High-quality and large-size two-dimensional material and preparation method thereof

A two-dimensional material, large-scale technology, applied in the field of high-quality large-scale two-dimensional materials and their preparation, can solve the problems of failing to meet the basic requirements of industrial commercial products, low single-layer yield, low total peeling rate, etc. Achieve the effect of industrialization promotion and application, simple technology, easy industrialization promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

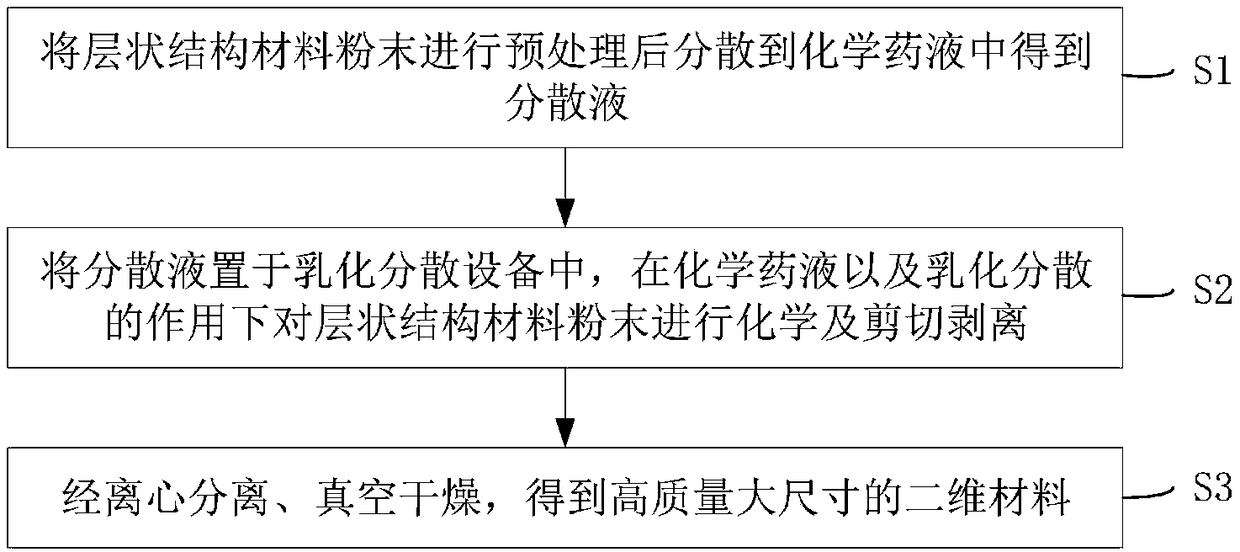

[0034] like figure 1 , a preferred embodiment of the present invention discloses a method for preparing a high-quality large-size two-dimensional material, comprising the following steps:

[0035] S1: Disperse the layered structure material powder into the chemical liquid after pretreatment to obtain the dispersion liquid;

[0036] Among them, the layered structure material powder is specifically a three-dimensional layered structure material. The three-dimensional layered structure material refers to a strong covalent bond or an ionic bond within the layer, and the layers are stacked together by weak van der Waals force. New materials, including but not limited to: graphite, expanded graphite, hexagonal boron nitride (h-BN), transition metal dichalcogenides (TMDs), transition metal oxides (TMOs), MAX (M is early transition metal, A It is the third or fourth main group element, X is C, N, Zr, Hf; such as Ti 3 AlC 2 、Cr 3 AlC 2 、Ti 2 SiC, Ti 2 AlN, Ta 4 AlC 3 , (Ti 0....

Embodiment approach 1

[0052] This embodiment specifically includes the following steps: take 40g of natural flake graphite powder with an average particle size of 10 μm and 1.5L N-methylpyrrolidone (NMP) and mix them in a stainless steel tank; feed argon gas and bubble for 30 minutes; set emulsification and dispersion machine (IKA Magic LAB, Germany) with a rotor-stator gap of 0.2mm, a speed of 5000rpm, and a working time of 2 hours. Turn on the equipment to peel off the graphite powder; set the speed of the centrifuge to 3000rpm, and the centrifugation time to 30min. The slurry is centrifuged; the upper layer liquid is taken and vacuum-dried at 100° C. for 24 hours to obtain graphene.

Embodiment approach 2

[0054] This embodiment specifically includes the following steps: take 40 g of natural flake graphite powder with an average particle size of 10 μm, 1.5 L of dimethyl sulfoxide (DMSO) and 45 g of sodium hydride and mix them in a stainless steel tank; feed argon gas and bubble for 30 minutes ; Turn on the emulsification disperser (PUC Colloid Mills, Japan), and peel off the graphite powder for 2 hours; Set the centrifuge speed to 3500rpm, and the centrifugation time is 30min, and turn on the equipment to centrifuge the peeled slurry; Get the upper layer of liquid at 100 It can be vacuum-dried at ℃ for 24 hours to obtain high-quality graphene with an average size larger than 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com