Inclined guy cable stretching torsion-proof jack

A jack and anti-rotation technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of prone to safety accidents and damage to the jack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

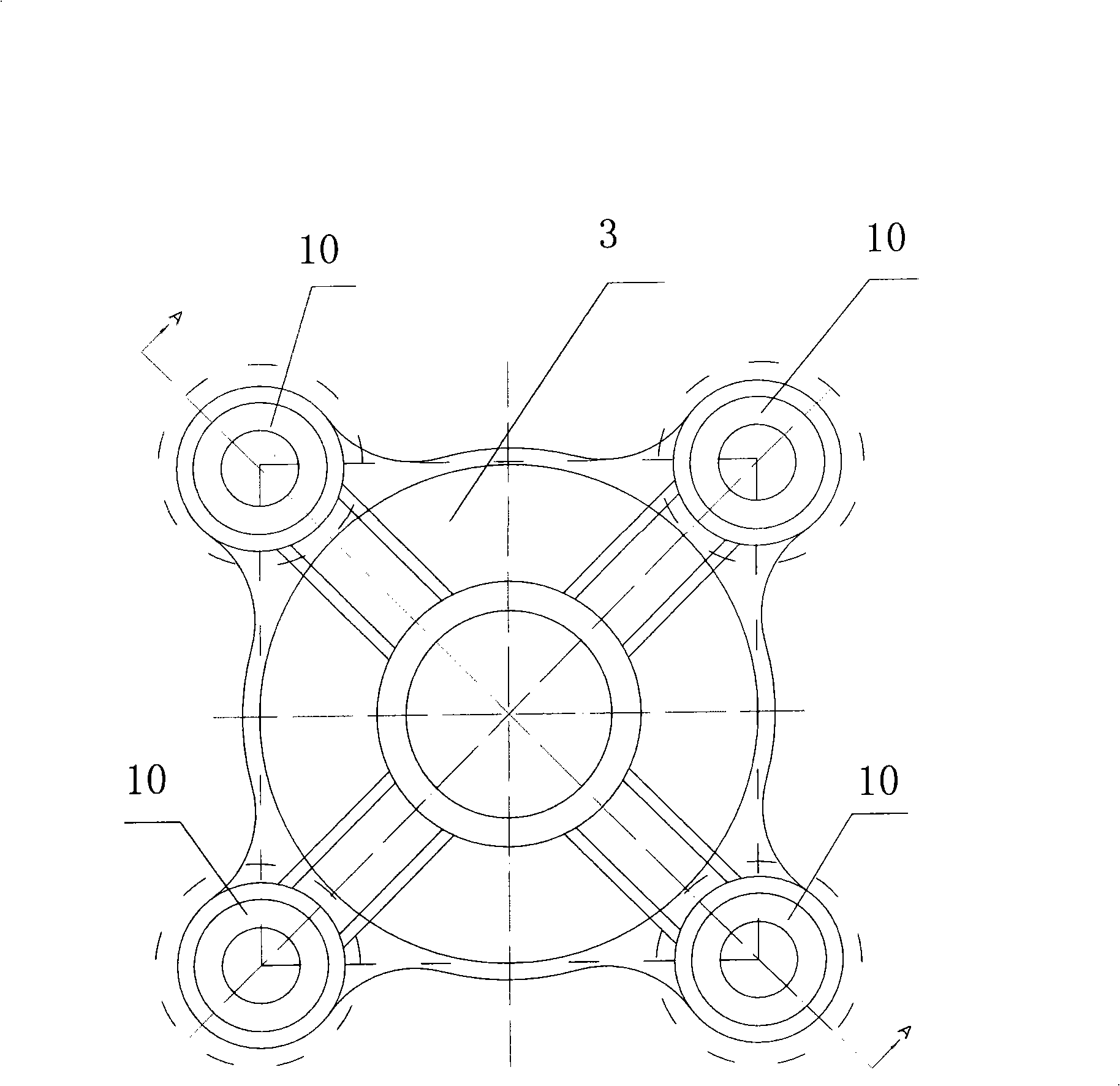

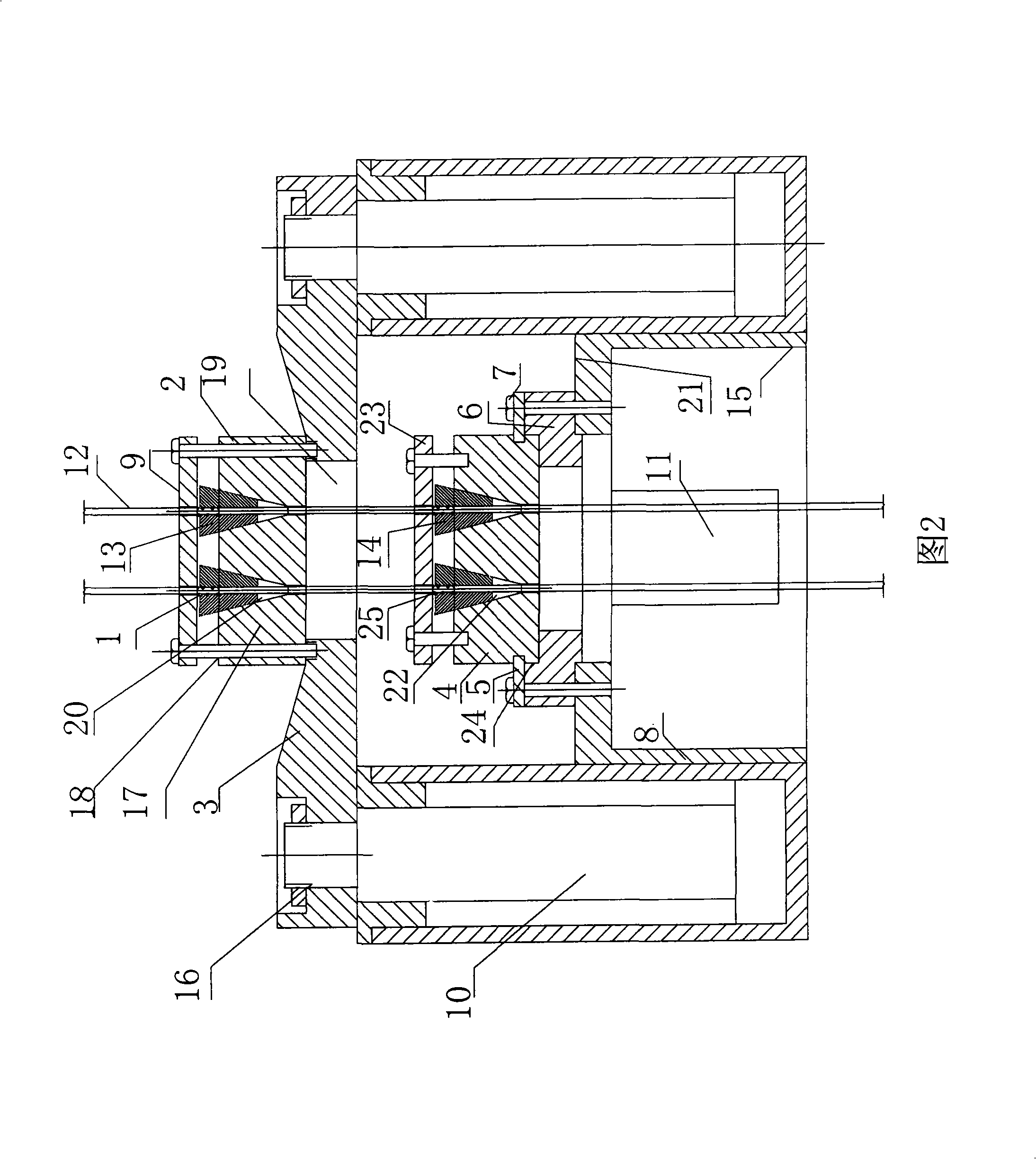

[0008] Such as figure 1 As shown, the bracket 15 is a frame structure, including an annular support leg 8, and a support plate 21 is arranged on the annular support leg 8. Here the bracket 15 and the support plate 21 are integral parts. Four oil cylinder jacks 10 are evenly and symmetrically arranged on the support 15 (shown in FIG. 2 ), and the four oil cylinder jacks 10 are connected with the annular support legs 8 . The piston rod 16 of the oil cylinder jack 10 is connected with the lifting plate 3 . The jacking plate 3 is connected to the first clamping device 17 of the steel strand. The steel strand first clamping device 17 includes a steel strand guide block 2 connected to the jacking plate 3, the steel strand guide block 2 and the jacking plate 3 can be the same part, or two parts connected to each other constitute. In this embodiment, the steel strand guide block 2 and the lifting plate 3 are two parts connected by bolts 18 . Holes 19 are provided on the lifting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com