Waste sole rubber modified asphalt and preparing method thereof

A technology for modifying asphalt and rubber powder, applied in building components, building insulation materials, construction and other directions, can solve the problems of cumbersome sorting process of rubber powder by color, difficult to implement, less road paving materials, etc., and achieve high temperature rutting resistance. , Enhance the effect of waterproof and interlayer adhesion, and reduce the amount of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

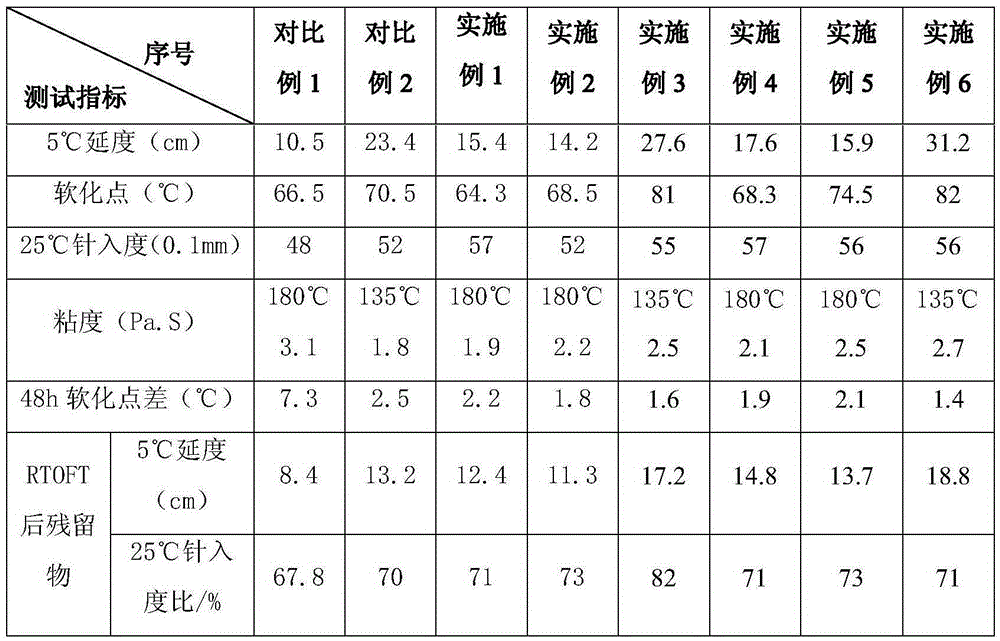

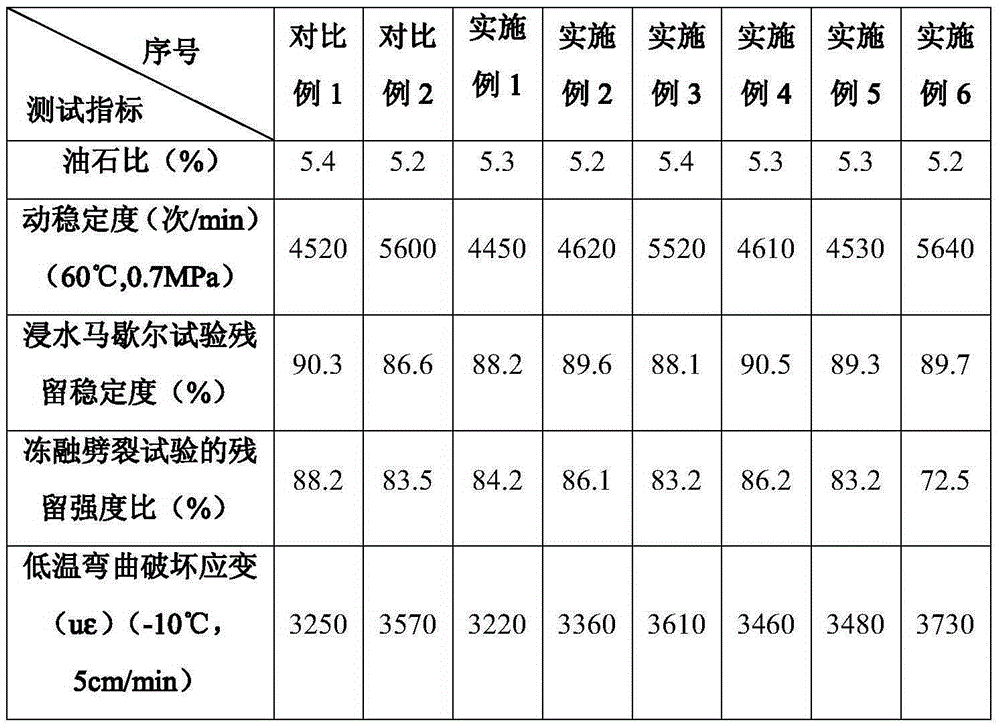

Embodiment 1

[0036] The base asphalt is rapidly heated to 185-190° C., and the waste shoe sole rubber powder (the shoe sole rubber powder is a composition of rubber bottom, tendon bottom, EVA bottom, and TPR bottom) that accounts for 30% of the mass percentage of pitch is added therein with stirring. Mass ratio is 50:25:5:20), in the premixing tank, it was insulated and stirred by high-speed disperser for 15 minutes, and the stirring rate was 400r / min, and then it was sheared for 20 minutes through high-shear emulsifying machine, and the shear rate was 3000r / min, then stirred and developed in the reaction tank for 3 hours, the reaction temperature was kept at 180-185°C, and finally the cross-linking agent accounting for 0.15% of the mass percentage of the base asphalt was slowly added, and the waste shoe sole was obtained by continuing to heat and stir for 1 hour Rubber powder modified asphalt, testing its performance.

Embodiment 2

[0038] The matrix asphalt is rapidly heated to 185-190° C., and the waste shoe sole rubber powder (the shoe sole rubber powder is a composition of rubber bottom, tendon bottom, EVA bottom, and TPR bottom) that accounts for 15% of the mass percentage of the pitch is stirred and added therein. The mass ratio is 50:25:5:20), adding the waste tire rubber powder that accounts for 10% of the asphalt by mass percentage, in the premix tank, it was insulated and stirred by a high-speed disperser for 15 minutes, and the stirring speed was 400r / min, followed by High-shear mixing and emulsifying machine sheared for 20 minutes at a shear rate of 3000r / min, then stirred and developed in a reaction tank for 3 hours, and the reaction temperature was kept at 180-185°C. Slowly add the coupling agent, continue to keep warm and stir for 1 hour to prepare waste shoe sole rubber powder modified asphalt, and test its performance.

Embodiment 3

[0040]The base asphalt is rapidly heated to 185-190°C, and the SBS791-H that accounts for 3.5% by mass of the asphalt is added with stirring, and 10% of the mass percent of the asphalt is added at the same time. , at the bottom of beef tendon, at the bottom of EVA, at the bottom of TPR, its mass ratio is 50:25:5:20), in the premix tank, it was insulated and stirred by a high-speed disperser for 15 minutes, and the stirring speed was 400r / min, and then passed through The high-shear mixing emulsifier shears for 15 minutes at a shear rate of 3000r / min, then stirs and develops in the reaction tank for 3 hours, and the reaction temperature is kept at 175-180°C. Slowly add the joint agent, continue to keep warm and stir for 2 hours to prepare SBS composite waste shoe sole rubber powder modified asphalt, and test its performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com