Mixing method of electrode slurry

A technology of electrode slurry and mixer, applied in mixing methods, mixers, mixers with rotating stirring devices, etc., can solve the problems of adequate mixing of electrode slurry and long mixing time, etc., so as to improve labor efficiency and improve High current discharge performance, overcome the effect of poor high current performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example is used to illustrate the electrode slurry mixing method provided by the present invention.

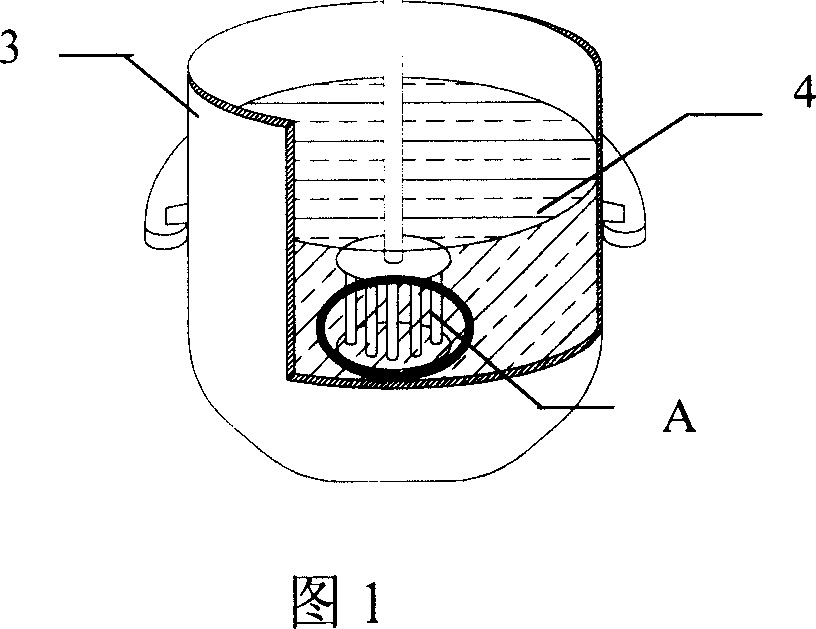

[0028]10 kg of lithium cobalt oxide, 0.5 kg of acetylene black, 4.0 kg of N-methylpyrrolidone (NMP), and 0.5 kg of polytetrafluoroethylene (PVDF) were stirred and mixed using a high-shear dispersing emulsifier as shown in Figure 1 to obtain lithium For the ion battery cathode slurry, the rotating speed of the rotor of the high-shear dispersing emulsifier is 2000 rpm, and the stirring time is 30 minutes.

Embodiment 2

[0030] This example is used to illustrate the electrode slurry mixing method provided by the present invention.

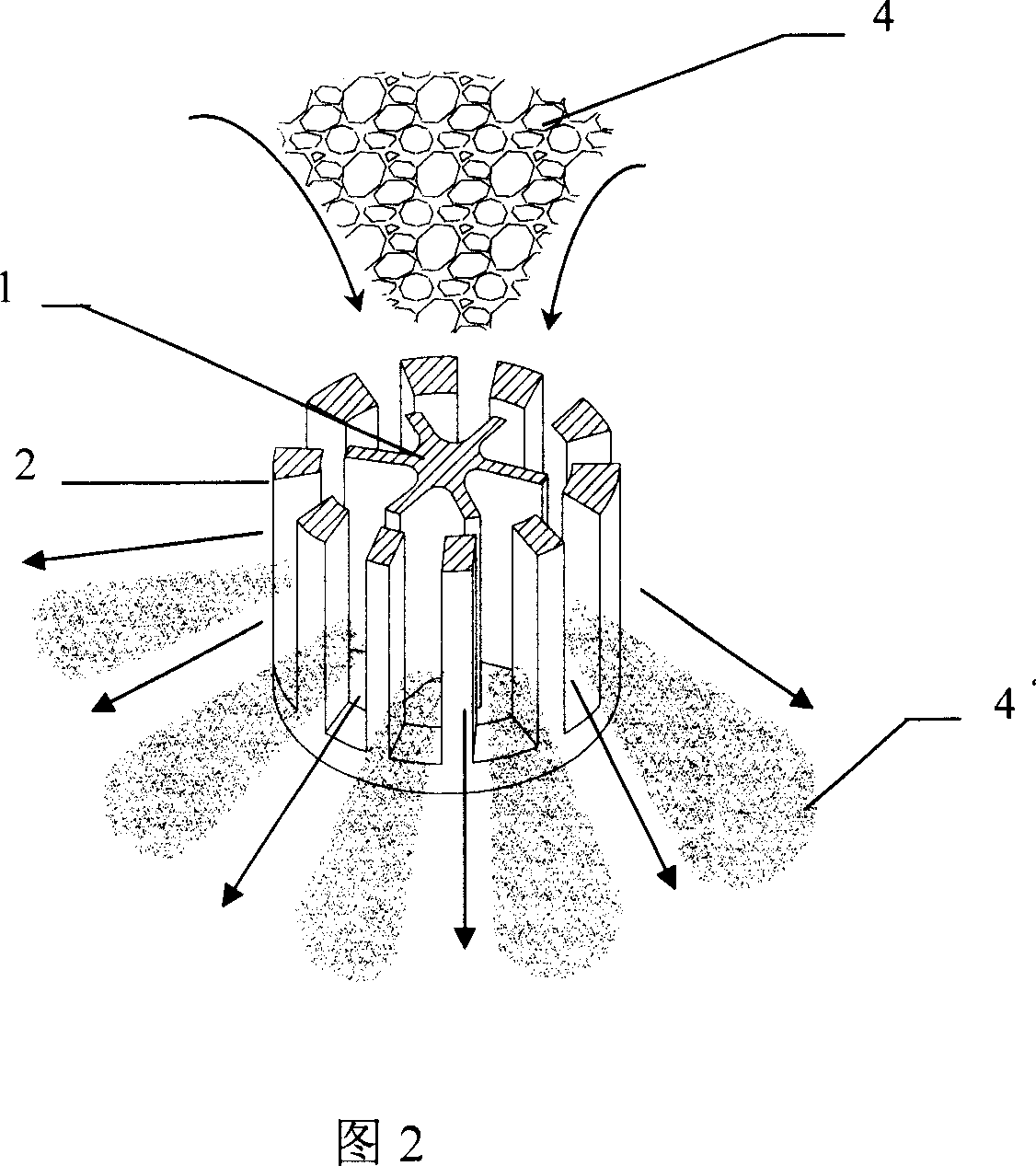

[0031] 10 kg of lithium cobalt oxide, 0.5 kg of acetylene black, 4.0 kg of N-methylpyrrolidone (NMP), and 0.5 kg of polytetrafluoroethylene (PVDF) were stirred and mixed for 60 minutes at a speed of 250 rpm in a conventional mixer to obtain a pre- The mixed electrode slurry 4 is then transferred to the high-shear dispersing emulsifier shown in Figure 1 for mixing, dispersing and refining to obtain dispersed and refined lithium-ion battery positive electrode slurry 4' , the rotor of the high-shear dispersing emulsifier first stirred at a speed of 1000 rpm for 10 minutes, and then stirred at a speed of 2000 rpm for 30 minutes.

Embodiment 3

[0033] This example is used to illustrate the electrode slurry mixing method provided by the present invention.

[0034] 10 kg of lithium cobalt oxide, 0.5 kg of acetylene black, 4.0 kg of N-methylpyrrolidone (NMP), and 0.5 kg of polytetrafluoroethylene (PVDF) were stirred and mixed for 40 minutes at a speed of 450 rpm in a conventional mixer to obtain the pre- The mixed electrode slurry 4 is then transferred to the high-shear dispersing emulsifier shown in Figure 1 for mixing, dispersing, and refining to obtain dispersed and refined lithium-ion battery positive electrode slurry 4', The high-shear dispersing emulsifier first stirred for 10 minutes at the rotor speed of the emulsifier at 1000 rpm, then stirred at 2000 rpm for 30 minutes, and then transferred the slurry to a vacuum mixer, at 200 rpm Stir at low temperature for 70 minutes, and at the same time reduce the temperature of the system to 30° C. with circulating cooling water to obtain a degassed lithium-ion battery po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com