Cream production line raw material storing and spice adding system

A storage system and production line technology, which is applied in the production/processing of edible oil/fat, can solve the problems of unfavorable quality of cream products, unfavorable product quality control, and easy occurrence of odors, etc., to achieve ingenious design, simple structure, and avoid odors of spices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

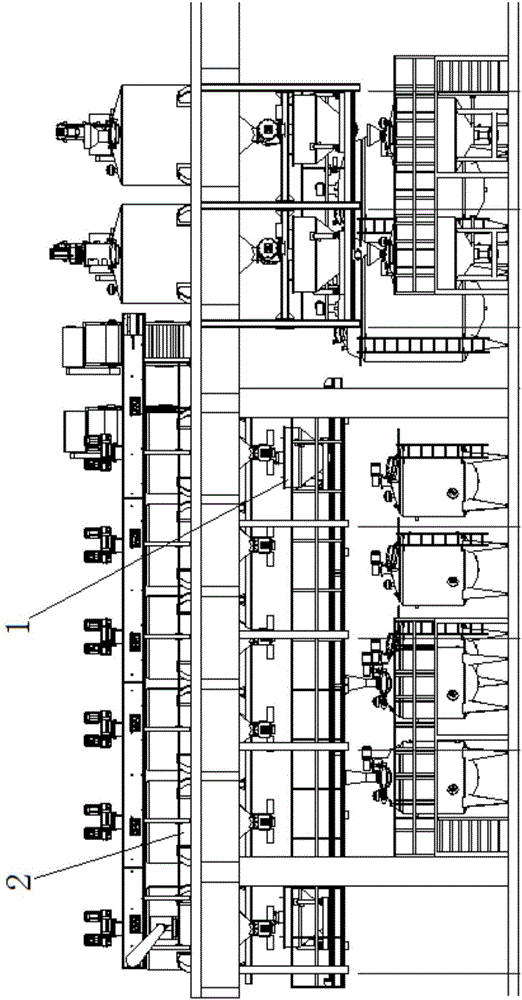

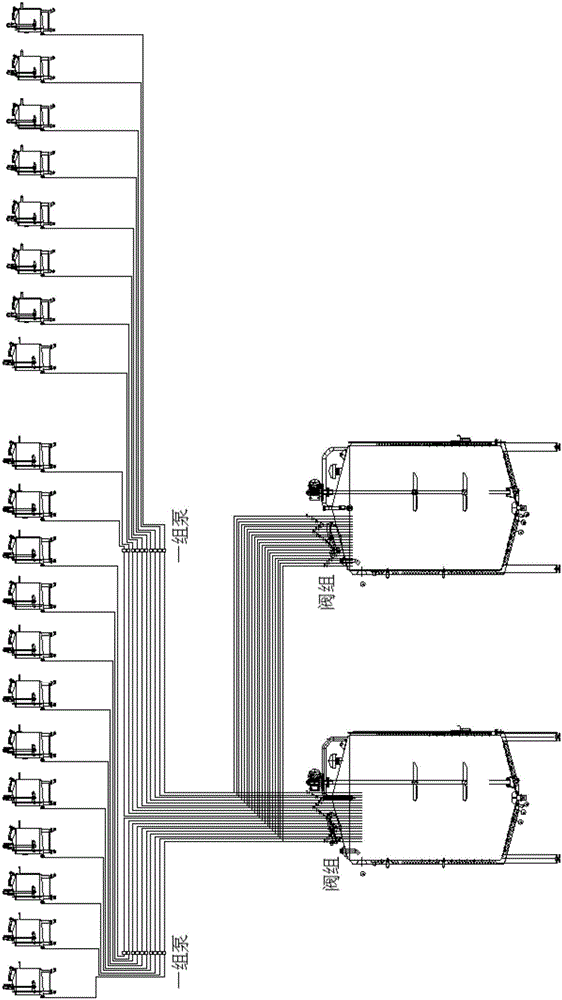

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] see Figure 1-Figure 7 , a raw material storage and spice addition system of a cream production line, including a raw material storage system and a spice addition system; the raw material storage system includes a plurality of storage areas, and each storage area has 10-20 raw material storage tanks 2; each The storage area is equipped with its own first code scanning device, each storage tank is equipped with its own second code scanning device, and each powder storage bag to be fed is provided with a barcode for recording product type, production date, and weight; Before the powder storage bag enters the storage area, the barcode needs to be identified by the first code scanning device, and it can only be entered after the verification is passed; The bar code can only be added after the secondary verification is passed; the spice addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com