A kind of preparation method of eva thin film surface coating

A surface coating and film technology, applied in conductive coatings, coatings, etc., can solve problems such as weakening of visible light, accelerated aging of EVA film, yellowing, etc., to achieve the effects of good adhesion, improved photoelectric conversion rate, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

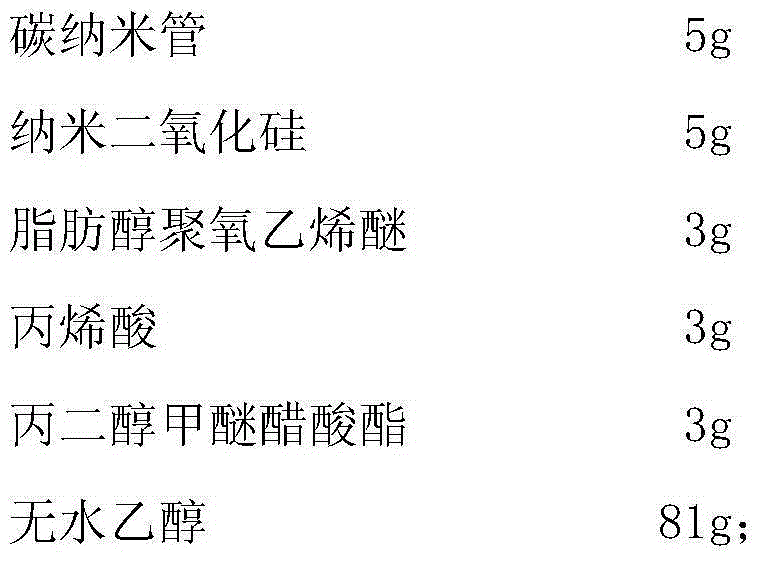

[0028] The EVA film surface coating of this embodiment is composed of the following components:

[0029]

[0030] The fatty alcohol polyoxyethylene ether is used as a dispersant, the acrylic acid is used as a binder, and the propylene glycol methyl ether acetate is used as a film forming aid.

[0031] The preparation method of the EVA film surface coating of this embodiment includes the following specific steps:

[0032] A. Ingredients: Weigh appropriate amount of carbon nanotubes, nano-silica, fatty alcohol polyoxyethylene ether, acrylic acid, propylene glycol methyl ether acetate, ethanol, water according to the above formula dosage, wherein the fatty alcohol polyoxyethylene ether is used as Dispersant, the acrylic acid is used as a binder, and the propylene glycol methyl ether acetate is used as a film-forming aid;

[0033] B. Mixing: add carbon nanotubes, nano-silica, fatty alcohol polyoxyethylene ether, acrylic acid, propylene glycol methyl ether acetate, organic solvent and wate...

Embodiment 2

[0037] The rest of the EVA film surface coating of this embodiment is the same as that of embodiment 1, except that:

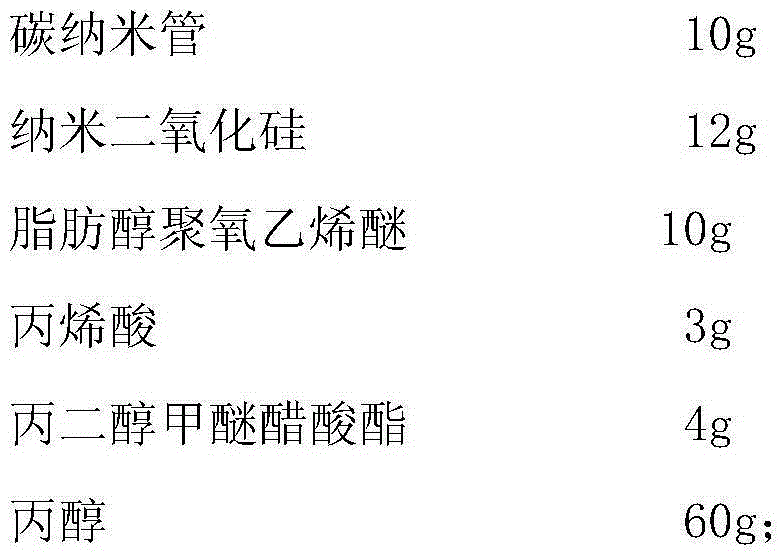

[0038] The EVA film surface coating of this embodiment is composed of the following components:

[0039]

[0040] The rest of the preparation method of the EVA film surface coating of this embodiment is the same as that of embodiment 1, except that: Step D is to spray the dispersion liquid on the EVA film at 20-40°C under ultrasonic oscillation for 30 minutes and diluted 2 times. After the surface is dried and cured.

Embodiment 3

[0042] The rest of the EVA film surface coating of this embodiment is the same as that of embodiment 1, except that:

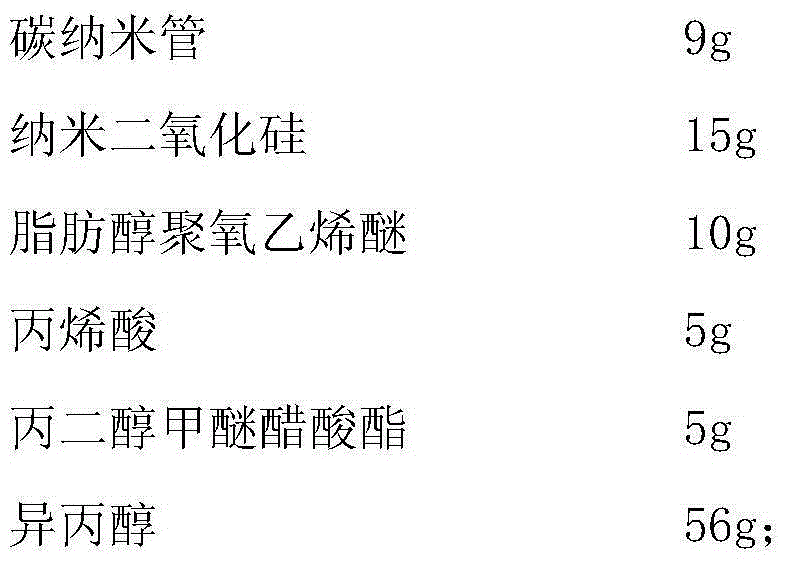

[0043] The EVA film surface coating of this embodiment is composed of the following components:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by mass | aaaaa | aaaaa |

| percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com