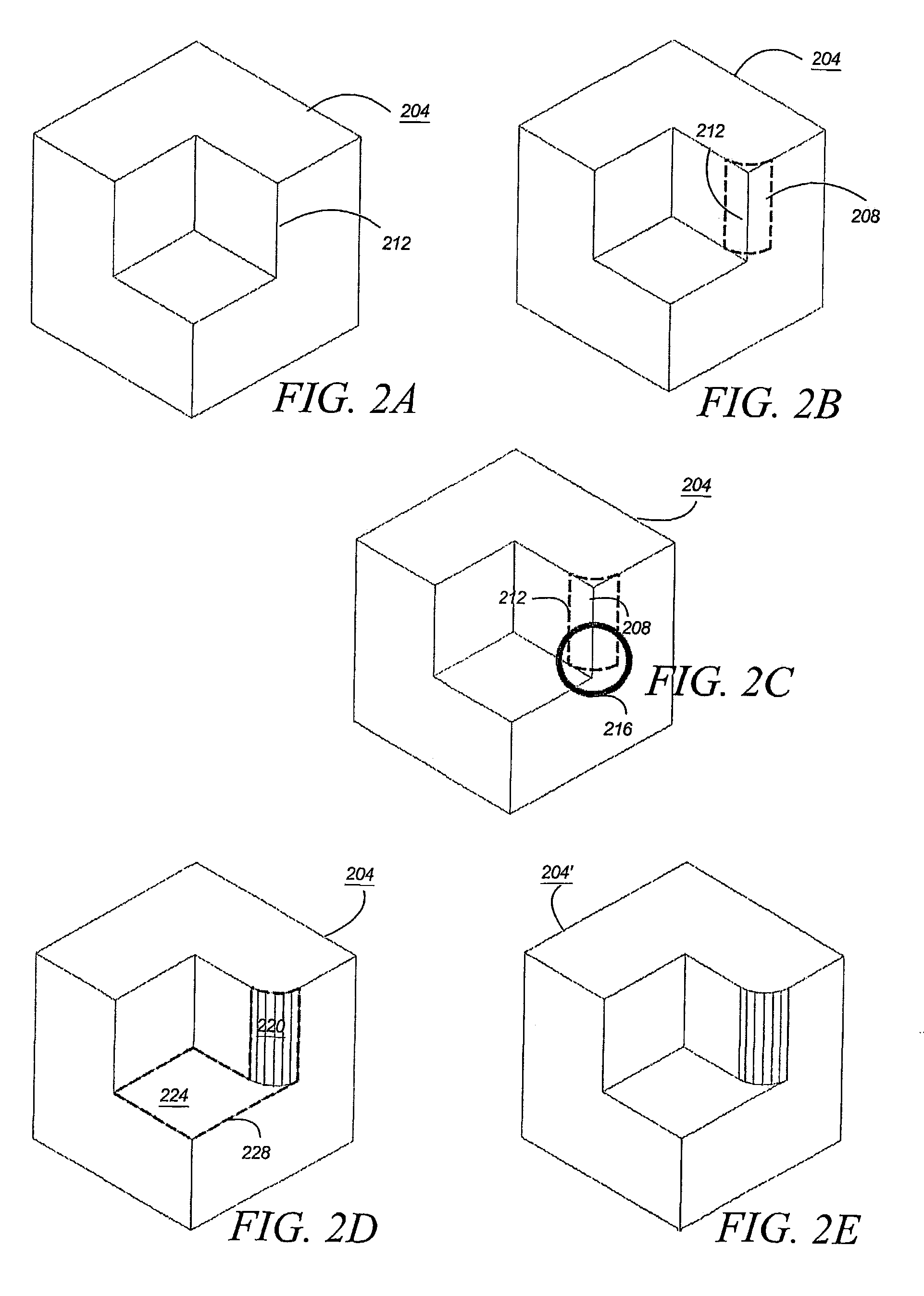

Method and system for designing objects using design intent merge

ActiveUS7155375B1Computation using non-denominational number representationComputer aided designFistDigital mockup

A method and apparatus for merging design intent of multiple designers with respect to a digital model of an object are described. In one embodiment, the method includes receiving data concerning a change to the digital model performed by a fist designer. The method further includes analyzing the data concerning the change performed by the first designer and data concerning a digital model version created by a second designer, and integrating the change performed by the first designer into the digital model version created by the second designer.

Owner:IMPACTXOFT

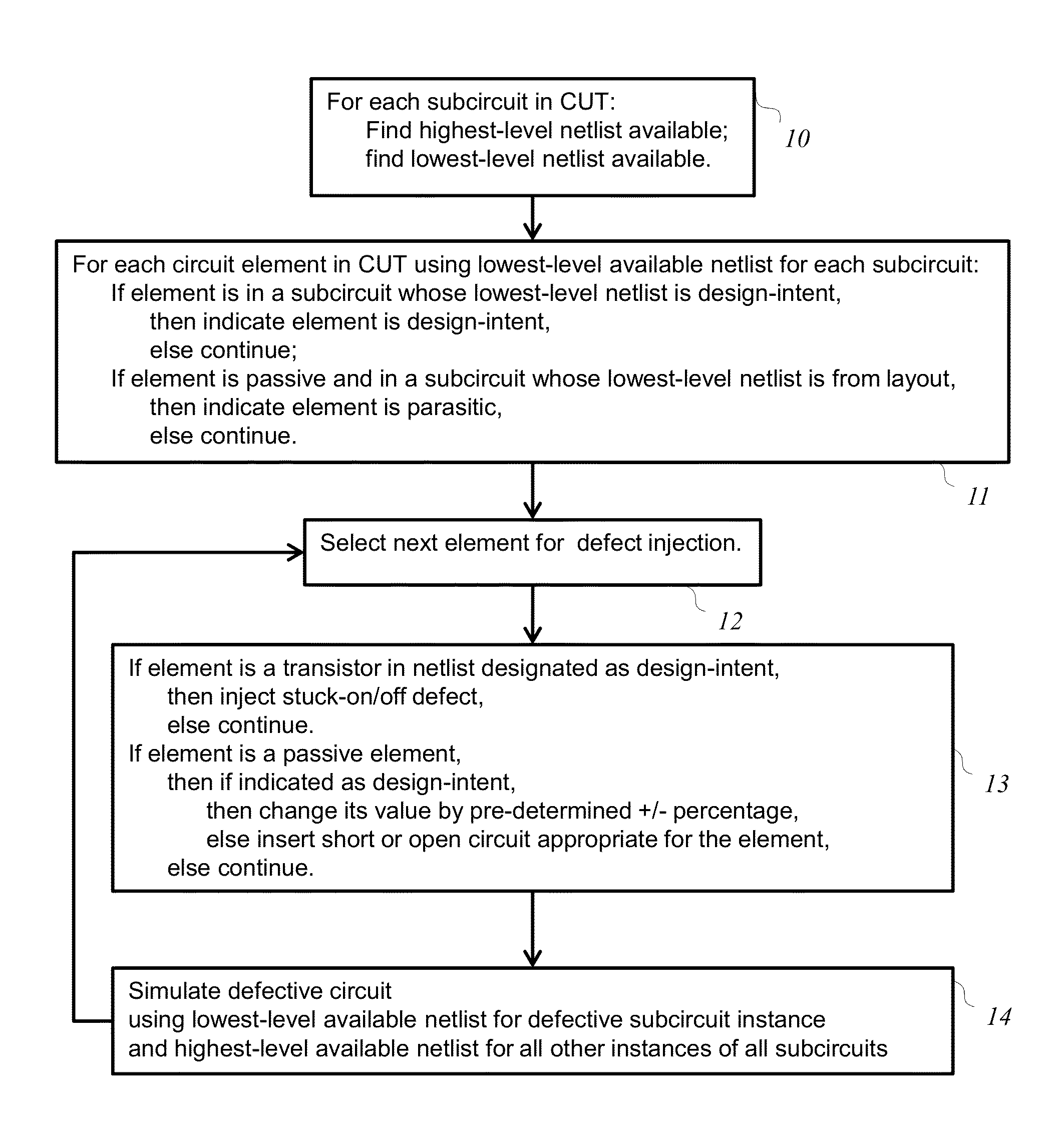

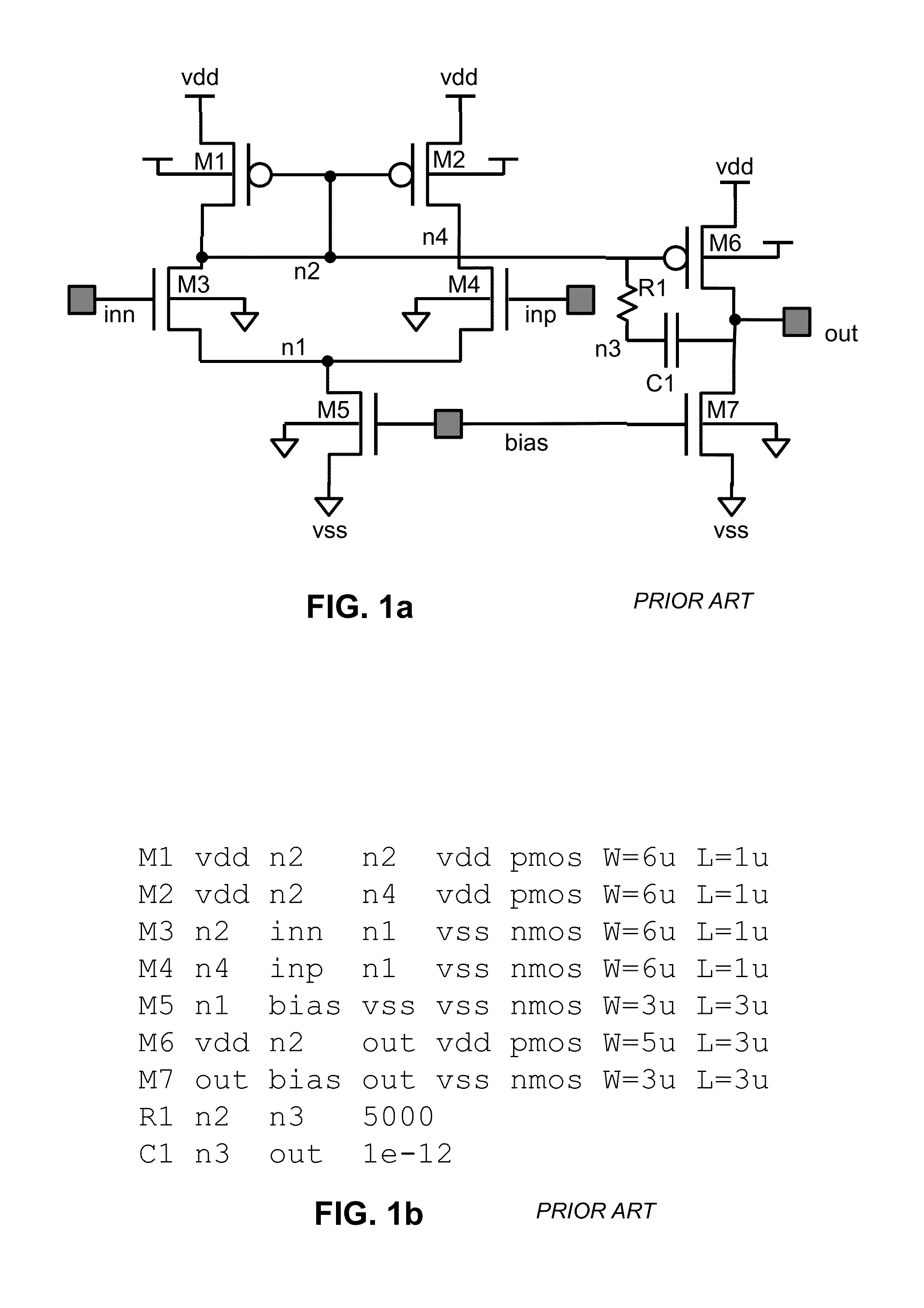

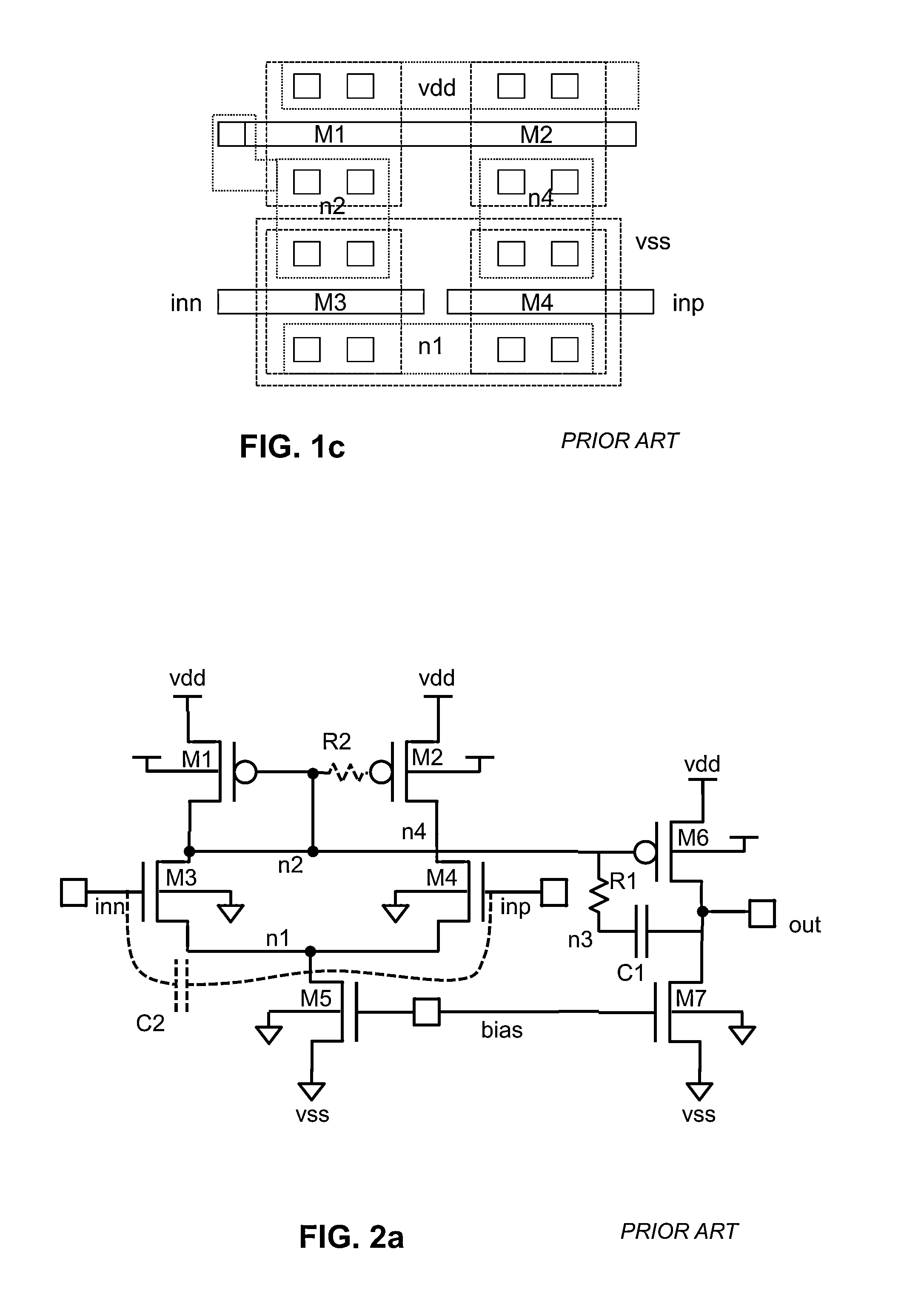

Defect Injection For Transistor-Level Fault Simulation

Aspects of the invention relate to techniques of defect injection for transistor-level fault simulation. A circuit element in a circuit netlist of a circuit is first selected for defect injection. Next, a defect is determined based on whether the selected circuit element is a design-intent circuit element or a parasitic circuit element. After the defect is determined, the defect is injected into the circuit netlist and then the circuit is simulated.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Laser scanner or laser tracker having a projector

A laser scanner or a laser tracker includes a light source that emits a light beam within an environment, and a data capture component that captures the light beam reflected back to the laser scanner or tracker from the environment. The laser scanner or tracker also includes a projector integrated within a body of the laser scanner or tracker or mounted to the body of the laser scanner or tracker at a predetermined location, the projector being operable to project visible information onto an object located within the environment, the projected visible information being indicative of images, data or information, the projected visible information being at least one of design intent information, information acquired by the laser scanner or tracker, or guidance to an operator.

Owner:FARO TECH INC

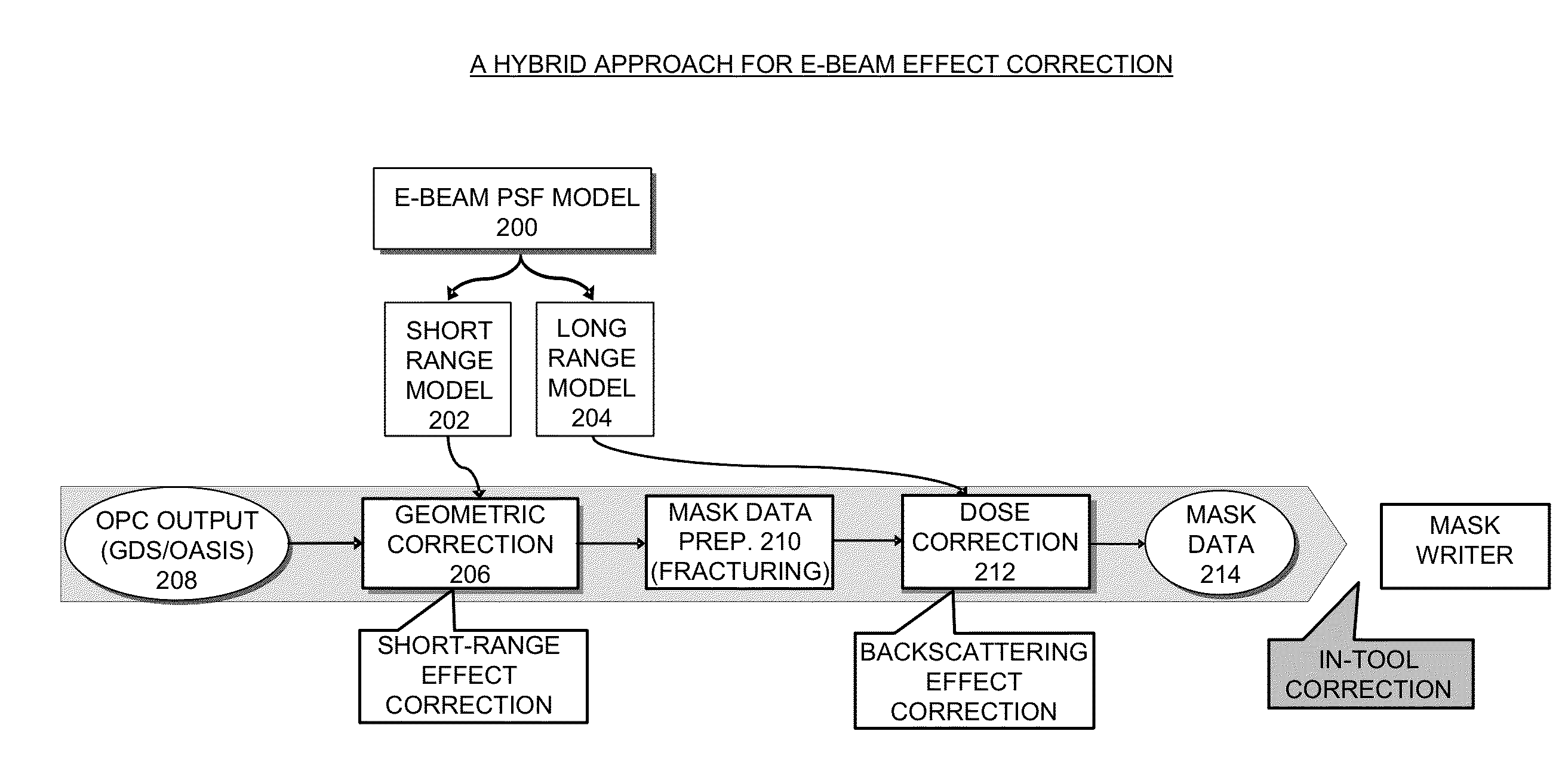

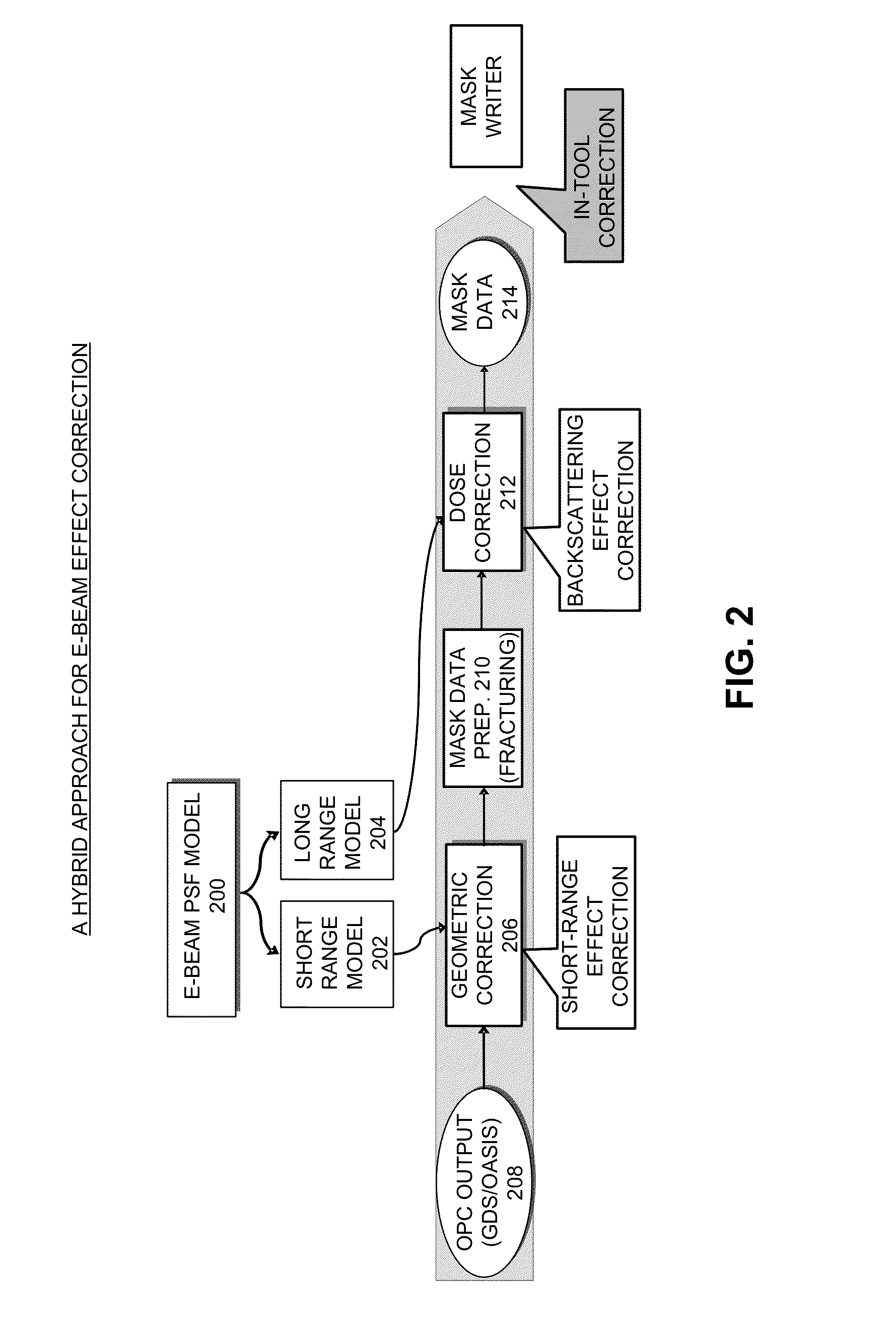

Modeling and correcting short-range and long-range effects in e-beam lithography

ActiveUS20140114634A1Increase weightReduce weightElectric discharge tubesAnalogue computers for electric apparatusLithography processLithographic artist

Processes and apparatuses are described for modeling and correcting electron-beam (e-beam) proximity effects during e-beam lithography. An uncalibrated e-beam model, which includes a long-range component and a short-range component, can be calibrated based on one or more test layouts. During correction, a first resist intensity map can be computed based on the long-range component of the calibrated e-beam model and a mask layout. Next, a target pattern in the mask layout can be corrected by, iteratively: (1) computing a second resist intensity map based on the short-range component of the calibrated e-beam model and the target pattern; (2) obtaining a combined resist intensity map by combining the first resist intensity map and the second resist intensity map; and (3) adjusting the target pattern based on the combined resist intensity map and the design intent.

Owner:SYNOPSYS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com