Desulfurization wastewater treatment process

A technology for desulfurization wastewater and treatment process, which is applied in gaseous effluent wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of cumbersome process and waste of reagents, and achieve improved economic benefits and high energy utilization rate. , the effect of reducing the cost of pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

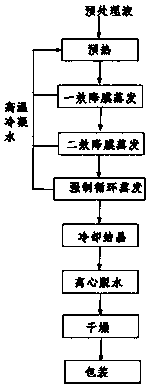

[0057] This embodiment provides a treatment process for desulfurization wastewater, through which MgSO 4 •7H 2 O, not only saves the use of reagents, simplifies the processing steps, but also recovers MgSO with high economic value 4 •7H 2 O, is a low-cost and energy-saving zero-discharge process for desulfurization wastewater, which realizes zero discharge of desulfurization wastewater from power plants. The process specifically includes the following steps:

[0058] Step 1, preprocessing

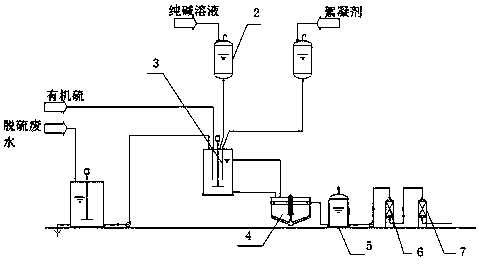

[0059] Add organic sulfur, soda ash and flocculant to the desulfurization wastewater to react, remove calcium ions and heavy metal ions in the desulfurization wastewater, and obtain a pretreatment liquid; the weight of the added organic sulfur, soda ash and flocculant is:

[0060] Organic sulfur: according to 1 m 3 It is required to add 0.05kg of organic sulfur to the desulfurization wastewater,

[0061] Soda ash: Measured according to the weight of calcium ions in the desulfurization...

Embodiment 2

[0072] This embodiment is basically the same as Embodiment 1, the difference is:

[0073] In step 1, organic sulfur: according to 1 m 3 It is required to add 0.08kg of organic sulfur to the desulfurization wastewater,

[0074] Soda ash is replaced by magnesium carbonate: according to the weight of calcium ions in the desulfurization wastewater, if there is 1g of calcium ions in the desulfurization wastewater, add 1.1g of magnesium carbonate,

[0075] Flocculant: The added flocculant is 0.6‰ of the weight of desulfurization wastewater.

[0076] Organic sulfur, magnesium carbonate, flocculant and desulfurization wastewater are mixed in a reaction tank, and reacted under normal temperature and pressure conditions, and the reaction time is 0.55h. The filtration method of primary filtration and secondary filtration is: ultrafiltration.

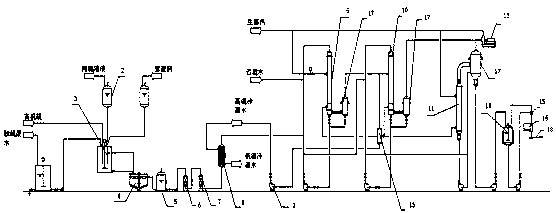

[0077] In step 2, the temperature of the feed liquid in the first-effect falling film evaporator 9 is 88°C. The temperature of the feed liquid...

Embodiment 3

[0080] Organic sulfur: according to 1 m 3 It is required to add 0.12kg of organic sulfur to the desulfurization wastewater,

[0081] Soda ash is replaced by potassium carbonate: according to the weight of calcium ions in the desulfurization wastewater, if there is 1g of calcium ions in the desulfurization wastewater, add 1.5g of potassium carbonate,

[0082] Flocculant: The added flocculant is 1.2‰ of the weight of desulfurization wastewater.

[0083] Organic sulfur, potassium carbonate, flocculant and desulfurization wastewater are mixed in a reaction tank, and reacted under normal temperature and pressure conditions, and the reaction time is 0.75h. The filtration method of primary filtration and secondary filtration is: microfiltration.

[0084] In step 2, the temperature of the feed liquid in the first-effect falling film evaporator 9 is 90°C. The temperature of the feed liquid in the two-effect falling film evaporator 10 is 80°C, the temperature of the feed liquid in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com