Cylindrical gearbox mechanical closed test bench suitable for any center distance

A gear box, closed technology, applied in the field of cylindrical gear box mechanical closed test bench, to achieve the effect of convenient use, solid theoretical basis, operability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

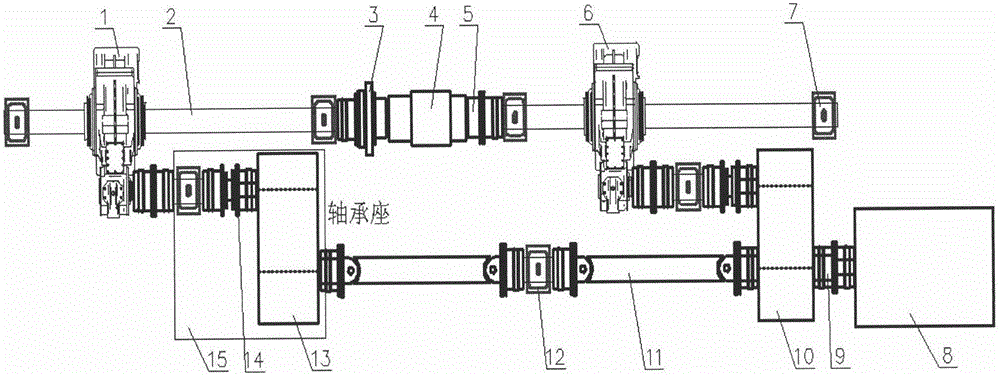

[0009] The specific implementation method is: take the tested gearbox 1 as the core, arrange 1 and the accompanying gearbox 6 in the same direction, and connect the shaft 2 and the torque meter 3 sequentially through different couplings 5 between the two large gear shafts and the hydraulic torque loader 4; the two connecting gear boxes 10 and 13 are also arranged in the same direction, and the two pinion shafts are respectively connected with the pinion shafts of 6 and 1 through couplings, and the ends of the shafts are provided with bearing seats 1, 7, etc., between the large gear shafts of 10 and 13, there are cardan shafts 11, couplings and bearing housings 2 12 in sequence; between the small shafts of 1 and 13, torque meter 2 14 and couplings are connected, 13, 14 and the bearing seat are located on the cross slide 15; the second coupling 9 connects the large gear shaft of 10 and the drive motor 8 to form a mechanically enclosed gearbox test bench.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com