Grinding-bed static head rack capable of realizing accurate ultra micro-finishing

A technology of ultra-precision and static pressure head, which is applied to the parts of grinding machine tools, ultra-finishing machines, grinding/polishing equipment, etc., and can solve the problems affecting the improvement of the surface quality of the grinding wheel grinding workpiece and the surface contour of the grinding wheel grinding workpiece. Reduced precision, easy changes in bearing clearances, etc., to achieve the effect of reducing equipment materials, saving equipment production costs, and reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

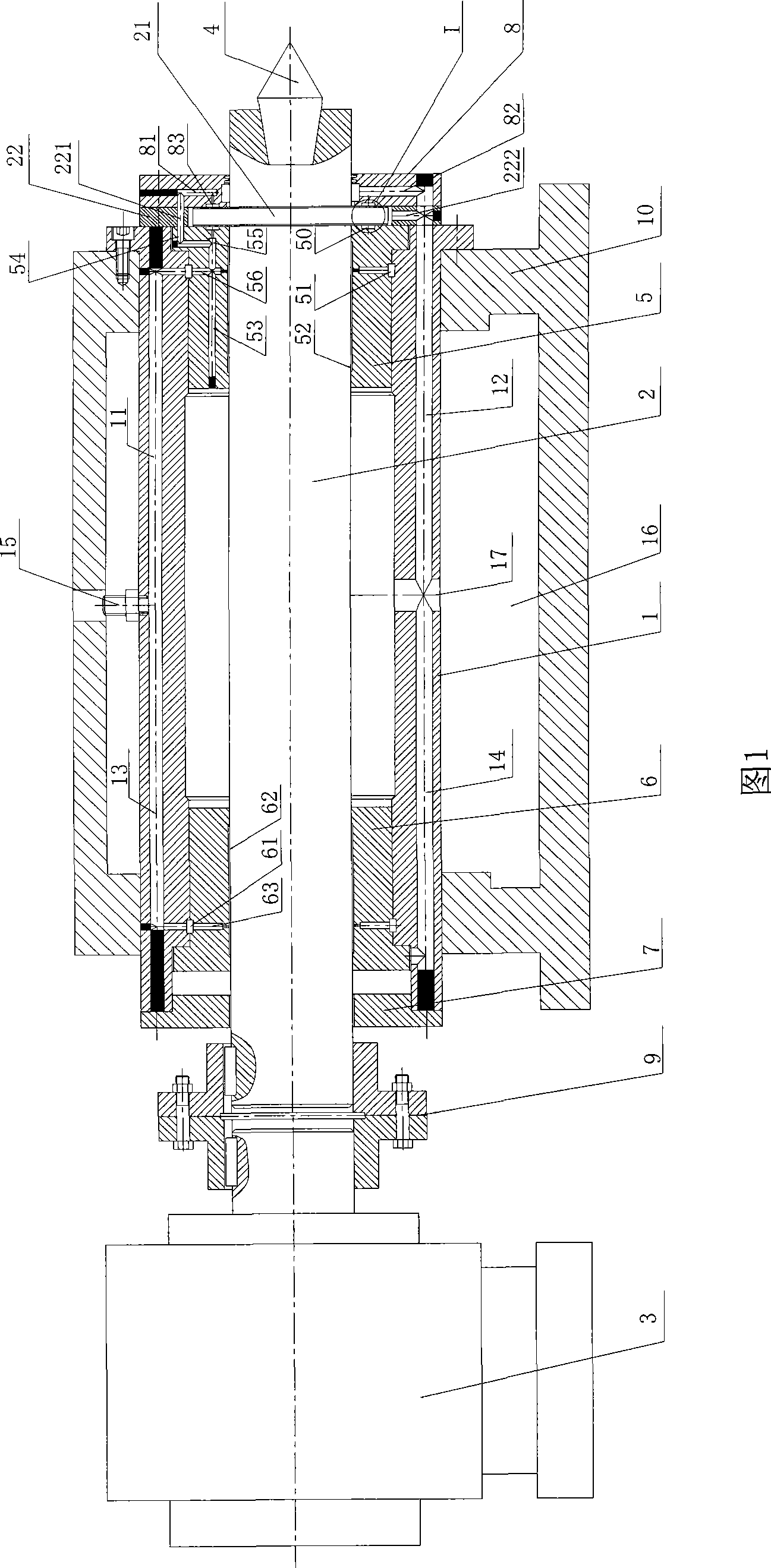

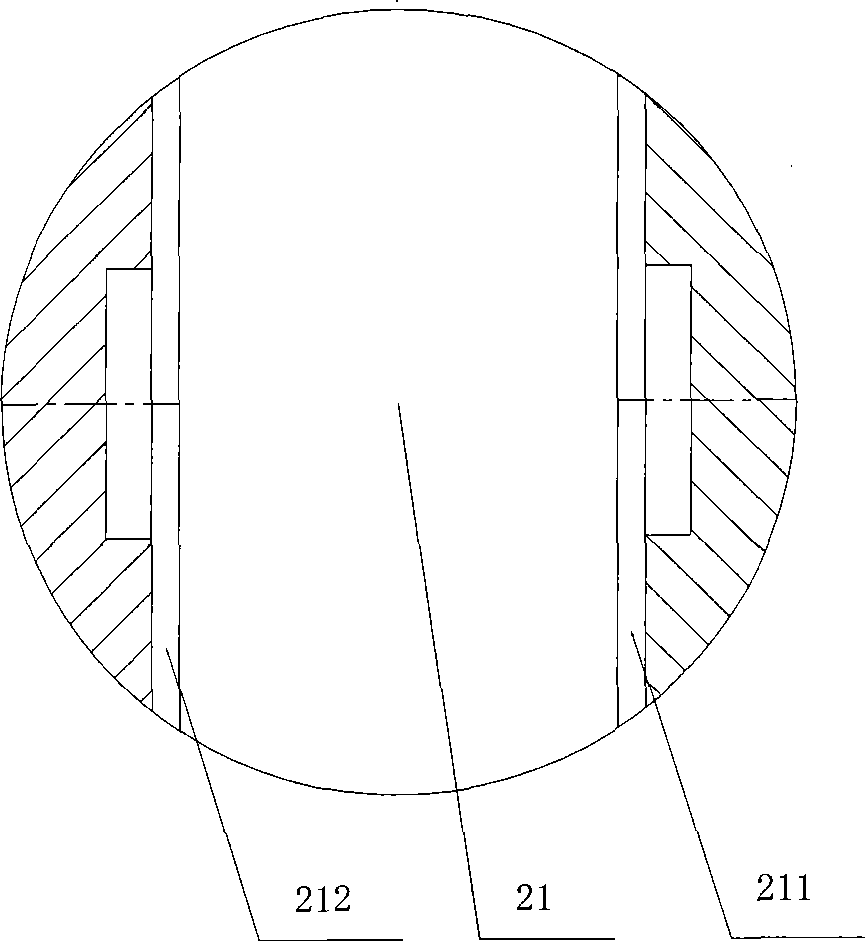

[0037] Embodiment 1: as shown in Figure 1, image 3 As shown, the static pressure head frame of the grinder that can realize precise ultra-precision grinding of the present invention includes a sleeve 1, a head frame spindle 2, a support box 10, a head frame motor 3 and a head frame top 4, and the head frame top 4 is installed Set at the front end of the headstock main shaft 2, the headstock motor 3 is directly connected to the rear end of the headstock main shaft 2 through the coupling 9, so as to reduce the space occupied by the equipment and reduce the cost of the equipment. The rear end of the sleeve 1 is equipped with a rear end cover 7, the front end of the sleeve 1 is equipped with a front end cover 8, and the sleeve 1 is provided with a forward liquid channel 11, a front liquid return channel 12, a rear liquid inlet channel 13, and a rear liquid return channel. The channel 14, the liquid supply channel 15 and the sleeve liquid return hole 17 located in the middle of the...

Embodiment 2

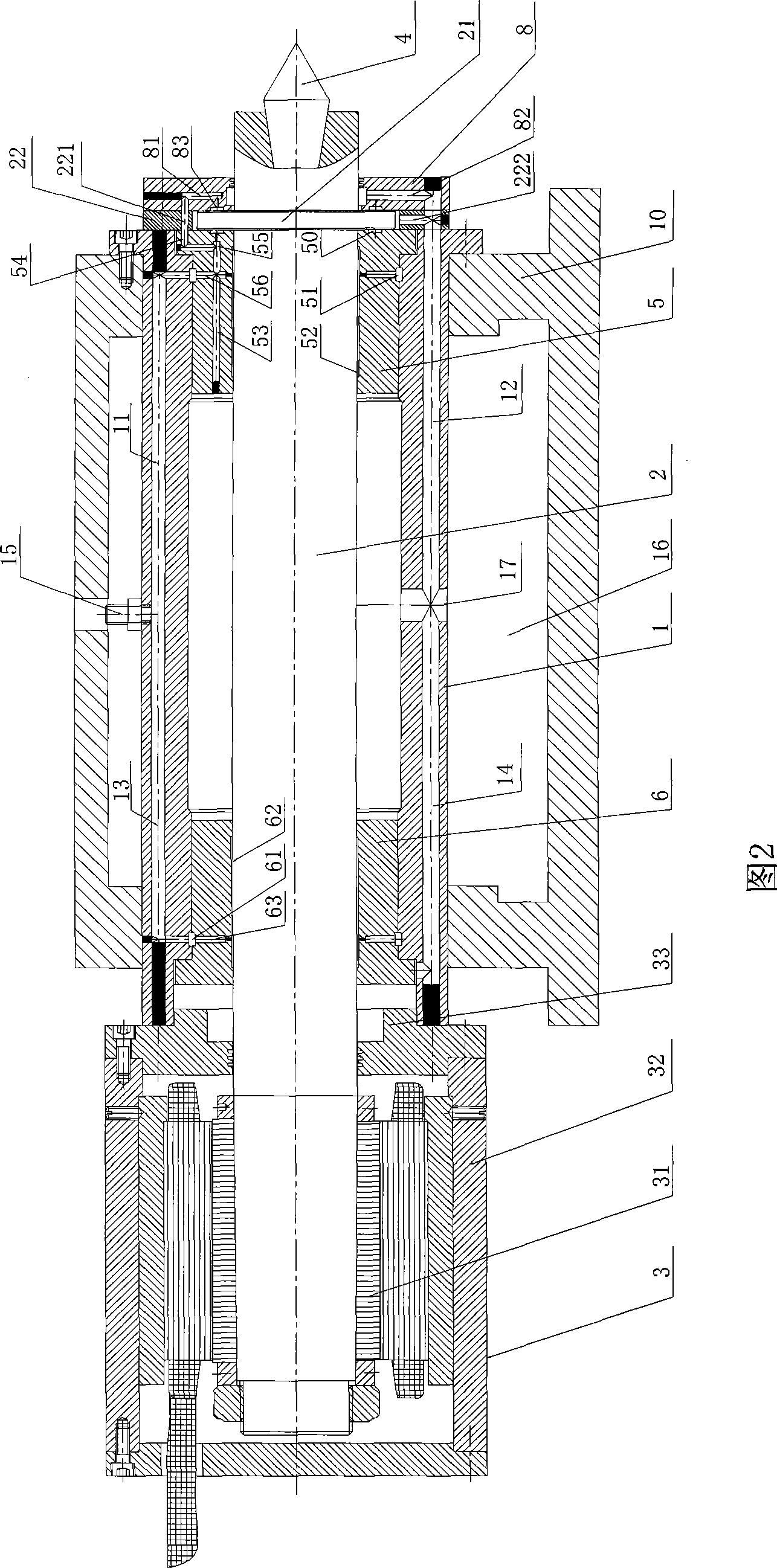

[0046] Embodiment 2: As shown in FIG. 2, the static pressure head frame of the grinder that can realize precise ultra-precision grinding of the present invention includes a sleeve 1, a head frame spindle 2, a support box 10, a head frame motor 3 and a head frame top 4. The headstock top 4 is installed at the front end of the headstock main shaft 2, the rear end of the headstock main shaft 2 is sheathed in the rotor 31 of the headstock motor 3, and the end of the headstock motor 3 close to the sleeve 1 is provided with a flange 33, and the headstock The stator shell 32 of the motor 3 is fixed on the sleeve 1 through the flange 33, and the function of the motor and the function of the headstock spindle 2 are structurally integrated, eliminating the need for complex intermediate transmission links, and having a compact structure and light weight. , small inertia, small vibration, low noise, fast response and so on. The front end of the sleeve 1 is provided with a front end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com