Patents

Literature

38results about How to "Uniform and fine dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

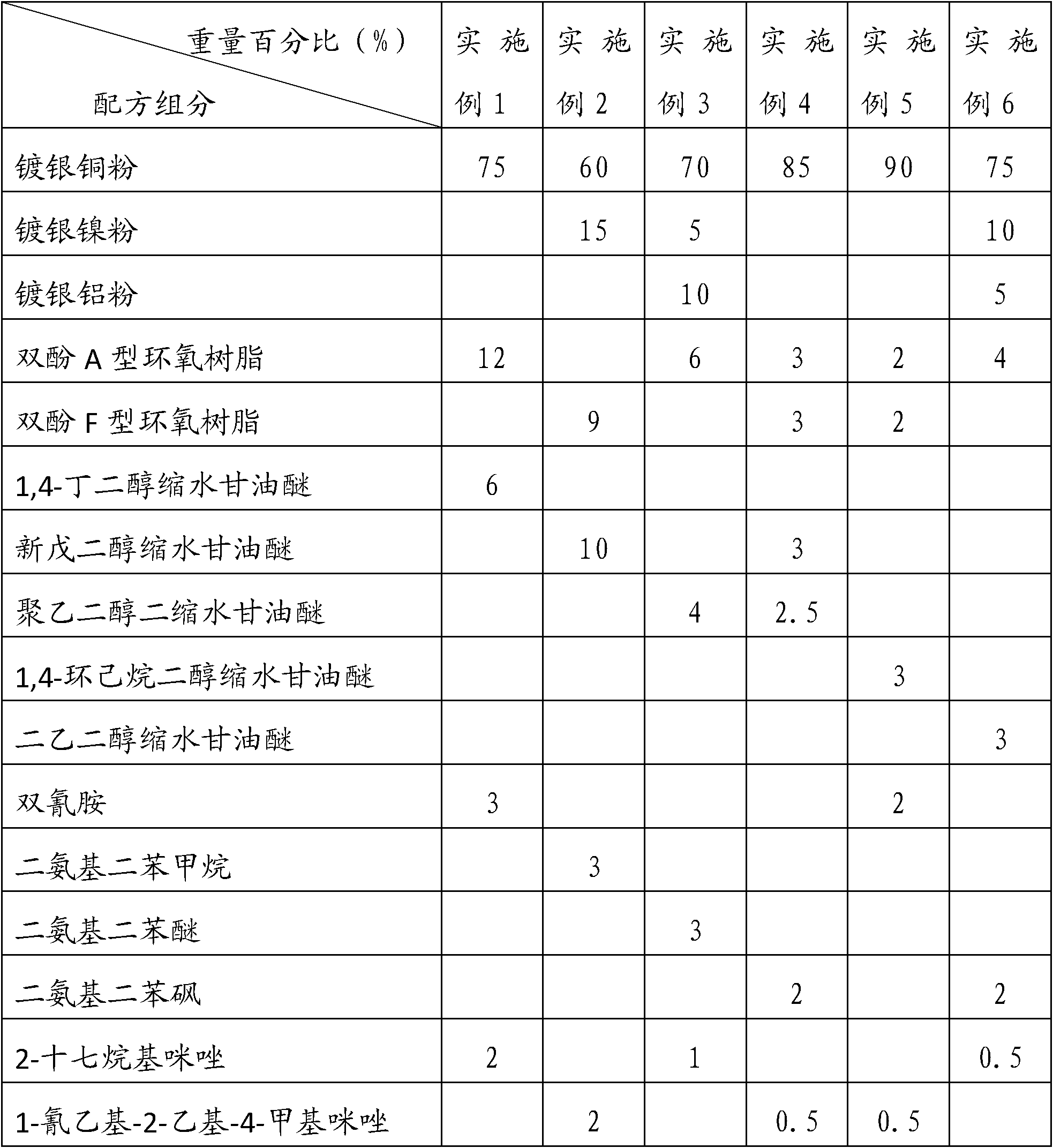

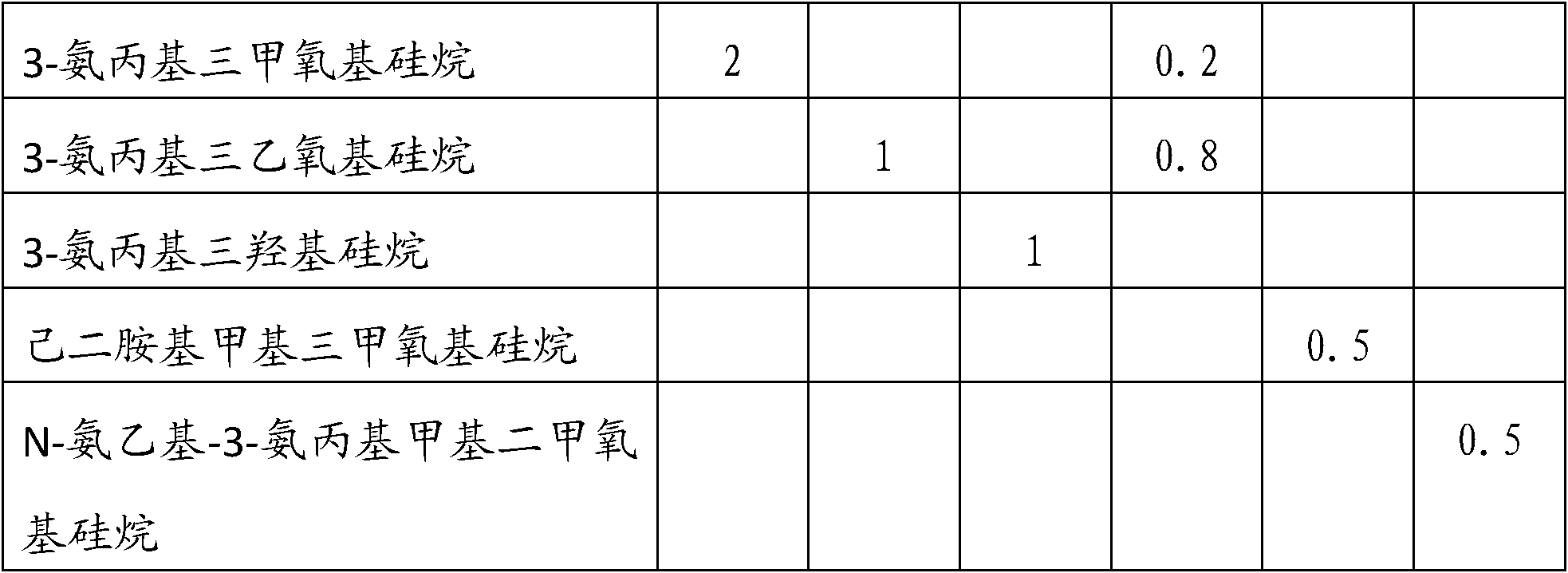

Silvering powder conductive adhesive for LED packaging and production method thereof

InactiveCN102634312AEasy to makeLow costEpoxy resin adhesivesSemiconductor devicesLed packagingThermal conductivity

The invention relates to silvering powder conductive adhesive for LED packaging and a production method thereof. The silvering powder conductive adhesive for LED packaging comprises, in weight percentage, 75-90% of silvering powder, 4-12% of epoxy resin, 3-10% of epoxy thinner, and 3-7% of additive. The production method includes: firstly, mixing the epoxy resin and the epoxy thinner at room temperature for 3-30 minutes; secondly, adding the additive in the mixture obtained in the step 1, and mixing at the room temperature for 3-30 minutes; thirdly, adding the slivering powder in the mixture obtained in the step 2, and vacuum-mixing at the room temperature to obtain the silvering powder conductive adhesive. The silvering powder conductive adhesive is simple in preparation and low in cost, and has fine and stable electric conductivity and thermal conductivity.

Owner:YANTAI DARBOND TECH

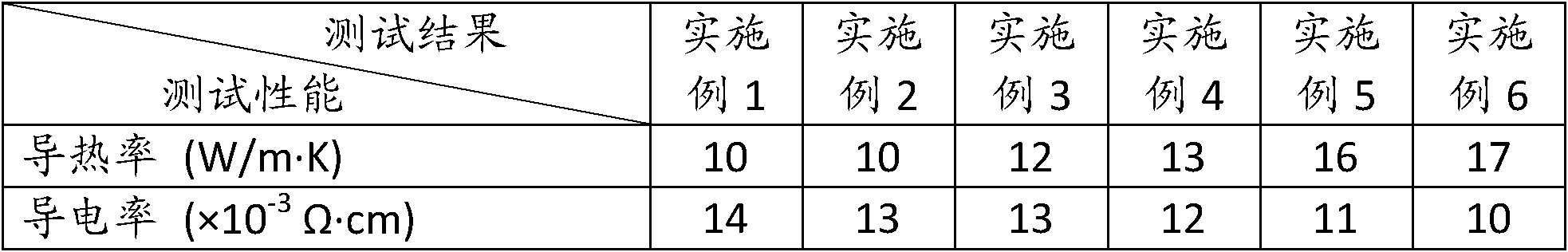

High-quality and large-size two-dimensional material and preparation method thereof

ActiveCN108793140AIncrease tangential speedImprove stripping efficiencyNitrogen compoundsTitanium carbidePre treatmentLarge size

The invention discloses a high-quality and large-size two-dimensional material and a preparation method thereof. The preparation method of the high-quality and large-size two-dimensional material comprises the following steps: S1, after pre-treating lamellar structure material powder, dispersing in chemical drug liquid, so as to obtain a dispersion solution; S2, putting the dispersion solution into emulsifying and dispersing equipment, and carrying out chemical and shearing peeling on the lamellar structure material powder under the action of the chemical drug liquid and emulsification and dispersion; S3, carrying out centrifugal separation and vacuum drying to obtain the high-quality and large-size two-dimensional material. The high-quality and large-size two-dimensional material and thepreparation method thereof, provided by the invention, have the advantages of simplicity and rapidness, high peeling efficiency and capability of realizing continuous scale production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method for high concentration dredging silt rapid dehydrating agent solution

ActiveCN102974239AEvenly dispersedSolve the problem of high concentration wet cakingSludge treatment by de-watering/drying/thickeningMixing methodsWater basedHigh concentration

The present invention discloses a preparation method for a high concentration dredging silt rapid dehydrating agent solution. The method comprises the following steps: adding sodium carbonate and sodium chloride compound particles to a powdery anionic polymer dehydrating agent, sufficiently mixing the dehydrating agent, sodium carbonate and sodium chloride compound particles by stirring; and dissolving the dehydrating agent mixed solution by high-speed dispersing emulsifying equipment with the dissolution time of less than 2 min. The dehydrating agent solution is prepared after dissolving. According to the present invention, a certain proportion of water-soluble sodium carbonate and sodium chloride compounds are added to the polymer dehydrating agent for modification, each particle is fast and fully contact with water base on the combination of influent water flow mist flow condition to achieve instantaneous uniform dispersion in water, and ultimately high concentration wet-caking problem of the polymer dehydrating agent material is solved.

Owner:江苏艾特克环境工程有限公司

Mixing method of electrode slurry

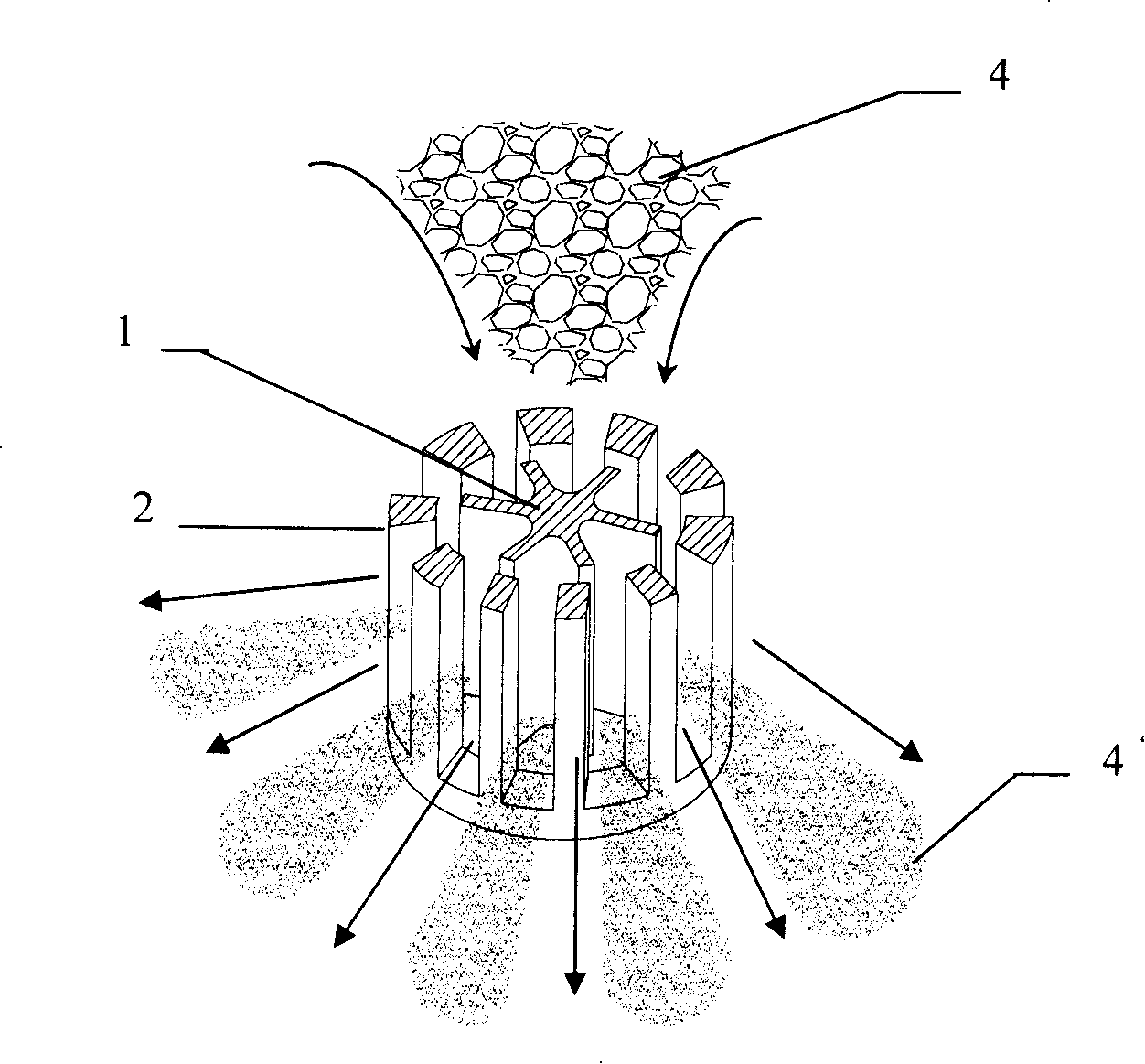

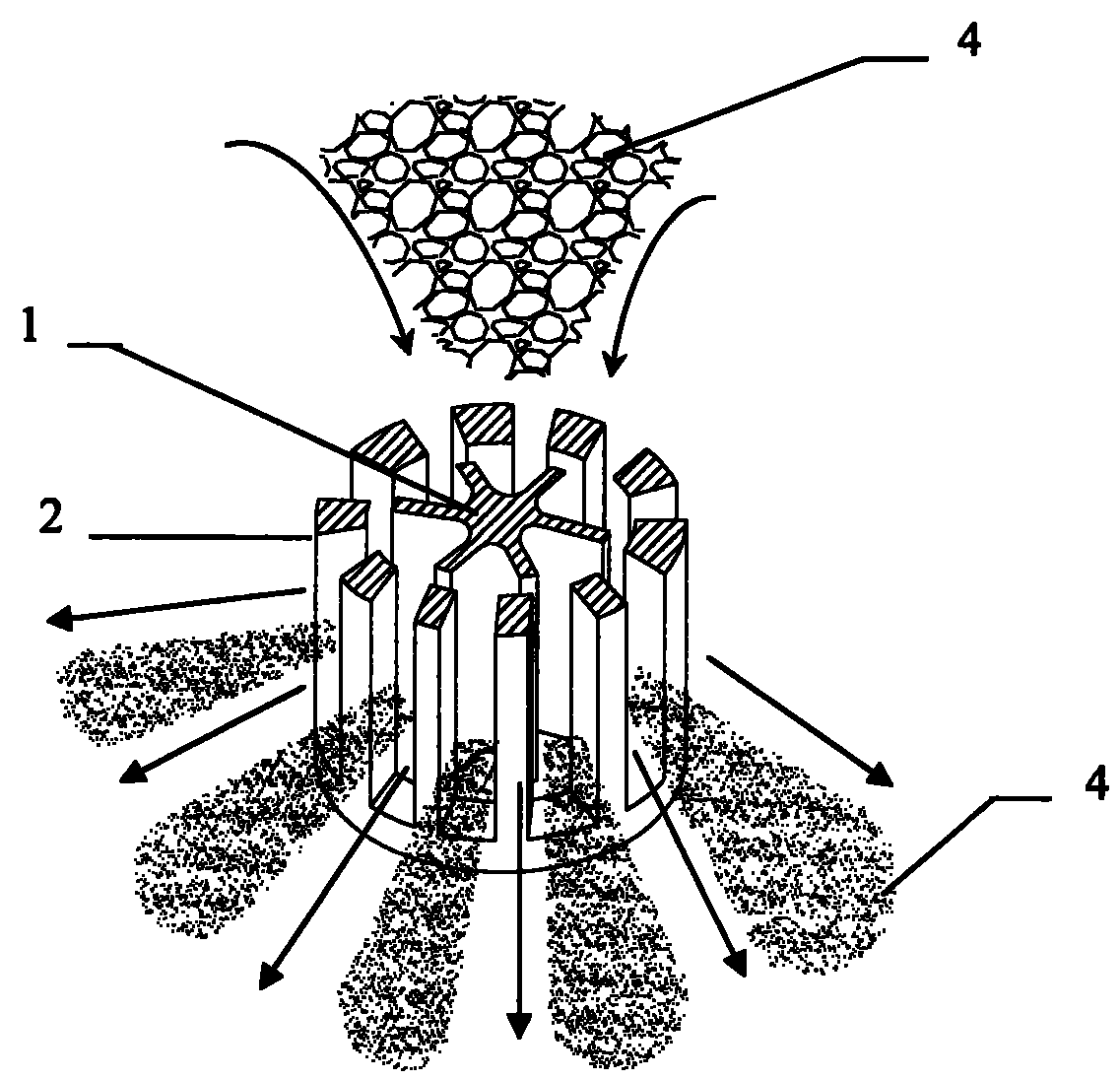

InactiveCN1990097AShorten mixing timeImprove high-current discharge performanceMixing methodsRotary stirring mixersElectricityEmulsion

An electrode paste mixed method including used mixer mixing the materials of electrode paste composition, which, the said mixer is high shear spread emulsion machine, the said high shear spread emulsion machine including rotor, stator and motor, the said stator is outside of the rotor, the said rotor connect and drive by the electric machine. With the invention of the electrode paste mixed method can raise large current discharge battery performance, capacity and cycle performance, and significantly shorten the time of mixed electrode paste, has greatly enhanced the efficiency of labor.

Owner:BYD CO LTD

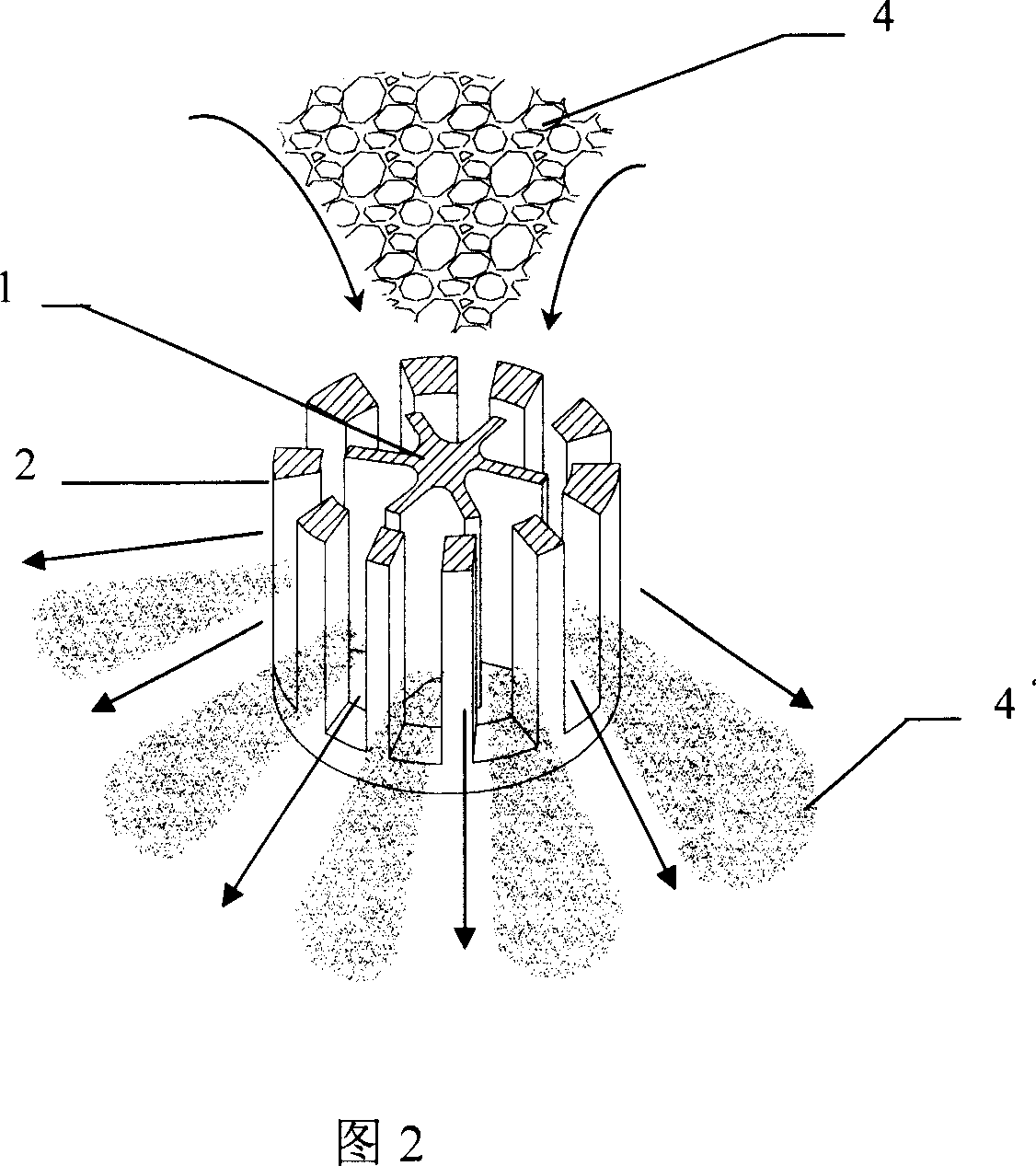

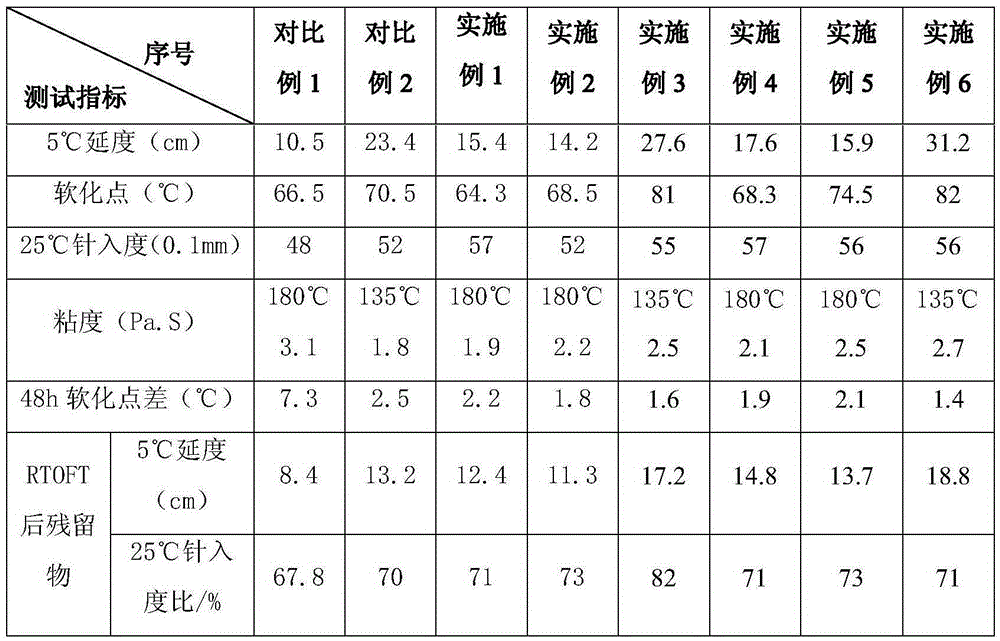

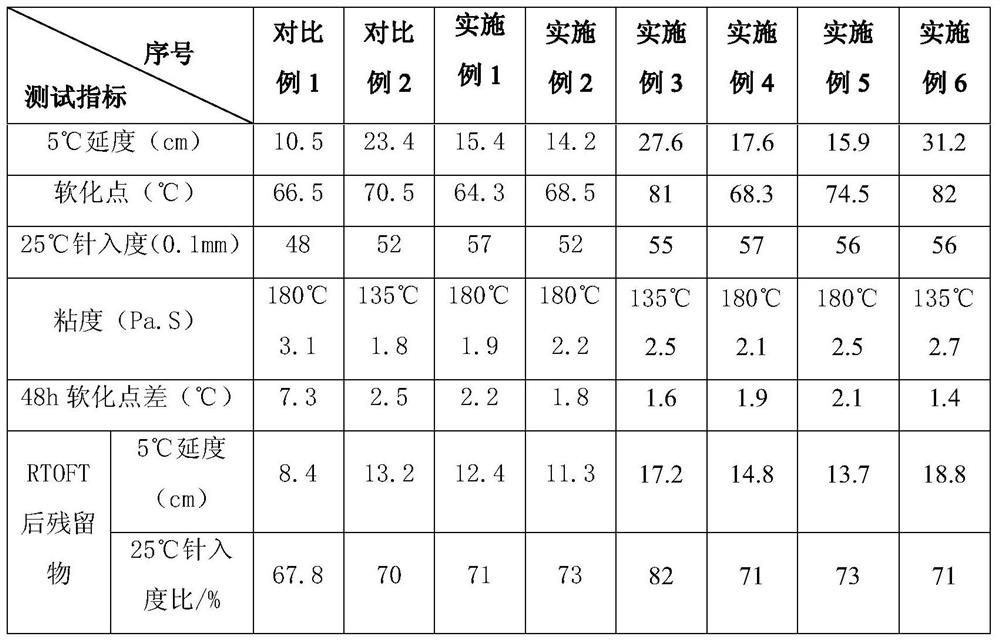

Waste sole rubber modified asphalt and preparing method thereof

ActiveCN105385179AUniform and fine dispersionSolve pollutionBuilding insulationsInter layerEngineering

The invention discloses waste sole rubber modified asphalt and a preparing method thereof. The waste sole rubber modified asphalt comprises the following components in parts by weight: 100 parts of matrix asphalt, 25-35 parts of waste sole rubber powder and 0.15-0.525 part of crosslinking agent. The problem of environment pollution caused by a waste shoe material is effectively solved by using the waste sole rubber powder as a modifier in the asphalt; the waste sole rubber modified asphalt can solve the problem of high temperature track resistance in a heavy load traffic environment, enhances waterproofness of a road surface and inter-layer cohesiveness, prolongs the service life of an asphalt road surface and reduces road surface noise. In addition, the waste sole rubber powder and waste tire rubber powder or SBS are compounded to modify the asphalt, the dosage of the waste tire rubber powder and the SBS is greatly reduced and the cost is saved.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

PVA-ECC (Polyvinyl Acetate-Engineered Cementitious Composite) high-toughness fiber cement based composite material and preparation method thereof

InactiveCN108675716AImprove liquidityImprove compactnessClimate change adaptationCelluloseMicrosphere

The invention belongs to the technical field of building materials and in particular relates to a PVA-ECC (Polyvinyl Acetate-Engineered Cementitious Composite) high-toughness fiber cement based composite material and a preparation method thereof. The PVA-ECC high-toughness fiber cement based composite material is prepared from the following components in parts by weight: 25 to 35 parts of 525 white cement, 40 to 60 parts of quartz sand, 18 to 20 parts of titanium white, 1 to 10 parts of pitchstone vitrified microspheres, 0.5 to 2 parts of PVA cellulose, 6 to 8 parts of ionic liquid, 10 to 12 parts of crop straw powder, 3 to 6 parts of clay, 3 to 5 parts of diatomite, 3 to 5 parts of maleic anhydride, 1 to 3 parts of crystal whiskers, 3 to 6 parts of a silane coupling agent, 0.5 to 2 partsof cellulose ether, 0.3 to 2 parts of redispersible latex powder, 0.1 to 3 parts of a high-efficiency water reducing agent, 0.5 to 2 parts of an inorganic pigment and 90 to 100 parts of water. The preparation method comprises the following steps: taking the maleic anhydride, the clay, the diatomite and the PVA cellulose as raw materials to prepare a PVA fiber / clay / diatomite nano composite material, and then mixing and stirring the PVA fiber / clay / diatomite nano composite material with other raw materials.

Owner:吴远怀

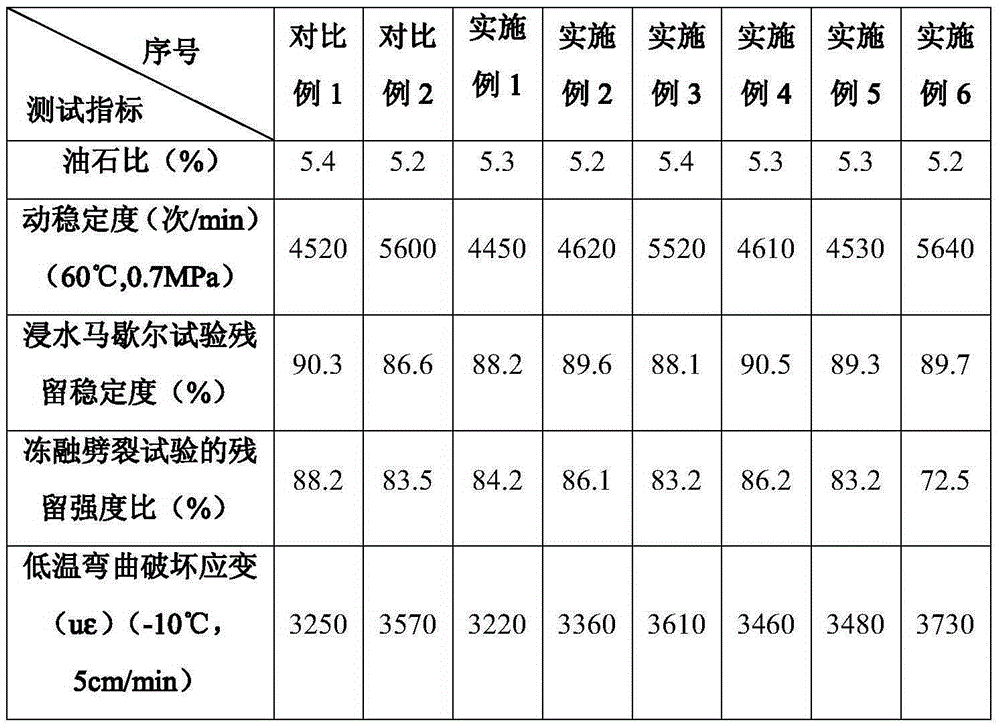

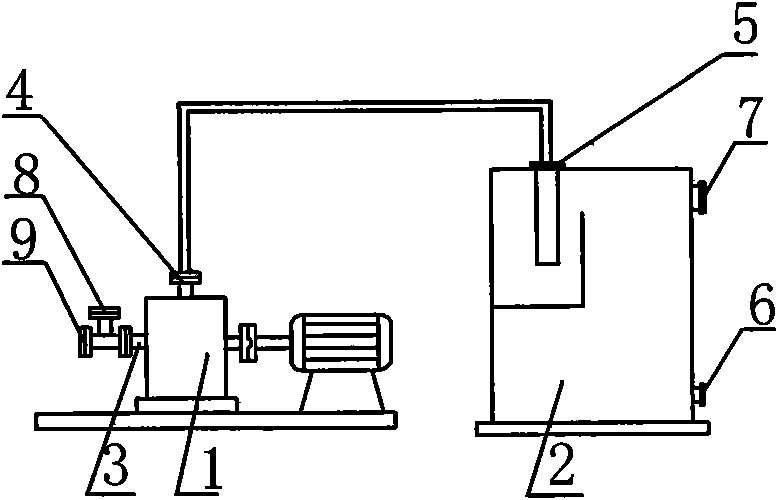

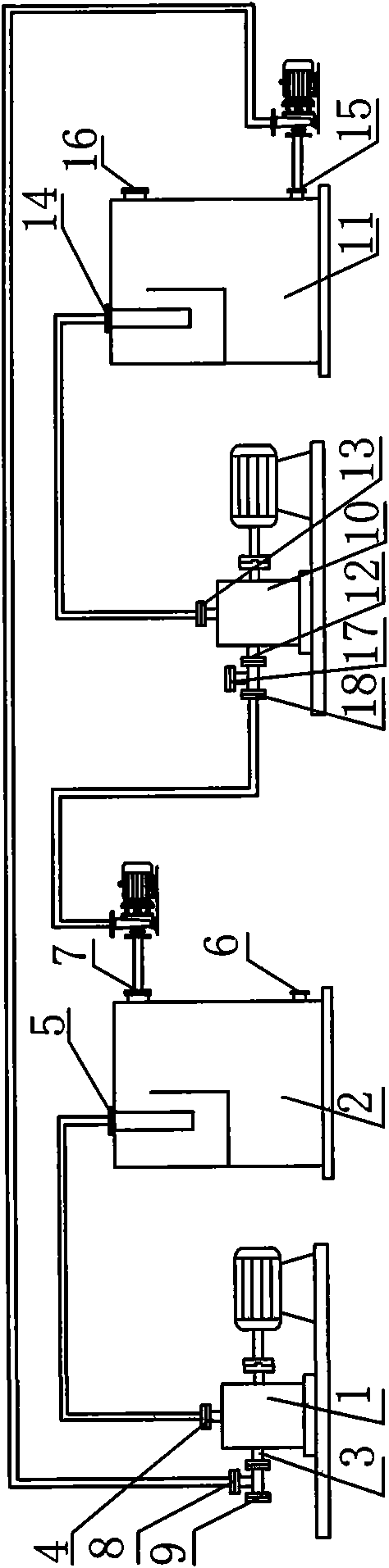

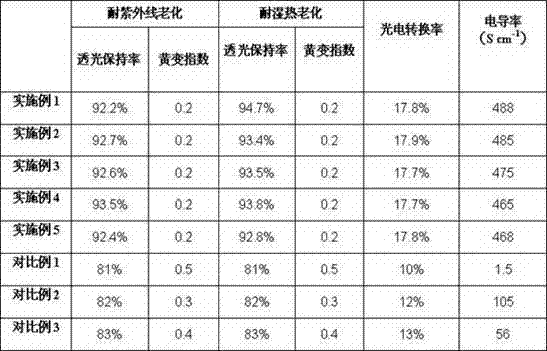

Extraction device

InactiveCN101898048ALarge mass transfer areaEasy to phaseLiquid solutions solvent extractionPhase splittingEngineering

The invention discloses an extraction device comprising an emulsifying machine (1) and a phase-splitting apparatus (2). The emulsifying machine (1) is provided with an emulsifying machine inlet (3) and an emulsifying machine outlet (4), the phase-splitting apparatus (2) is provided with a mixed phase inlet (5), a heavy phase outlet (6) and a light phase outlet (7), the emulsifying machine inlet (3) is connected with an extracted object inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed phase inlet (5) of the phase-splitting apparatus. When multistage extraction devices are combined, the light phase outlet of the phase-splitting apparatus in the extraction device at the current level is connected with the solvent inlet of the extraction device at the next level through a pipeline provided with a pump, and the heavy phase outlet of the phase-splitting apparatus in the extraction device at the next level is connected with the extracted object inlet of the extraction device at the current level through the pipeline provided with the pump. The invention has high extraction efficiency, small size, less occupied area, simple operation and capability of saving apparatus investment and running cost.

Owner:WENGFU (GRP) CO LTD

Blended fertilizer based on steel production waste and preparation method thereof

InactiveCN102795910AMeet nutrient requirementsTo achieve the effect of increasing efficiency and increasing productionFertilizer mixturesSlagPotassium

The invention discloses a blended fertilizer based on steel production waste and a preparation method thereof. The blended fertilizer is prepared by mixing 1-10 parts of steel making byproduct steel slag, 5-15 parts of waste powder formed by drying sintering flue gas ammonia desulfurization waste mud, and 3-6 parts of potassium fertilizer, wherein the total nutrient weight content of N, P and K is not lower than 35%. The preparation method comprises the following steps: preparing steel slag fine powder, waste powder and potassium fertilizer according to parts by weight, detecting to determine that the total nutrient weight content of N, P and K is not lower than 35%, and evenly mixing. The blended fertilizer disclosed by the invention contains sufficient nitrogen, phosphorus, potassium and microelements, and can sufficiently satisfy the nutrient requirements for plant growth without adding any microelement or fertilizer synergist, thereby achieving the synergistic and yield increase effects; the blended fertilizer has uniform and fine particle size, thereby avoiding soil salinization and hardening; and the invention recycles steel waste resources, thereby greatly lowering the production cost.

Owner:武汉钢铁有限公司

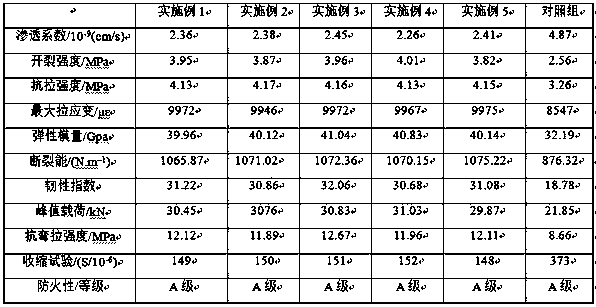

High-impermeability cement-based composite material and method for preparing same

The invention relates to a high-impermeability cement-based composite material and a method for preparing the same. The high-impermeability cement-based composite material comprises, by weight, 20-30parts of 525 white cement, 40-60 parts of quartz sand, 18-20 parts of titanium dioxide powder, 10-12 parts of fly ash, 5-15 parts of chitosan nanogel, 3-5 parts of polyacrylate emulsion, 1-10 parts ofpitchstone vitrified micro-spheres, 0.5-2 parts of PVA (polyvinyl alcohol) celluloses, 6-8 parts of ionic liquid, 10-12 parts of crop straw powder, 3-6 parts of clay, 3-5 parts of diatomaceous earth,3-5 parts of maleic anhydride, 1-3 parts of whiskers, 3-6 parts of silane coupling agents, 0.5-2 parts of cellulose ether, 0.3-2 parts of redispersible latex powder, 0.1-3 parts of superplasticizers,0.5-2 parts of inorganic pigment and 60-70 parts of water. The method includes preparing composite materials from the maleic anhydride, the clay, the diatomaceous earth and the PVA celluloses; mixingand stirring the composite materials and other raw materials with one another to obtain the high-impermeability cement-based composite material which is a product.

Owner:吴远怀

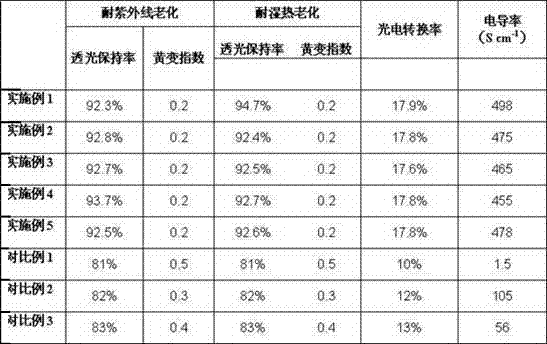

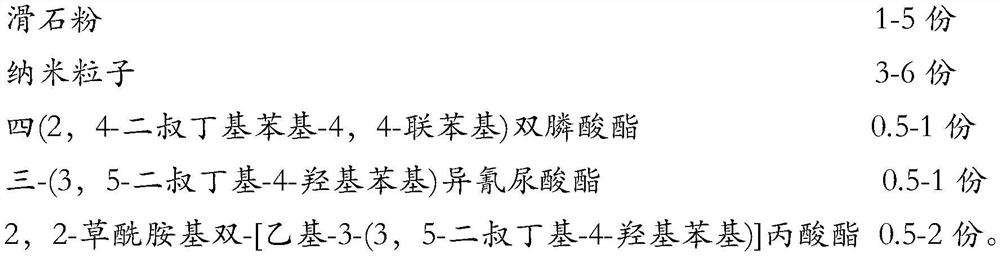

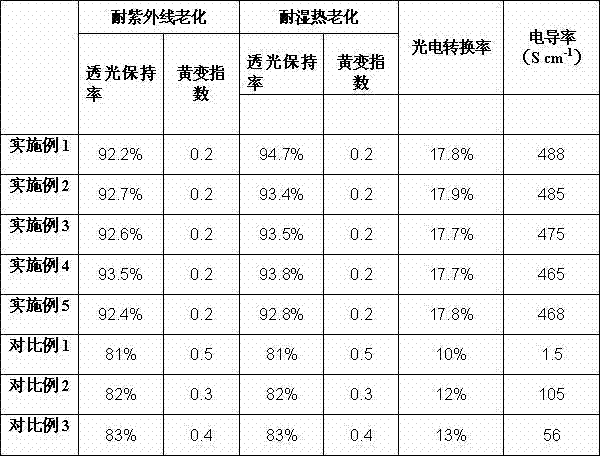

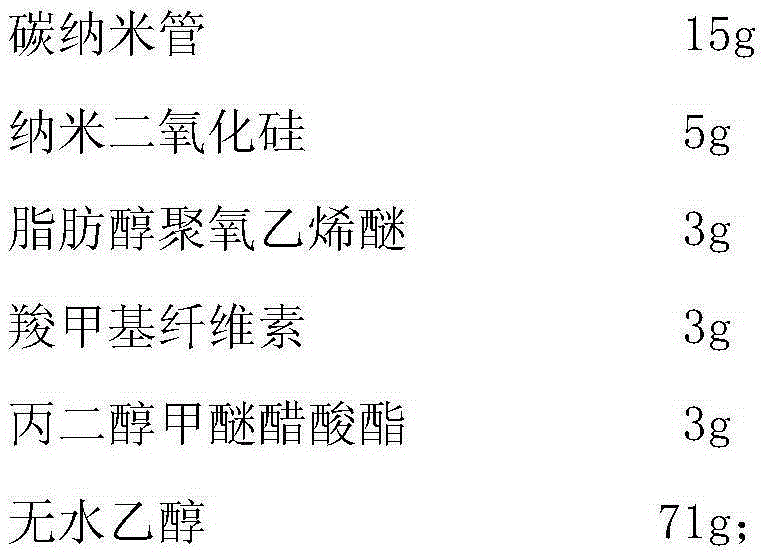

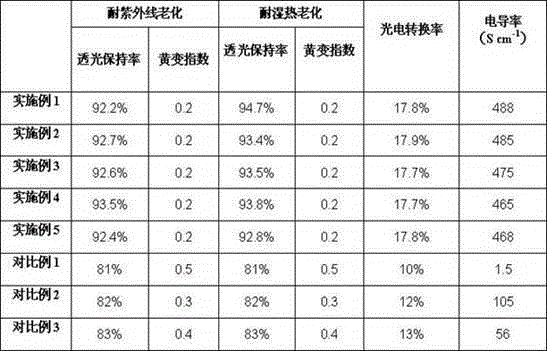

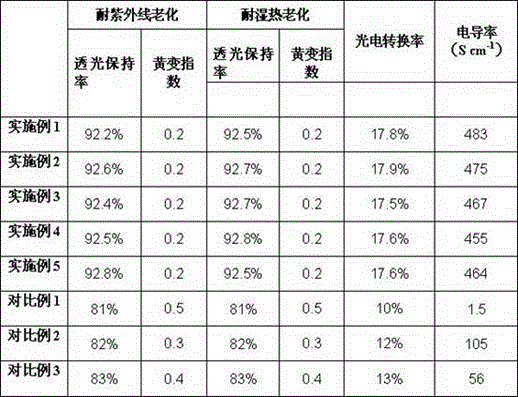

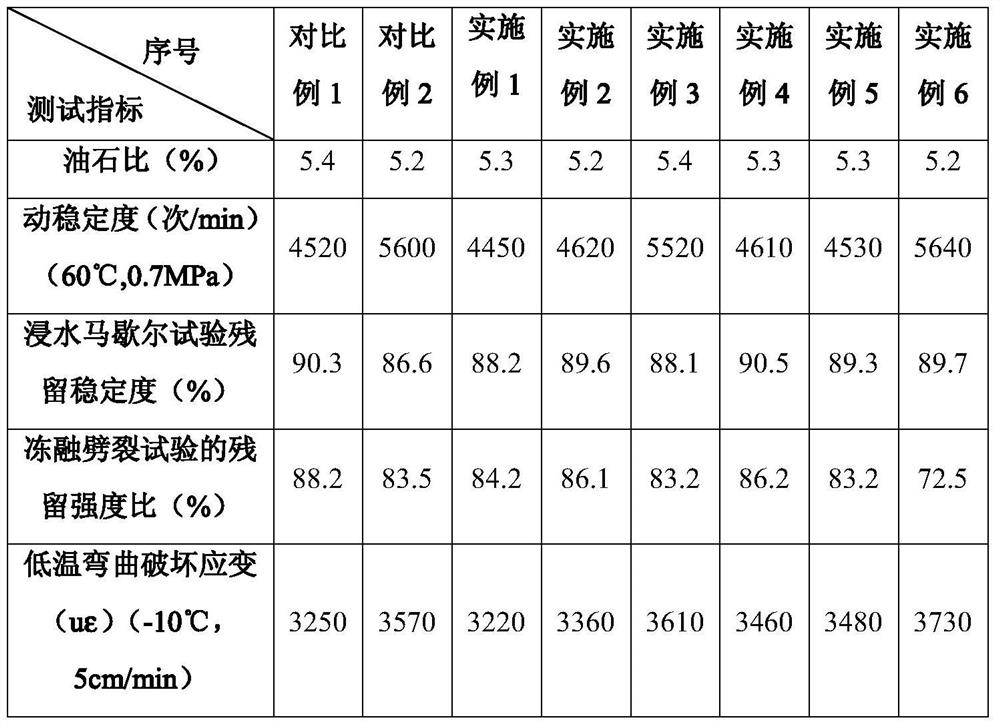

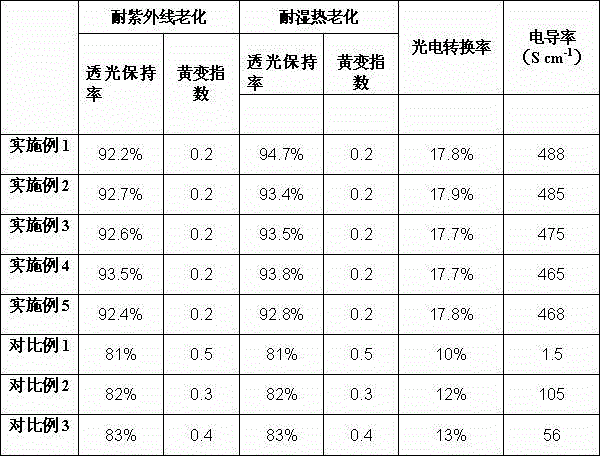

Preparation method of nano coating for EVA (ethylene-vinyl acetate copolymer) film surface

InactiveCN103571320ASimple processImprove conductivityPolyether coatingsElectrically-conductive paintsCarbon nanotubeFatty alcohol

The invention relates to a preparation method of a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol methyl ether acetate and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol methyl ether acetate serves as a film forming aid. A film covered by a coat formed by the nano coating has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. The preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:广东奥优涂料有限公司

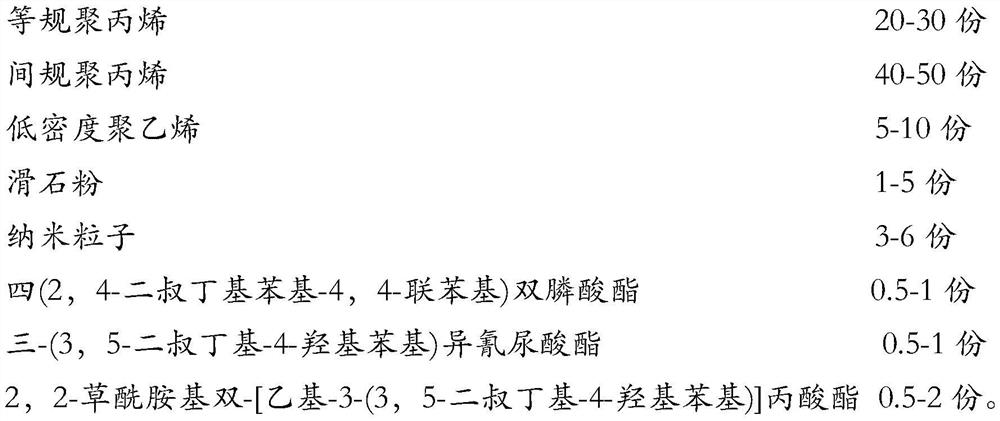

Non-crosslinked polypropylene material and cable

ActiveCN112646266AHigh glass transition temperatureGood flexibilityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a non-crosslinked polypropylene material and a cable, and belongs to the technical field of cables, and the non-crosslinked polypropylene material comprises the following raw materials by weight: 20-30 parts of isotactic polypropylene, 40-50 parts of syndiotactic polypropylene, 5-10 parts of low density polyethylene, 1-5 parts of talcum powder, 3-6 parts of nanoparticles, 0.5-1 part of tetra (2, 4-di-tert-butylphenyl-4, 4-biphenyl) bisphosphonate, 0.5-1 part of tris- (3, 5-di-tert-butyl-4-hydroxyphenyl) isocyanurate and 0.5-2 parts of 2, 2-oxamido bis-[ethyl-3-(3, 5-di-tert-butyl-4-hydroxyphenyl) ] propionate. The cable material still has ultrahigh flexibility and toughness at the temperature of -30 DEG C and lower, therefore, the cold resistance, weather resistance and low-temperature impact resistance of the cable material are improved, the application range is wide, the practicability is high, and the oxidation resistance of the cable material is improved by using multiple antioxidants.

Owner:杭州龙源电力有限公司 +2

Super-fine gelatinization method of infant nutritional rice flour

InactiveCN107198230AUniform tasteUniform and delicate tasteMilk preparationFood ingredient as mouthfeel improving agentRice milkNutrient

The invention provides a super-fine gelatinization method of infant nutritional rice flour. The infant nutritional rice flour is prepared from the following raw materials in parts by weight: 40 to 60 parts of rice, 10 to 15 parts of tartary buckwheat flour, 3 to 5 parts of fructus jujubae powder, 5 to 7 parts of rock candy, 3 to 5 parts of milk powder, 1 to 3 parts of beef powder, 1 to 3 parts of chestnut powder, 1 to 3 parts of vegetable powder and 0.5 to 1 part of a compound nutrient. A production method of the infant nutritional rice flour comprises the following steps: a, preparing rice milk; b, preparing primary pulp; c, gelatinizing the primary pulp through a three-step method; d, drying and sheeting through a three-step method; e, preparing the infant nutritional rice flour. According to the super-fine gelatinization method provided by the invention, the steps of gelatinizing the primary pulp through the three-step method and drying and sheeting through the three-step method are adopted and the produced infant nutritional rice flour is uniform, fine and smooth powder and has the advantages that the infant nutritional rice flour has a strong rehydration characteristic and is not caked after being diluted, all the raw materials are uniformly dispersed in a dry-method material mixing process and the infant nutritional rice flour is easily digest and absorb by infants.

Owner:广东金祥食品有限公司

Preparation method of nano coating for EVA (ethylene-vinyl acetate copolymer) film surface of solar packaged cell

ActiveCN103571248ASimple processImprove conductivityElectrically-conductive paintsReflecting/signal paintsCarbon nanotubeSilicon dioxide

The invention relates to a preparation method of a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol butyl ether and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol butyl ether serves as a film forming aid. A film covered by a coat formed by the nano coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. The preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:浙江兆泽实业有限公司

Mixing method of electrode slurry

InactiveCN1990097BShorten mixing timeImprove high-current discharge performanceRotary stirring mixersMixing methodsElectricityEmulsion

Owner:BYD CO LTD

Differential preparation equipment, preparation process and ratio of the inner wall water -based coatings

ActiveCN110841536BUniform and fine dispersionSimple structureShaking/oscillating/vibrating mixersTransportation and packagingStructural engineeringMechanical engineering

Owner:惠州市山宝实业有限公司

Nano coating for EVA (ethylene-vinyl acetate copolymer) film surface of solar packaged cell

ActiveCN103571236ASimple processImprove conductivityPhotovoltaic energy generationElectrically-conductive paintsCarbon nanotubeFatty alcohol

The invention relates to a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol butyl ether and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol butyl ether serves as a film forming aid. A film covered by a coat formed by the nano coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. A preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

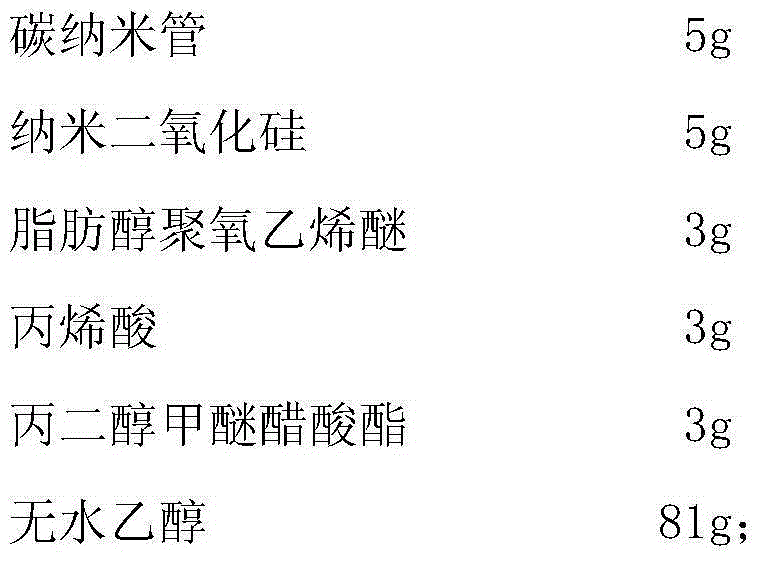

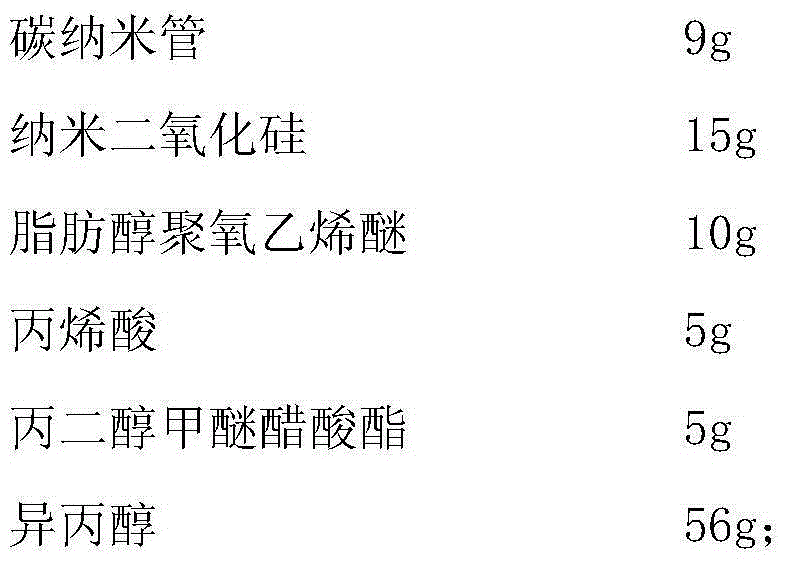

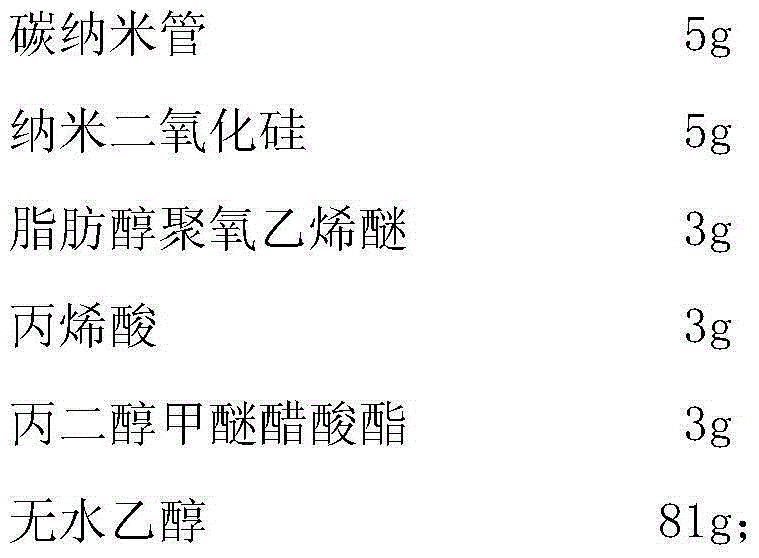

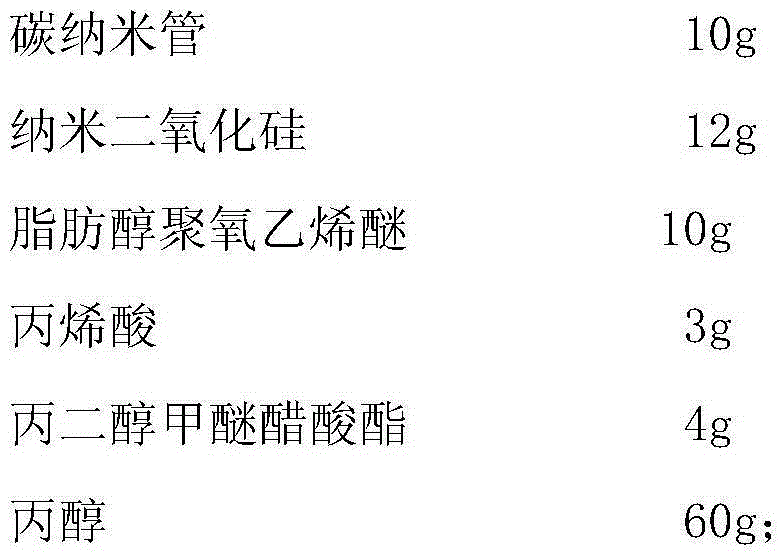

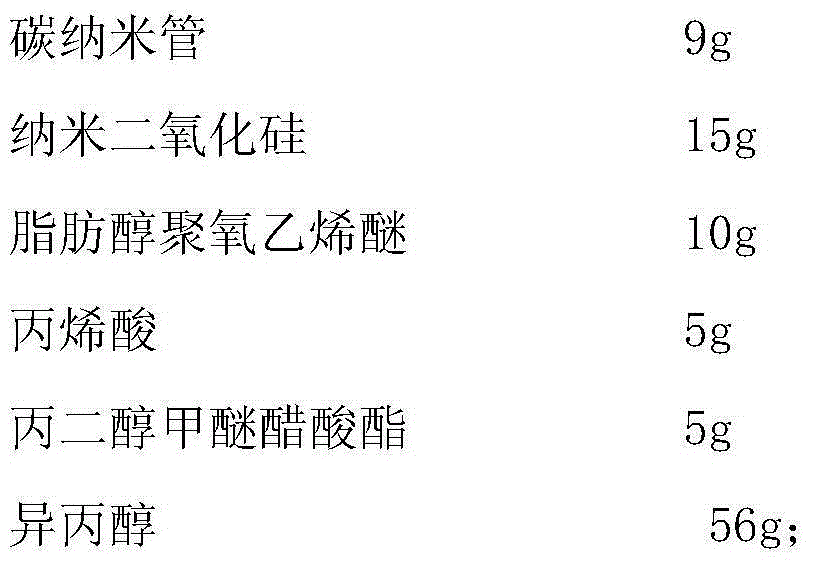

A kind of preparation method of eva thin film surface coating

ActiveCN103555025BSimple processImprove conductivityElectrically-conductive paintsAdhesiveCarbon nanotube

The invention relates to a preparation method of an EVA (ethylene-vinyl acetate) film surface paint. The EVA film surface paint is composed of the following components in percentage by mass: 5-10% of carbon nanotube, 5-15% of nano silicon dioxide, 3-15% of fatty alcohol polyethenoxy ether, 3-5% of acrylic acid, 3-5% of propylene glycol monomethyl ether acetate and the balance of organic solvent. The mass ratio of the fatty alcohol polyethenoxy ether to the acrylic acid is 1:1-3:1; and the fatty alcohol polyethenoxy ether is used as a dispersant, the acrylic acid is used as an adhesive, and the propylene glycol monomethyl ether acetate is used as a film-forming assistant. The coating film formed by the EVA film surface paint has electric conductivity and low yellowing rate, and enhances the photoelectric conversion rate of the battery pack; and the preparation method is simple in technique and convenient to operate, and can efficiently enable the carbon nanotubes and silicon dioxide nanotubes to be uniformly dispersed and fixed to the EVA film surface.

Owner:广东绿树环保涂料科技有限公司

A kind of eva adhesive film surface nano-coating

ActiveCN103555040BSimple processImprove conductivityElectrically-conductive paintsAdhesiveCarbon nanotube

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

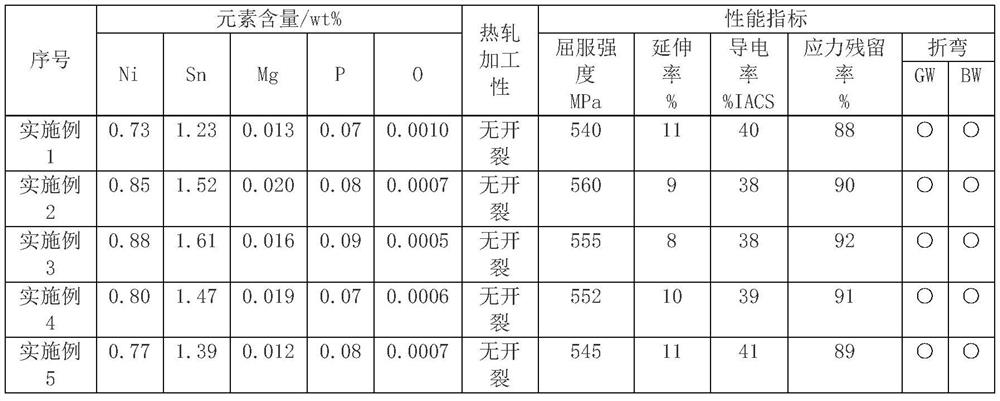

Copper alloy with excellent hot rolling performance and manufacturing method thereof

InactiveCN113981265AReduce performanceGuaranteed performanceConductive materialProcess efficiency improvementIngotHot working

The invention discloses a copper alloy with excellent hot rolling performance and a manufacturing method thereof, the copper alloy comprises the following components in percentage by weight: 0.6-1.0 wt% of Ni, 1.0-2.0 wt% of Sn, 0.01-0.03 wt% of Mg, 0.06-0.10 wt% of P, less than or equal to 0.0010 wt% of O, and the balance of Cu, and inevitable impurity alloy, oxygen-free copper is used as a matrix, the oxygen content is controlled to be less than or equal to 0.0010 wt%, the trace element Mg is added, the alloy has excellent hot workability, in the process of melting casting and hot rolling, the ingot has no cracking phenomenon and has excellent hot workability, the yield strength Rp of the alloy is larger than or equal to 520 Mpa, the ductility A11.3 is larger than or equal to 6%, the electric conductivity is larger than or equal to 38% IACS, the bending machining performance (GW and BW directions) R / t is smaller than or equal to 1, the stress residual rate is larger than or equal to 85% after heat preservation is conducted for 1000 hours at the temperature of 150 DEG C, and a plate strip processed by the alloy is widely applied to connectors, terminals or switch parts of electrical, automobile and communication devices and the like.

Owner:TONGLING NON FERROUS METAL GROUP CORP

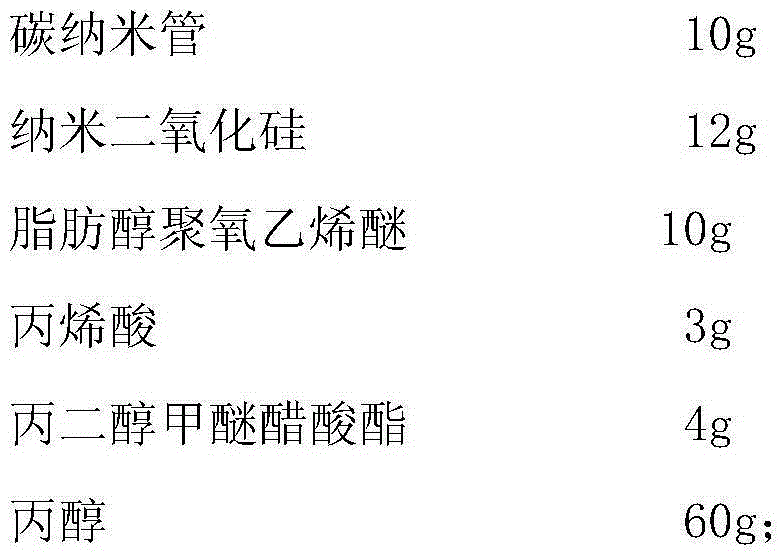

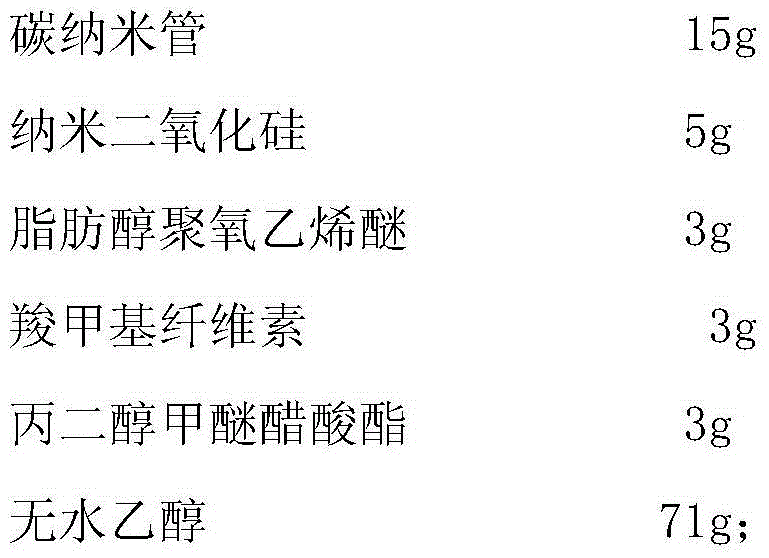

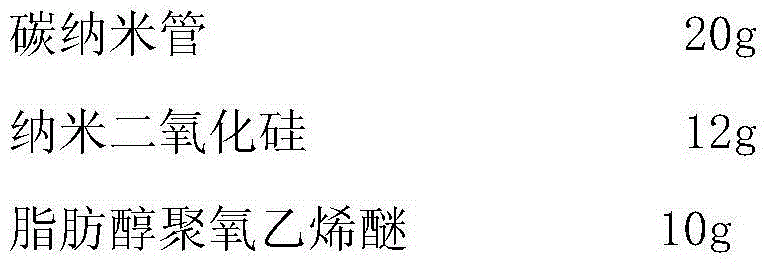

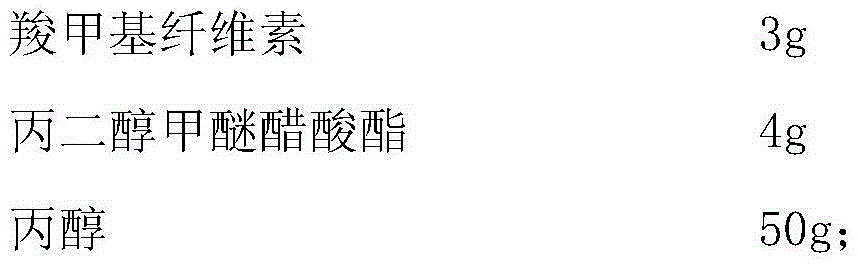

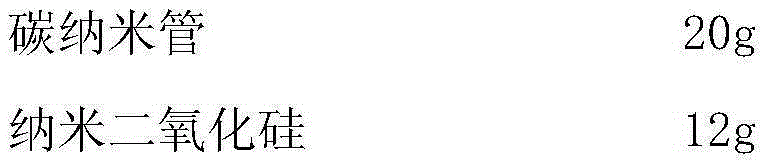

A kind of preparation method of EVA adhesive film surface nano-coating

ActiveCN103555015BSimple processImprove conductivityPolyether coatingsElectrically-conductive paintsPolymer scienceAdhesive

The invention relates to a preparation method of an EVA (ethylene-vinyl acetate) adhesive film surface nano paint. The EVA adhesive film surface nano paint is composed of the following components in percentage by mass: 10-20% of carbon nanotube, 5-15% of nano silicon dioxide, 3-15% of fatty alcohol polyethenoxy ether, 3-5% of carboxymethyl cellulose, 3-5% of propylene glycol monomethyl ether acetate and the balance (10-30%) of organic solvent. The mass ratio of the fatty alcohol polyethenoxy ether to the carboxymethyl cellulose is 1:1-3:1; and the fatty alcohol polyethenoxy ether is used as a dispersant, the carboxymethyl cellulose is used as an adhesive, and the propylene glycol monomethyl ether acetate is used as a film-forming assistant. The coating film formed by the EVA adhesive film surface nano paint has electric conductivity and low yellowing rate, and enhances the photoelectric conversion rate of the battery pack; and the preparation method is simple in technique and convenient to operate, and can efficiently enable the carbon nanotubes and silicon dioxide nanotubes to be uniformly dispersed and fixed to the EVA adhesive film surface.

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

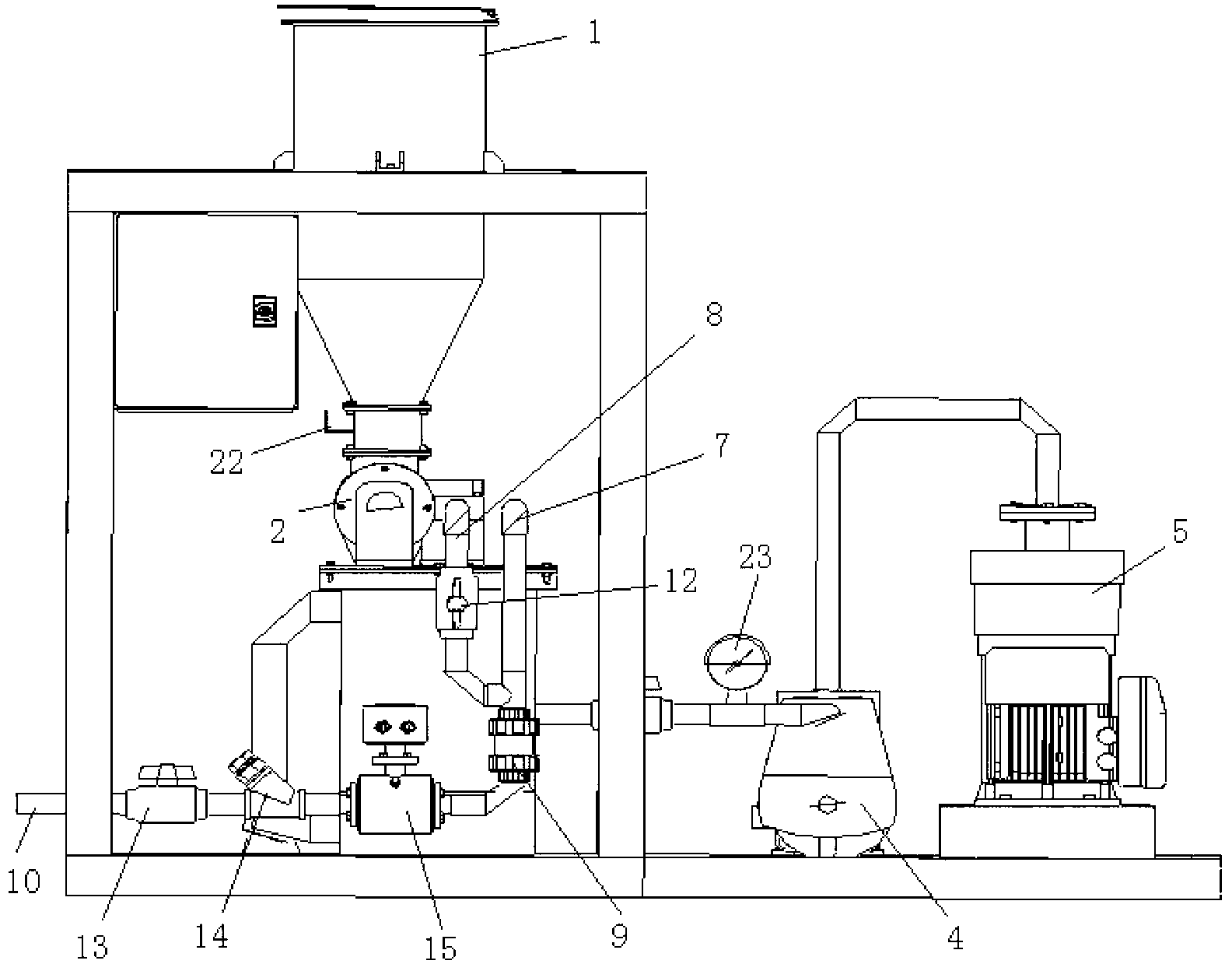

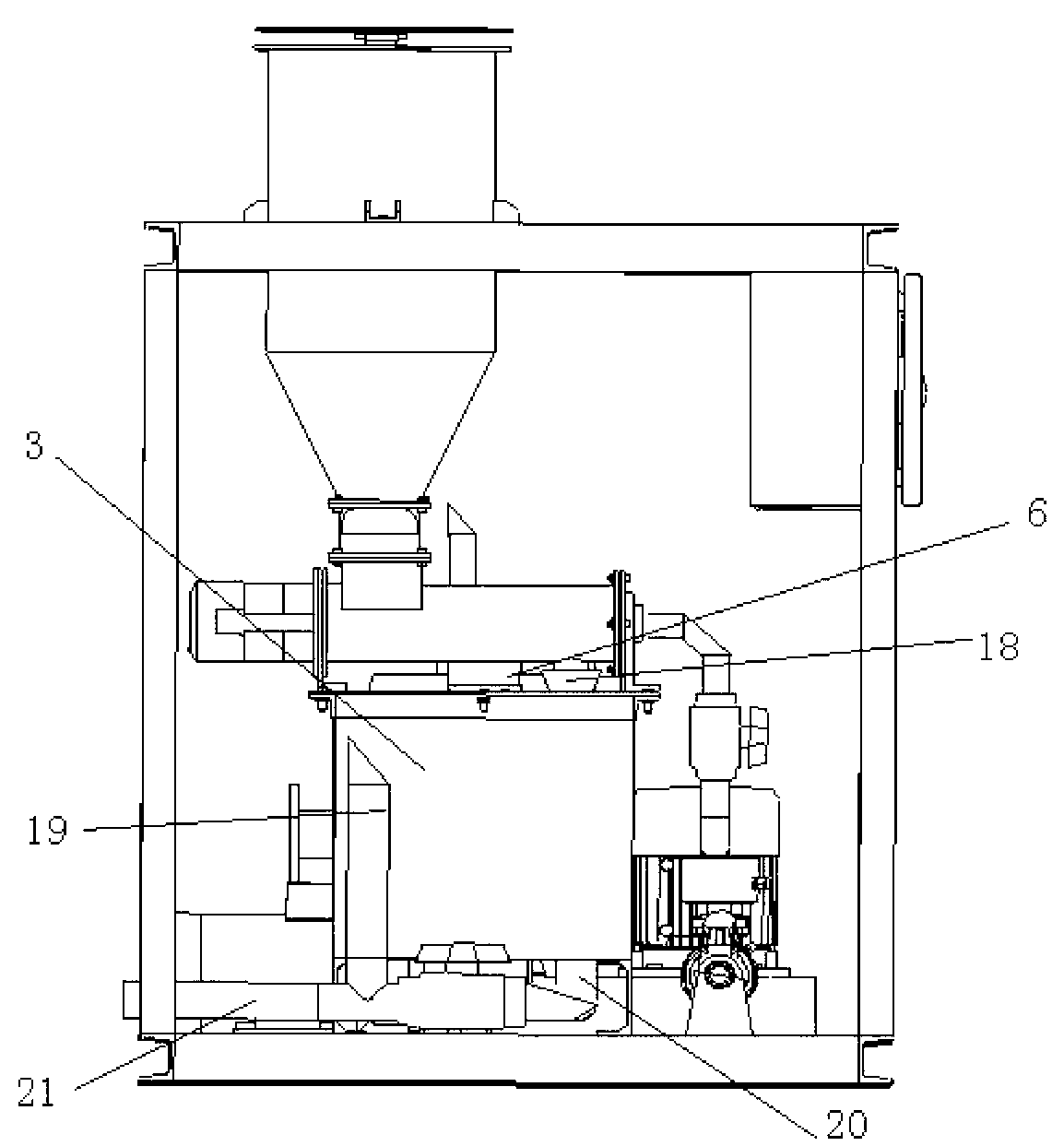

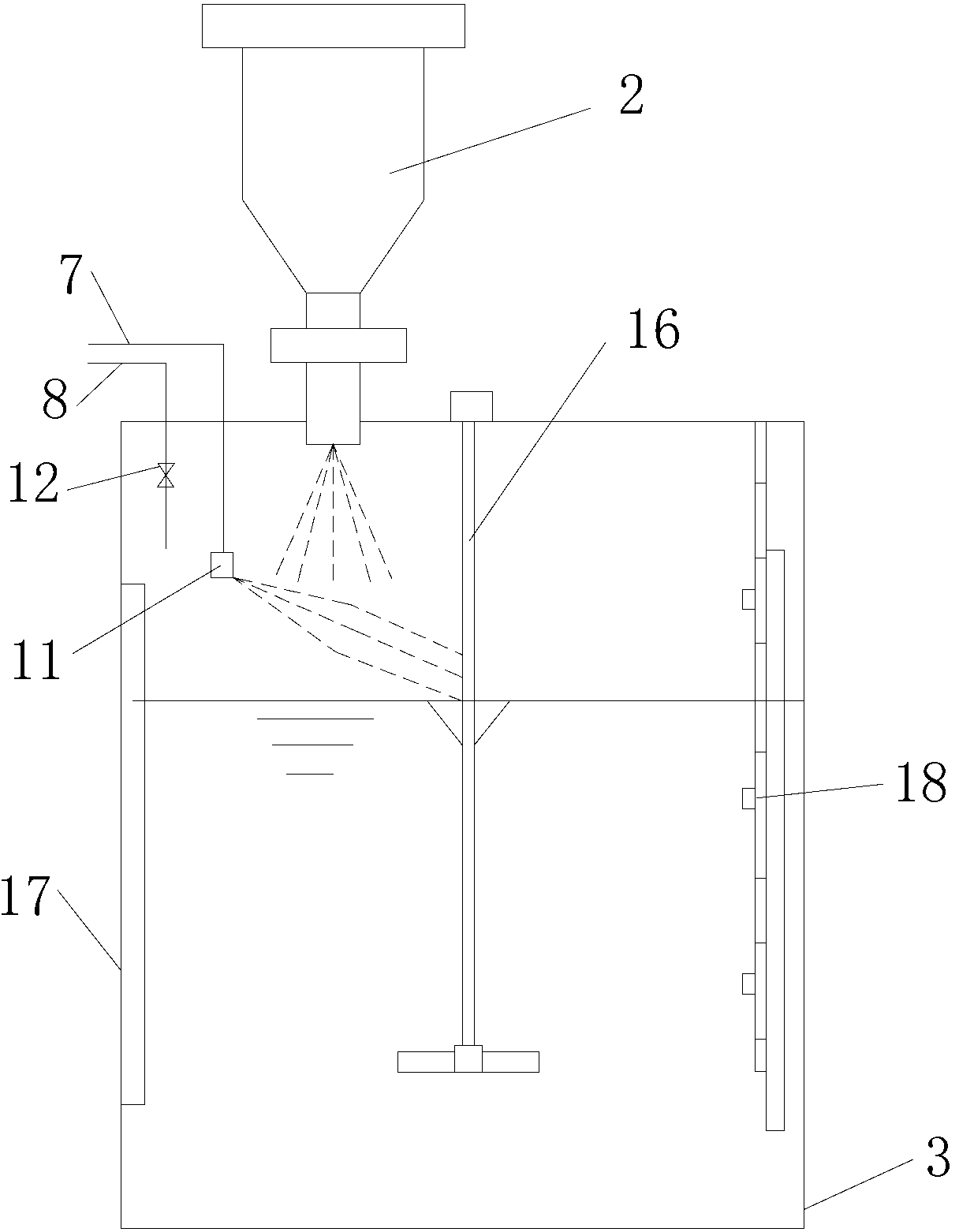

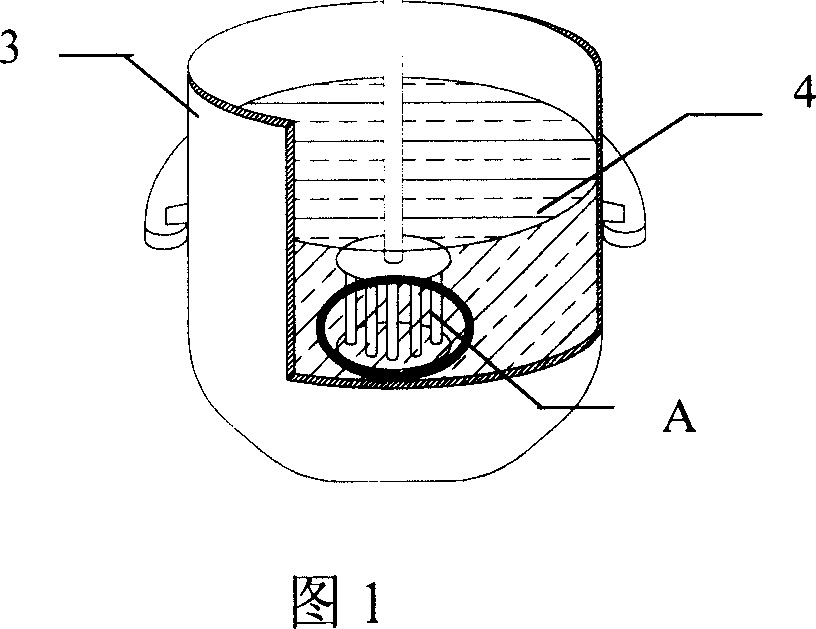

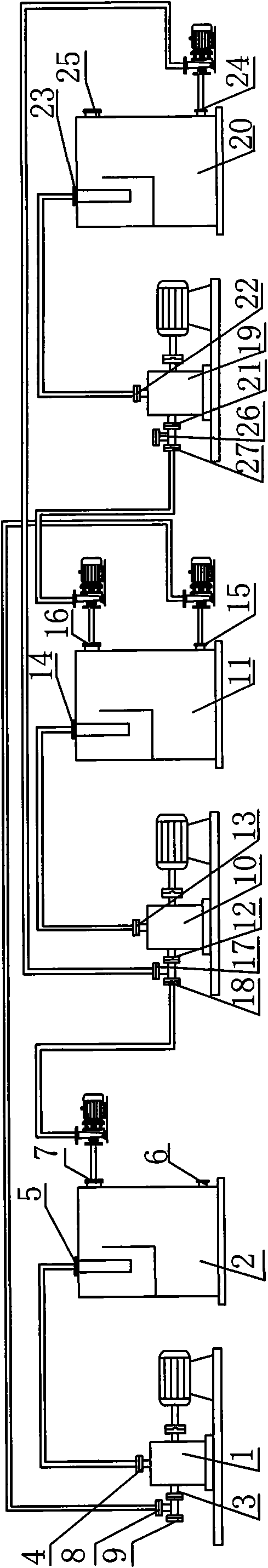

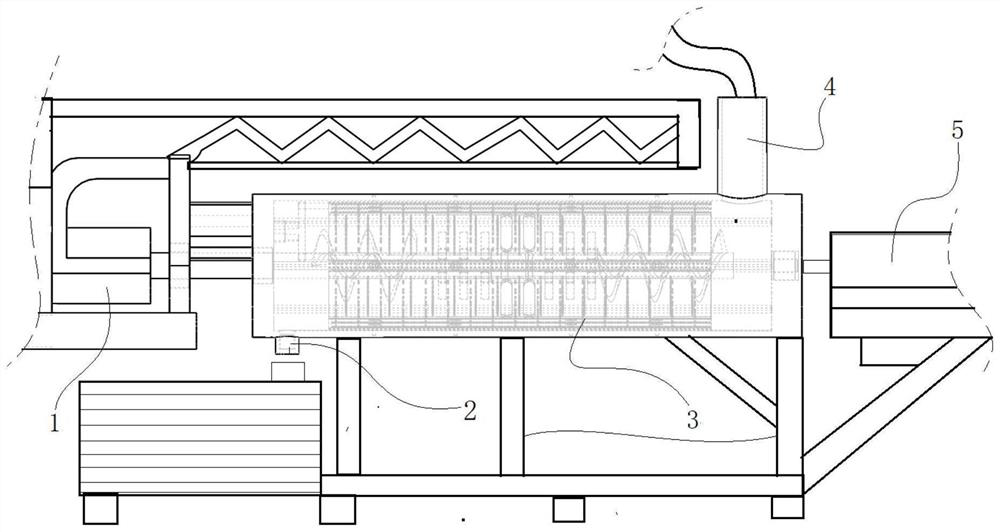

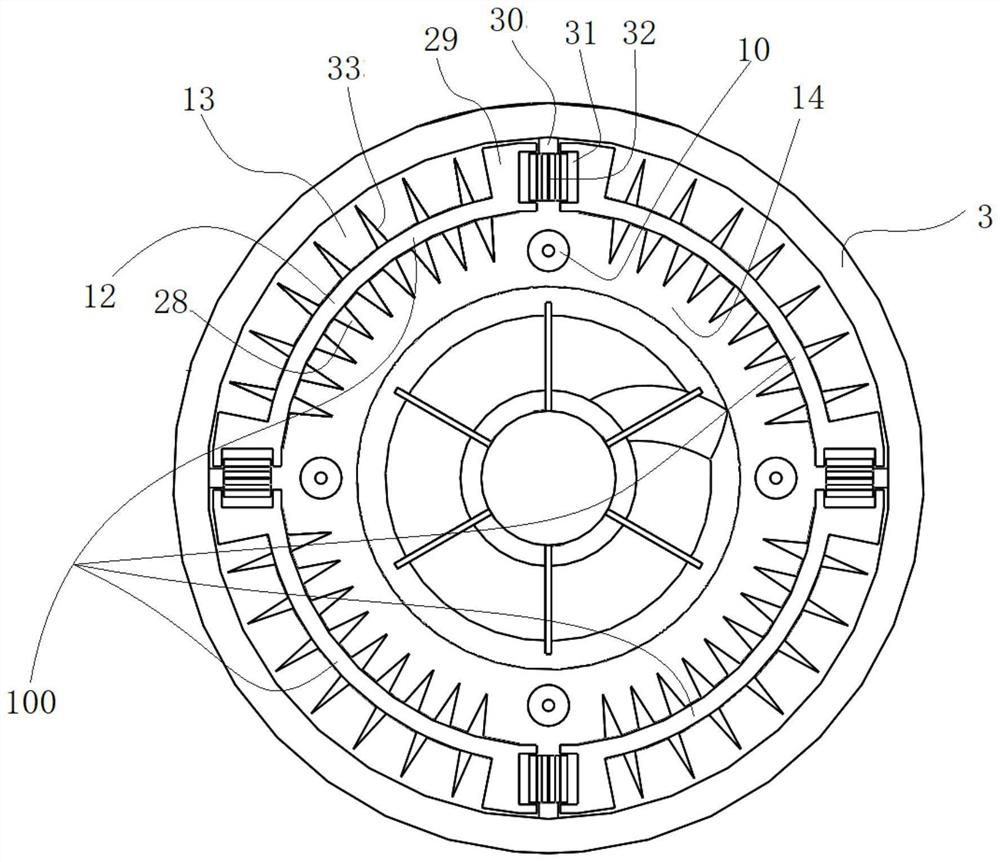

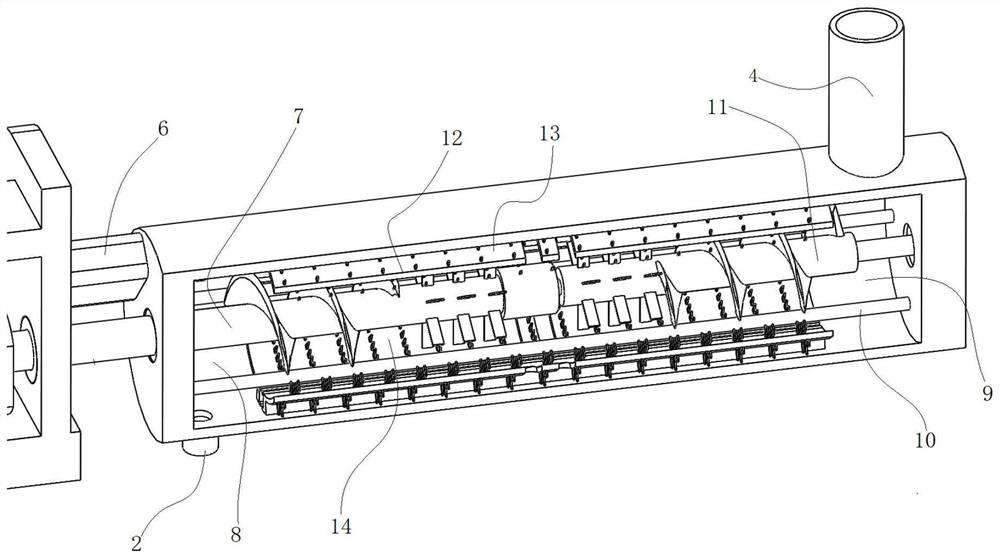

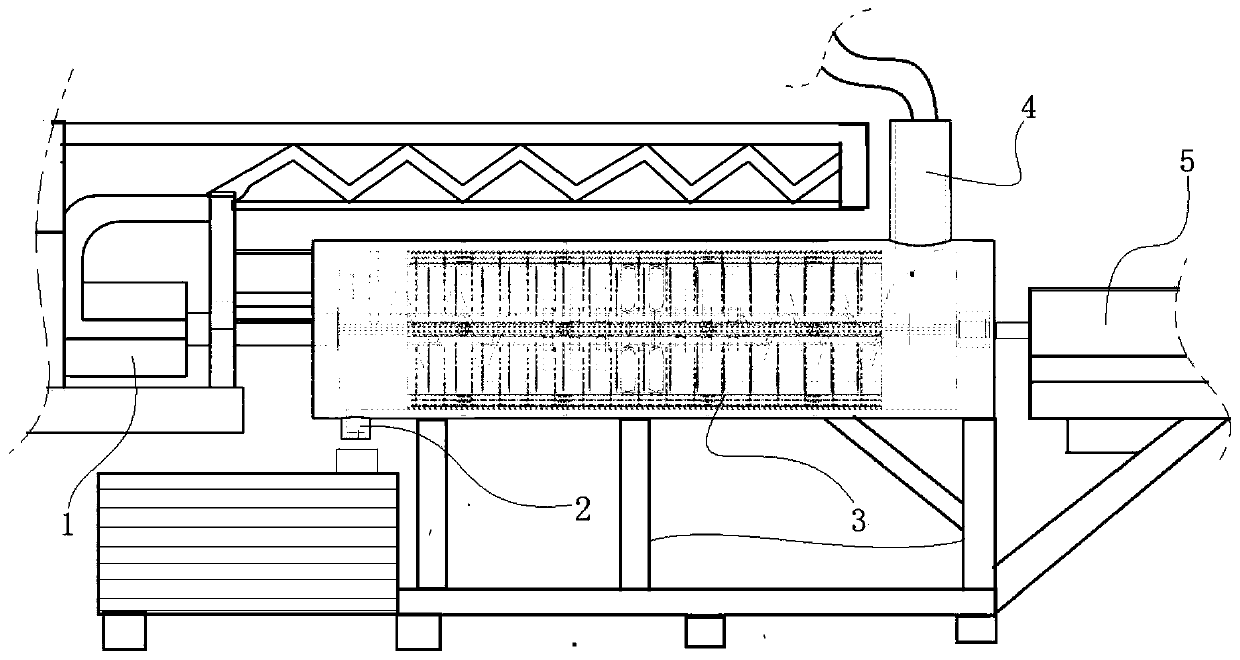

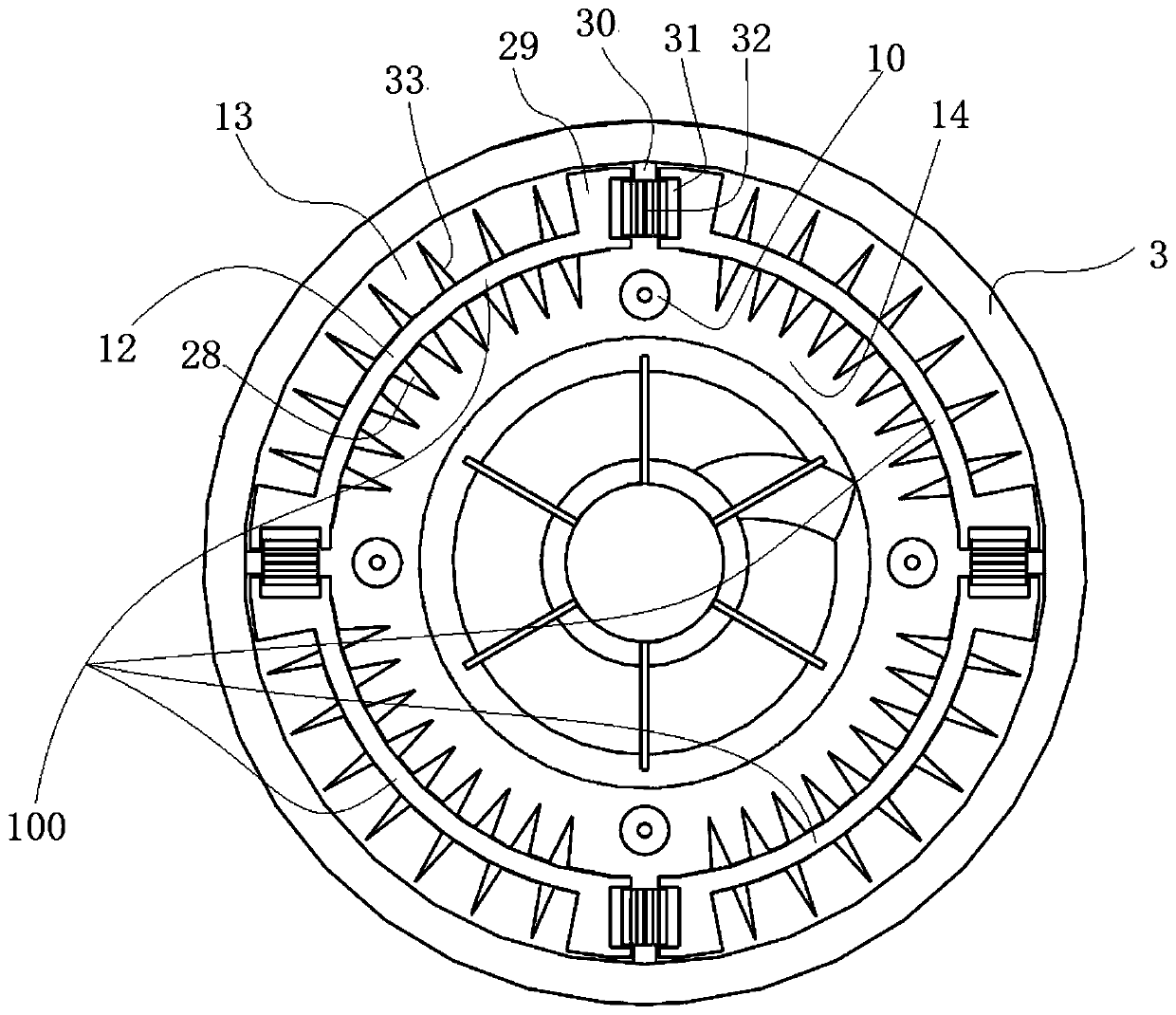

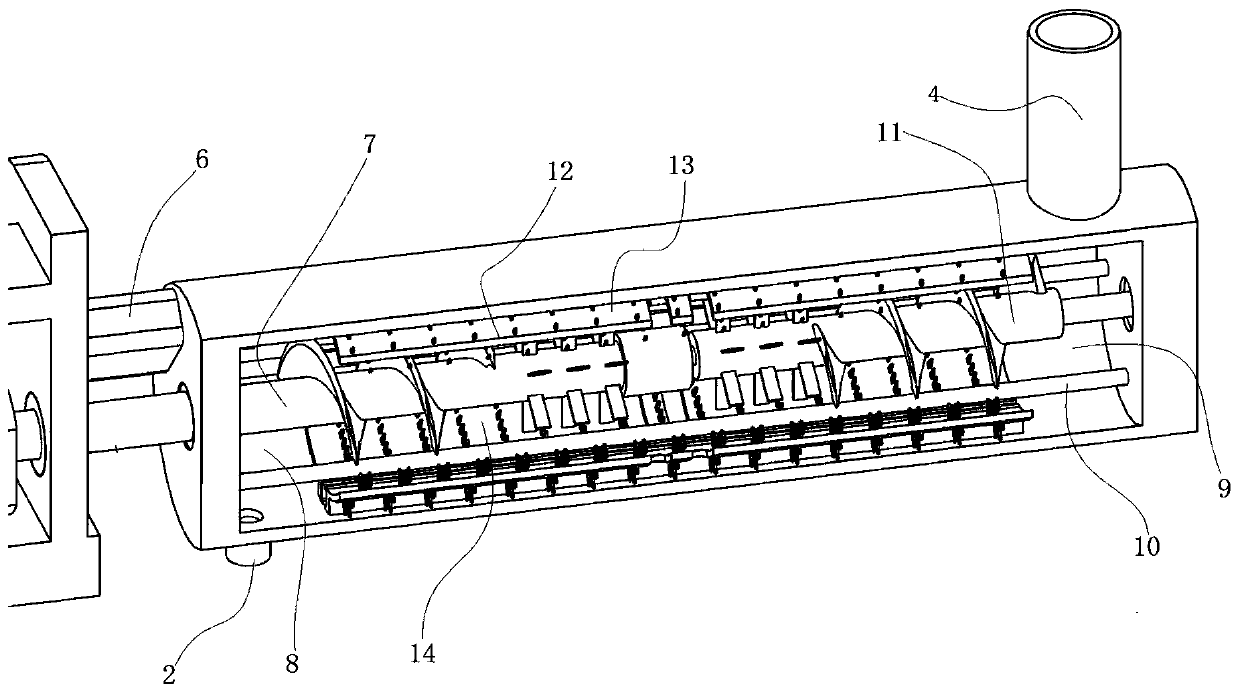

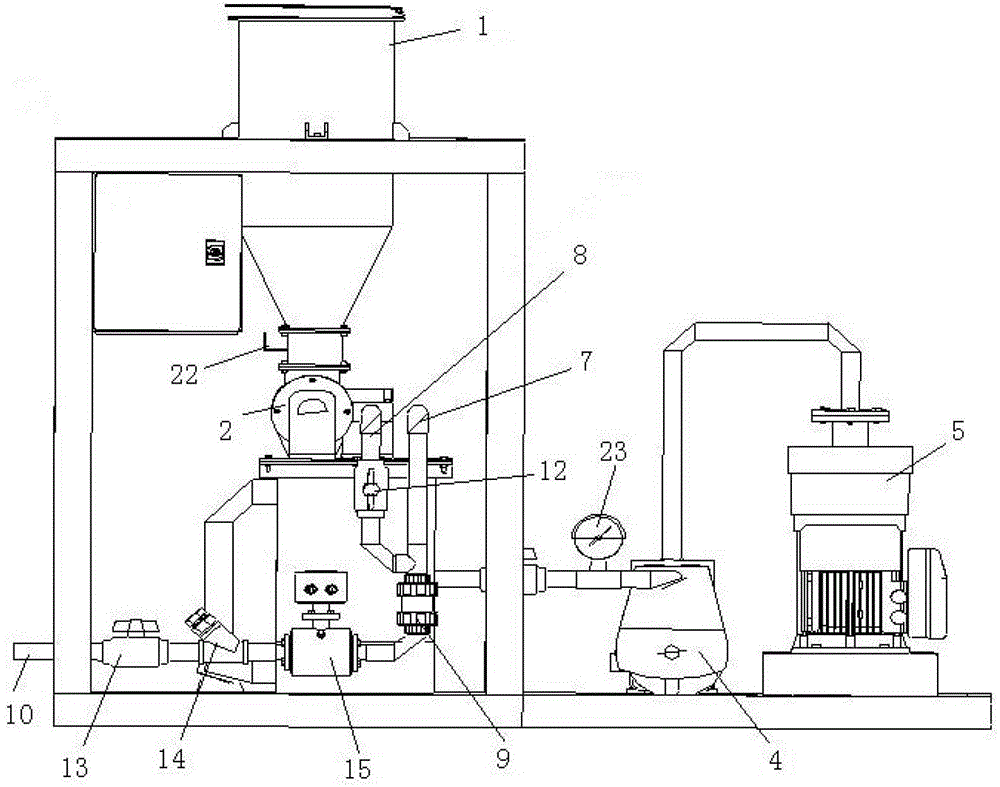

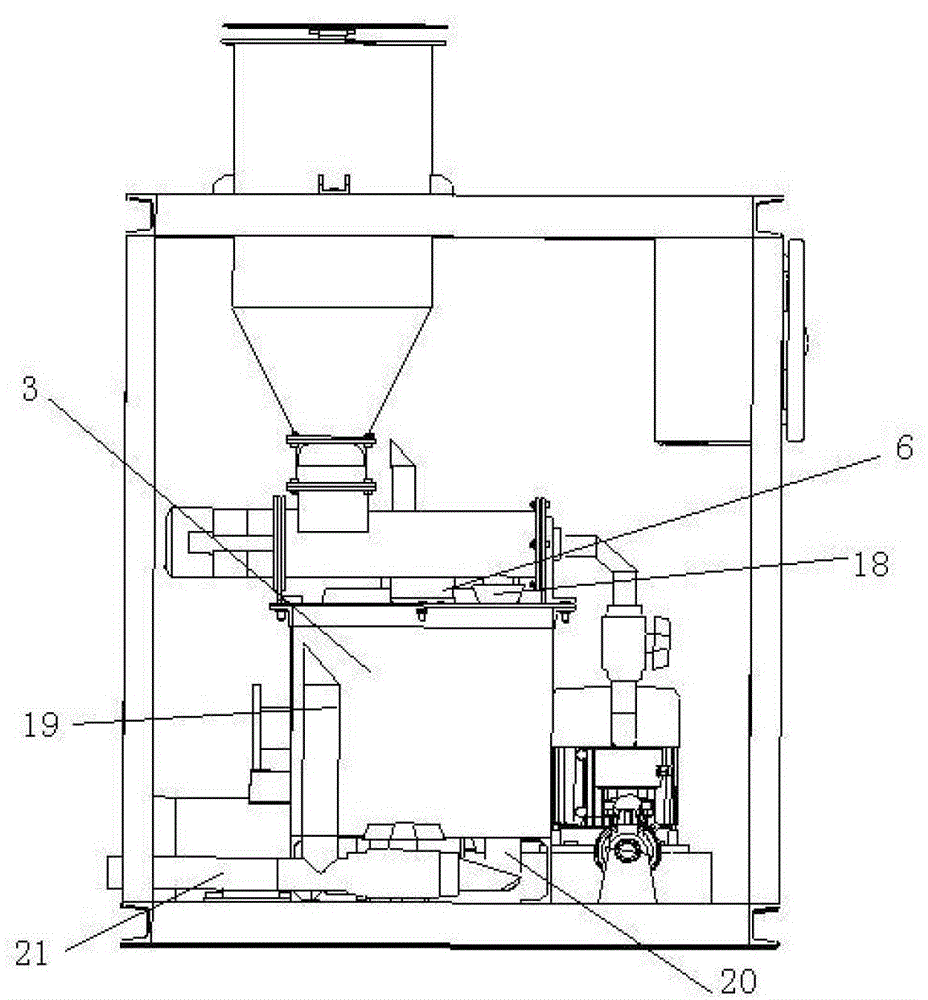

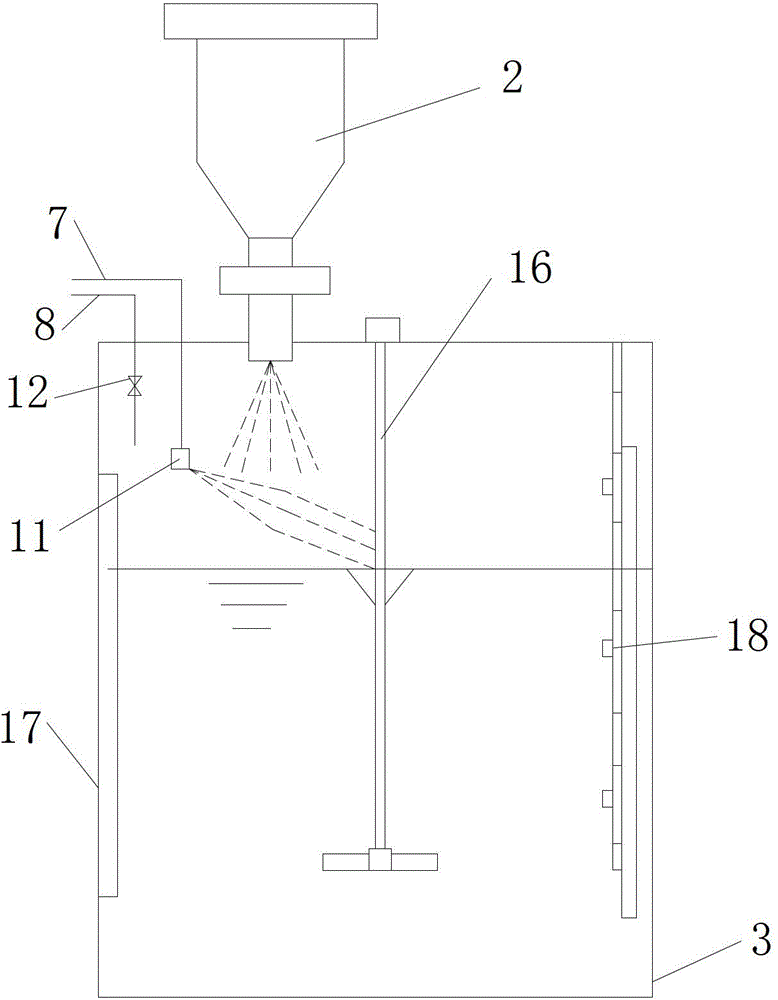

Dispersion preparation equipment, preparation process and proportion of interior wall water-based paint

ActiveCN110841536AUniform and fine dispersionSimple structureShaking/oscillating/vibrating mixersTransportation and packagingEmulsionMechanical engineering

The invention discloses dispersion preparation equipment for interior wall water-based paint. The dispersion preparation equipment comprises a transverse columnar coating dispersion tank, a transversecylindrical dispersion cavity is formed in the coating dispersion tank; a left transmission shaft and a right transmission shaft are coaxially arranged on the left side and the right side in the cylindrical dispersion cavity respectively, a connecting shaft is coaxially arranged at the right end of the left transmission shaft, a bearing sleeve is coaxially arranged at the left end of the right transmission shaft, and the connecting shaft and the bearing sleeve are coaxially and rotationally matched in the middle of the cylindrical dispersion cavity through a bearing; flowing circulation is formed in the whole coating dispersion tank, so that emulsion in the coating dispersion tank can continuously flow through the left half section and the right half section of a rotational flow tearing channel; and the emulsion in the coating dispersion tank is dispersed more uniformly and finely.

Owner:惠州市山宝实业有限公司

Preparation method for high concentration dredging silt rapid dehydrating agent solution

ActiveCN102974239BEvenly dispersedSolve the problem of high concentration wet cakingSludge treatment by de-watering/drying/thickeningTransportation and packagingHigh concentrationWater based

The present invention discloses a preparation method for a high concentration dredging silt rapid dehydrating agent solution. The method comprises the following steps: adding sodium carbonate and sodium chloride compound particles to a powdery anionic polymer dehydrating agent, sufficiently mixing the dehydrating agent, sodium carbonate and sodium chloride compound particles by stirring; and dissolving the dehydrating agent mixed solution by high-speed dispersing emulsifying equipment with the dissolution time of less than 2 min. The dehydrating agent solution is prepared after dissolving. According to the present invention, a certain proportion of water-soluble sodium carbonate and sodium chloride compounds are added to the polymer dehydrating agent for modification, each particle is fast and fully contact with water base on the combination of influent water flow mist flow condition to achieve instantaneous uniform dispersion in water, and ultimately high concentration wet-caking problem of the polymer dehydrating agent material is solved.

Owner:江苏艾特克环境工程有限公司

A kind of preparation method of nano-coating on the surface of EVA thin film of solar energy encapsulation battery

ActiveCN103571248BSimple processImprove conductivityElectrically-conductive paintsReflecting/signal paintsCarbon nanotubeSolar cell

The invention relates to a preparation method of a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol butyl ether and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol butyl ether serves as a film forming aid. A film covered by a coat formed by the nano coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. The preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:浙江兆泽实业有限公司

A kind of preparation method of EVA thin film surface nano-coating

InactiveCN103571320BSimple processImprove conductivityPolyether coatingsElectrically-conductive paintsCarbon nanotubeFatty alcohol

The invention relates to a preparation method of a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol methyl ether acetate and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol methyl ether acetate serves as a film forming aid. A film covered by a coat formed by the nano coating has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. The preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:广东奥优涂料有限公司

Blended fertilizer based on steel production waste and preparation method thereof

InactiveCN102795910BMeet nutrient requirementsTo achieve the effect of increasing efficiency and increasing productionFertilizer mixturesSlagPotassium

The invention discloses a blended fertilizer based on steel production waste and a preparation method thereof. The blended fertilizer is prepared by mixing 1-10 parts of steel making byproduct steel slag, 5-15 parts of waste powder formed by drying sintering flue gas ammonia desulfurization waste mud, and 3-6 parts of potassium fertilizer, wherein the total nutrient weight content of N, P and K is not lower than 35%. The preparation method comprises the following steps: preparing steel slag fine powder, waste powder and potassium fertilizer according to parts by weight, detecting to determine that the total nutrient weight content of N, P and K is not lower than 35%, and evenly mixing. The blended fertilizer disclosed by the invention contains sufficient nitrogen, phosphorus, potassium and microelements, and can sufficiently satisfy the nutrient requirements for plant growth without adding any microelement or fertilizer synergist, thereby achieving the synergistic and yield increase effects; the blended fertilizer has uniform and fine particle size, thereby avoiding soil salinization and hardening; and the invention recycles steel waste resources, thereby greatly lowering the production cost.

Owner:武汉钢铁有限公司

A kind of eva thin film surface coating of solar energy encapsulation battery

ActiveCN103571237BSimple processImprove conductivityElectrically-conductive paintsElectrical batteryCarbon nanotube

The invention relates to a coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The coating comprises the following components by mass percent: 5-10% of carbon nano tube, 5-15% of nano silica, 3-15% of free alkylphenol ethoxylates, 3-5% of acrylic acid, 3-5% of propylene glycol methyl ether acetate and the balance of organic solvent, wherein the mass ratio of free alkylphenol ethoxylates to acrylic acid is (1:1)-(3:1); free alkylphenol ethoxylates serve as a dispersing agent; the acrylic acid serves as a binding agent; propylene glycol methyl ether acetate serves as a film forming aid. A film covered by a coat formed by the coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. A preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:浙江兆泽实业有限公司

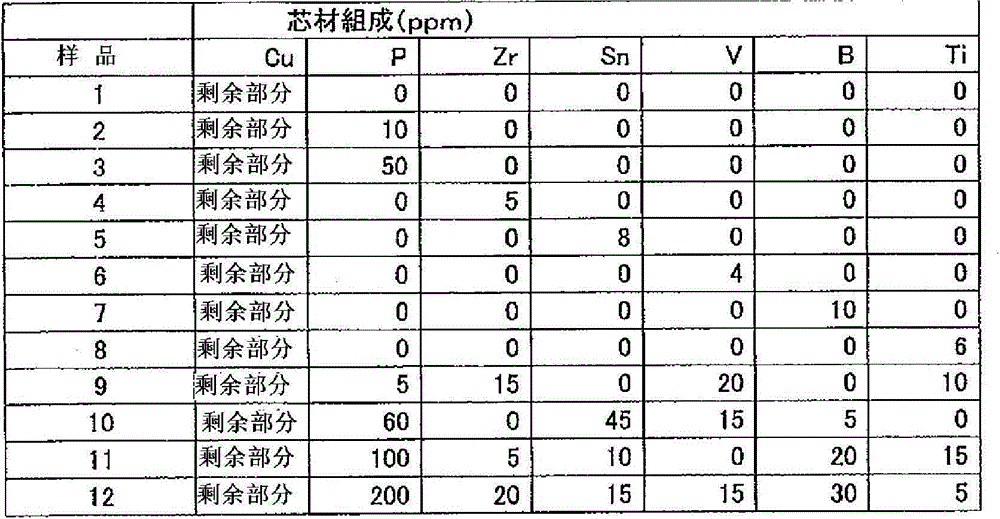

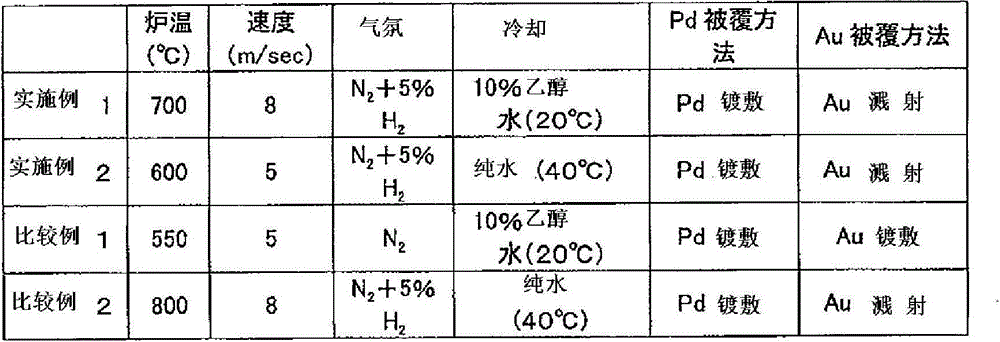

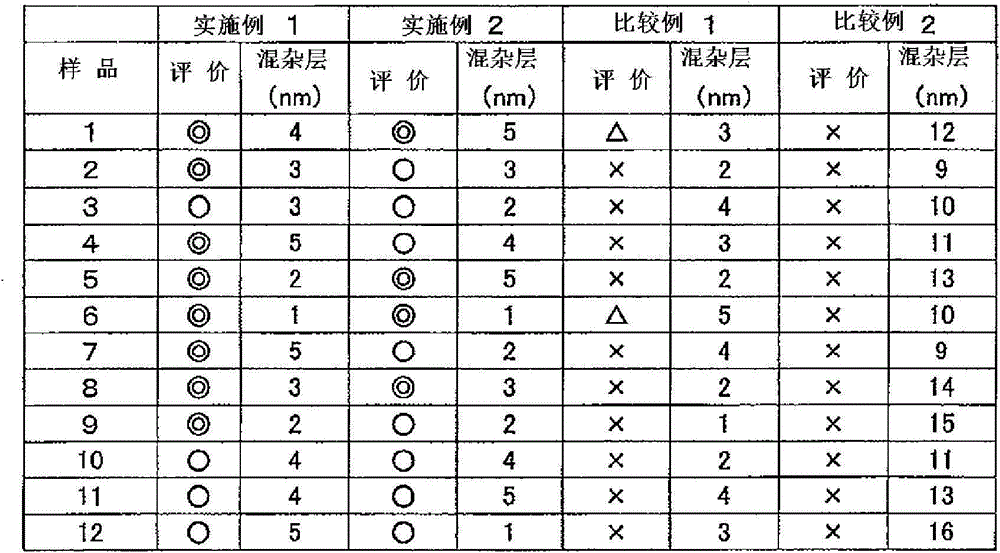

copper ball bonding wire covered with pd

ActiveCN103339719BUniform and fine dispersionReliable stabilizationConductive materialSolid-state devicesBond interfaceCopper wire

[Problem] To increase the reliability of joins to an aluminum electrode in a palladium-coated copper wire for ball bonding. [Solution] A gold (Au) layer comprising an ultra-thin layer having a thickness of no greater than 5 nm is formed at the surface of a palladium (Pd) intermediate layer and heat processing is performed in an inert atmosphere containing hydrogen, causing the palladium of the intermediate layer to infiltrate the ultra-thin gold layer, forming a gold-palladium intermingled layer by means of Stranski-Krastanov growth such that a minute gold phase and palladium phase grow in 3D. In the heat processing process, the palladium absorbs hydrogen, and by means of rapid cooling after heat processing, the palladium in the intermingled layer is stabilized, and along with the gold that melts early during molten ball formation and covers a wire end surface, the palladium that has reached the end surface melts and is dispersed uniformly and minutely at the molten ball surface layer, suppressing the oxidation of aluminum at the bond interface with the aluminum.

Owner:TANAKA DENSHI KOGYO KK

A kind of waste shoe sole rubber powder modified asphalt and preparation method thereof

ActiveCN105385179BUniform and fine dispersionSolve pollutionBuilding insulationsRoad surfaceCross linker

The invention discloses a waste shoe sole rubber powder modified asphalt and a preparation method. The waste shoe sole rubber powder modified asphalt comprises the following components in terms of mass fraction: base asphalt: 100 parts; waste shoe sole rubber powder: 25-35 parts; Cross-linking agent: 0.15 to 0.525 parts. In the present invention, the waste shoe sole rubber powder is used in the asphalt as a modifier to effectively solve the problem of environmental pollution caused by waste shoe materials; Waterproof and interlayer adhesion of pavement, prolong the service life of asphalt pavement and reduce road noise. In addition, the compound modified asphalt of waste shoe sole rubber powder and waste tire rubber powder or SBS will greatly reduce the mixing amount of waste tire rubber powder and SBS and save costs.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

A kind of eva film surface coating

ActiveCN103555024BSimple processImprove conductivityElectrically-conductive paintsAdhesiveCarbon nanotube

The invention relates to an EVA (ethylene-vinyl acetate) film surface paint which is composed of the following components in percentage by mass: 5-10% of carbon nanotube, 5-15% of nano silicon dioxide, 3-15% of fatty alcohol polyethenoxy ether, 3-5% of acrylic acid, 3-5% of propylene glycol monomethyl ether acetate and the balance of organic solvent. The mass ratio of the fatty alcohol polyethenoxy ether to the acrylic acid is 1:1-3:1; and the fatty alcohol polyethenoxy ether is used as a dispersant, the acrylic acid is used as an adhesive, and the propylene glycol monomethyl ether acetate is used as a film-forming assistant. The coating film formed by the EVA film surface paint has electric conductivity and low yellowing rate, and enhances the photoelectric conversion rate of the battery pack; and the preparation method is simple in technique and convenient to operate, and can efficiently enable the carbon nanotubes and silicon dioxide nanotubes to be uniformly dispersed and fixed to the EVA film surface.

Owner:广东东能新材料有限公司

A kind of nano-coating on the surface of eva thin film of solar energy encapsulation battery

ActiveCN103571236BSimple processImprove conductivityPhotovoltaic energy generationElectrically-conductive paintsCarbon nanotubeFatty alcohol

The invention relates to a nano coating for an EVA (ethylene-vinyl acetate copolymer) film surface of a solar packaged cell. The nano coating comprises the following components by mass percent: 15-20% of carbon nano tube, 5-15% of nano silica, 3-15% of fatty alcohol-polyoxyethylene ether, 3-5% of silane coupling agent, 3-5% of propylene glycol butyl ether and 10-30% of organic solvent, wherein the mass ratio of fatty alcohol-polyoxyethylene ether to the silane coupling agent is (1:1)-(3:1); fatty alcohol-polyoxyethylene ether serves as a dispersing agent; the silane coupling agent serves as a binding agent; propylene glycol butyl ether serves as a film forming aid. A film covered by a coat formed by the nano coating for the EVA film surface has electrical conductivity and low yellowing rate and simultaneously improves the photoelectric conversion rates of battery packs. A preparation method is simple in process and convenient to operate and can be used for efficiently dispersing and fixing the carbon nano tube and the silica nano tube on the EVA film surface uniformly.

Owner:ZHEJIANG KELI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com