Automatic structure for regulating level part and preventing frame from opening of washing machine

An automatic adjustment and washing machine technology, which is applied in the field of washing machines, can solve the problems of staggering, the height of the automatic adjustment horizontal piece 100 is lowered, the automatic adjustment level piece 100 cannot work normally, etc., so as to ensure the normal operation and prevent the reduction of the working height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following description, the same parts as the conventional structure are used with Figure 1 to Figure 3 The same symbols as those in are indicated, and their detailed explanations are omitted.

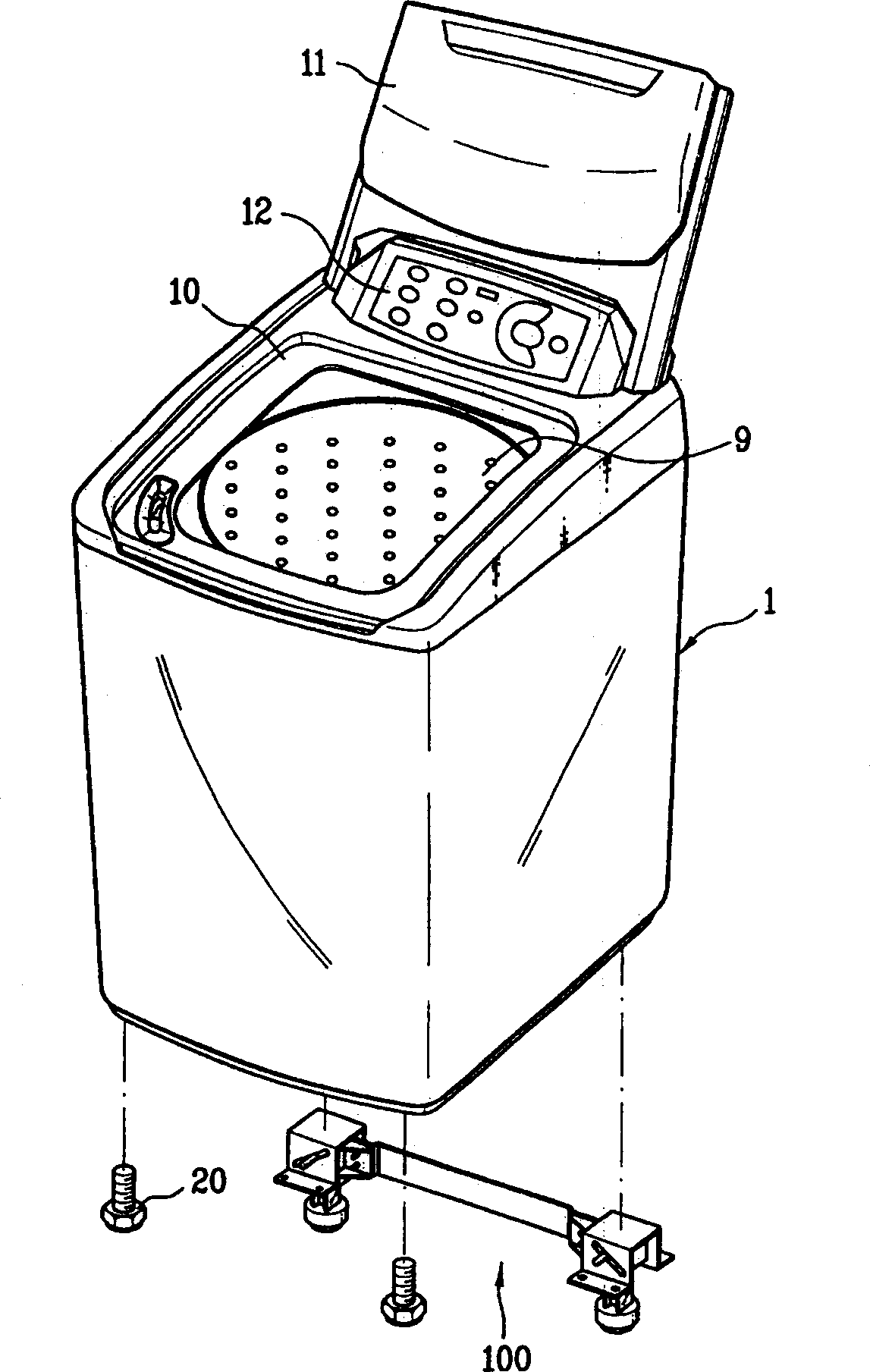

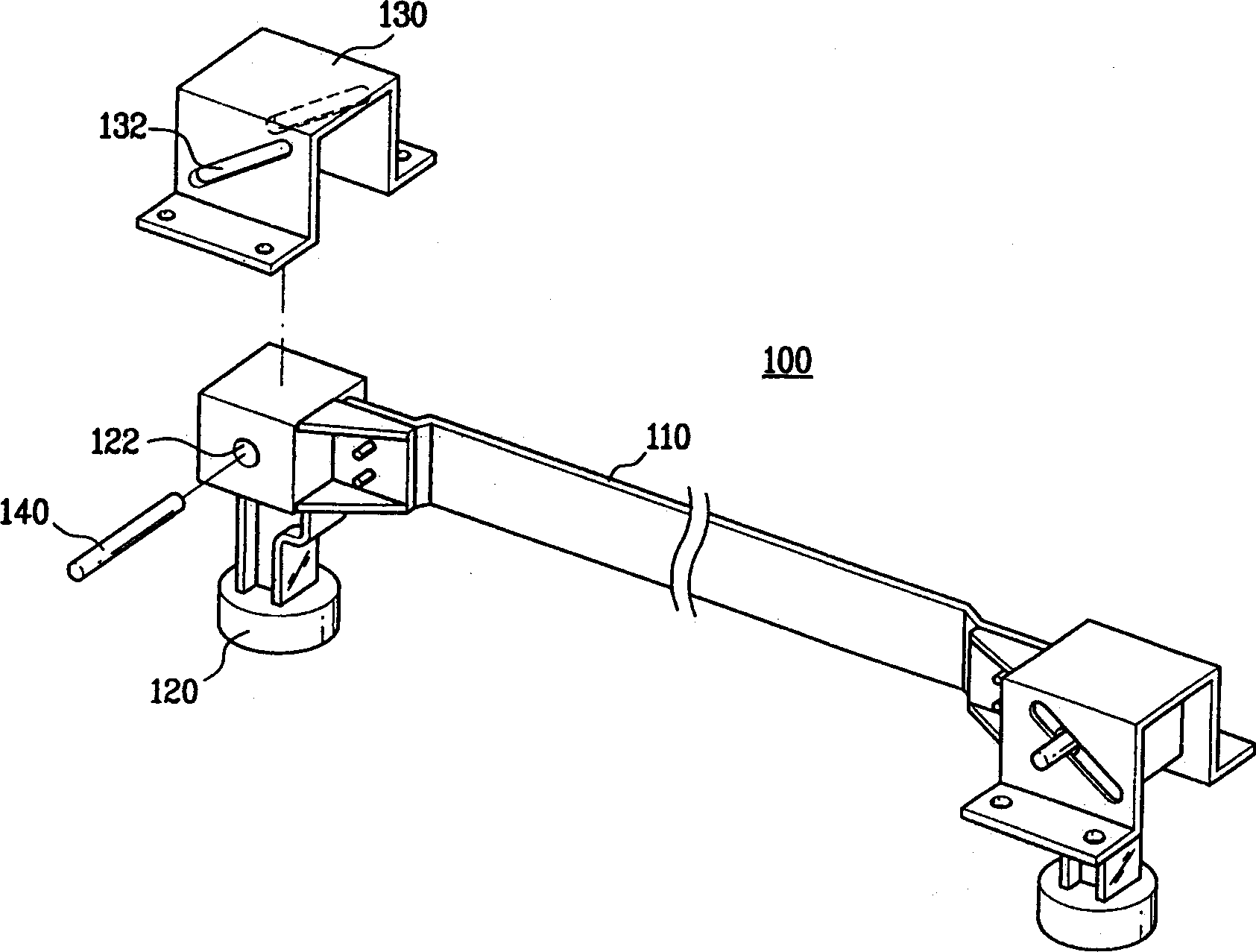

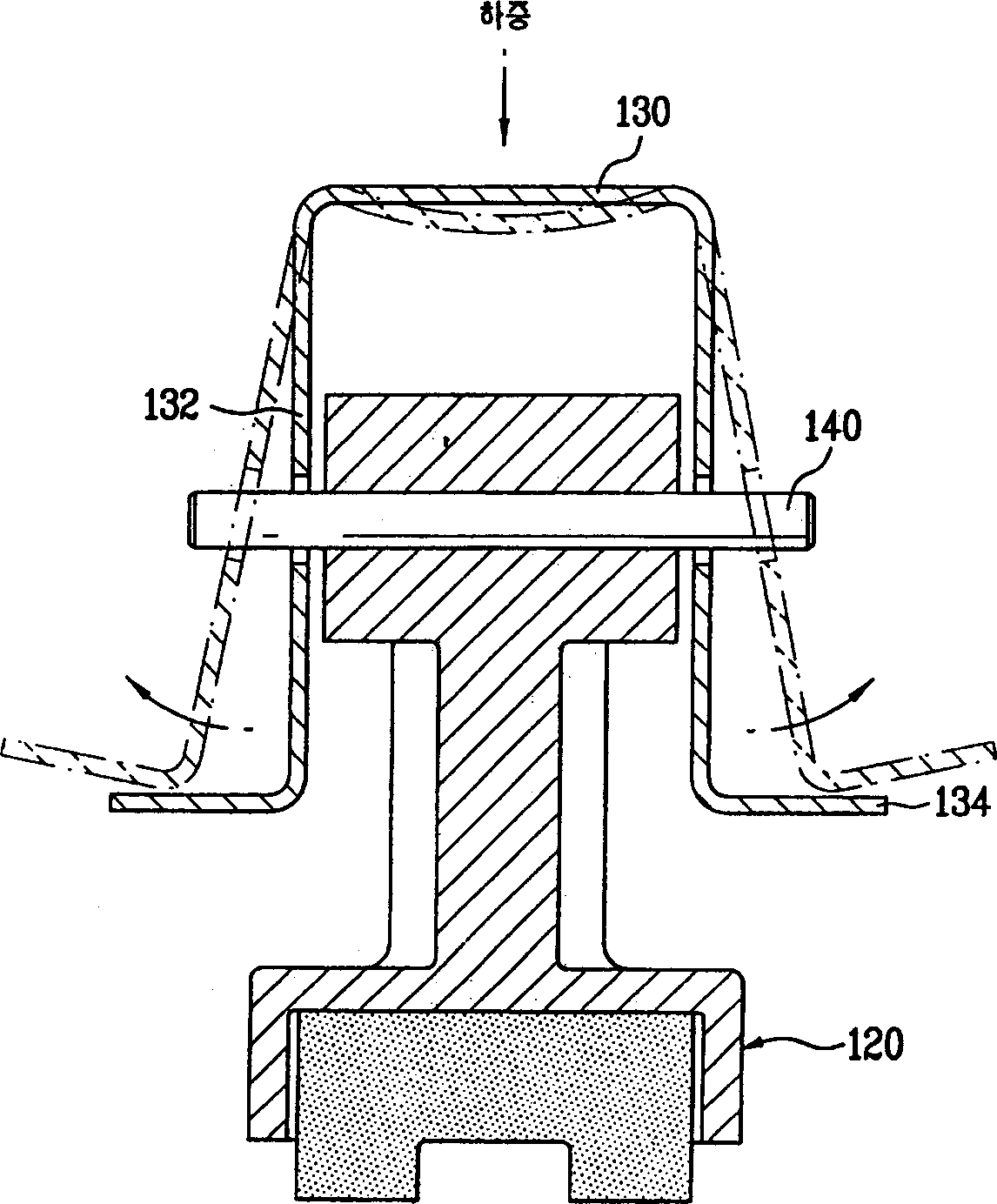

[0041] see Figure 4 , Figure 5 As shown, the automatic leveling member of the washing machine of the present invention prevents the structure from opening the frame, and the automatic leveling member 200 is composed of a rod-shaped connecting part 210 , a bracket 220 , and an upper frame 230 . The bracket 220 is vertically combined with the two ends of the connection part 210 . The upper frame 230 is arranged on the bottom surface of the main body 1 , is formed by bending in the shape of a door, and is combined on the upper side of each bracket 220 .

[0042] A central part of the main body of the bracket 220 is formed with a hole 222 penetrating through the main body. The shaft 240 is inserted into the above-mentioned hole 222 .

[0043]In addition, slide grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com