Dispersion preparation equipment, preparation process and proportion of interior wall water-based paint

A water-based coating and dispersion technology, applied in coating, mixer, shake/oscillation/vibration mixer, etc., can solve the problems of insufficient fineness of the product, uneven dispersion of the emulsion, poor dispersion effect, etc. Disperse evenly and finely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

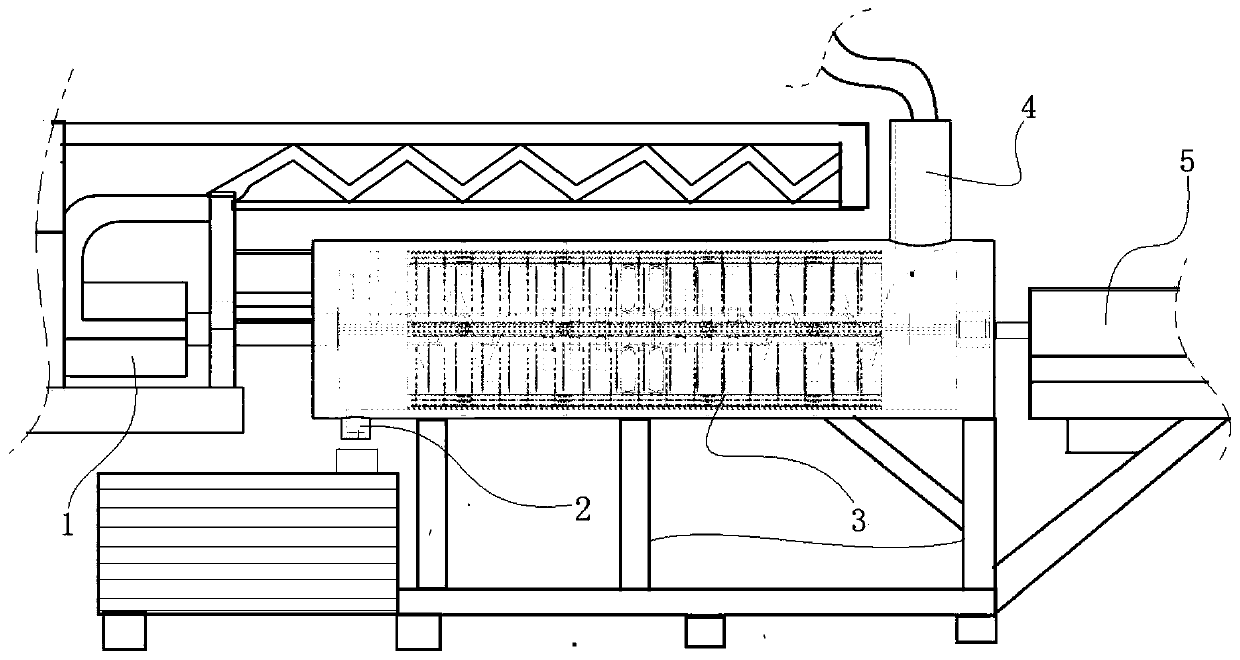

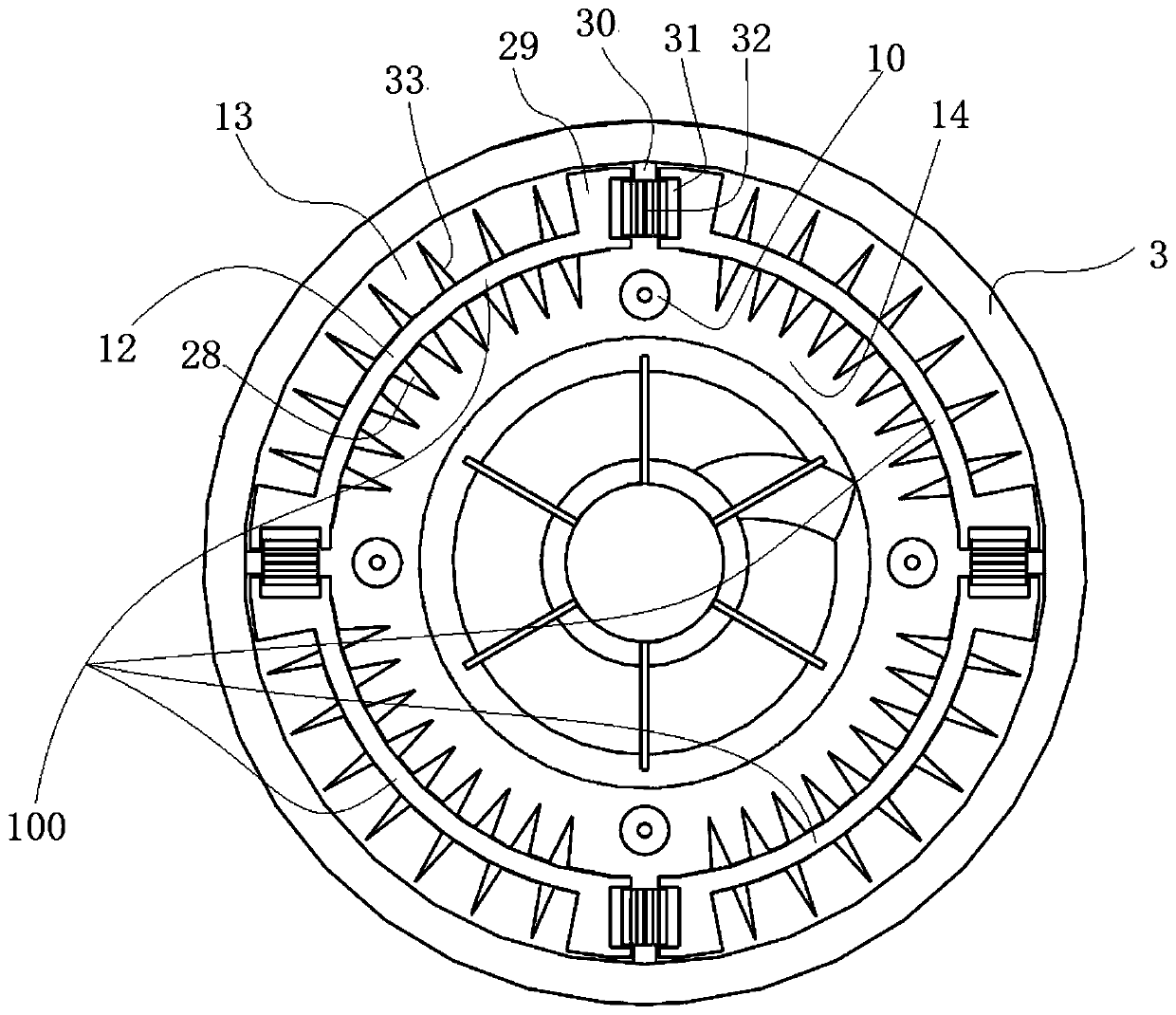

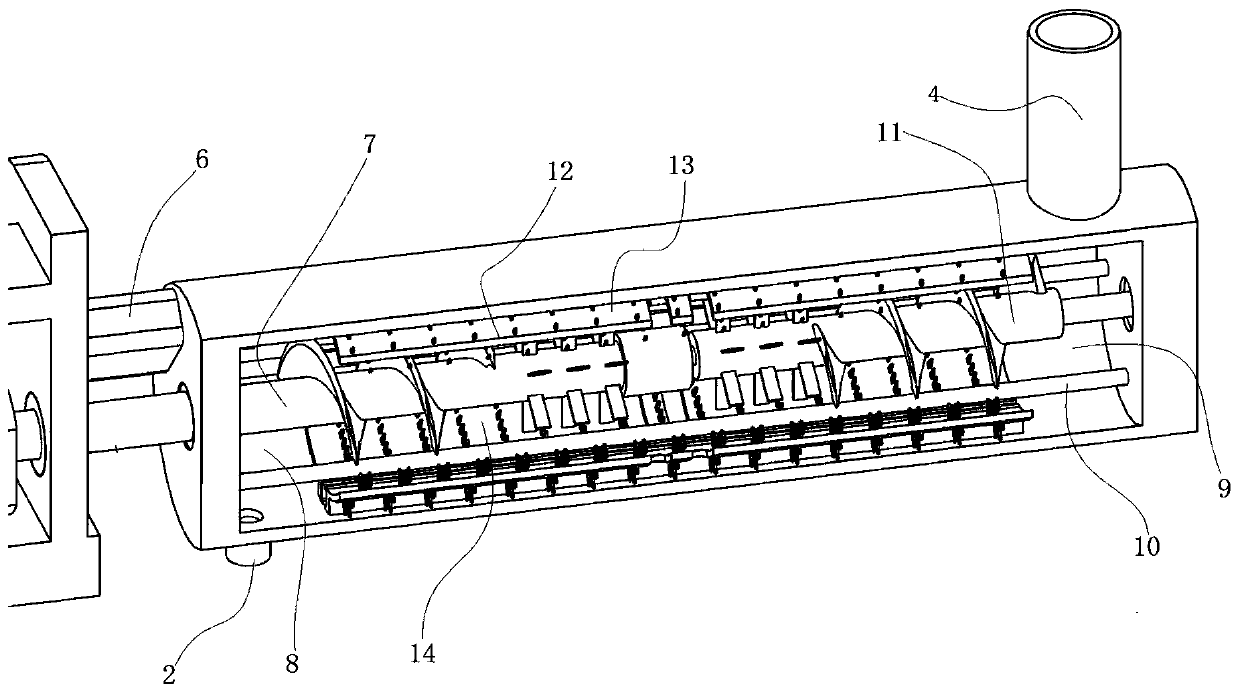

[0046] as attached Figures 1 to 13 The dispersion preparation equipment of the shown interior wall water-based paint comprises a horizontal columnar paint dispersing tank 3, the tank of the paint dispersing tank 3 is a horizontal columnar dispersing cavity, and the left and right sides in the columnar dispersing cavity are respectively The left transmission shaft 7 and the right transmission shaft 11 are arranged on the same axis, the right end of the left transmission shaft 7 is provided with the connecting shaft 15, and the left end of the right transmission shaft 11 is provided with the bearing sleeve 18 on the same axis. The connecting shaft 15 and the bearing sleeve 18 are rotated coaxially in the middle of the cylindrical dispersing cavity through the bearing 17;

[0047] Also comprise left drive motor 1 and right drive motor 5, described left drive motor 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com