Construction method for deep pit excavation

A construction method and deep foundation pit technology, applied in excavation, infrastructure engineering, construction, etc., can solve problems affecting personal safety, many safety hazards, high fuel consumption, etc., to reduce the operating height, avoid personal safety accidents, increase The effect of working height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

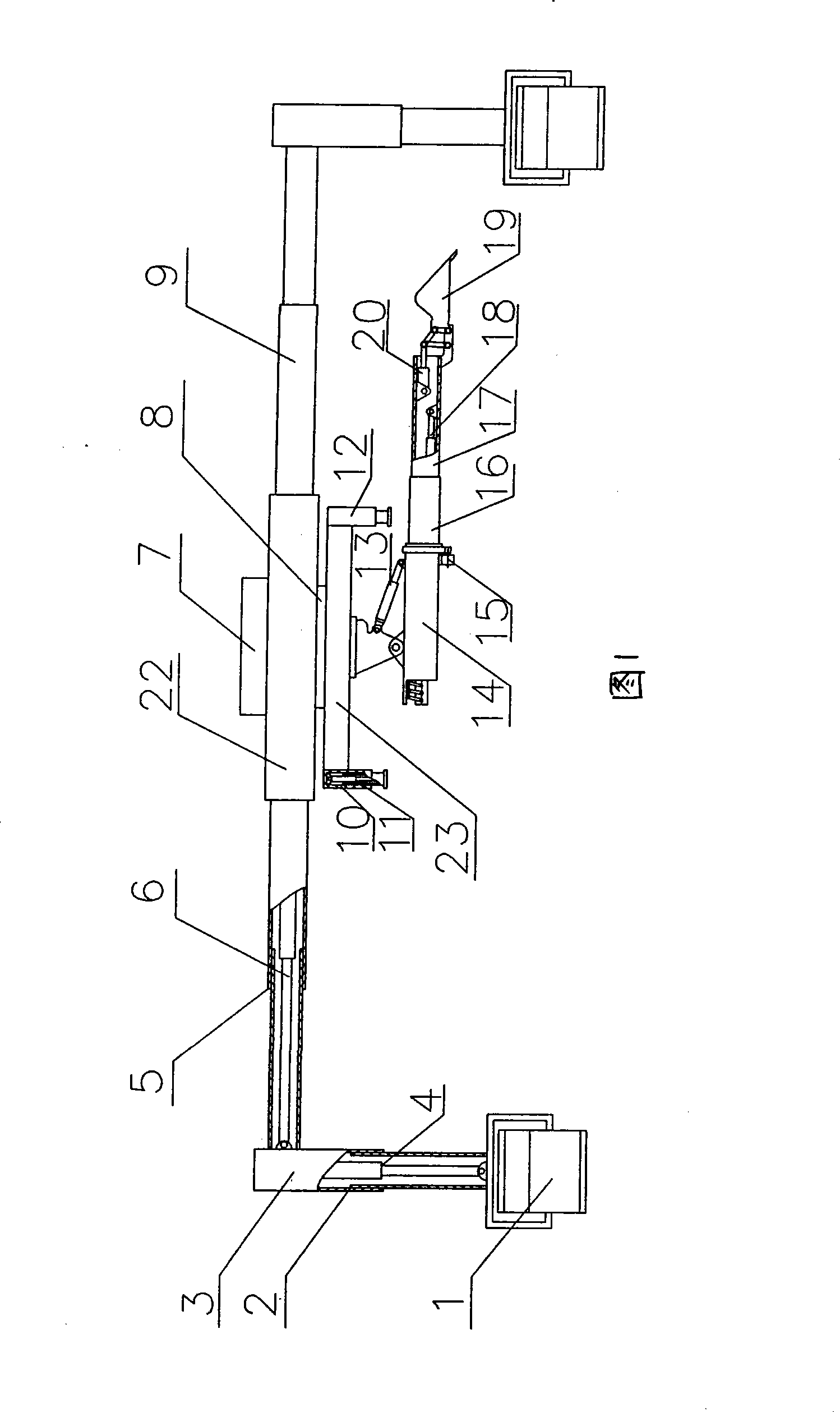

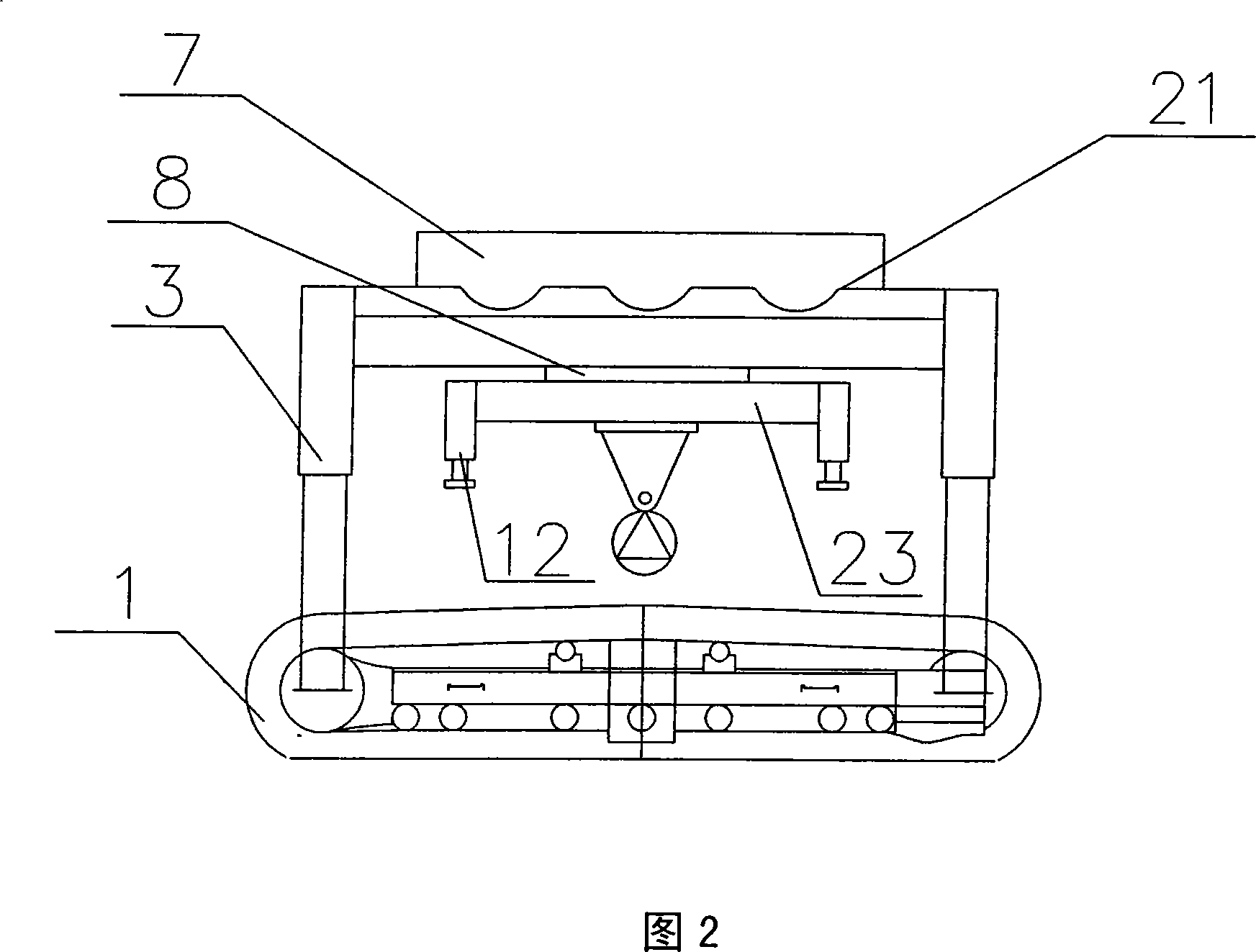

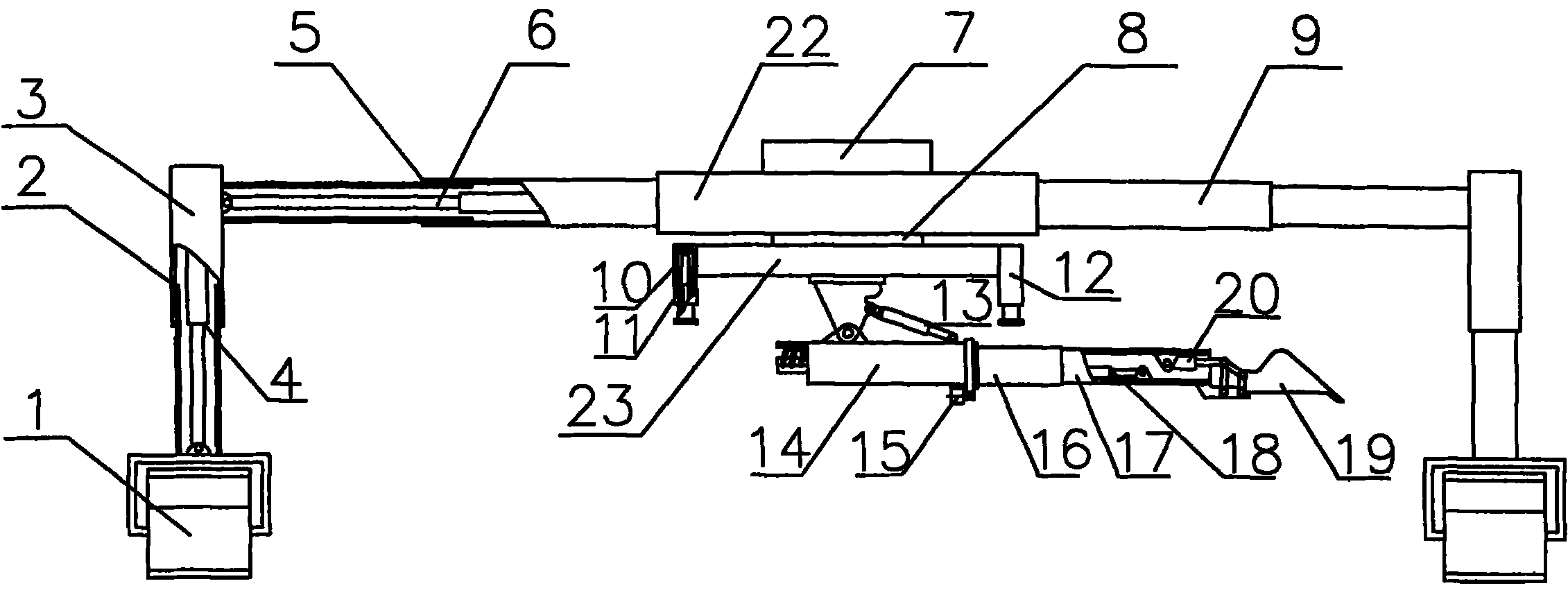

[0021] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0022] As shown in Figure 1-2, the labels 1-24 represent respectively: track 1, sleeve 2, vertical telescopic beam 3, oil cylinder 4, sleeve 5, oil cylinder 6, pump station and valve body assembly 7, rotary turntable 8, Horizontal telescopic beam 9, sleeve 10, oil cylinder 11, vertical telescopic outrigger 12, boom cylinder 13, boom 14, small arm rotary motor 15, small arm 16, stick 17, stick telescopic cylinder 18, bucket 19 , bucket oil cylinder 20, support beam bracket 21, upper platform 22, lower platform 23, track support 24.

[0023] The construction method involved in this embodiment: by setting the walking device crawler belt 1 at the bottom of the excavator, a vertical telescopic beam 3 is installed above the crawler belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com