Extraction device

An extraction device and extraction technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of complex internal structure, difficult internal cleaning, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

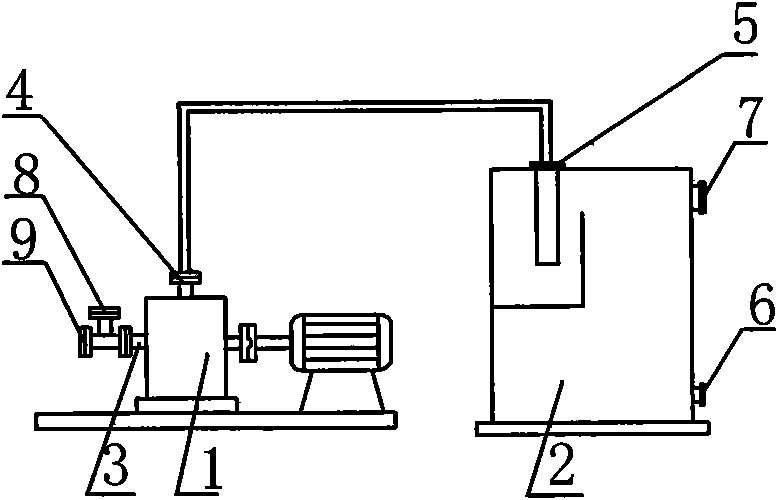

Embodiment 1

[0019] see figure 1 , a single-stage extraction device, including a pipeline type high-shear dispersing emulsifier 1 and a phase separation device 2 (using a phase separation tank), the emulsification machine 1 is provided with an emulsification machine inlet 3 and an emulsification machine outlet 4, and the phase separation device 2 is provided with There are mixed phase inlet 5, heavy phase outlet 6 and light phase outlet 7, of which: emulsifier inlet 3 is connected to extract inlet 8 and solvent inlet 9, and emulsifier outlet 4 is connected to mixed phase inlet 5 of phase separation equipment.

[0020] Take the extraction process in wet-process phosphoric acid purification as an example. When in use, phosphoric acid enters the emulsifier from the extractant import 8, and the extractant enters the emulsifier from the solvent import 9 through the emulsifier import 3. The extractant and phosphoric acid complete efficient mass transfer in the emulsifier 1. process, the formed m...

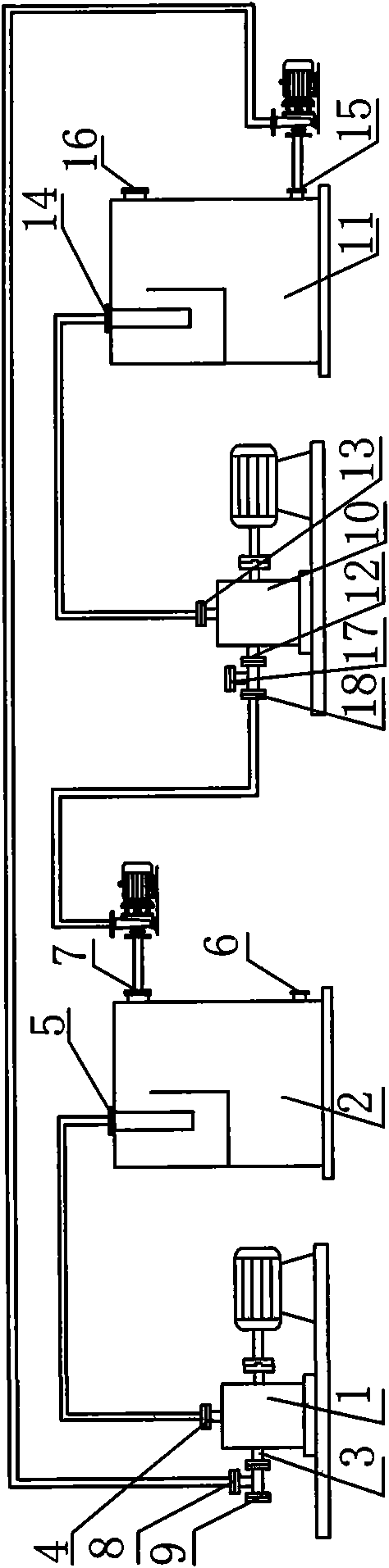

Embodiment 2

[0022] see figure 2 , the secondary extraction device is composed of two groups of single-stage extraction devices, the phase separation equipment (using a clarifier) in the first-stage extraction device, the light phase outlet 7, is connected to the second-stage extraction device through a pipeline provided with a pump The secondary solvent inlet 17 is connected; the secondary heavy phase outlet 15 of the secondary phase separation equipment 11 in the second-stage extraction device is connected with the extracted substance inlet 8 in the first-stage extraction device through a pipeline provided with a pump.

[0023] Take the extraction process in the purification of wet-process phosphoric acid as an example, when in use: the phosphoric acid from the secondary heavy phase outlet 15 in the second-stage extraction device is imported from the extracted material in the first group of extraction devices under the action of the pump 8, The extractant enters the emulsifier 1 from ...

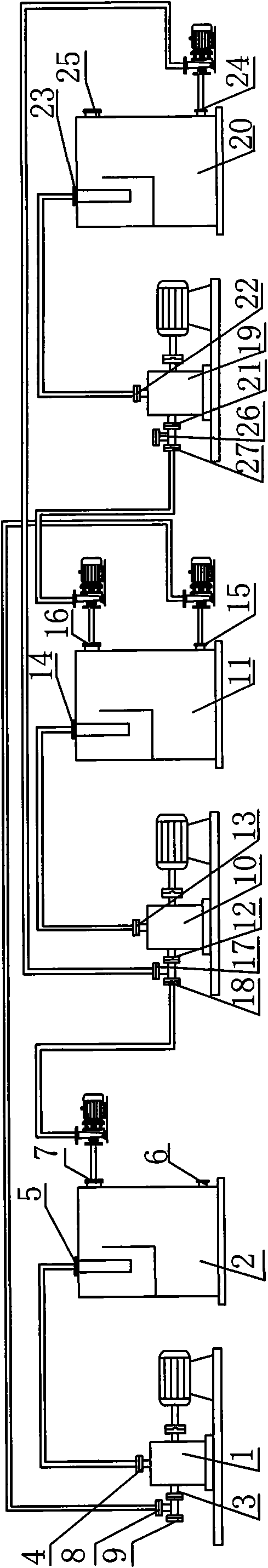

Embodiment 3

[0025] see image 3 , the three-stage extraction device is composed of three groups of single-stage extraction devices, the secondary light phase outlet 16 in the second-stage extraction device is connected with the third-stage solvent inlet 27 in the third-stage extraction device by a pipeline provided with a pump ; The three-stage heavy phase outlet 24 of the three-stage phase separation equipment 20 in the third-stage extraction device is connected with the secondary extracted substance inlet 17 in the secondary extraction device by a pipeline provided with a pump; all the other are the same as embodiment 2.

[0026] Taking the extraction process in the purification of wet-process phosphoric acid as an example, when in use: the phosphoric acid from the third-stage heavy phase outlet 24 in the third-stage extraction device returns to the secondary emulsifier 10 under the action of the pump, and the load solvent is separated from the secondary phase The light phase outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com