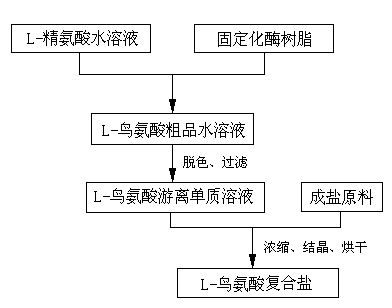

Method for continuously producing L-ornithine composite salt by enzyme immobilization

An enzyme immobilization, ornithine technology, applied in the direction of immobilization on/in organic carriers, fermentation, etc., can solve the complex strain control and production control, restrict the promotion and popularization of production methods, and unstable product quality, etc. problems, to achieve the effects of easy molding, high production yield and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ① Soak the macroporous adsorption resin and 10% sodium carbonate solution for 12 hours, filter, wash the filtered resin with pure water, and then mix according to the mass ratio of resin: sodium carbonate: pure water = 1:0.3:30 Form a solution, adjust the pH value of the solution to 9, stir and lower the temperature to ≤-5°C, slowly add sodium carbonate with a mass of 0.3% of the resin dropwise, and after holding for 2 hours, add sodium carbonate with a concentration of 1% and a mass of 0.001% of the mass of the resin Enzyme aqueous solution, warmed up to 0°C for 10 hours, filtered out the resin, washed three times with 10 times pure water to obtain immobilized enzyme resin;

[0024] ②Put 1000L of deionized water into a 2000L reactor, add 300kg of L-arginine while stirring, and raise the temperature to 25°C to obtain an aqueous solution of L-arginine with a mass concentration of 300g / l;

[0025] ③Put 150g of manganese acetate into the reaction kettle, stir for 10 minute...

Embodiment 2

[0028] ① Soak the macroporous adsorption resin and 10% sodium carbonate solution for 12 hours, filter, wash the filtered resin with pure water, and then mix according to the mass ratio of resin: sodium carbonate: pure water = 1:0.5:60 To form a solution, adjust the pH value of the solution to 11, stir and lower the temperature to ≤-5°C, slowly add cyanogen bromide with a mass of 0.5% of the resin, and keep it for 2 hours, then add a concentration of 1% and a mass of 0.003% of the resin The enzyme aqueous solution was heated to 5°C for 13 hours, the resin was filtered out, and washed three times with 10 times pure water to obtain the immobilized enzyme resin;

[0029] ②Put 1000L of deionized water into a 2000L reactor, add 400kg of L-arginine while stirring, and raise the temperature to 40°C to obtain an aqueous solution of L-arginine with a mass concentration of 400g / l;

[0030] ③ Add 200g of manganese acetate into the reaction kettle, stir for 10 minutes, add 8 kg of immobili...

Embodiment 3

[0033] ① Soak the macroporous adsorption resin and 10% sodium carbonate solution for 12 hours, then filter, wash the filtered resin with pure water, and then mix it according to the mass ratio of resin: sodium carbonate: pure water = 1:0.8:100 Form a solution, adjust the pH value of the solution to 13, stir and lower the temperature to ≤-5°C, slowly add cyanogen bromide with a mass of 0.8% of the resin, and keep it for 2 hours, then add a concentration of 1% and a mass of 0.005% of the mass of the resin The enzyme aqueous solution was heated to 10°C for 16 hours, the resin was filtered out, and washed three times with 10 times pure water to obtain the immobilized enzyme resin;

[0034] ②Put 1000L of deionized water into a 2000L reactor, add 500kg of L-arginine while stirring, and raise the temperature to 55°C to obtain an aqueous solution of L-arginine with a mass concentration of 500g / l;

[0035] ③Put 250g of manganese acetate into the reaction kettle, stir for 10 minutes, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com