copper ball bonding wire covered with pd

A coating and copper wire technology, applied in the direction of conductive materials, conductors, electrical components, etc., can solve the problems of peeling joint interface, etc., and achieve the effect of reliable stabilization and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

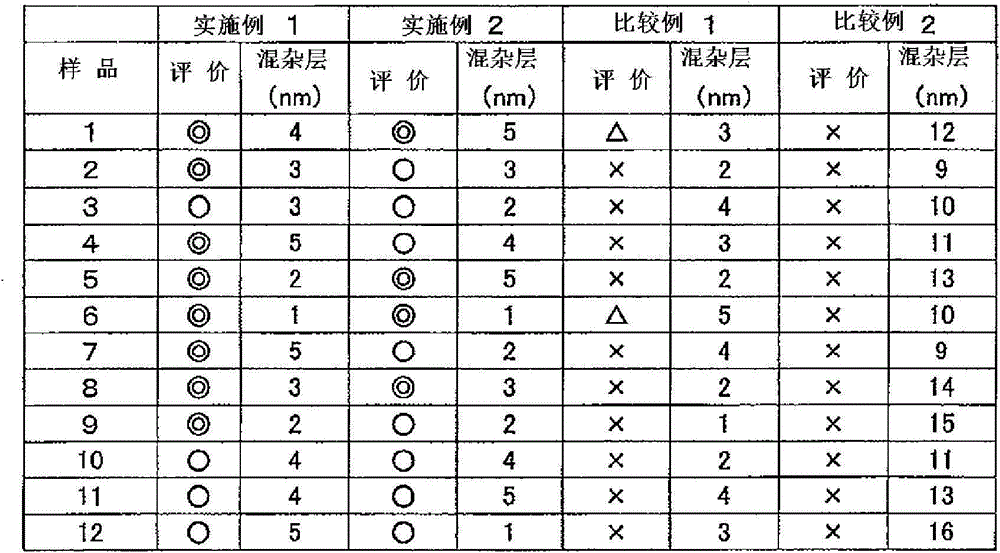

[0071] Examples are described below.

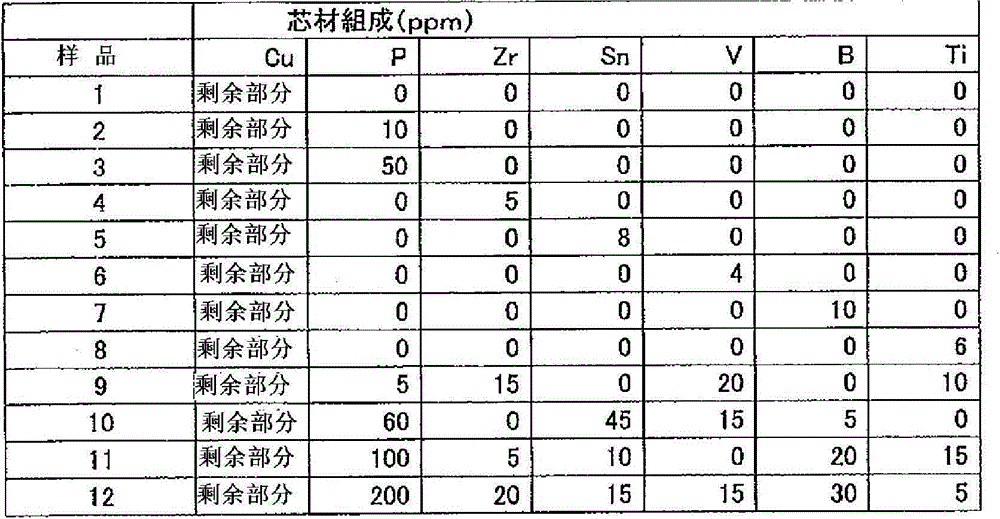

[0072] A copper wire drawn from a copper (Cu) ingot described in Table 1 to a wire diameter of 500 μm was used as a core material, and an electrolytic plating film of a 2.0 μm palladium (Pd) intermediate layer was deposited on the surface of the wire by a usual method. The palladium (Pd) plating bath was obtained by adding 10 gW / l of phosphate to a neutral dinitrodiamine palladium bath, and the purity of the obtained palladium (Pd) was 99%. Next, gold (Au) with a purity of 99.99% by mass was magnetron sputtered at room temperature to deposit 0.08 μm. In addition, the coating thickness was measured by Auger electron spectroscopy (AES).

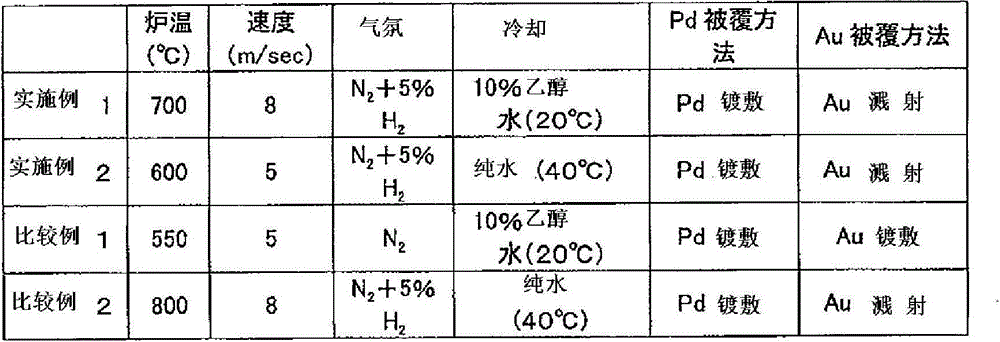

[0073] Thereafter, the coated copper wire was die-drawn to a final diameter of 17 μm. The theoretical film thickness of gold (Au) is 0.0027 μm. Next, processing strain is removed, and a predetermined final heat treatment is performed until the elongation value reaches about 10%. As for the final ...

Embodiment 2

[0078] The coated copper wire produced under the same conditions as in Example 1 was passed through a heat treatment furnace at 600° C. in a 5% hydrogen+nitrogen atmosphere at a speed of 5 m / s, and cooled in pure water (40° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com