Method for coating brazing filler metal layer

A solder and brazing technology, applied in welding/welding/cutting items, manufacturing tools, metal processing, etc., can solve the problem of the inability to guarantee the quantitative application of flux and the rapid automatic pre-coating of solder sheets, unstable production quality, and product scrapping The problem of high rate of production can be improved to achieve the effect of improving production efficiency and yield, strong practicability, and simple and feasible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for coating the solder layer, which can realize automatic continuous solder coating by using an automatic paste dispensing device and an automatic feeding device. The basic operation steps are as follows:

[0027] In the first step, use YCL B-800 dispenser to control the extrusion of solder paste, set the input air pressure to 60psi, fill the syringe with solder paste, and adjust the solder paste extrusion volume to about 0.05ml;

[0028] In the second step, the silver contacts are placed on the conveyor belt with a vibrating plate feeder;

[0029] The third step is to fill the syringe with 15% silver solder paste, adjust the position of the syringe and the contact, and turn on the paste dispensing device. After the solder paste is extruded, it is just coated on the contact surface;

[0030] In the fourth step, the conveyor belt moves the silver contacts to directly below the induction welder coil;

[0031] The fifth step is to set the...

Embodiment 2

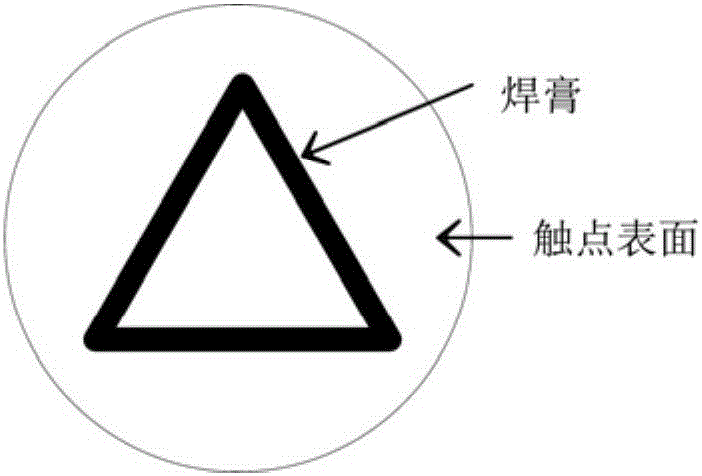

[0036] This embodiment provides a method for coating the solder layer, which can realize automatic continuous solder coating by using an automatic paste dispensing device and an automatic feeding device. The difference between this embodiment and Embodiment 1 is that the paste dispensing device is used to The point surface forms a triangle, the basic operation steps are as follows:

[0037] This embodiment provides a method for coating the solder layer, which can realize automatic continuous solder coating by using an automatic paste dispensing device and an automatic feeding device. The basic operation steps are as follows:

[0038] The first step is to use a special continuous dispenser to control the extrusion of solder paste, set the input air pressure to 40psi, fill the syringe with solder paste, and adjust the solder paste extrusion volume to about 0.01ml;

[0039] In the second step, the contacts are placed on the conveyor belt with a vibrating plate feeder;

[0040] T...

Embodiment 3

[0047] This embodiment provides a method for covering a solder layer. The difference between this embodiment and Embodiment 1 is that the paste is dispensed manually, and the heating method of the solder paste is changed. The basic operation steps of this embodiment are as follows:

[0048] In the first step, the solder paste is evenly coated on the contact surface manually;

[0049] In the second step, the solder paste is heated by flame brazing;

[0050] In the third step, the solder paste is heated and melted to spread, forming a solder layer on the contact surface.

[0051] The solder-clad contacts prepared by the above solution can be directly used for automatic welding. The formed welded joint has high strength and high brazing rate. 26wt% flux is evenly mixed in the solder paste in advance, so the produced contacts with solder layer can be directly used for automatic soldering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com