Replaceable removal tool structure

A technology for dismantling tools and tool bodies, applied in hand-held tools, manufacturing tools, etc., can solve the problems of reducing work efficiency, increasing working hours, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

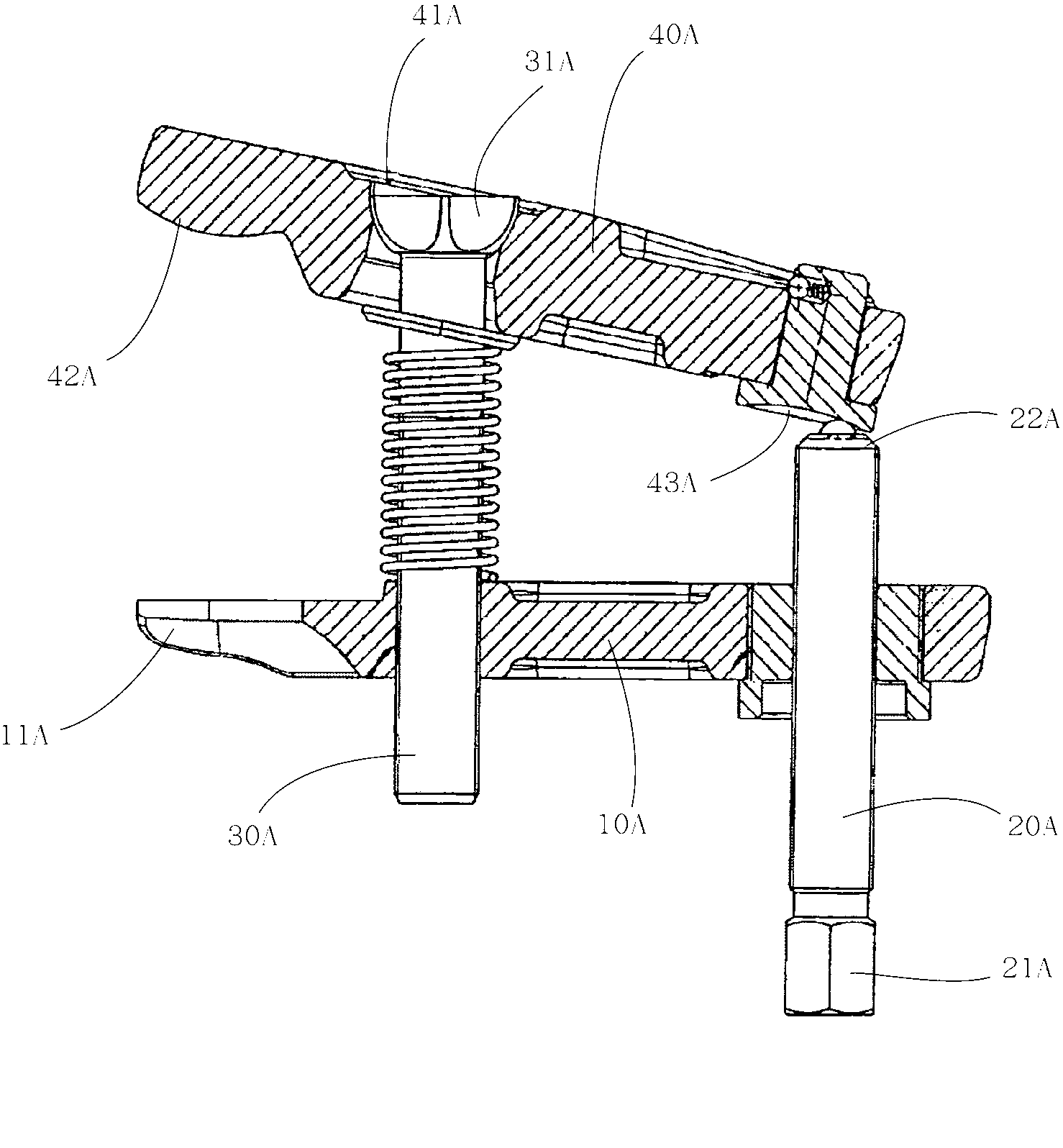

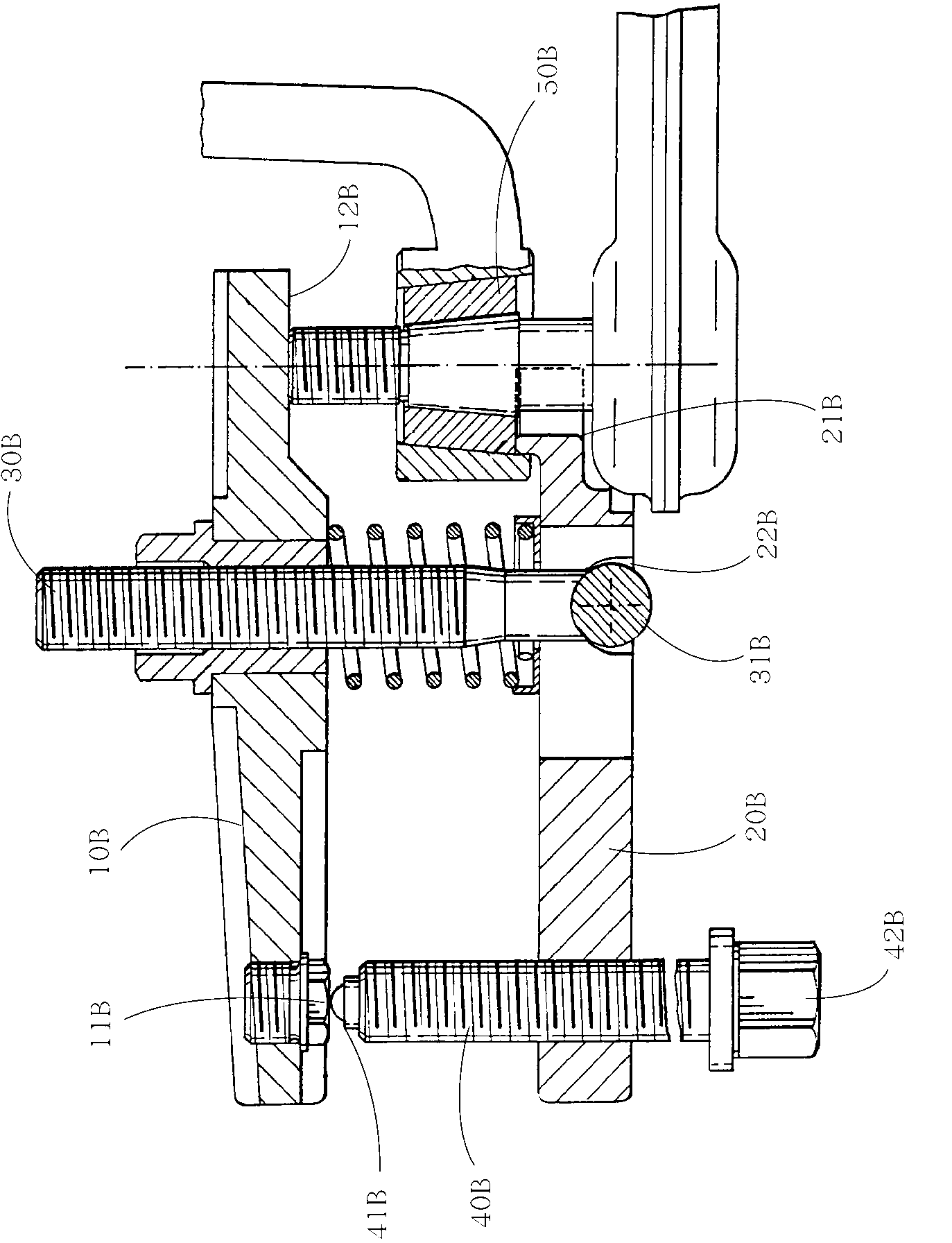

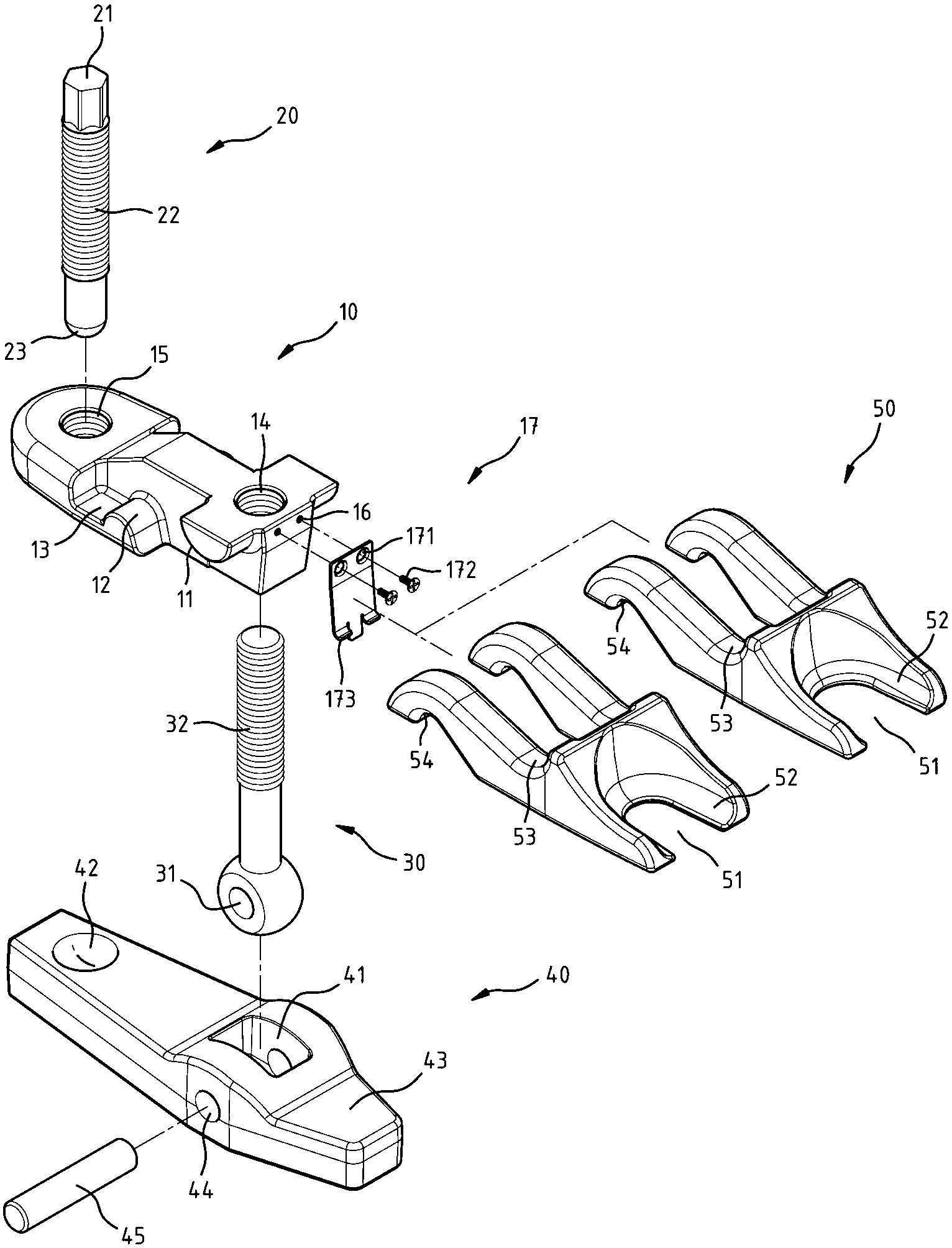

[0027] see Figure 3 ~ Figure 6 Shown is a preferred embodiment of the structure of the replaceable removal tool of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in the patent application.

[0028] The replaceable demounting tool structure of the present invention comprises:

[0029] A tool body 10, which is assembled with an adjusting screw 20 as a lead screw at one end, wherein one end of the adjusting screw 20 is provided with a driving end 21, the other end is provided with a top end 23, and the other end of the tool body 10 is fixed with a longitudinal strut 30, wherein the predetermined position of the tool body 10 is provided with a fixed hole 14 in the form of an internal thread, and the support rod 30 is provided with a fixed portion 32 in the form of an external thread corresponding to the fixed hole 14, so that the support rod 30 can be The relative screw lock is fixed on the tool body 10, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com