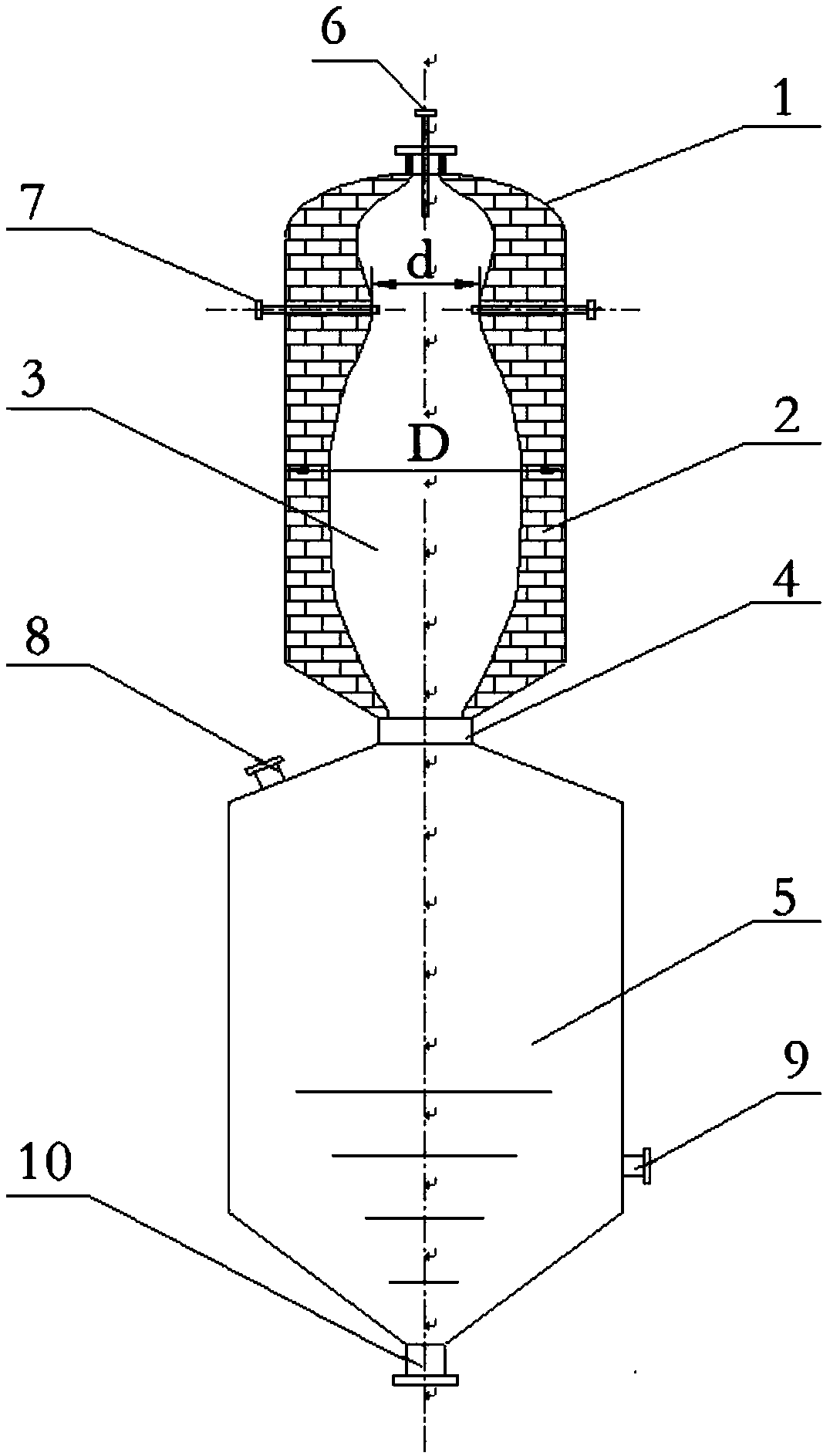

Method for preparing synthetic gas from C1 chemical fuel in multivariate conjugation manner

A synthesis gas and multi-component technology, applied in the direction of granular/powdered fuel gasification, gasification process, and production of combustible gas, can solve the problems of complex structure, waste of coal resources, shortage, etc., and achieve the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment includes the following steps:

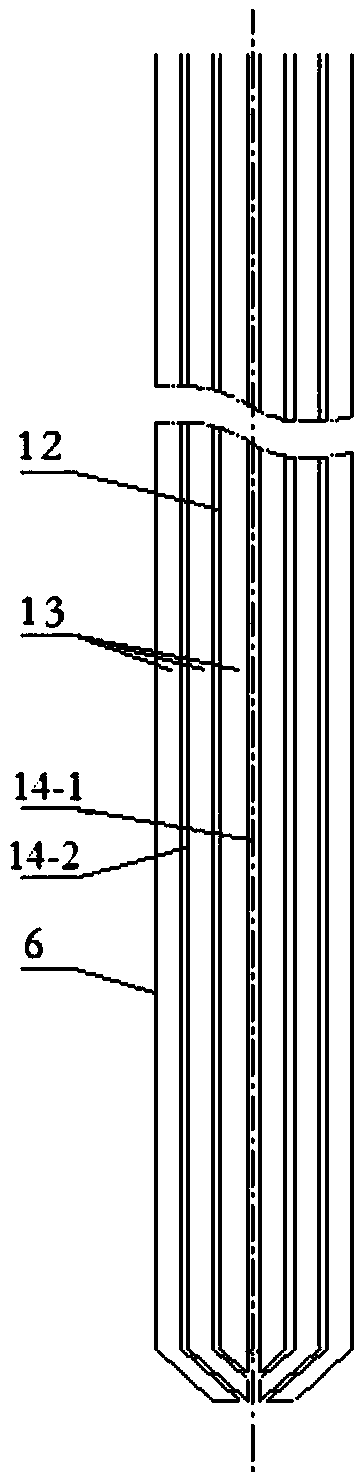

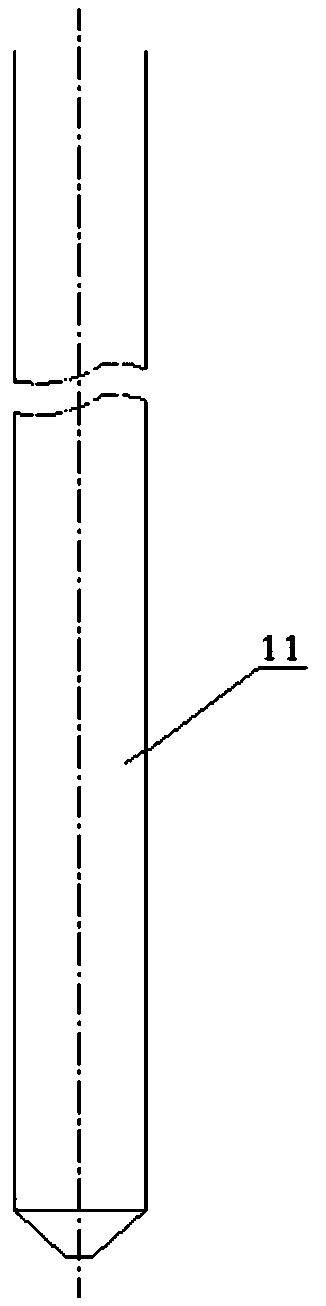

[0056] Step 1. Embed the oven burner 11 in the gaseous fuel nozzle 6 installed on the top of the gasifier 1, and then use gaseous methanol as fuel to bake the oven until the gasifier 1 is preheated to above 1000°C;

[0057] Step 2: Disassemble the oven burner 11 from the gaseous fuel nozzle 6, and make the first oxidant pipeline 14-1, the gaseous fuel pipeline 12 and the second oxidant pipeline 14-2 coaxial from the inside to the outside in sequence according to the sleeve method Assembled in the gaseous fuel nozzle 6, then pass the carbon-gaseous fuel into the gasification furnace 1 through the gaseous fuel pipeline 12, and simultaneously pass the carbon-solid fuel and oxidant through the slurry nozzle 7 located above the gasification furnace 1 side In the gasifier 1, after carbon-gaseous fuel and high-concentration slurry enter the gasification section 2 of the gasifier 1, the oxidant is passed into the gasifier through ...

Embodiment 2

[0076] The difference between this embodiment and Example 1 is that in step one, natural gas is used as raw material for oven; the carbon-solid fuel used in step two is Inner Mongolia coal, and the carbon-gaseous fuel is CH 4 Natural gas with a content of 96.63%, the physical parameters of carbon-solid fuel and carbon-gaseous fuel are shown in Table 6 and Table 7 below, the oxidant is oxygen with a volume purity of 99.6%, and the reaction distribution parameters of the oxidant are shown in Table 8 below. Carbon- The furnace parameters of the water-based slurry made from solid fuel grinding are shown in Table 9 below. The temperature of the multi-component conjugation reaction is 1250° C., and the pressure is 1.0 MPa. The pressure of the multi-component conjugation reaction is gauge pressure (G) The dry gas volume composition of the crude syngas produced in step 3 is as shown in Table 10 below, and the carbon element content in the dry matter of the unreacted solid residue slag ...

Embodiment 3

[0089] The difference between this embodiment and Example 1 is that in step one, natural gas is used as a raw material for drying, the carbon-solid fuel used in step two is Xinjiang coal, and the carbon-gaseous fuel is natural gas with a CH4 content of 96.63%. The physical parameters of the solid fuel and the carbon-gaseous fuel are shown in Table 11 and Table 12 respectively. The oxidant is oxygen with a volume purity of 99.6%. The reaction distribution parameters of the oxidant are shown in Table 13. The furnace parameters of the base slurry are shown in Table 14 below. The pressure of the multi-component conjugation reaction is 9.0 MPa, and the temperature is 1350 ° C. The pressure of the multi-component conjugation reaction is gauge pressure (G); the crude The composition of the dry gas volume of the synthesis gas is shown in Table 15 below. The carbon element content in the dry mass of the unreacted solid residue slag discharged from the gasifier after heat exchange is 2.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com