Integrated method for measurement and reconstruction of three-dimensional model and system thereof

A three-dimensional model and three-dimensional coordinate technology, which is applied in measurement devices, 3D modeling, stereo photography, etc., can solve the problems of low reconstruction model accuracy, high commercialization difficulty, and measurement accuracy impact, so as to simplify the reverse reconstruction process and avoid The effect of repeating the measurement and ensuring the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

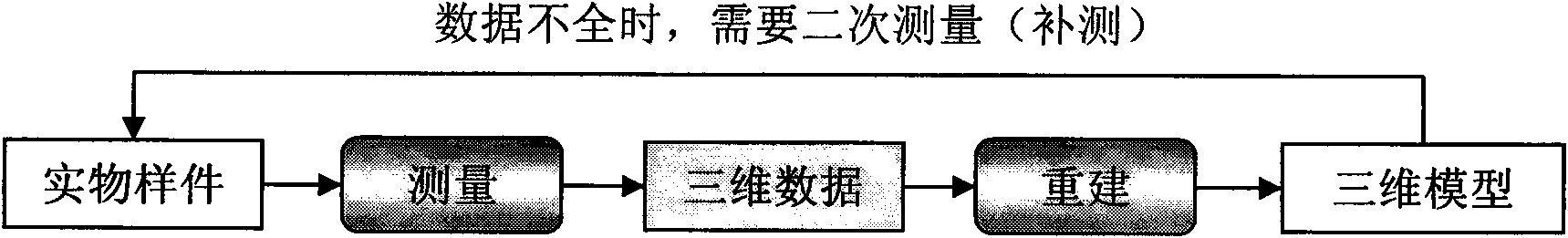

[0079] The present invention provides a method for integrating measurement and reconstruction of a three-dimensional model, which is special in that the method includes the following steps:

[0080] 1) Obtain the three-dimensional coordinates of the marked points on the surface of the physical sample;

[0081] 2) Interactively build a 3D model based on 3D coordinate points.

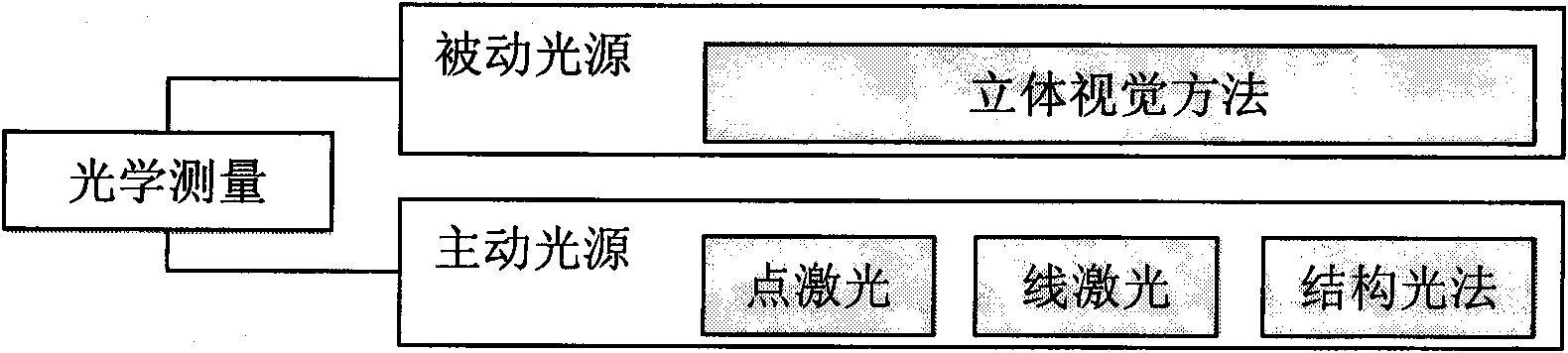

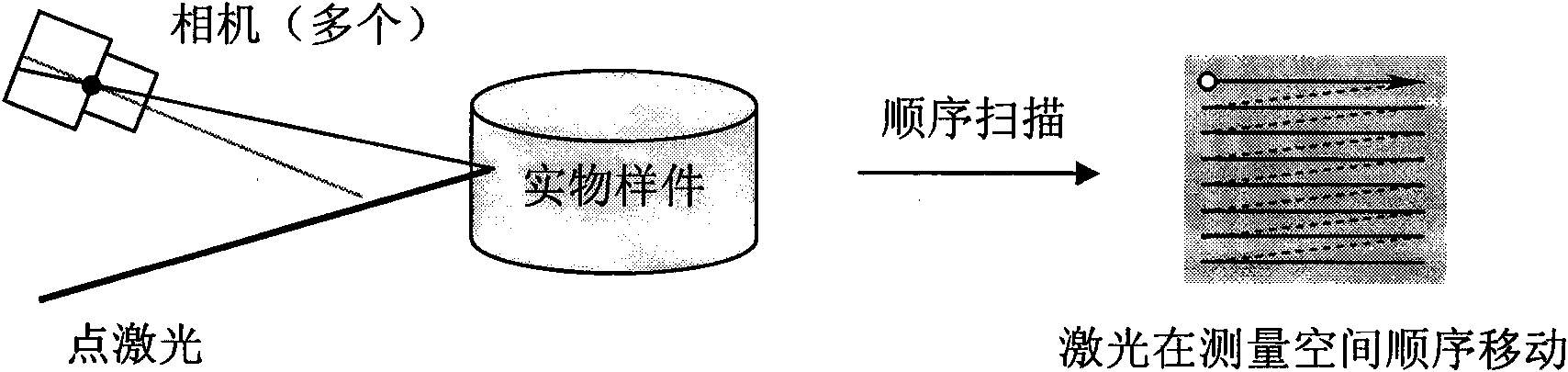

[0082] see Figure 9 a and 9b, the specific implementation of step 1 includes the following two methods: 1.1) a random control method of a single camera light source; and 1.2) a manual control method of a multi-camera light source.

[0083] In step 1.1), the random control of the light source means that the light source can point to any direction according to the given requirement.

[0084] The concrete implementation steps of step 1.1) are:

[0085] 1.1.1) Obtain a surface image of a physical sample through the camera;

[0086] 1.1.2) Interactively designate a two-dimensional pixel on the image obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com