Vacuum furnace equipment for reflow soldering machine

A technology of reflow soldering machine and vacuum furnace, which is applied in the direction of welding equipment, metal processing equipment, electric heating device, etc., can solve the problems of PCB circuit board stroke error, chain friction coefficient reduction, chain and PCB circuit board friction reduction, etc. Achieve the effects of promoting temperature, accurate stroke control, and preventing feeding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

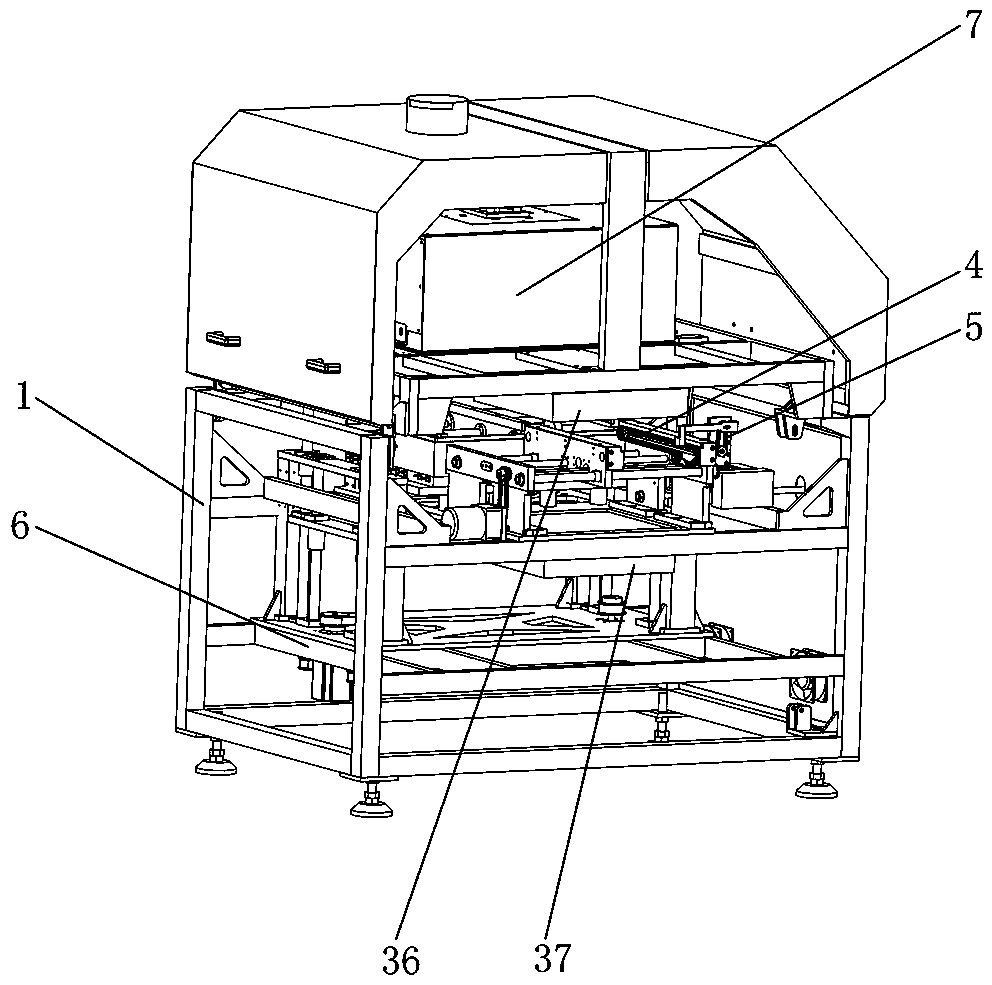

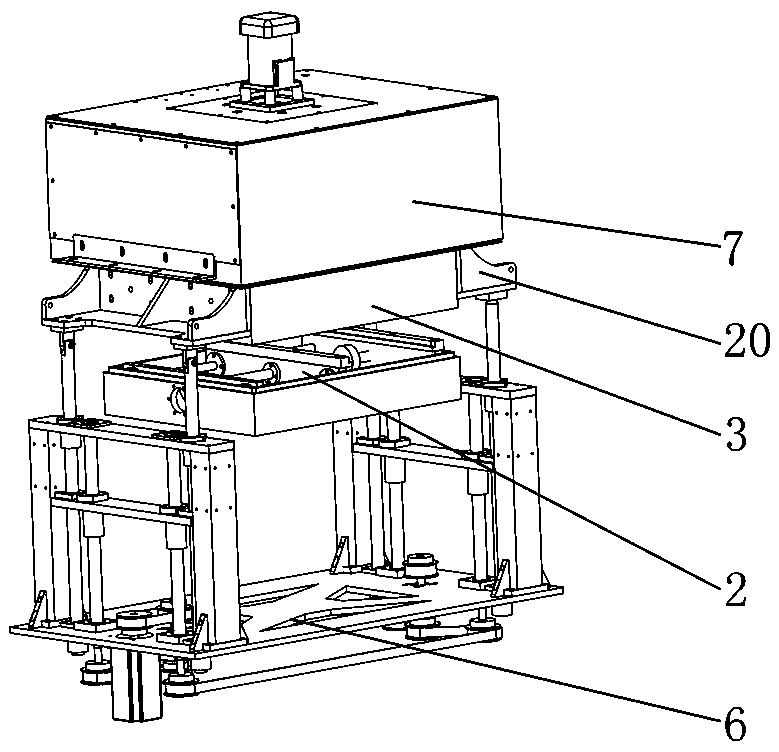

[0029] A vacuum furnace equipment for a reflow soldering machine, comprising a frame 1, a lower furnace body 2, an upper furnace body 3 and a furnace feeding assembly 4, the two ends of the frame 1 are respectively provided with the lower furnace body 2 and the furnace-in transfer assembly 4; it also includes a furnace-input material picking assembly 5, an upper furnace body jacking assembly 6 and an upper furnace body heating assembly 7.

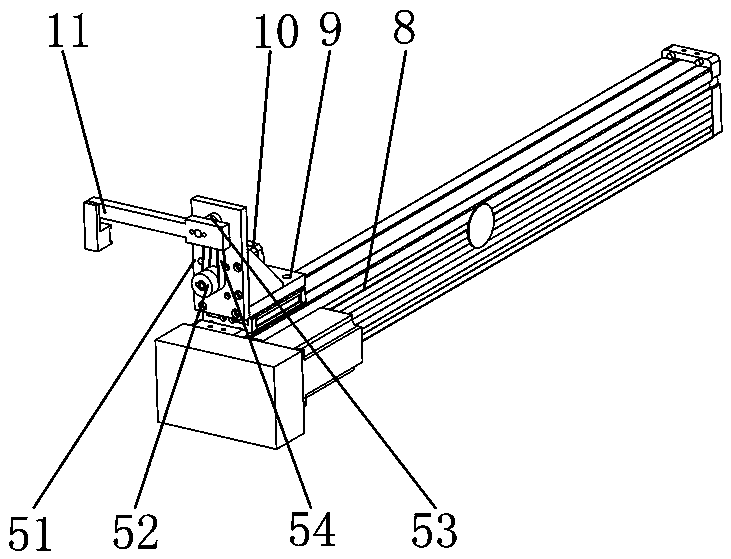

[0030]The furnace-input material pulling assembly 5 cooperates with the furnace-entry transmission assembly 4, and includes a linear module 8, a first base 9, a first motor 10, a vertical plate 51, a fifth synchronous wheel 52, and a sixth synchronous wheel 53 , the third synchronous belt 54 and the material rod 11; the linear module 8 is fixed on the frame 1, and the linear module 8 drives the first base 9 along the feeding direction of the furnace conveying assembly 4 reciprocating movement; the first base 9 is provided with the first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com