Assembling structure of diode of rectifier and heat-radiating plate for automotive

A technology for automotive rectifiers and assembly structures, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device parts, etc., can solve the problems of complex sintering process, influence of diode chips, and high chip damage rate, so as to shorten working hours and reduce The effect of scrap rate and improvement of production efficiency

Inactive Publication Date: 2011-05-18

阚勇

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the high temperature and stress during sintering will affect the diode chip. After sintering, the chip damage rate is as high as 40%, and it must be reworked.

At the same time, the melting point of the solder paste is too low, and the rectifier will generate high temperature during operation, which will easily cause the sintered solder paste to melt, causing the product to fail suddenly and causing serious consequences to the customer terminal

This sintering method is complicated. It is necessary to apply solder paste on the fixed position of the heat sink first, then place the diode on the solder paste, and fix the position of the diode with a sintering fixture to prevent the diode from moving when the solder paste melts, and then put it into the tunnel for sintering. Furnace for sintering, this sintering process takes 15-20 minutes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

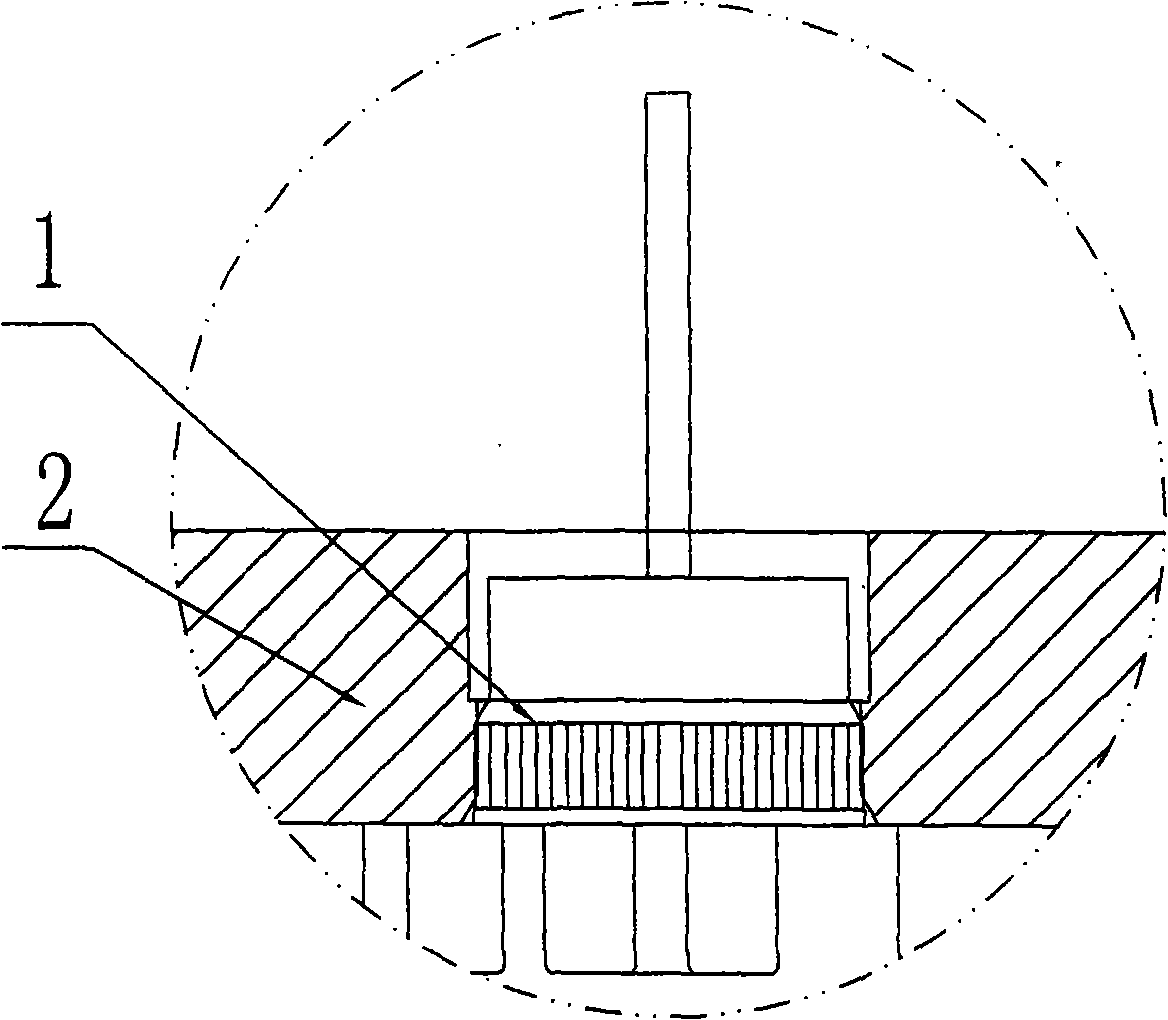

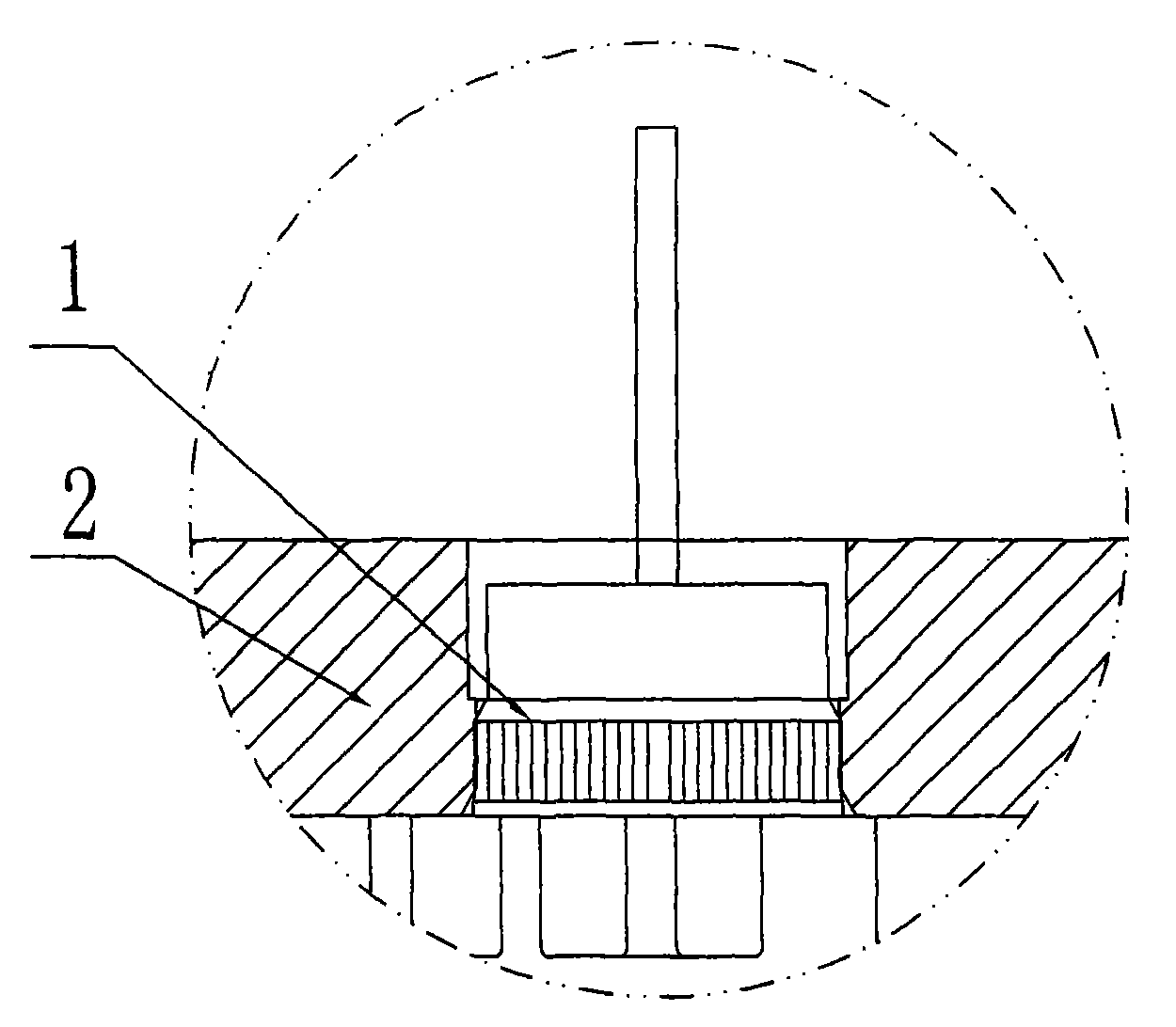

[0009] With reference to the accompanying drawings, the present invention includes that the heat dissipation plate (2) of the rectifier is made of die-cast aluminum, and the heat dissipation plate (2) is provided with through holes required for press fitting. The diode (1) adopts a copper base structure with straight lines on the circumferential surface. The diode (1) and the cooling plate (2) are press-fitted together through the through hole.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an assembling structure of a diode of a rectifier and a heat-radiating plate for an automotive, comprising the diode and the heat-radiating plate. The assembling structure is characterized in that the heat-radiating plate is provided with a through hole needed by press mounting; the diode adopts a copper base structure with a circumferential surface provided with straight lines; and the diode and the heat-radiating plate are pressed and mounted together in an interference way through the through hole. The invention has the advantages of effectively simplifying the process, reducing the defective index, also enhancing the heat-radiating effect of products and enhancing the reliability of the products.

Description

technical field [0001] The invention relates to an assembly method of an automobile rectifier diode and a heat dissipation plate of the automobile rectifier, in particular to an assembly structure of an automobile rectifier diode and a heat dissipation plate. Background technique [0002] The current VALEO series of dual-group automotive rectifiers are assembled with diodes and heat sinks by integral sintering, which is a complex production process with high costs and long working hours. This type of assembly requires the diode to be sintered to the heat sink. However, the high temperature and stress during sintering will affect the diode chip. After sintering, the damage rate of the chip is as high as 40%, and it must be reworked. At the same time, the melting point of the solder paste is too low, and the rectifier will generate high temperature during operation, which will easily cause the sintered solder paste to melt, causing the product to suddenly fail, causing seriou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L23/40H01L23/367H02M7/02

Inventor 阚勇

Owner 阚勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com