Motor rotor iron core potting lamination device and potting method

A pressing device and rotor core technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of reducing and easily entering the performance of the rotor core between the core punching sheets, and achieve The overall structure is simple, the effect of locking and pressing is good, and the effect of preventing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

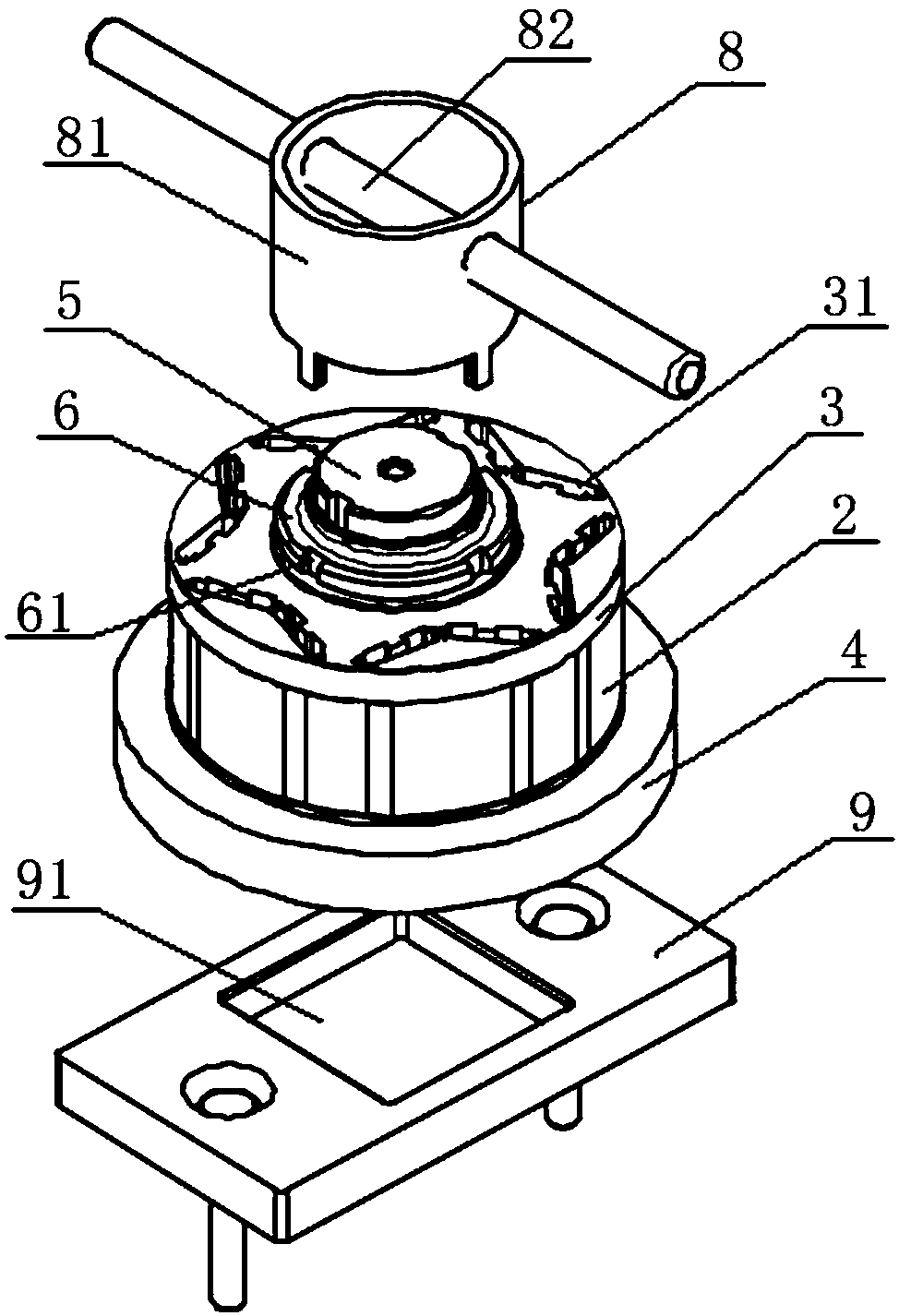

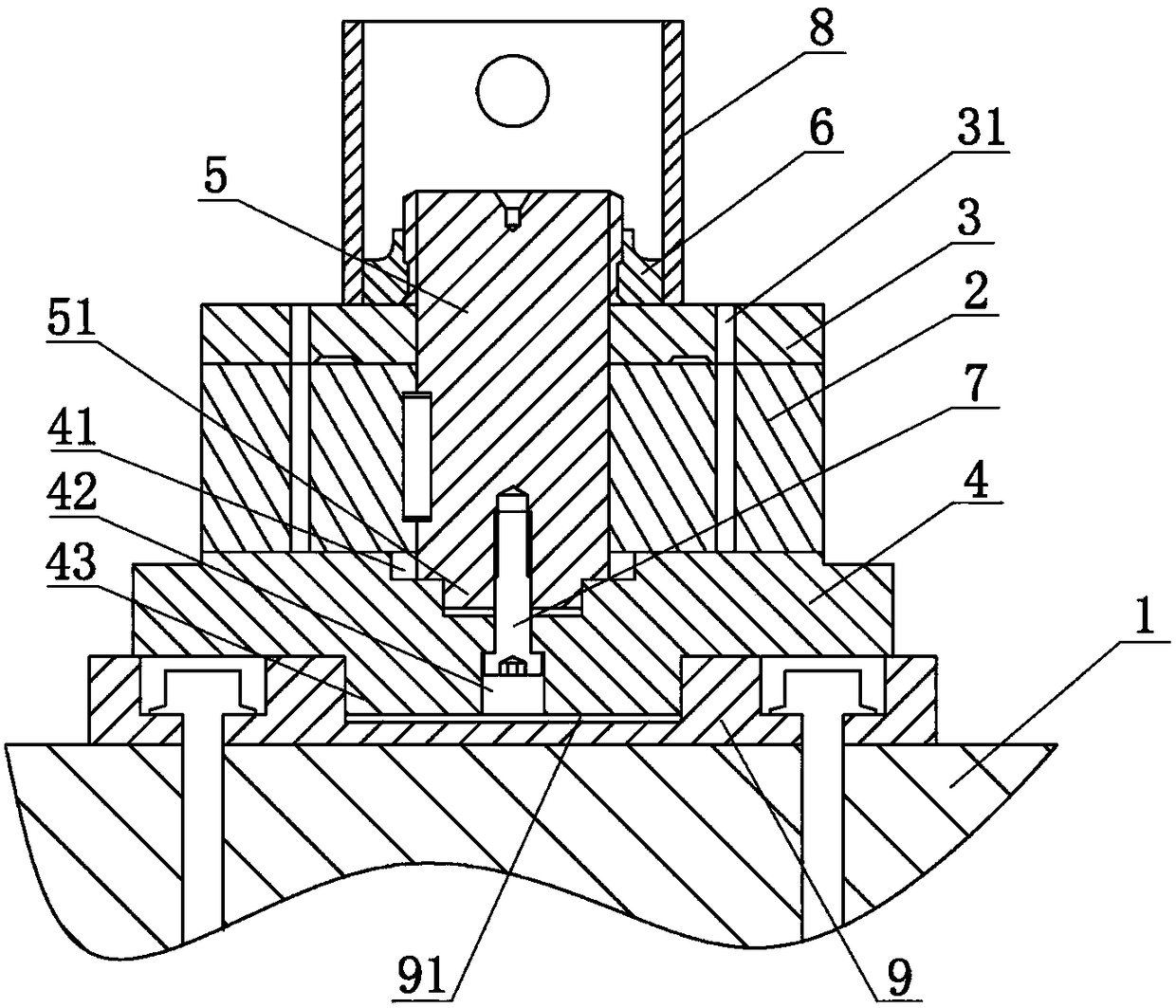

[0030] Concrete embodiment of the present invention is: as figure 1 , figure 2 As shown, a motor rotor core glue filling and pressing device is placed on the operating platform 1, including a cover plate 3 and a base 4 respectively arranged on the upper and lower end faces of the rotor core 2, and positioned in the rotor core 2 and The cover plate 3 and the base 4 are locked and connected to the connecting shaft 5. The cover plate 3 is provided with a glue injection groove 31 communicating with the magnetic steel groove of the rotor core 2. The notch area of the glue injection groove 31 is not larger than the magnetic steel groove The area of the notch avoids the unevenness of the end surface of the rotor core 2 caused by the potting glue flowing to the end surface of the rotor core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com