Low-carbon ultra-low sulfur steel smelting method

A technology of ultra-low sulfur steel and smelting method, applied in the field of metallurgy, can solve the problems of long electrode carbonization, strict sulfur content requirements, smelting desulfurization process can not fully meet the needs of large-scale production, etc., to reduce electrode carbonization and control stability. , The effect of stable detection pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

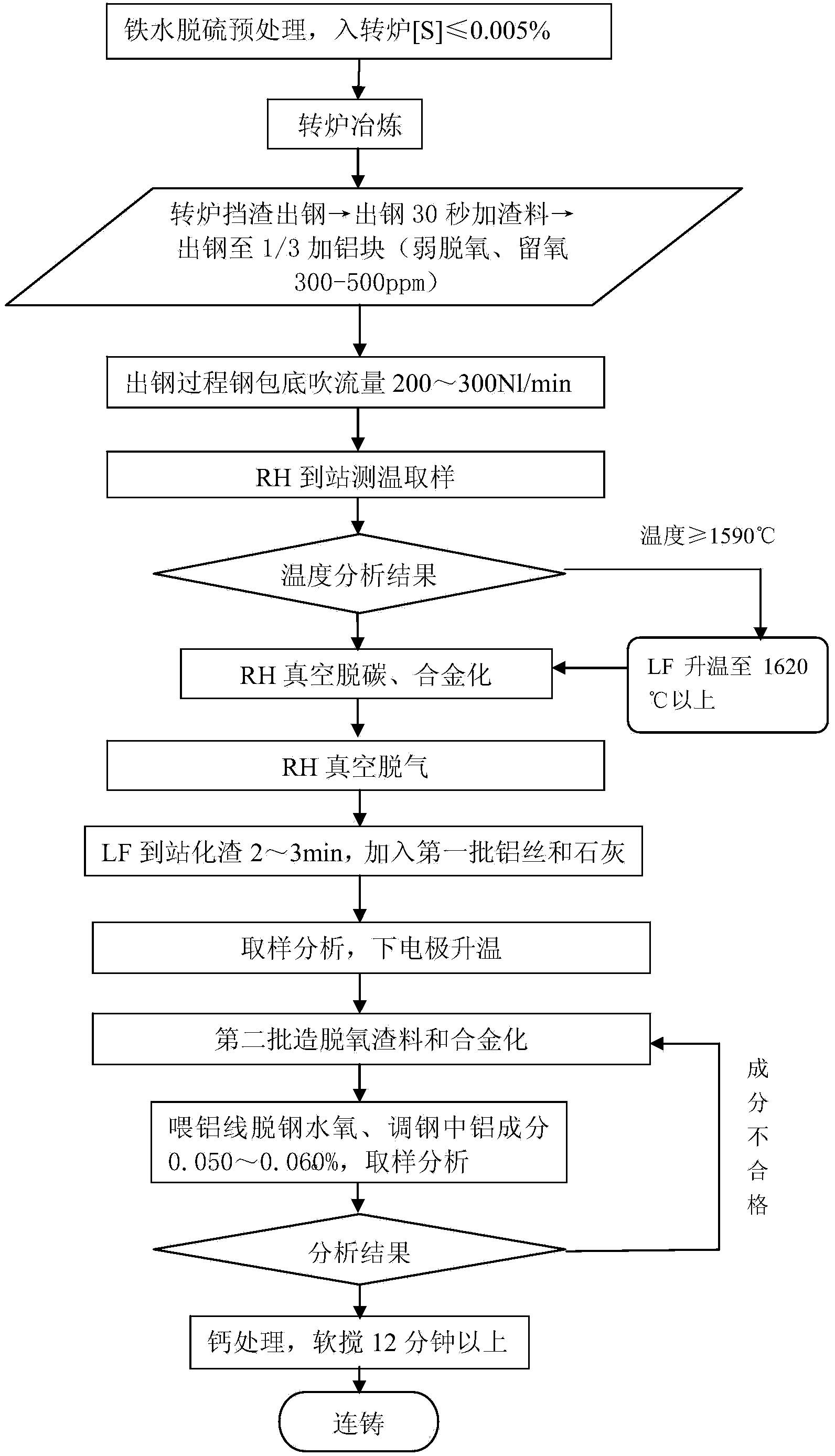

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, X65MS pipeline steel is selected, and it is smelted in a 150-ton converter and a 150-ton ladle furnace. The chemical composition of its X65MS pipeline steel is shown in Table 1, and the entire smelting process is controlled as follows:

[0030] Table 1 X65MS main chemical composition (%)

[0031]

[0032] (1) Converter blowing. The composition and temperature control at the end of blowing are shown in Table 2.

[0033] Table 2 Converter end point composition (%)

[0034]

[0035] (2) Deoxidation and slagging alloying after converter. The order of adding auxiliary materials in the tapping process: the beginning of tapping→lime, refining slag→aluminum block. See Table 3 for the amount of addition and composition control after furnace.

[0036] Table 3 Composition after furnace

[0037]

[0038] (3) RH treatment. RH is decarburized by carbon-oxygen reaction, deep deoxidized by adding aluminum, preliminary alloyed and vacuum degassed to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com