Semi-latent curing type single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the field of materials, can solve the problems of water leakage risk, short storage time, poor performance, etc., and achieve the effect of no bubbles in appearance, precise addition amount, and excellent storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

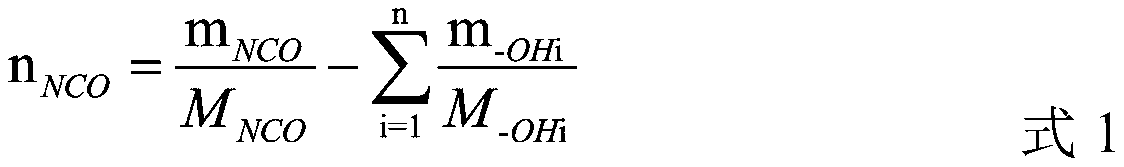

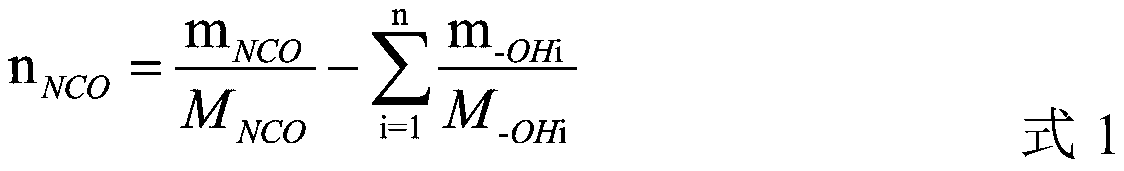

Method used

Image

Examples

Embodiment 1

[0054] 1) 225g polyether glycol, 62g polyether triol, 30.35g chlorinated paraffin, 54.1g synthetic vegetable ester, 29.4g DINP, 2.1g defoamer BYK-065, 1g acidic dispersant non-special FT-202, 115g talcum powder and 329g heavy calcium are stirred evenly at a rotation speed of 200-400r / min, then heated to 95-115℃, and then vacuum dehydrated at a pressure of -0.09 to -0.1MPa and a temperature of 105-110℃ for 1 to 3h;

[0055] 2) When the moisture content of the mixture in step 1) is ≤0.02wt%, start to cool; when the temperature drops to 75~85℃, add 85g of 150# solvent oil; when the temperature continues to drop to 60~70℃, add 39.85 g TDI-80, stir for 5-15min, then heat to 80~90℃, react for 1~3h;

[0056] 3) Cool the mixture obtained in step 2) to 60~70℃, then add 0.5g of organotin catalyst T-12 and stir for 2~8min, then heat up to 70~80℃, and react for 0.2~0.8h;

[0057] 4) Cool the mixture obtained in step 3) to 60~70℃, add 15g latent curing agent ALT-402, 1g leveling agent AFCONA 323...

Embodiment 2

[0062] 1) 105.89g polyether glycol, 37.4g polyether triol, 20.66g chlorinated paraffin, 21g synthetic vegetable ester, 18.97g DINP, 1.72g defoamer BYK-065, 0.57g acidic dispersant non-special FT -202, 61.53g talcum powder and 188.31g heavy calcium are stirred evenly at a speed of 200~400r / min, then heated to 95~115℃, and then vacuum dehydrated at a pressure of -0.09 to -0.1MPa and a temperature of 105~110℃ for 1~ 3h;

[0063] 2) When the moisture content of the mixture in step 1) is ≤0.02wt%, start to cool down; when the temperature drops to 75~85℃, add 48.66g 150# solvent oil; when the temperature continues to drop to 60~70℃, add After 22.81g TDI-80, stir for 5~15min, then heat to 80~90℃, react for 1~3h;

[0064] 3) Cool the mixture obtained in step 2) to 60~70℃, then add 0.29g of organotin catalyst T-12, stir for 2~8min, then heat up to 70~80℃, and react for 0.2~0.8h;

[0065] 4) Cool the mixture obtained in step 3) to 60~70℃, add 5.60g latent curing agent ALT-402, 0.57g leveling...

Embodiment 3

[0071] 1) Combine 450g polyether glycol, 132g polyether triol, 83.03g chlorinated paraffin, 60.7g synthetic vegetable ester, 124.43g DINP, 6.9g defoamer BYK-065, 2.3g acidic dispersant non-special FT- 202,247.25g talcum powder and 783.43g heavy calcium are stirred evenly at a speed of 200~400r / min, then heated to 95~115℃, and then vacuum dehydrated at a pressure of -0.09 to -0.1MPa and a temperature of 105~110℃ for 1~3h ;

[0072] 2) When the moisture content of the mixture in step 1) is ≤0.02wt%, start to cool; when the temperature drops to 75~85℃, add 205.6g of 150# solvent oil; when the temperature continues to drop to 60~70℃, add After 91.66g TDI-80, stir for 5~15min, then heat to 80~90℃, react for 1~3h;

[0073] 3) Cool the mixture obtained in step 2) to 60~70℃, then add 1.15g organotin catalyst T-12, stir for 2~8min, then heat up to 70~80℃, react for 0.2~0.8h;

[0074] 4) Cool the mixture obtained in step 3) to 60~70℃, add 27.58g latent curing agent ALT-402, 2.3g leveling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com