A method for real-time high-precision positioning of drill pipes in open-pit mine drilling rigs

A high-precision, drilling rig technology, applied in the fields of high-precision GPS positioning and electronic technology, can solve the problems that the accuracy cannot guarantee the service life of the equipment, and achieve the effect of solving the problem of the service life of the equipment and the inability to guarantee the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

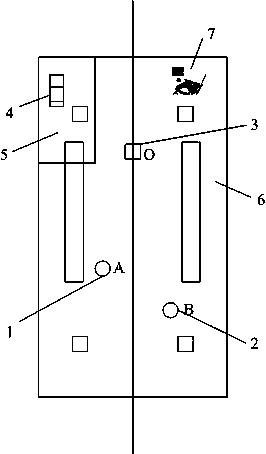

[0027] 1. Install high precision positioning equipment. Intelligent vehicle-mounted terminal (7) is installed on the drilling rig, and the high-precision GPS device A point (1) and the high-precision GPS device B point (2) can be installed on the drilling rig at any position except the drill pipe O point (3). Choose an easy-to-install location with less vibration, but point A (1) and point B (2) cannot overlap; the installation of the electronic compass (4) must be parallel to the drilling rig platform (6), and the direction should be in line with the body direction of the drilling rig Consistent, this case is installed in the rig cab (5); A point (1), B point (2) and electronic compass (4) are connected to the intelligent vehicle terminal (7) by cables.

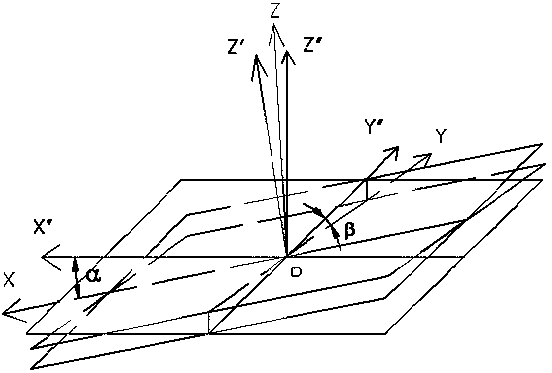

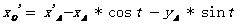

[0028] 2. Initialize point A (1), point B (2) and electronic compass (4). First put the drilling rig in a stable horizontal state, record the coordinate values taken out of the equipment at point A (1) and point B (2), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com