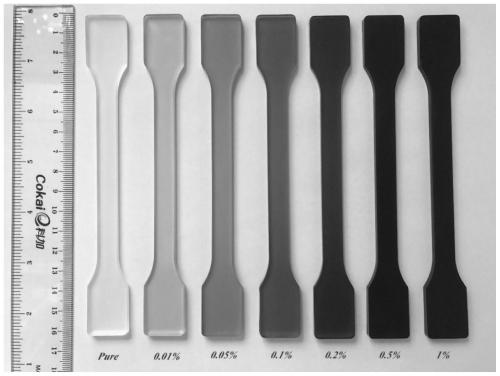

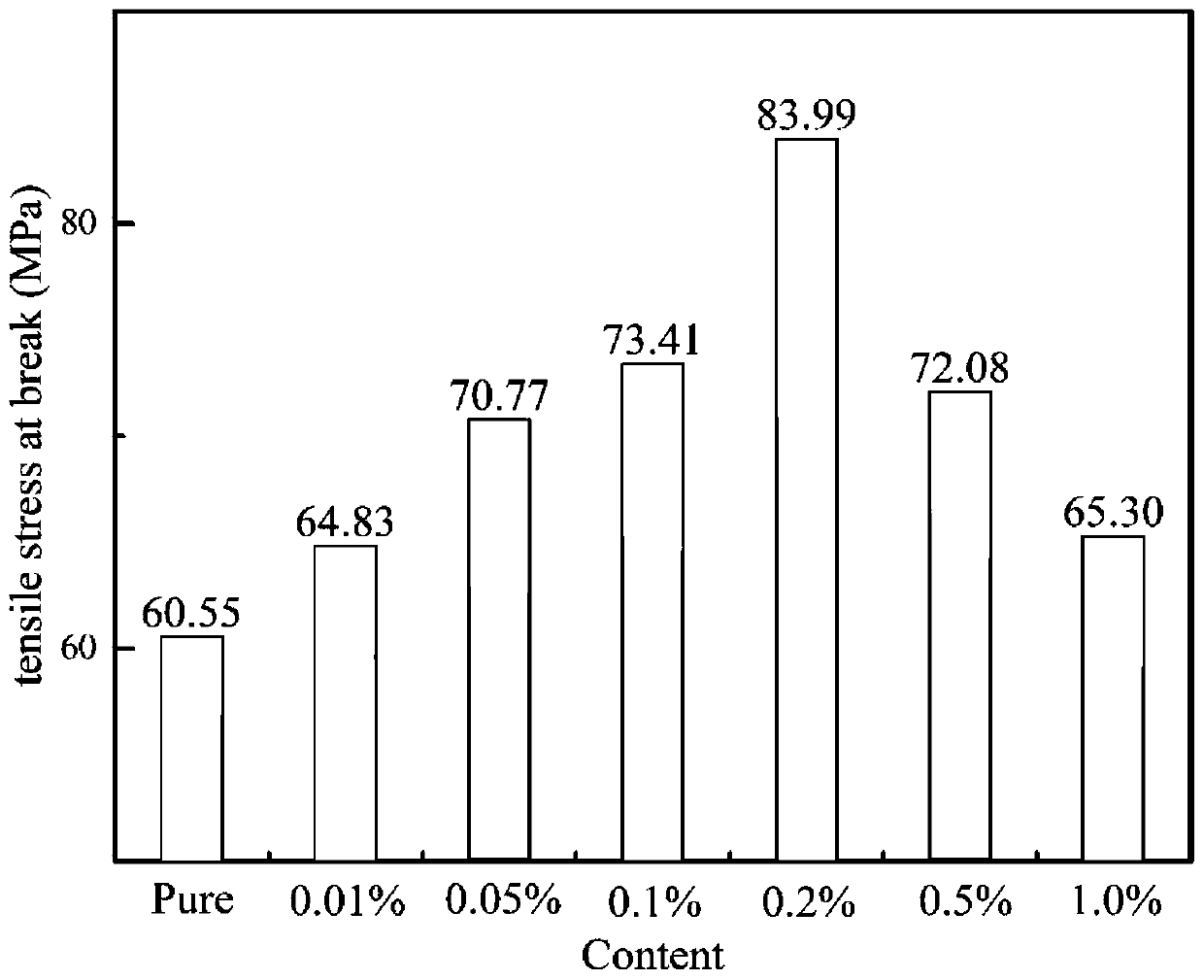

Preparation method of epoxy resin/MXene composite material

A technology of epoxy resin and composite materials, which is applied in the field of material science, can solve the problems of weakened ability to withstand strong force, limit the application of epoxy resin, and high surface energy, and achieve increased elastic modulus, low cost, and improved tensile fracture strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of epoxy resin / Mxene composite material comprises the following steps:

[0037] Step 1, the preparation of MXene:

[0038] (1) After mixing Ti, Al, and C powders according to the molar ratio of 3:1.2:2, a high-purity ternary layered Ti3AlC2 ceramic bulk material was prepared by a pressureless sintering process at 1500 ° C, and the prepared Ti3AlC2 ceramic material was used Drilling machine drills powder, obtains Ti3AlC2 ceramic powder, and the prepared Ti3AlC2 ceramic powder passes through 200 mesh sieves;

[0039](2) Add 1 g of the prepared Ti3AlC2 ceramic powder to a mixed solution of 10 ml of hydrochloric acid with a concentration of 12 mol / ml and 1 g of lithium fluoride, add a magnetic rotor and stir in an oil bath environment at 40 ° C for 48 hours to corrode Al in Ti3AlC2 Atomic layer;

[0040] (3) Wash the corroded mixture suspension with 40ml of deionized water and centrifuge, pour off the supernatant, repeat several times until t...

Embodiment 2

[0054] Embodiment 2: the preparation of MXene-epoxy resin composite material comprises the following steps:

[0055] Step 1, the preparation of MXene:

[0056] (1) After mixing Ti, Al, and C powders according to the molar ratio of 3:1.2:2, a high-purity ternary layered Ti3AlC2 ceramic bulk material was prepared by a pressureless sintering process at 1500 ° C, and the prepared Ti3AlC2 ceramic material was used Drill the powder to obtain Ti3AlC2 ceramic powder. The prepared Ti3AlC2 ceramic powder is processed through a 325 mesh sieve;

[0057] (2) A total of two parts are prepared, and each part uses 1g of Ti3AlC2 ceramic powder prepared by adding 15ml of a mixed solution of hydrochloric acid with a concentration of 10mol / ml and 1g of lithium fluoride, adding a magnetic rotor and stirring in an oil bath environment at 50°C 72h, corrode the Al atomic layer in Ti3AlC2;

[0058] (3) Wash the corroded mixture suspension with 45ml of deionized water and centrifuge, pour off the su...

Embodiment 3

[0071] Embodiment 3: the preparation of epoxy resin / Mxene composite material comprises the following steps:

[0072] Step 1, the preparation of MXene:

[0073] (1) After mixing Ta, Al, and C powders according to the molar ratio of 2:1.2:1, a high-purity ternary layered Ta2AlC ceramic bulk material was prepared by a pressureless sintering process at 1200 ° C, and the prepared Ta2AlC ceramic material was used Drill the powder to get Ta2AlC ceramic powder. The prepared Ta2AlC ceramic powder is processed through a 200-mesh sieve;

[0074] (2) Add 1 g of the prepared Ta2AlC ceramic powder into 10 ml of an aqueous solution with a HF content of 50%, add a magnetic rotor and stir in an oil bath environment at 50°C for 72 hours to corrode the Al atomic layer in Ta2AlC;

[0075] (3) Wash the corroded mixture suspension with 40ml of deionized water and centrifuge, pour off the supernatant, repeat several times until the pH value of the supernatant is greater than or equal to 6;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com