Semiconductor device and method of manufacturing the same

A technology for semiconductors and devices, which is applied in the field of manufacturing semiconductor devices, can solve the problems of increased man-hours, etc., and achieve the effects of suppressing changes in coating thickness and suppressing the deterioration of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now, the present invention will be described herein with reference to exemplary embodiments. Those skilled in the art will recognize that many alternative embodiments can be accomplished using the teachings of the present invention and that the invention is not limited to the embodiments illustrated for explanatory purposed.

[0020] Embodiments of the present invention will be described below with reference to the accompanying drawings. Note that any similar components in all drawings will be denoted by like reference numerals or symbols, and descriptions thereof will not be repeated.

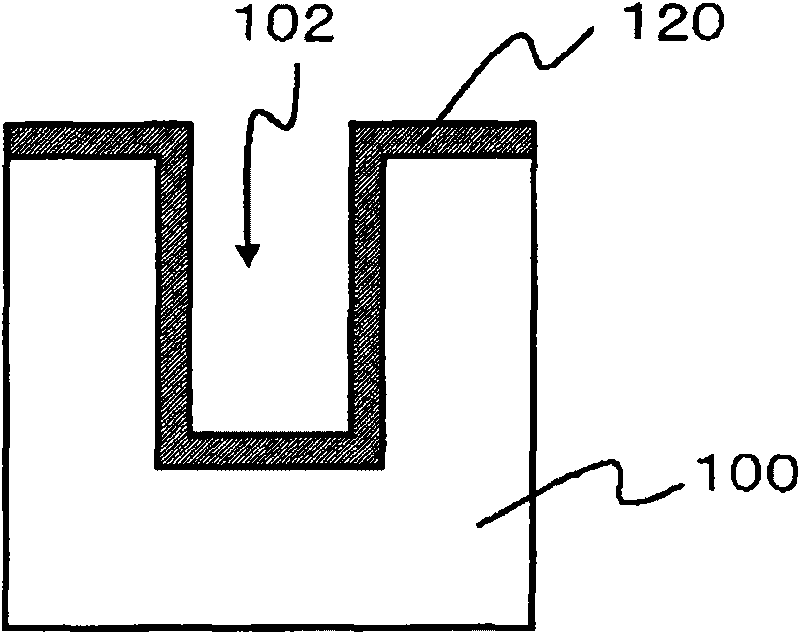

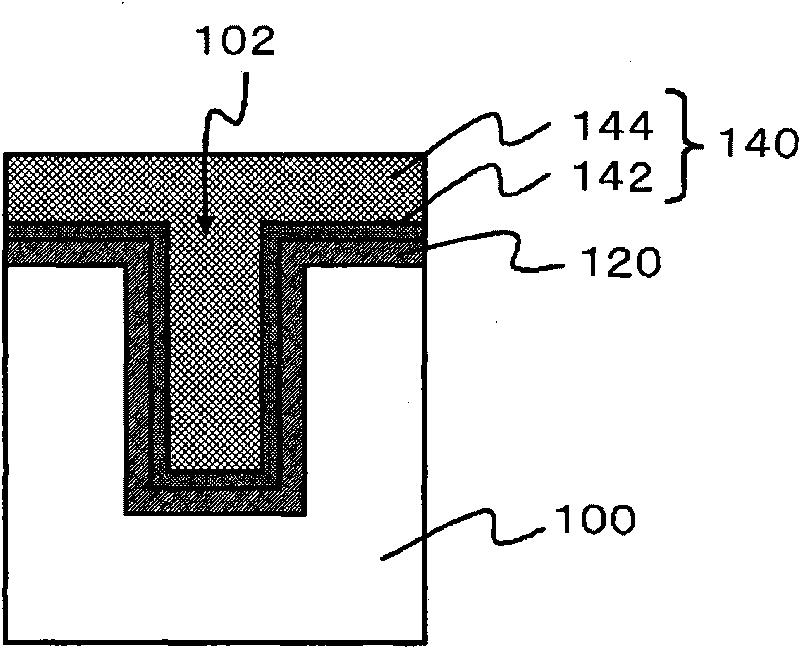

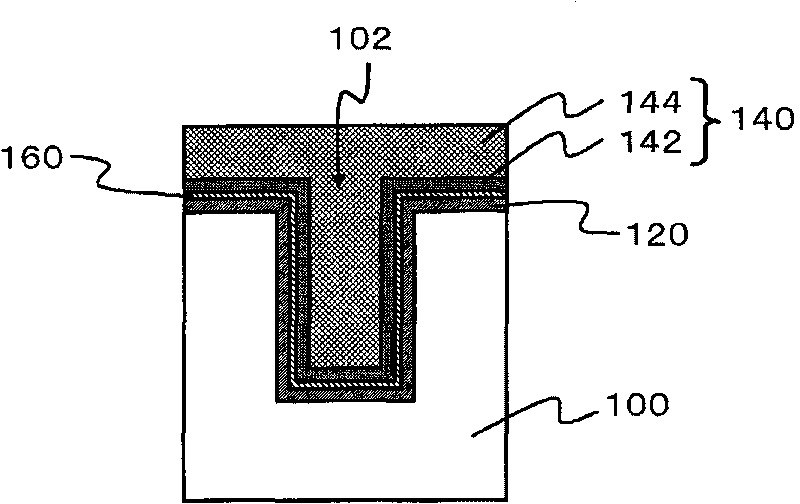

[0021] Figure 1A , Figure 1B , Figure 2A and Figure 2B is a cross-sectional view illustrating a method of manufacturing a semiconductor device according to the first embodiment. The method of manufacturing a semiconductor device has the steps described below. First, trench 102 is formed in insulating film 100 formed over a semiconductor substrate (not shown). Next, a barrier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com