Anaerobic fluidized bed bioreactor and using method thereof

An anaerobic fluidized bed and bioreactor technology, applied in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of long treatment time and large area, and achieve the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

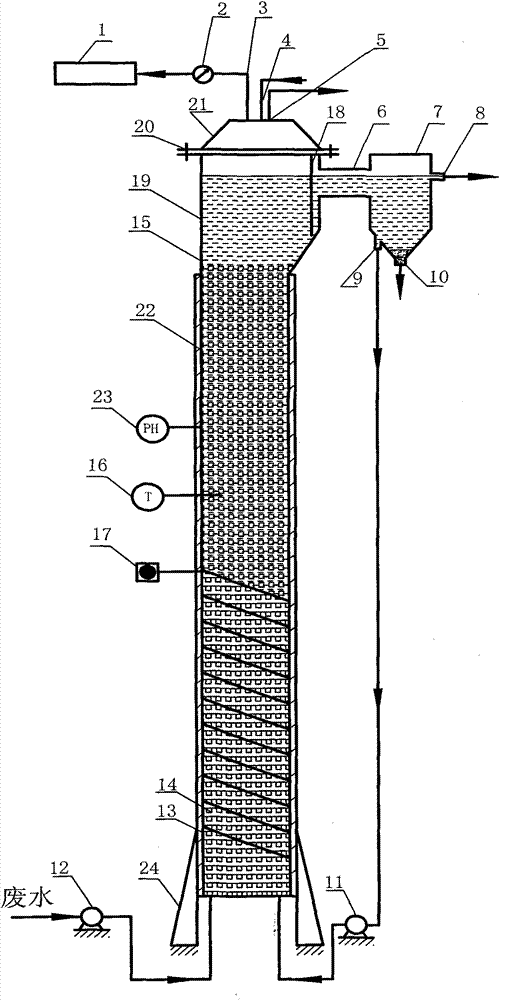

[0044] Such as figure 1 As shown, the anaerobic fluidized bed bioreactor of the present invention includes a bed body, a head 21, a separator 7, a peristaltic pump 12, and a centrifugal pump 11. The bed body consists of a straight pipe 22, a reducing pipe 15 and a top pipe 19. The top tube 19 is above the straight tube 22, the reducing tube 15 is connected between the top tube 19 and the straight tube 22, the straight tube 22, the reducing tube 15 and the top tube 19 are connected together, and the head 21 passes through the method The flange 20 is installed on the top pipe 19, and the head 21 is provided with a methane mixed gas outlet 3, a nitrogen inlet 4 and an air outlet 5. The methane mixed gas outlet 3 communicates with the gas cylinder 1 through a pipe. A wet gas flow meter 2 is installed on it. The top pipe 19 is connected to the separator 7 through the connecting pipe 6. The bottom of the separator 7 is provided with a circulating liquid port 9 and a waste sludge dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com