Preparation of Notoginsen triterpenes injection

A technology of Panax notoginseng saponins and injection, which is applied in the field of preparation of Panax notoginseng saponins injection, can solve problems such as difficult control of technical parameters in production, inconsistent adsorption of active ingredients, and fluctuating product yields. Achieve the effects of environmental protection, easy operation and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

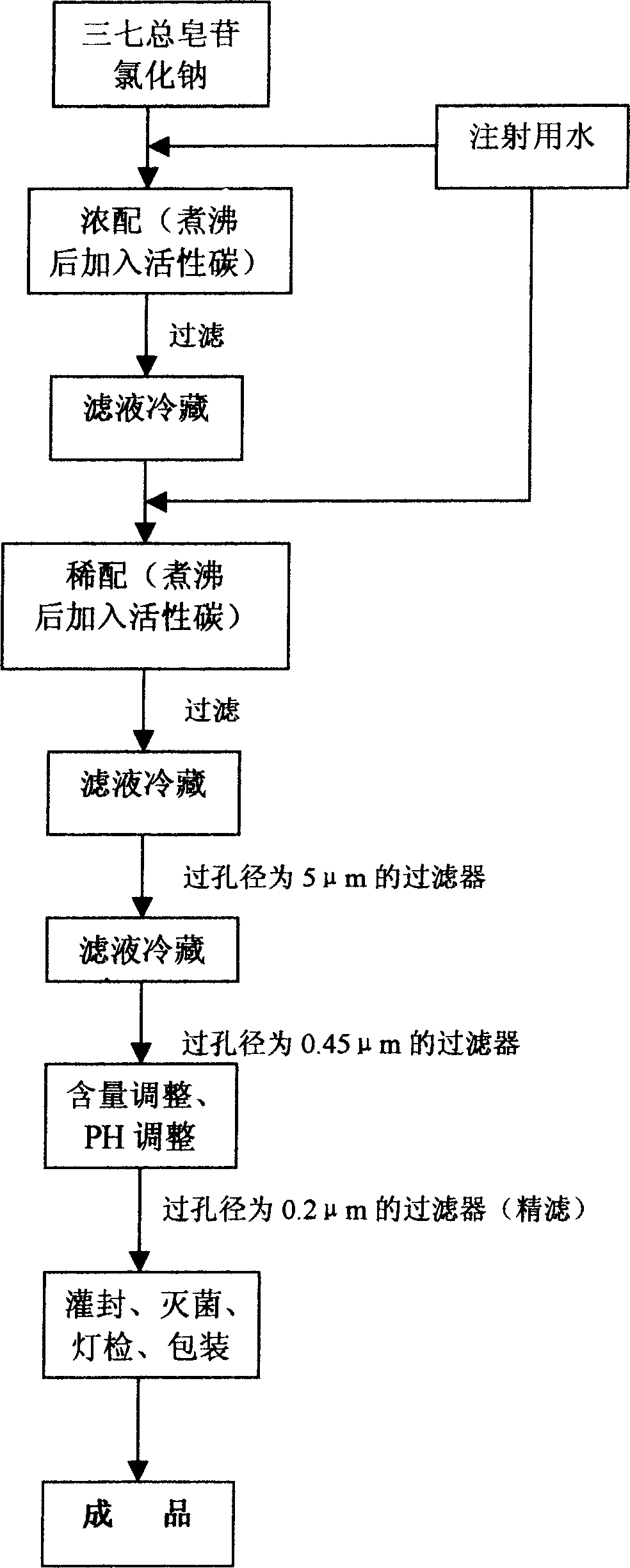

Method used

Image

Examples

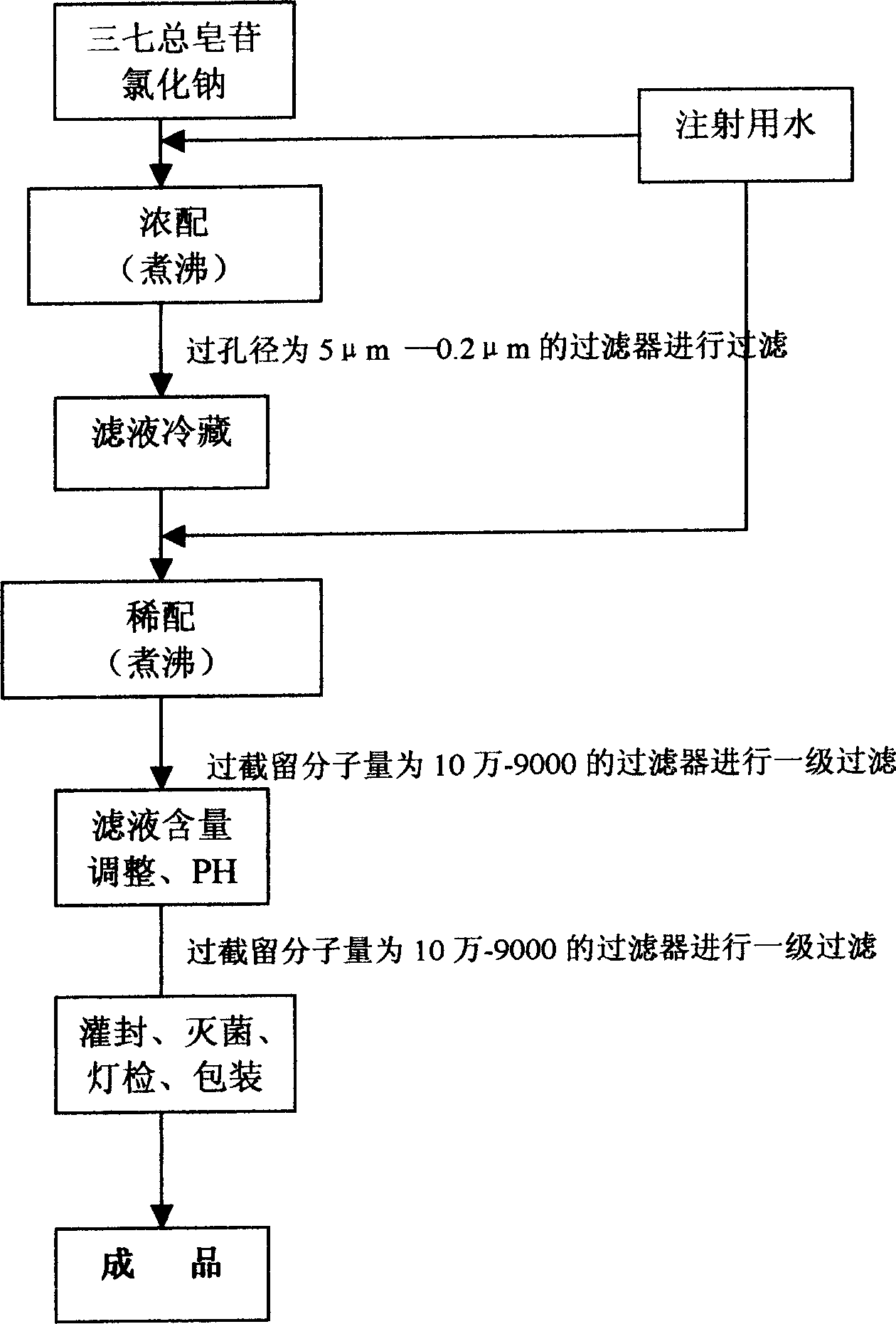

Embodiment 1

[0046]Take 100 g of Panax notoginseng saponins, 9 g of sodium chloride, add 1000 ml of water for injection, stir evenly, heat and boil for 20 minutes, cool the medicinal solution to 50° C., and filter through microporous membranes with pore diameters of 5 μm and 0.2 μm respectively (microporous filter) The membrane is a ceramic membrane material with a molecular weight cut-off of 100,000); the filtrate was refrigerated at 1°C for 5 hours, diluted with water for injection to 3 times the original liquid and boiled, cooled to 15°C, and filtered through one stage respectively ( This filtration is ultrafiltration, membrane material is polysulfone, molecular weight cut-off 80,000), adjusts filtrate content to be 55%, pH value is 6, passes one-stage filtration (this one-stage filtration is that ultrafiltration membrane material is polyacrylonitrile, cut-off Molecular weight 10,000); Fill into 10ml ampoule bottle, seal, sterilize, pack, and obtain the finished product.

Embodiment 2

[0048] Take 100g of Panax notoginseng total saponins, 9g of sodium chloride, add 1000ml of water for injection, stir evenly, heat and boil for 8 minutes, cool the medicinal solution to 50°C, and filter through a 0.45 μm microporous membrane (the microporous membrane is a ceramic membrane material, The membrane molecular weight cut-off is 100,000); the filtrate was refrigerated at 1°C for 6 hours, diluted with water for injection to 3 times of the original medicinal liquid, boiled, cooled to 30°C, and subjected to primary filtration respectively (this secondary filtration is ultra- After filtration, the membrane material is polyamide, and the membrane molecular weight cut-off is 60,000), adjust the filtrate content to be 78%, and the pH value is 6.5, and pass through secondary filtration (this secondary filtration is ultrafiltration, and the membrane material is cellulose diacetate, membrane Molecular weight cut off 9000); Fill into 10ml ampoule bottle, seal, sterilize, pack, ob...

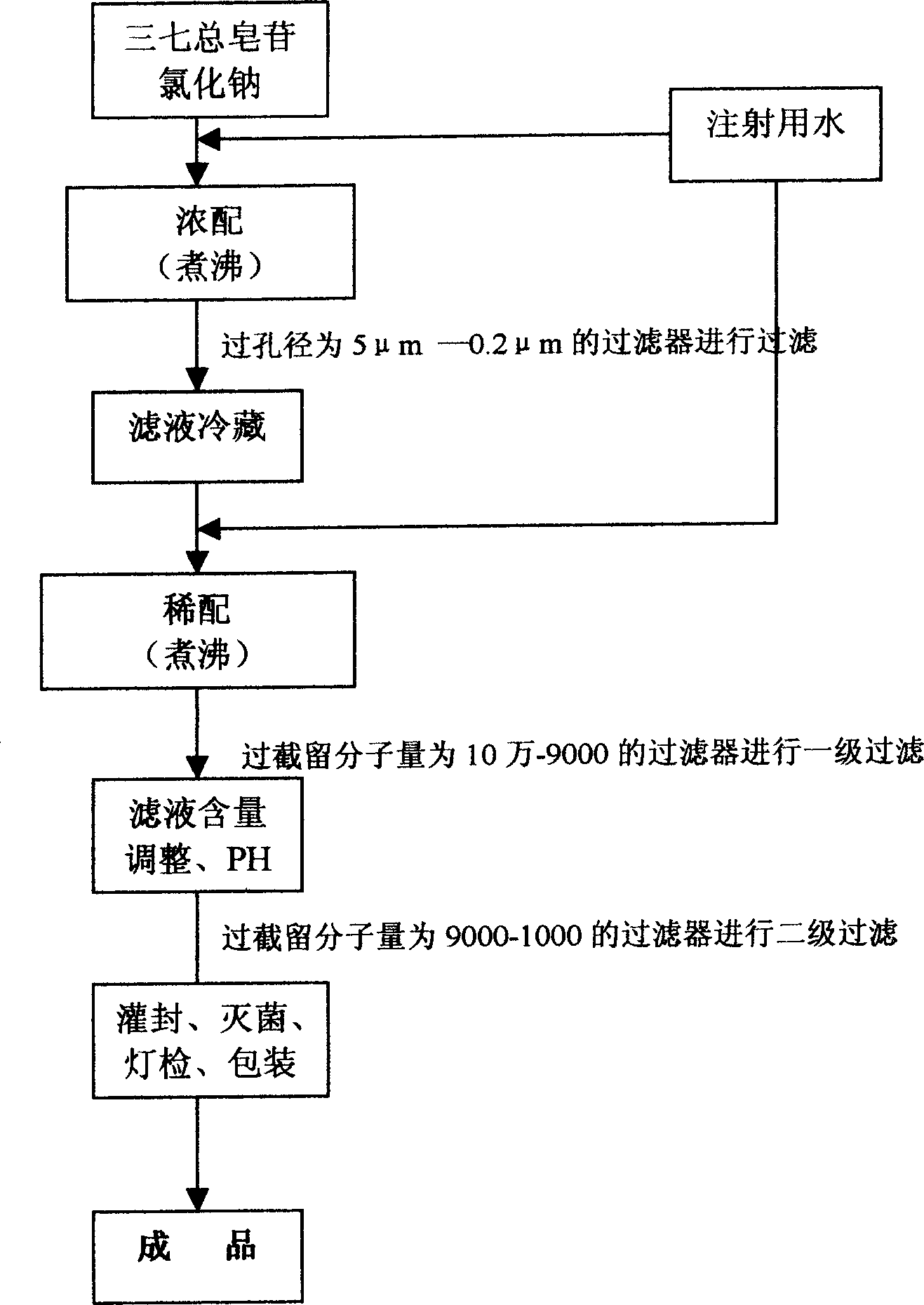

Embodiment 3

[0050] Take 100g of Panax notoginseng saponins, 9g of sodium chloride, add 1000ml of water for injection, stir evenly, heat and boil for 5 minutes, cool the liquid to 55°C, filter through a 0.2 μm microporous membrane (the microporous membrane is a ceramic membrane material, The membrane molecular weight cut-off is 100,000); the filtrate was refrigerated at 4°C for 4 hours, diluted with water for injection to 3 times of the original liquid and boiled, cooled to 20°C, and passed through a stage of filtration respectively (this stage of filtration is ultra- Filter, membrane material is polyamide membrane, molecular weight cut-off 10,000), adjust filtrate content to be 80%, pH value is 6.1, pass secondary filtration (this secondary filtration is ultrafiltration, membrane material is protein membrane, molecular weight cut-off 4000) Fill into 10ml ampoule bottle, seal, sterilize and pack to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com