Tail filling bag body fixture

A technology for filling bags and fixtures, applied in the field of new tail filling bag body fixtures, can solve the problems of inability to realize the positioning and filling and sealing of non-PVC film infusion soft bags for tail filling, low positioning accuracy, and large friction coefficient of guide rails. , to achieve the effect of simple structure, high positioning accuracy and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

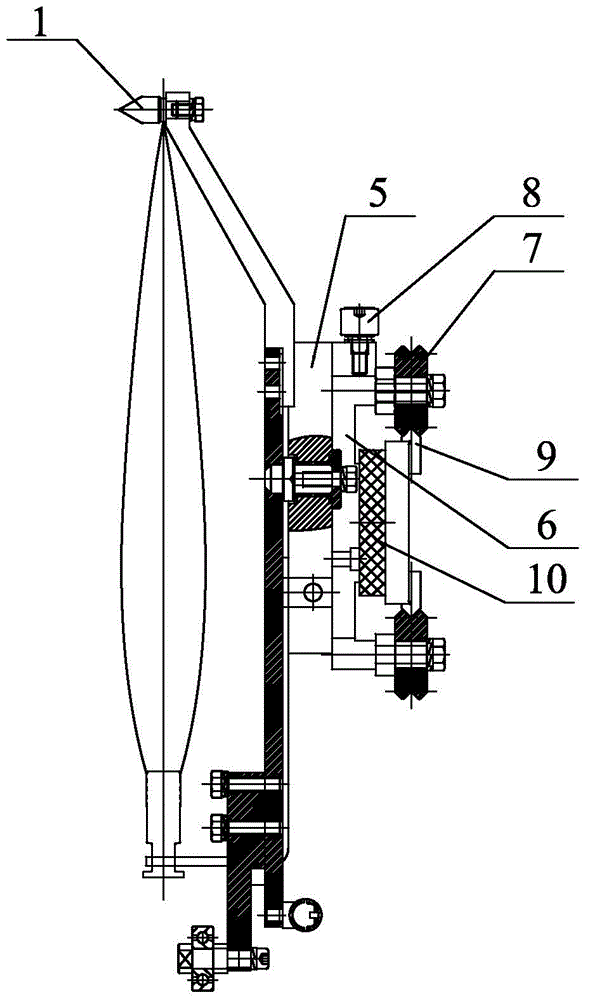

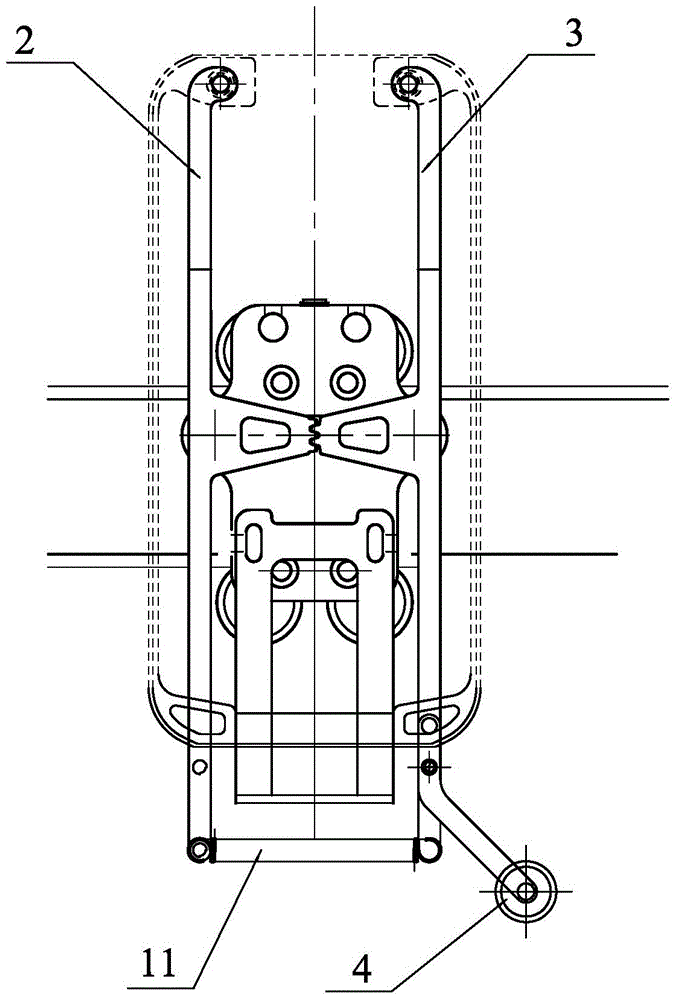

[0012] Such as figure 1 The shown bag body clamp is provided with two positioning pins 1 corresponding to the positions of the positioning holes of the bag body. Locating pin 1 is installed on left and right two swing arms 2,3, and the swing arm below is connected by extension spring 11, and the bottom of right swing arm 3 is equipped with deep groove ball bearing 4. The left and right swing arms are installed on the nylon fixed seat 5, and the nylon fixed seat 5 is connected with the synchronous belt installation block 6; four guide rollers 7 with V-shaped grooves are installed on the side of the synchronous belt installation block 6, and a needle roller bearing 8 is installed on the top . The V-shaped guide rail 9 that cooperates with the guide roller 7 has a V-shaped surface that cooperates with the V-shaped groove.

[0013] The left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com