Rapid construction method of arched pipe truss

A construction method and technology of an arched tube, which are applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high equipment requirements, long construction time, low construction efficiency, etc., to improve the operational safety factor, ensure Accuracy and improved ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

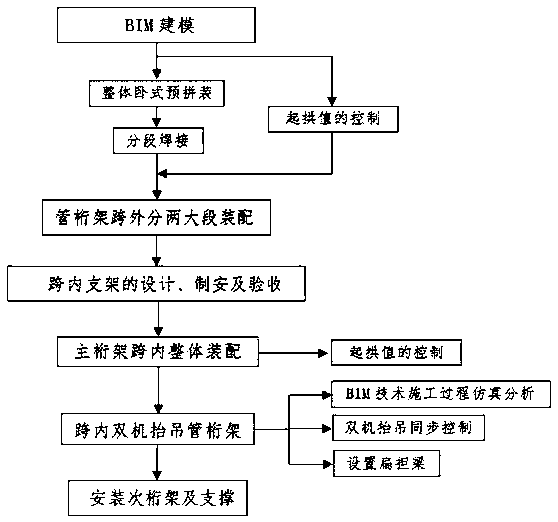

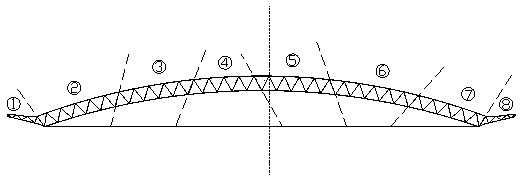

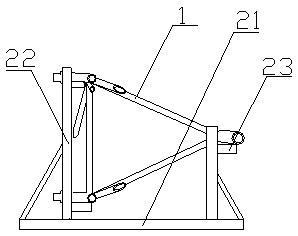

[0051] Taking the roof of a certain laboratory as an example, the roof adopts a spatial inverted triangular arched steel pipe truss structure. The roof has a total of 40 main trusses, with a single-span maximum span of 90m and cantilevered at both ends of about 105m. Moreover, the conditions of the construction site are poor and the construction period is tight. see Figure 1-Figure 7 , the construction of the laboratory roof is as follows:

[0052] 1) Use the Tekla steel structure software to establish the BIM structure model of the arched tube truss 1, and divide the arched tube truss 1 into two main trusses, and then divide the two main trusses into several truss bodies.

[0053] On the premise of fully understanding the design intent and complying with the relevant current codes, carry out reasonable and specific detailed design of the structure, focus on rationally handling the connection forms of different specifications and types of connecting rods, and classify and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com