Safety protection device for power battery pack

A technology of safety protection device and power battery pack, applied in emergency protection circuit devices, electric traction, electric vehicles, etc., can solve problems such as safety and hidden dangers, and achieve the effect of preventing personal safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

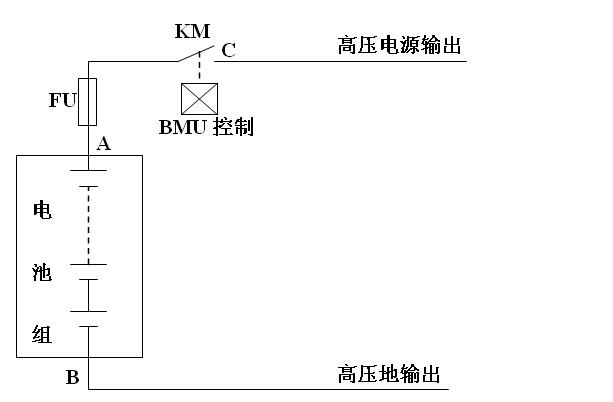

[0021] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

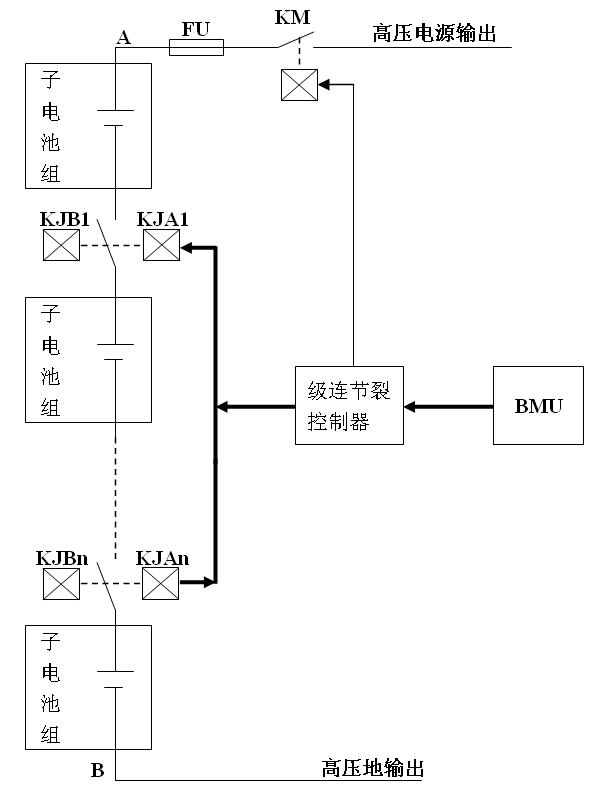

[0022] Such as figure 2 As shown, the power battery pack of the present invention is formed by connecting several sub-batteries in series, including a battery management unit BMU, a cascaded joint relay, a cascaded joint controller, and a high-voltage main contactor KM; the cascaded joint relay adopts For magnetic latching relays, each cascaded joint relay has an independent cascaded coil KJAn and an independent joint joint coil KJBn. The cascaded coil KJAn is the cascaded coil of the nth cascaded joint relay, and the joint coil KJBn is the joint coil of the nth cascaded joint relay.

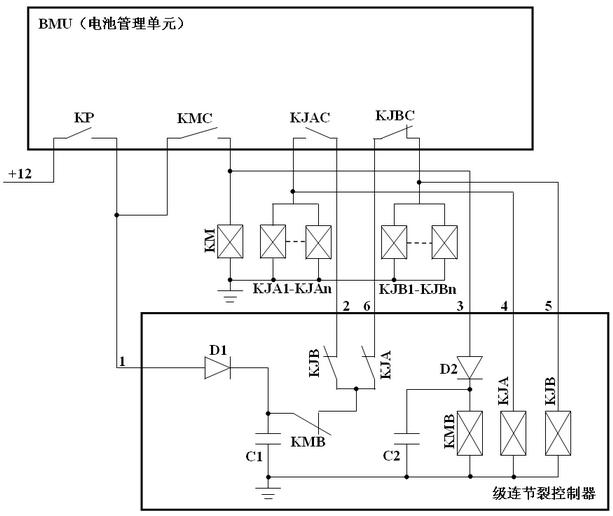

[0023] Such as image 3 As shown, there are two relays KJA, KJB, normally closed contact relay KMB, capacitor C1, and capacitor C2 inside the cascade joint controller; there are two relays KJA and KJB in the cascade controller for interlocking, and the battery The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com