Assembly tooling for hose throttle

A technology for assembling tooling and throttle valves, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of noise and impact, oil pipe falling off, position consistency cannot be guaranteed, and hoses are missing throttle valves, etc. To achieve the effect of ensuring product quality, avoiding the phenomenon of throttle valve leakage, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

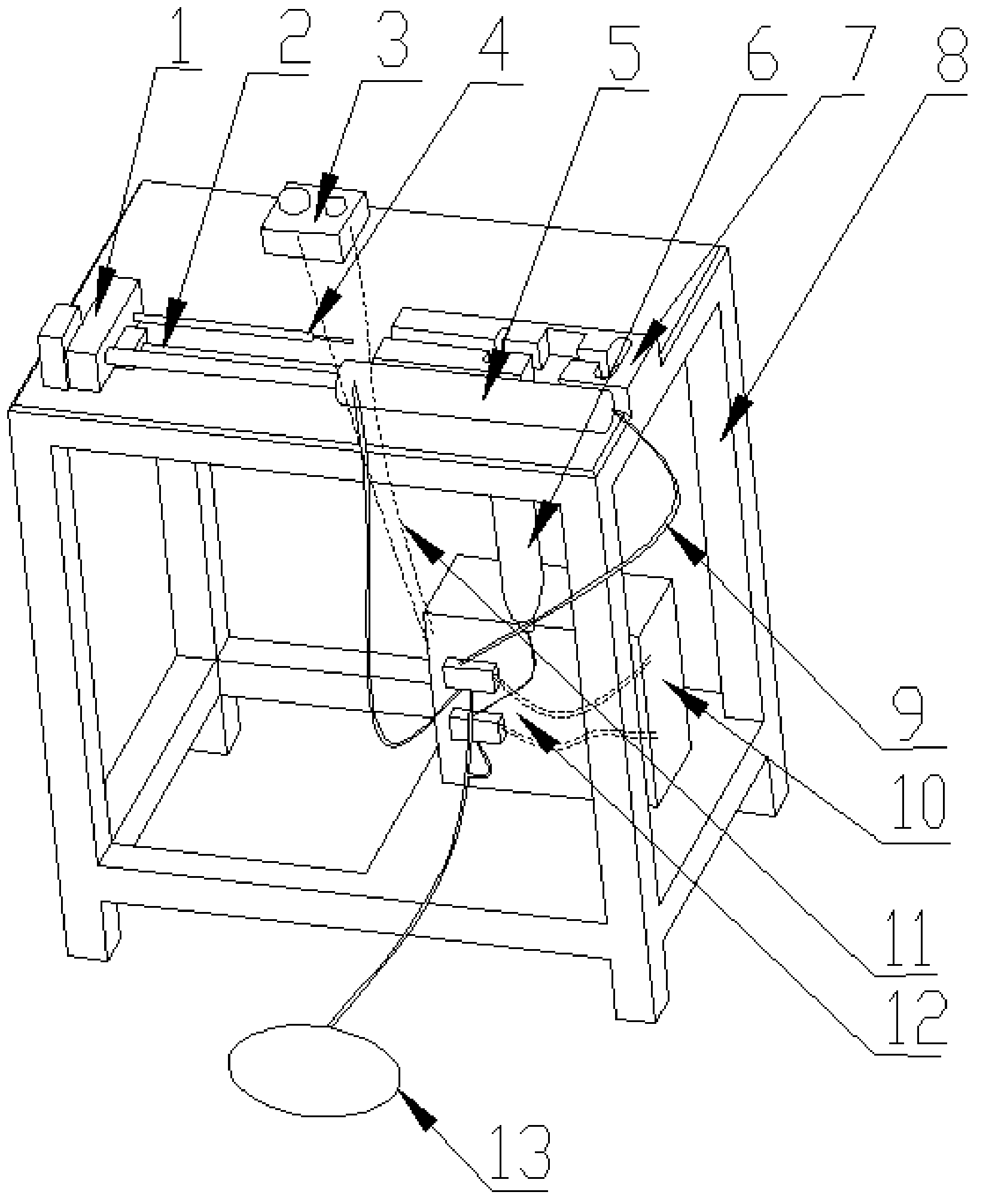

[0010] refer to figure 1 , figure 1 It is a structural schematic diagram of an embodiment of a hose throttle valve assembly tool proposed by the present invention.

[0011] like figure 1 As shown, a hose throttle valve assembly tool proposed by the embodiment of the present invention includes an air pipe 9, a distribution box 10, an air source 13, an electric wire 11, a moving slider 1, a guide rail 2, a control switch 3, and a guide rod 4. Positioning groove 7, first cylinder 5, second cylinder 6, time solenoid valve 12 and tooling platform 8 on which the above components can be installed, the solenoid valve 12 is connected with the first cylinder 5 and the second cylinder 6 Connect and control both actions, the guide rod 4 is fixed with the moving slider 1, the guide rod 4 is aligned in the positioning groove 7 and guided, the first cylinder 5 and the moving slider 1 connection, the moving slider 1 is installed on the guide rail 2, and can move along the guide rail 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com