Workpiece conveying device

A technology for conveying devices and workpieces, applied in the direction of conveyor objects, transportation and packaging, furnace components, etc., can solve problems such as inconvenient operation, and achieve the effect of convenient operation, simple structure, and low working height

Inactive Publication Date: 2008-11-19

JIANGSU SUSHENG AUTOMATION EQUIP

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the high working height of the upper conveyor line, it is inconvenient to operate when the upper conveyor line needs maintenance or manual operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

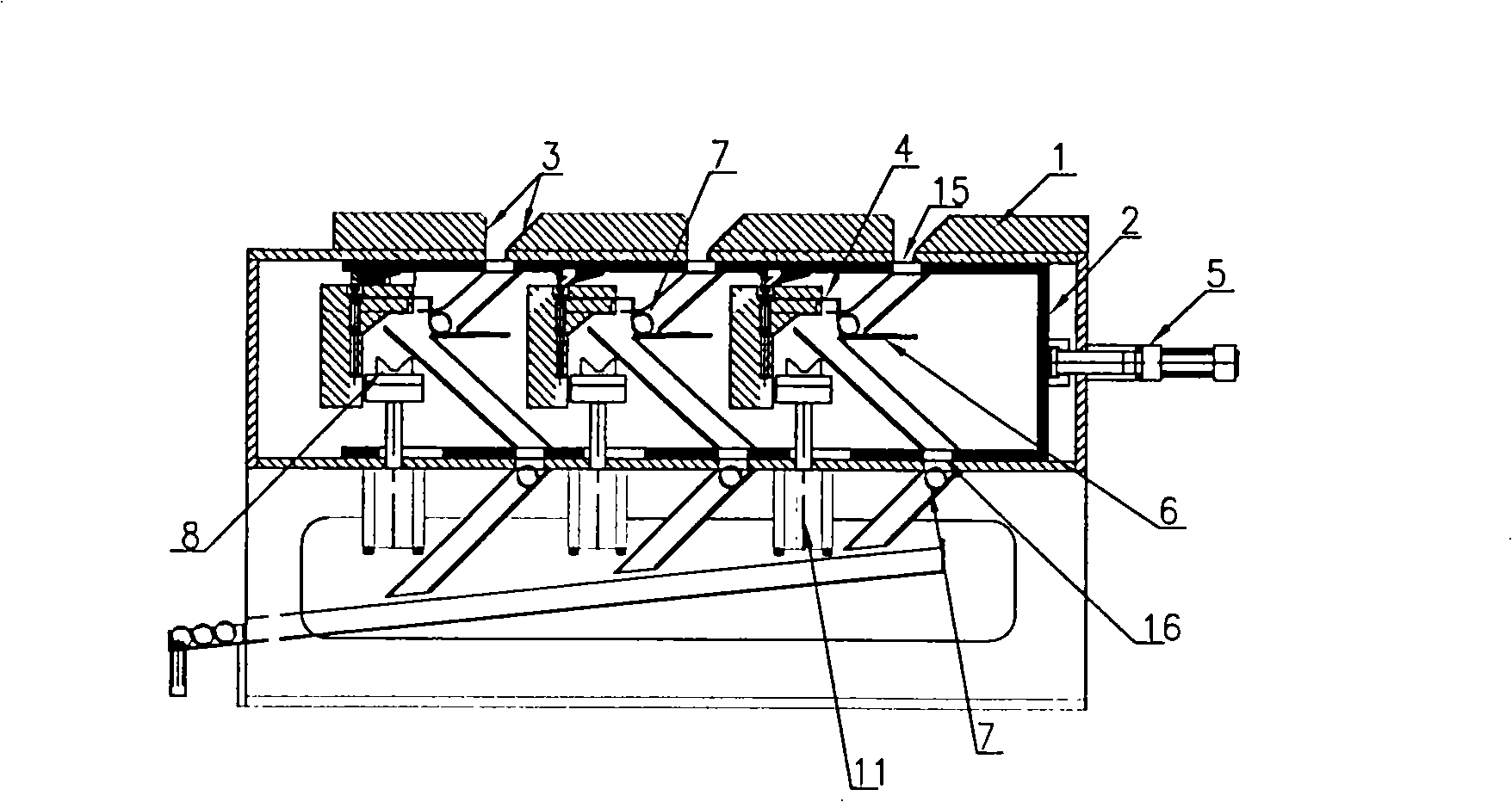

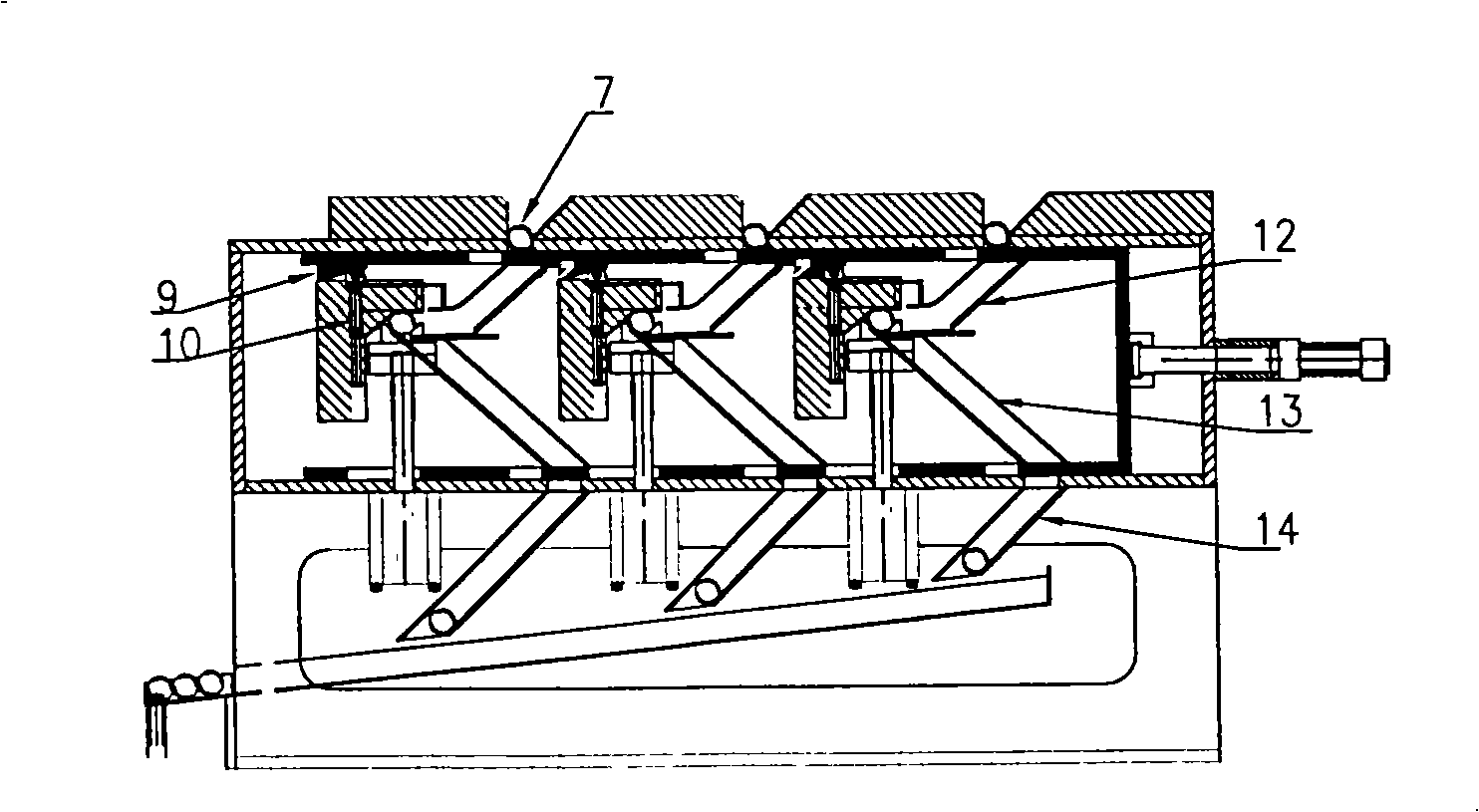

The invention relates to a workpiece delivery device, which is characterized in that an air cylinder (or oil cylinder) for controlling a movable frame is installed at one side of a fixed frame; the movable frame is installed inside the fixed frame; a guide column is installed on the fixed frame; a workpiece holding device with a V-shaped groove is installed on an cylinder (or oil cylinder) for controlling the workpiece holding device with the V-shaped groove; a feeding track is formed on the movable frame, a movable baffle is fixed on the fixed frame via an expansion link with a spring, an inclined movable track is arranged on the movable frame, a sloping block on the movable frame is fixed on the movable frame, and the inclined plane of the sloping block on the movable frame is connected with the expansion link with the spring; and the movable track capable of moving leftwards and rightwards with the movable frame is fixed on the movable frame. The inventive workpiece delivery device has the advantages of simple structure, automatic feed, isolation and discharge, low operating height, convenient operation, improved efficiency, and simultaneous delivery of workpieces at a plurality of rows.

Description

Workpiece Conveyor technical field The invention relates to a workpiece conveying device for automatic feeding, isolation and discharging of cylindrical or tapered workpieces, which belongs to the field of logistics conveying devices. Background technique In the production and processing of products, it is necessary to isolate the workpiece and process a certain part, and then flow into the next process. Manual processing can not keep up with the progress. Existing conveying device is to adopt multi-layer conveying, and fractional layer conveys up and down. Due to the higher working height of the upper conveyor line, it is inconvenient to operate when the upper conveyor line needs maintenance or manual operation. Contents of the invention The purpose of the present invention is to provide a workpiece conveying device that can automatically feed materials to processing stations and automatically discharge materials after processing. The workpiece conveying device is d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G47/88B65G11/20B65G11/00B65G49/00

Inventor 郑卫星杨学明林志勇

Owner JIANGSU SUSHENG AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com