Feeding mistake-proofing control method and system

A control method and technology of a control system, which are applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of reducing the stability of the production line, high difficulty in inspection work, and prone to errors, to prevent artificial wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

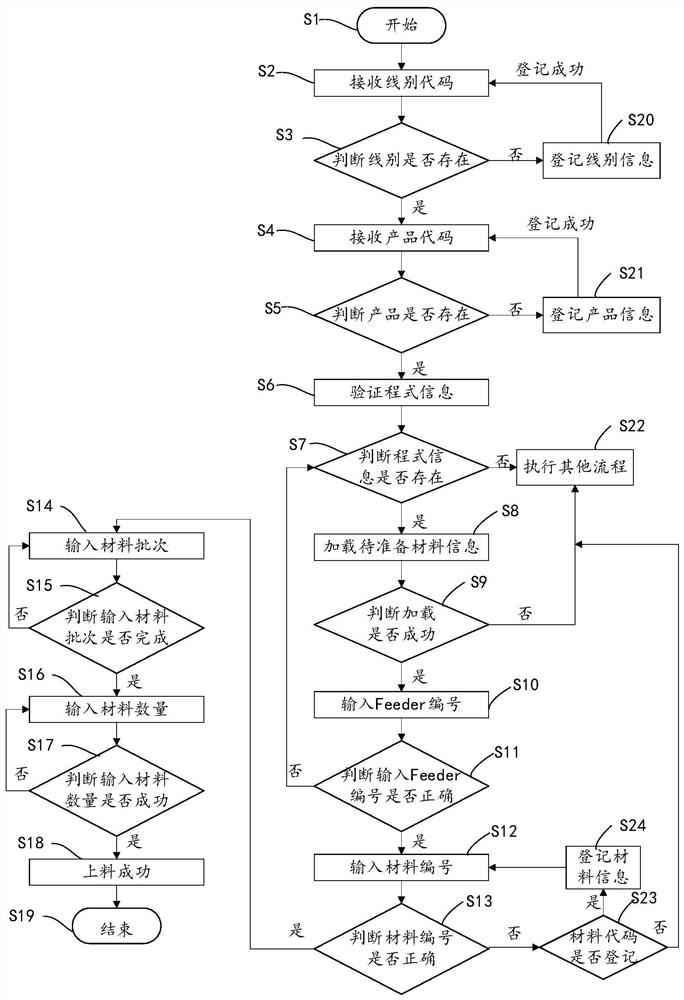

[0065] refer to figure 1 , providing a material loading error prevention control method, comprising the following steps:

[0066] S1: start.

[0067] S2: Receive line code;

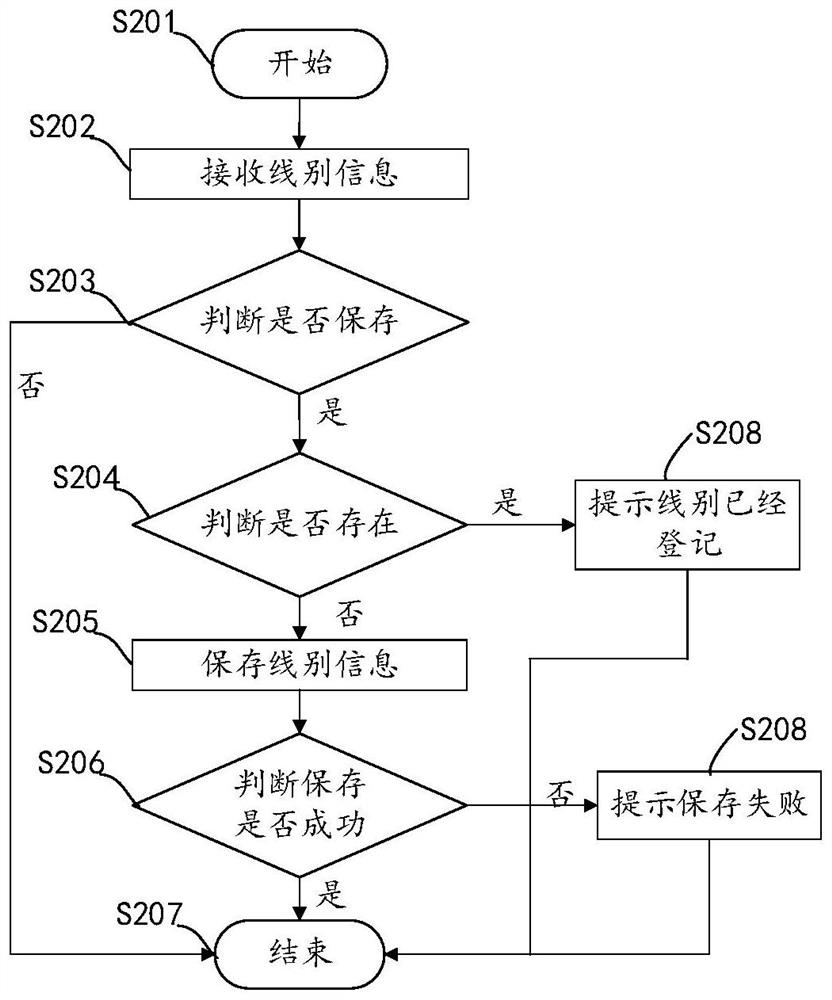

[0068] S3: Determine whether the line type exists; if so, go to the next step, if not, then S20: After registering the line type information and succeeding, return to the previous step;

[0069] S4: receiving the product code;

[0070] S5: Determine whether the product exists; if yes, go to the next step, if not, then S21: After registering the product information and succeeding, return to the previous step;

[0071] S6: verification program information;

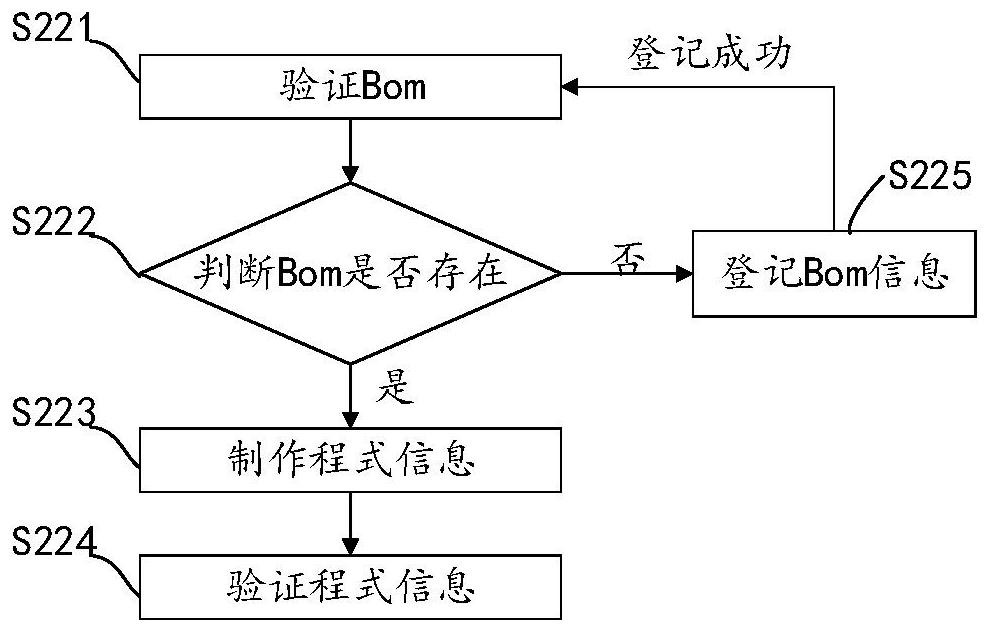

[0072] S7: Determine whether the program information exists; if yes, go to the next step, if not, then S22: execute other processes;

[0073] S8: Loading material information to be prepared;

[0074] S9: Determine whether the loading is successful; if so, enter the next step, if not, then S22: execute other processes;

[0075] S10: Input the Feed...

Embodiment 2

[0132] According to another aspect of this application, such as Figure 8 As shown, there is provided a feeding error prevention control system 3 for performing the aforementioned method, including,

[0133] An information receiving module 301, configured to receive line codes, product codes and other system information;

[0134] Information input module 302, used to input Feeder number information, input material number, input material batch, input material quantity, and other information that needs to be input involved in the previous embodiments;

[0135] The information judging module 303 is used to judge whether the line does not exist, judges whether the product exists, judges whether the program information exists, judges whether the loading is successful, judges whether the input Feeder number is correct, judges whether the material batch input is correct, judges whether the input quantity is completed, and Other information that needs to be judged in the system invol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com