Demoulding method for metal template and cement product

A technology of metal formwork and cement products, which is applied in the processing of formwork, formwork/formwork components, and on-site preparation of building components, which can solve the problems of consumption management, mechanical and human resources, air, groundwater source environmental pollution, impact Operators' health and other issues, to achieve the effect of strong versatility, guarantee of inherent strength and quality, and improvement of labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

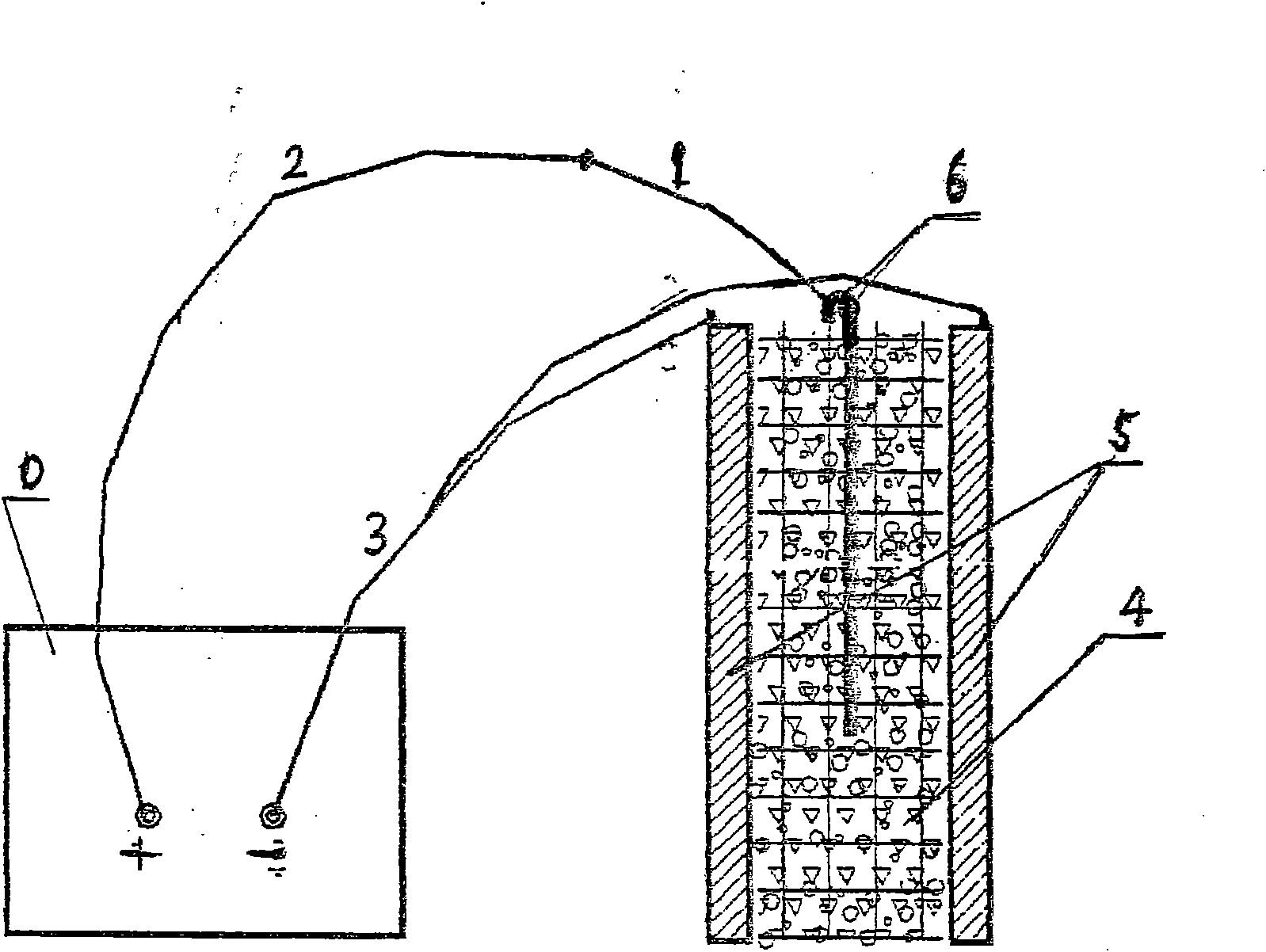

[0023] In the present invention, the metal steel formwork of a reinforced concrete wall of a commercial building in Beijing and the automatic demoulding treatment method for the surface of cast-in-place concrete cement products are realized in this way:

[0024] 1. Arrangement of electrode rods: When the steel grid is bound and formed, insert the electrode rods made in advance into the middle part of the wall thickness direction of the steel grid, and fix them at an appropriate distance to complete the arrangement of the electrode rods.

[0025] 2. Wire group connection: Before the wall concrete is poured, the branch wire is drawn out from the top of the electrode rod with a wire. Connect the lead wires of the electrode rods in groups and lead out the grouping wires.

[0026] 3. The connection between the power output terminal of the special power supply equipment and the wire: connect the group wires together through two main wires. Connect the electrode rod and the positive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com