Silvering powder conductive adhesive for LED packaging and production method thereof

A technology of LED packaging and conductive adhesive, which is applied in the direction of conductive adhesives, circuits, adhesives, etc., can solve the problems of unobvious cost control and rising proportion of cost, and achieve stable electrical conductivity, simple preparation, and stable thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

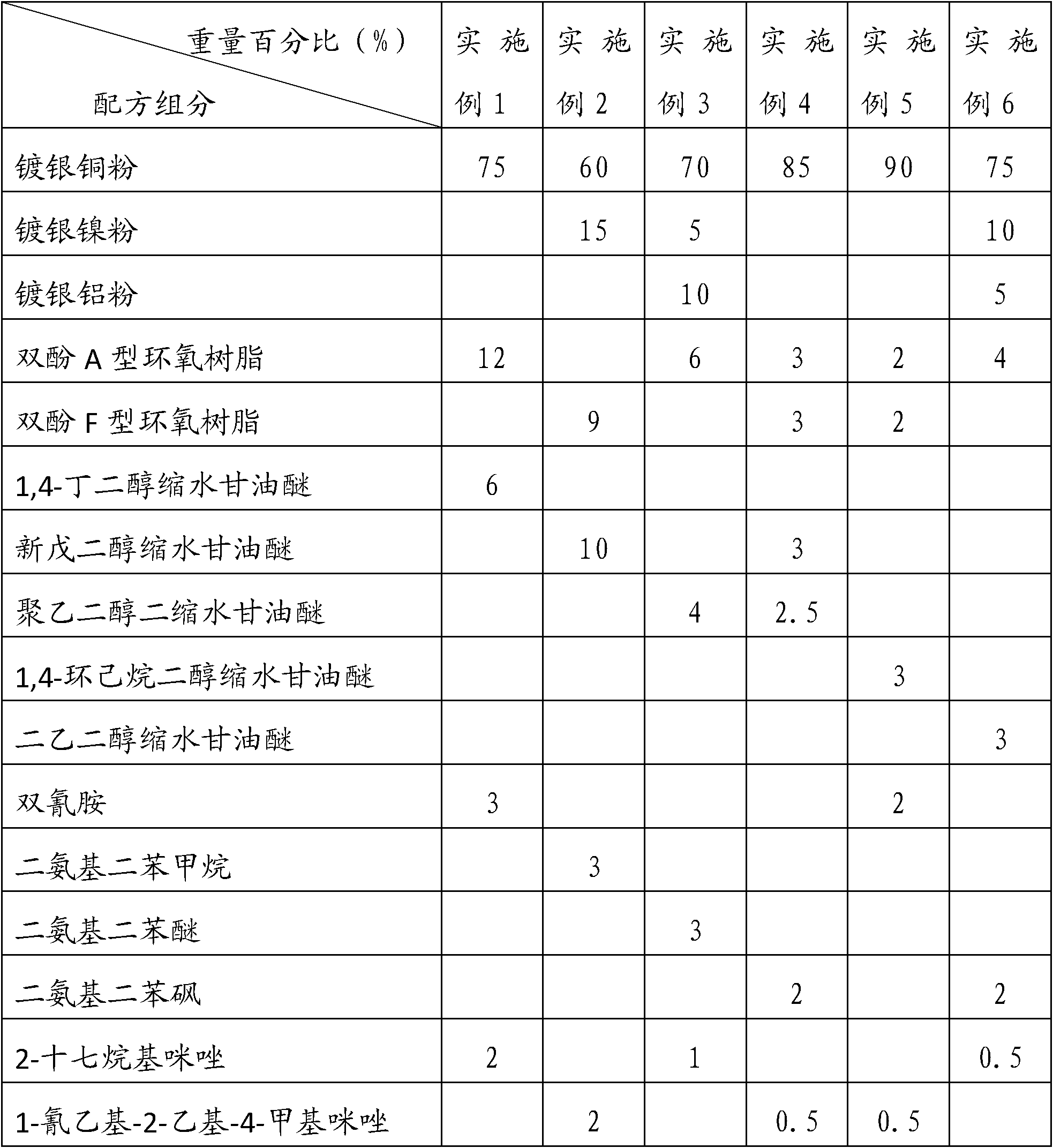

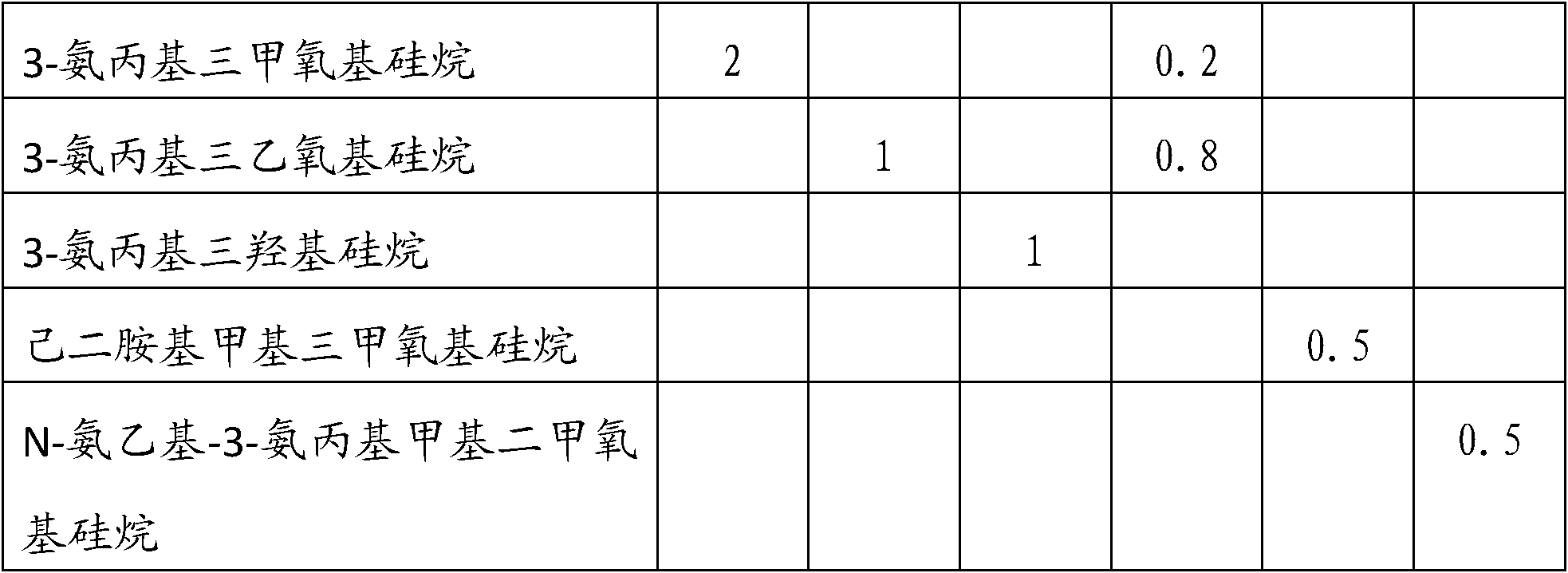

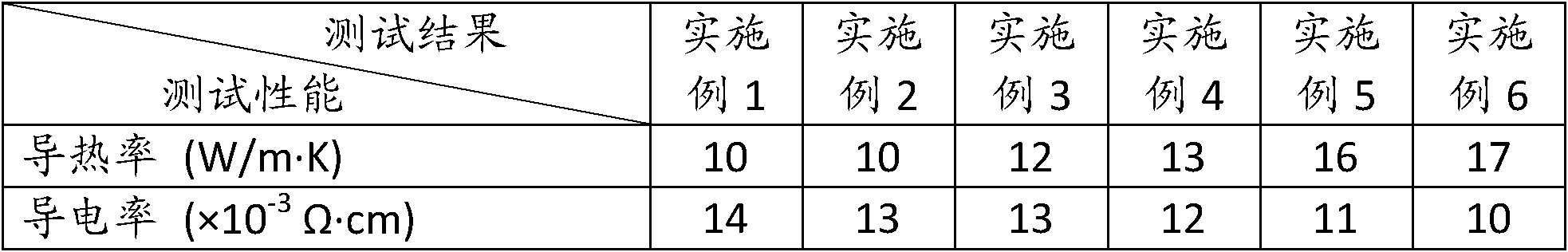

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] Then follow the steps below to prepare silver-plated powder conductive adhesive:

[0024] 1) Mix epoxy resin and epoxy diluent at room temperature for 10 minutes;

[0025] Wherein, the epoxy resin accounts for 4-12% of the total weight of the formula, and the epoxy diluent accounts for 3-10% of the total weight of the formula;

[0026] 2) Add additives to the mixture prepared in step 1), and mix at room temperature for 10 minutes;

[0027] Wherein, the additives include a curing agent accounting for 2-3% of the total weight of the formula, a curing accelerator and a coupling agent accounting for 0.5-2% of the total weight of the formula.

[0028] 3) Grinding the mixture prepared in step 2) on a three-roll mill at room temperature to become a fine and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com