Infrared setting, color fixing and yarn winding machine

A technology of infrared rays and winder, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as unreliable coloring, achieve the effects of preventing personal safety accidents, reasonable structure, and improving coloring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

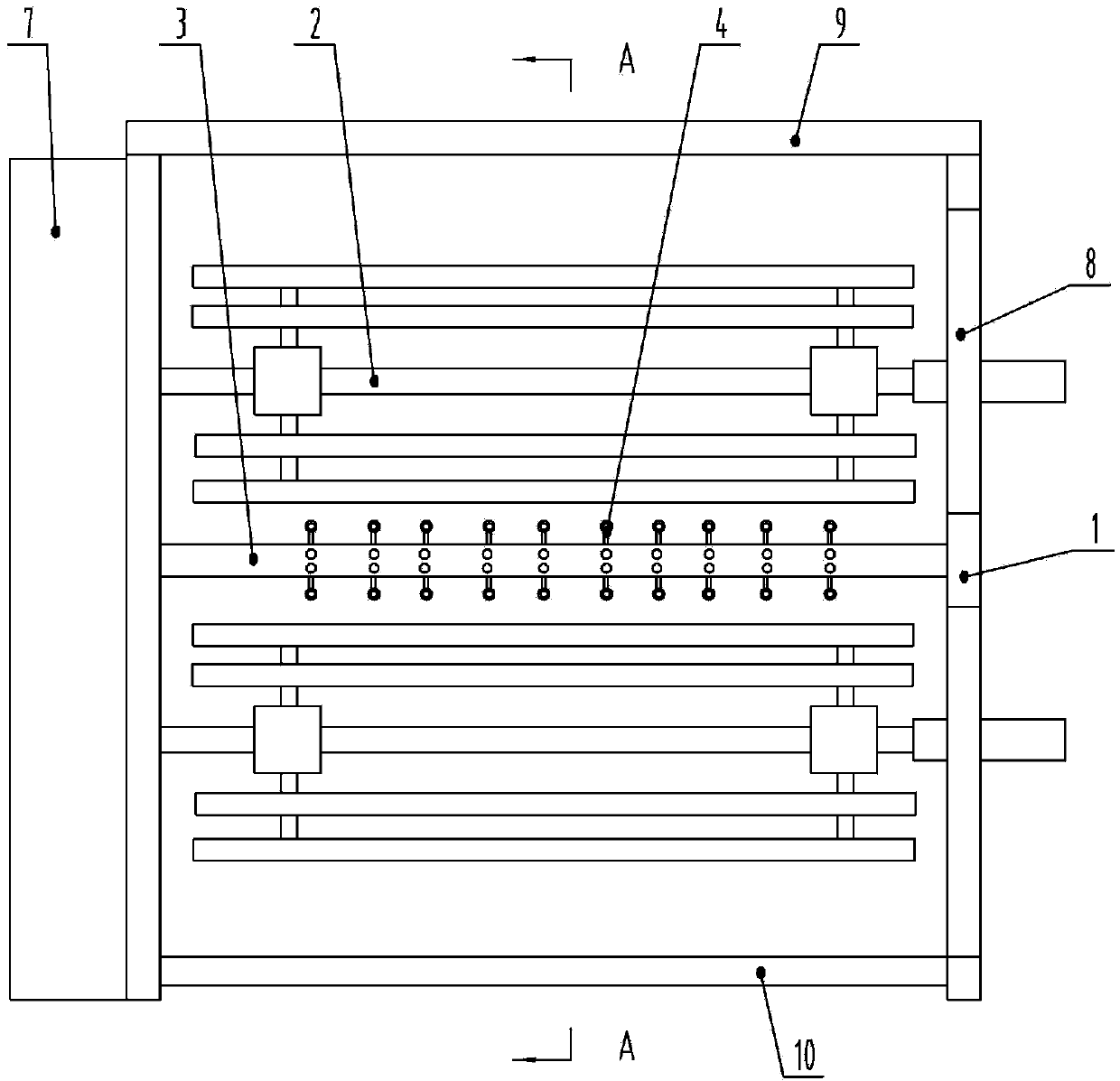

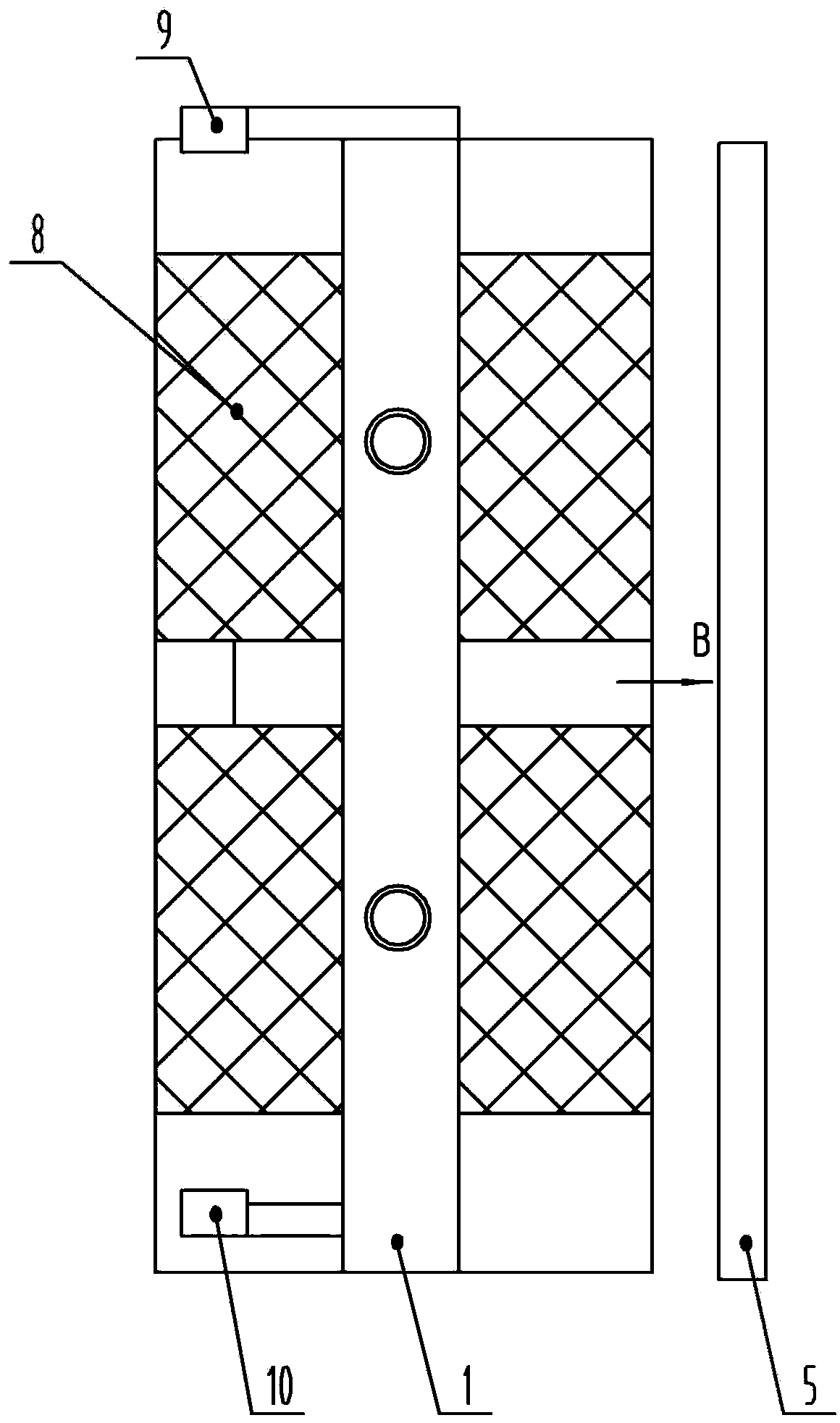

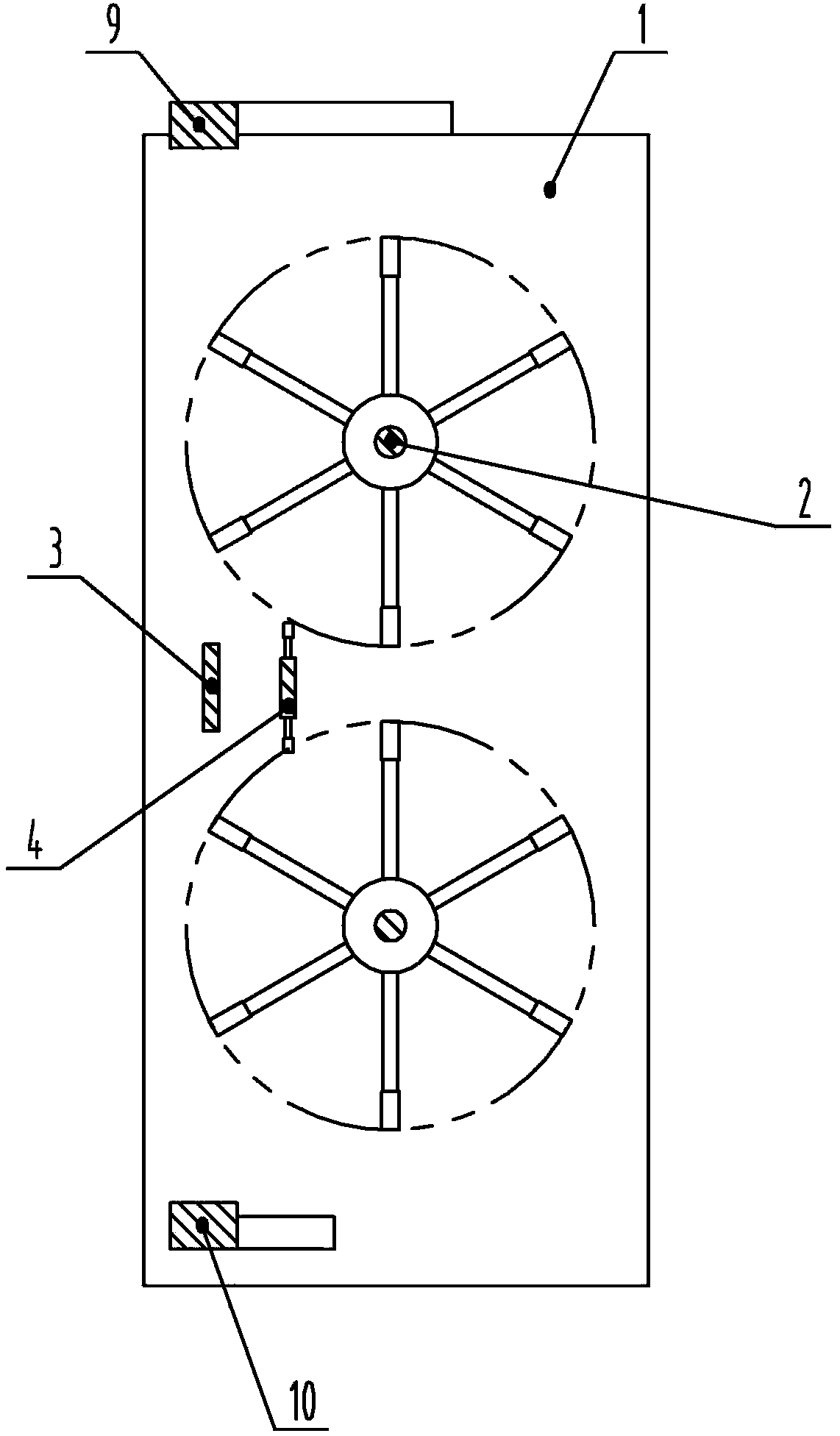

[0028] see Figure 1-4 , in the figure, the infrared ray fixing and color-fixing yarn receiving machine of the present invention comprises a frame 1, a pair of pan heads 2 are arranged up and down in the frame, and a yarn dividing reed 3 and a row of yarn guides are sequentially arranged horizontally and horizontally in front of the pan heads. Rod 4, a row of holes is respectively arranged on the upper and lower ends of the yarn dividing reed, and a yarn guide hole is respectively arranged on the upper and lower sides of the yarn guide rod, and an infrared drying device 6 is installed between the rear side of the frame and the corresponding upper and lower pan heads for drying after dyeing. The yarn is warmed, the color fastness of the yarn is increased, and the coloring quality of the yarn is improved.

[0029] A protective net 5 is arranged on the rear side of the frame, an infrared drying device is installed on the inner surface of the protective net, an electric control ca...

Embodiment 2

[0032] see Figure 1-3 and Figure 7 , the structure of this embodiment is similar to that of Embodiment 1, and the same numbers in the figure represent the same meaning, which will not be repeated here. The difference is that this embodiment is equipped with an infrared grating safety device at the front end of the rack. Described infrared grating safety device comprises a group of infrared gratings, and this group of infrared gratings comprises the transmitting end 9 and the sensing end 10 that are set correspondingly up and down, is connected with switching power supply 12 at power supply input end 11, and the input end of switching power supply is connected with transmitting end, emits The output end of the terminal is connected to the sensing end through the infrared grating module 13 , the output end of the sensing end is connected to the relay module 14 , and the output end of the relay module is controlled by the emergency stop switch 15 .

[0033] Compared with Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com