Method for manufacturing HDPE double-wall corrugated pipe on vehicle-mounted movable pipeline production line and vehicle-mounted movable pipeline production line

A double-wall corrugated pipe and production line technology, which is applied to tubular objects, applications, household appliances, etc., can solve the problems of high transportation costs and small quantities of single transportation, and achieve the requirements of production technology, reduce transportation costs, and balance production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

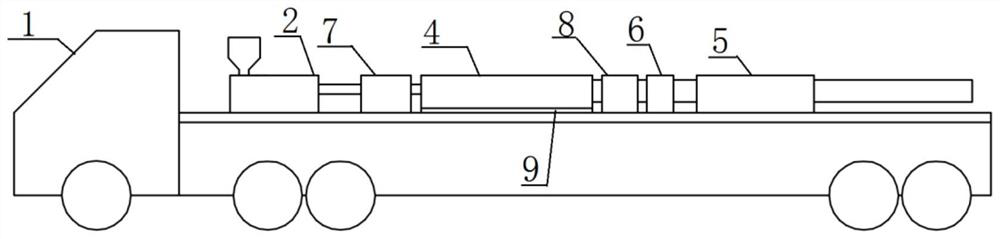

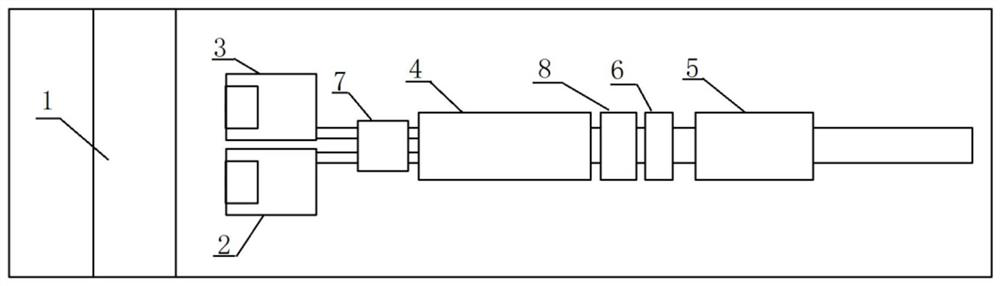

[0062] Figure 1-2 Shown is the method for manufacturing HDPE double-wall bellows, specifically comprises the following steps:

[0063] S1: install the inner wall extruder 2 and outer wall extruder 3 molds on the mobile car 1;

[0064] S2: Feed materials, turn on the inner wall extruder 2 to extrude the inner wall tube, open the outer wall extruder 3 to extrude the outer wall tube, the inner wall tube and the outer wall tube are formed by vacuum adsorption of the molding machine 4, and the corrugation is extruded by the molding machine 4 module. The feeding rack 5 delivers the pipes, and the pipes are cut by the cutting machine 6 .

[0065] The equipment for producing HDPE double-wall corrugated pipes is installed on the mobile vehicle 1, which facilitates the direct transportation of raw materials to the vicinity of the construction site, and the production of HDPE double-wall corrugated pipes on the mobile vehicle 1 is conducive to saving the transportation cost of finished...

Embodiment 2

[0102] Figure 1-2 It also shows a vehicle-mounted movable pipeline production line, including:

[0103] A movable car 1; inner wall extruder 2, outer wall extruder 3, molding machine 4, discharge rack 5, cutting machine 6 installed on the movable car 1; inner wall extruder 2, outer wall extruder 3 The extruded inner and outer wall sheets are absorbed and formed by the forming machine 4, and the corrugated tube is extruded by the module on the forming machine 4, and the corrugated tube is sent to the pipe by the discharge rack 5, and is cut by the cutting machine 6 into finished pipes.

[0104] The equipment for producing corrugated pipes is installed on the movable vehicle 1, which can directly transport raw materials to the vicinity of the construction site for nearby production, avoiding the loss of long-distance transportation of pipes.

[0105] As a further improvement of the vehicle-mounted movable pipeline production line of the present invention, it also includes a co...

Embodiment 3

[0112] The present invention relates to the production process of HDPE double-wall corrugated pipe:

[0113] 1. The installation and adjustment of the mold

[0114] 1.1 According to the production operation notice, replace the mold of the corresponding specification;

[0115] 1.2 The bolts of the connecting parts of the mold must be tightened, and tightened again after heating to the process temperature to prevent material leakage.

[0116] 1.3 When installing the cooling water jacket, the water inlet pipe should be below the water jacket, and the return pipe should be above the water jacket. The return pipe should be installed on the side of the extrusion die lip, and the gap between the root of the water jacket and the die head should be consistent on all sides. After installation, use a frame level to adjust the level of the water jacket.

[0117] 1.4 When installing the forming aluminum mold, ensure that the mold and base are clean, and tighten the compression bolts to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com